April 24, 2020

Stainless steel is used in all areas of human activity, from heavy engineering to electronics and precision mechanics. It has found its greatest application in:

- Construction and architecture

- Food Industry

- Household appliances

- Chemical and petrochemical industry

- Pulp and paper production

- Electric power industry

- Environmental protection

- Transport engineering.

Construction and architecture

Stainless steel first appeared more than a hundred years ago, but it began to be widely used in construction and architecture recently. It was used in the construction and design of the largest shopping centers - La Defense in Paris, Canary Wharf in London, Sony Center in Berlin, Petronas Towers in Kuala Lumpur.

Stainless steel is an alloy of iron and chromium. Its anti-corrosion properties appear due to the presence of a chromium oxide layer on the metal surface. This protective layer is very stable and even after mechanical or chemical damage it quickly regains its previous appearance and the anti-corrosion properties of the metal remain unchanged.

Stainless steel is a very practical material, at the same time noble and aesthetic. Thanks to the variety of grades and surface types, it is able to satisfy the different conditions that arise for construction and finishing materials.

Why does metallic materials deteriorate?

Before moving on to the question of what corrosion-resistant steel is, let's understand the concept of corrosion and the essence of this process.

Translated from the Latin corroder - corroding. The slow spontaneous destruction of metals and alloys based on them, which occurs under the chemical influence of the environment, is called corrosion. The reason for this destruction is the chemical interaction (redox reactions) of metal materials with the gaseous or liquid medium in which they are located.

In addition to the anti-corrosion properties of stainless steel, the following qualities should be noted:

- variety of products (sheet, pipe, profile, rod, angle, mesh)

- large selection of surface types (sanded, polished, matte, decorative, as well as colored surfaces)

- many brands with different qualities

- durability of the material

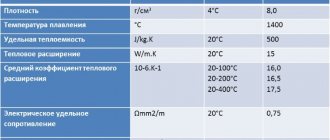

- high melting temperature

The reliability of stainless steel elements is much higher than that of other finishing materials. Their appearance does not change for decades. Stainless steel has much higher heat-resistant properties than other steels.

Stainless steel is used in construction most often as a material for railings, window and door openings, and fire doors. Swimming pools and elevators are made from it. It is also a good decorative material for restaurants, offices, pubs, discos and metro stations. Increasingly, it is used to produce furniture for offices and shops. By combining stainless steel with glass, wood or stone, beautiful and elegant products are obtained.

There are decorative stainless steel sheets. These sheets have a number of properties that give them an advantage over traditional sheets - ground or polished. Their important property is scratch resistance. Decorative sheets do not leave fingerprints.

It should be noted the aesthetic properties of sheets, especially colored ones. The color of the sheet is stable and does not change even when bent.

There is a misconception that stainless steel is an expensive material. In fact, since it is a durable material, its cost is not high.

Most popular brands:

GOST 20Х13 (AISI 420, DIN 1.4021)

– stainless steel with a martensitic structure, cannot be welded, is not prone to temper brittleness, and does not form internal defects during the production process. Used for the manufacture of measuring and cutting tools, springs, leaf springs.

GOST 12Х17 (AISI 430, DIN 1.4016)

– ferritic stainless steel heat-resistant grade, does not contain nickel. Characterized by good anti-corrosion resistance in moderately aggressive chemical environments and high temperatures.

GOST 12Х18Н9 (AISI 304, DIN 1.4301)

– a heat-resistant, corrosion-resistant alloy used in welded structures in contact with aggressive environments. It is used for sheet parts, welded equipment, heat exchangers, pressure devices.

GOST 08Х18H10 (AISI 304H, DIN 1.4948)

– an austenitic type of heat-resistant, corrosion-resistant alloy, used for the production of rolled pipes, components and assemblies for the chemical and engineering industries, heat exchangers, and industrial tanks.

GOST 03Х18H11 (AISI 304L, DIN 1.4306)

– chromium-nickel grade is used for the production of equipment, tanks and pipelines for the chemical industry, in the production of nitric acid and other aggressive substances.

GOST 08Х18H10Т (AISI 321, DIN 1.4541)

– a stainless, heat-resistant and heat-resistant alloy, non-magnetic, resistant to oxidation and has good weldability without preheating. It is used as food and technical stainless steel for the production of rolled sheets and pipes, welded equipment, the manufacture of containers, tanks, tanks and equipment in the chemical and oil and gas industries.

GOST 03Х17H14М2, 03Х17H14М3, (AISI 316, 316S, 316L)

– non-hardening austenitic grade, areas of application – welded parts, equipment for the pulp and paper and chemical industries, boiler bodies, tanks and installations for the coal industry.

GOST 08Х17H13М2Т (AISI 316Ti, DIN 1.4571)

– structural heat-resistant heat-resistant stainless alloy is used for fasteners and welded structures in various industries.

GOST 20Х23H18 (AISI 310S, DIN 1.4845)

– heat-resistant and heat-resistant austenitic stainless steel used for the manufacture of forgings, clamps, combustion chambers, fasteners and boiler elements, used pipes, couplings.

When choosing stainless steel, you should take into account the operating conditions of the metal, the expected load, and the necessary additional properties of the product. If you are in doubt about how to choose the right stainless steel, it is better to contact a specialist. Leave a request on the website, and our managers will give recommendations on selecting the optimal grades of stainless alloys for the given operating conditions.

Food industry

Stainless steel is today, together with glass and some other synthetic materials, an almost indispensable material for the manufacture of equipment for processing, storing and transporting food products. This is due to high hygienic, aesthetic and toxicological requirements. There are specific requirements regarding the washability of heavy metals from equipment that is in constant contact with food. In accordance with European standards, the number of np. chromium and nickel washed off from stainless steel in the standard ISO 6486/1 test is a maximum of 2 mg/dm3. For austenitic steels, this amount is less than 0.02 mg/dm3, in a word, about 1% of the permissible norm.

The grades of stainless steel used in the food industry are AISI 304 and AISI 316; steels with a large number of alloy constituents are rarely necessary. A good surface appearance is of great importance. A standard 2B surface is enough for this, but sometimes polishing is necessary.

Characteristics of stainless steels and their areas of application

All types of stainless steel compounds can be divided into several groups. Each combines materials with specific chemical properties and internal structure.

- Austenitic (highly alloyed chromium-nickel metals, marking A)

- Ferritic (chromium, marking F)

- Martensitic (carbon, marking C)

- Combined

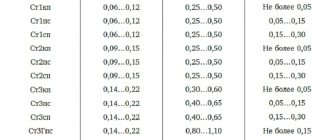

One of the most common and sought after types. The high content of nickel and chromium (up to 33%) provides exceptional corrosion resistance and unsurpassed strength to the products. An important advantage is manufacturability. The material welds well, is more viscous and plastic than ferrite, and is not magnetic. Austenitic grades include: 04Х18Н10, 12Х18Н10Т, 12Х18Н9Т, 12Х18Н9, 08Х18Н10, AISI 304, AISI 316, etc. The scope of their use is wide. Austenitic types of alloys are used as a structural material from which products are made by cold stamping and welding. These can be various containers, casing, pipelines, equipment for food processing and storage, pharmaceutical, medical, laboratory equipment, parts for the mechanical engineering, automotive, aircraft industries, technological units for the chemical industry.

Brands: 15Х28, 08Х18Т, etc. This group of metals has a high chromium content (up to 20%). It ensures product resistance to extremely aggressive chemical environments and high magnetic properties. Anti-corrosion resistance is lower than that of metals of the austenitic group, therefore ferritic types are used in those areas where the requirements for this parameter are not so significant. The main consumers of chromium ferritic steels are manufacturing enterprises in the chemical industry, heavy engineering, and the energy sector. They are used for the production of equipment and parts operating in acidic and alkaline solutions, household instrument making, and the food industry.

Grades: 20Х13, 40Х13, 30Х13, etc. Due to the high carbon content, these are the most durable alloys among stainless steel. Metal products of this group are extremely wear-resistant, work well at high temperatures, but are more susceptible to corrosion processes. This type of metal can be subject to thermal hardening; this type includes corrosion-resistant, heat-resistant steel, which successfully resists oxidation and is suitable for use at high temperatures. Metal products retain their original properties even under constant thermal influence; the material is characterized by a minimal content of harmful impurities.

Examples of grades: 08Х22Н6Т, 12Х21Н5Т, etc. Combined grades can have an austenitic-martensitic or austenitic-ferritic structure and organically combine the positive properties of alloys of these types.

Transport engineering

Recently, the need to transport goods and materials has increased significantly. To ensure maximum safety of cargo during transportation, special containers are required. Stainless steel containers are now being produced suitable for transporting both food products and other cargo. In the automotive industry, stainless steel is used in the manufacture of catalysts and exhaust pipes. Ferritic and austenitic grades are used. One car requires 10-20 kg of stainless steel.

How to decipher the markings

Marking of stainless steels, the rules for the formation of which are stipulated by the provisions of regulatory documents, carries the following information:

- the number in first place indicates the quantitative content of such a chemical element as carbon in the alloy composition (for example, in steel grade 08Х17 carbon is contained in an amount of 0.08%, and in 40Х13 - 0.4%);

- after the letters in the marking, each of which indicates the corresponding chemical element (X - chromium, H - nickel, M - manganese), numbers are placed indicating its content in whole percentages.

An example of decoding the designation of stainless steel

In general, if we talk about the rules for marking steel alloys classified as stainless, they are practically no different from those adopted for marking steels of any other type.

Types of scrap metal: ferrous, non-ferrous and precious metals

The official classification of metal waste is extensive and multi-stage. It takes into account numerous characteristics by which or the combination of which this or that scrap metal belongs to a certain type, group, class, category.

In the usual practice adopted in relations between organizations that procure secondary metals and deliverers, types of scrap metal are categorized more simply, which ensures optimal mutual understanding and a transparent system of purchase prices when making delivery/reception transactions.

Chemical composition

The properties of a metal are determined by its chemical composition. With a chromium content of 12-13%, steel becomes stainless, that is, stable in the atmosphere and chemical environments. An increase in chromium content to 28-30% makes it stable in aggressive environments.

Other elements used for alloying include manganese, aluminum, titanium, and nickel. The most widely used alloys are those containing an average nickel content of 10%, chromium - 18%, carbon - from 0.08 or 0.12%, titanium - 1% (12Х18Н10Т - corrosion-resistant steel, GOST 5632).

What are corrosion-resistant steels and alloys?

Products made of stainless and heat-resistant steel or their alloys are designed to work in aggressive environments at high or normal temperatures. Therefore, the main requirement for materials in this group is heat resistance (resistance to a gas environment or high temperature steam) or corrosion resistance (the ability to effectively withstand the effects of aggressive factors at normal temperatures).

Corrosion resistance is characteristic of metal products, on the surface of which in an aggressive environment a strong passivating film is formed, which prevents the penetration of aggressive substances into deeper layers of the metal and interaction with them.

In other words, corrosion-resistant steel is steel that is resistant to intergranular, chemical, electrochemical and other corrosion.

Mechanical properties

Grades of corrosion-resistant steels must have mechanical properties that meet the requirements of established manufacturing standards. These include:

- maximum hardness on the Brinell scale (HB);

- relative extension (%);

- yield strength (N/mm2);

- tensile strength (N/mm2).

After production, each batch (melting) of commercial products is checked for compliance of the mechanical properties and microstructure of the steel grade with GOST. The results of laboratory testing of samples are indicated in the manufacturing certificate.

Classification by microstructure type: austenitic grade stainless steel

The resistance of this class to corrosion is increased due to the alloying elements of nickel (from 5 to 15%) and chromium (from 15 to 20%). Austenitic alloys are insensitive to intergranular corrosion, provided that the carbon content in them is less than its solubility limit in austenite (0.02-0.03% or less). Non-magnetic, well subject to welding, cold and hot deformation. They have excellent technology. This is the best steel for the manufacture of fasteners, welded structures and use in various industries.

Austenitic-ferritic class

Corrosion-resistant stainless steels of this class are characterized by a reduced nickel content and a high chromium content (from 21 to 28%). Additional alloying elements include niobium, titanium, and copper. After heat treatment, the ratio of ferrite and austenite is approximately one to one.

The strength of austenitic-ferritic steels is twice that of austenitic steels. At the same time, they are ductile, resist shock loads well, have a low level of stress-corrosion cracking and high resistance to intergranular corrosion. Recommended for use in construction, manufacturing industry, and for the manufacture of products that will come into contact with sea water.

Areas of use of stainless steel

It should immediately be noted that the use of stainless steel directly depends on its type, or more precisely on its corrosion resistance. It is also important that the corrosion resistance of steels is applicable in certain aggressive environments. That is, it is necessary to take into account which components of the environment will act on the stainless steel and what type of corrosion it will be predominantly exposed to. Let's consider options for using stainless steel in various areas of the national economy and industry, taking into account the characteristics of their classes.

Stainless alloys with high resistance to scaling are used in electrical engineering. This stainless steel also has significant electrical resistance. In addition, their use is also beneficial from the economic side - the basis of scale-resistant ones is inexpensive iron. Scale resistance is achieved through additives made of passive metals - chromium, aluminum, silicon. Thus, these elements act as alloying elements.

Heat-resistant stainless steel is used in shipbuilding and for the manufacture of aircraft and missile components. For example, parts of turbines and jet engines are made from such stainless steels.

Ferritic steels are actively used in the food industry. The specific properties of these steels make it possible to satisfy the most stringent demands in this area. Stainless steel sheets with the desired properties are smelted from them. The main restrictions here are due to hygiene requirements. In particular, the use of alloying additives has been significantly reduced. Various instruments for medical purposes and parts for automobiles are also made from such steels.

Stainless steels with a high content of alloying elements are used for pipelines and power generation. Only such stainless steel has the necessary corrosion resistance.

Austenitic stainless steels are widely used. Various equipment for the chemical, food and pulp and paper industries are made from this stainless steel. Pipes and stainless steel circles are used in the machine tool industry and the automotive industry. All kinds of metal structures are produced from it, which are increasingly popular in building architecture. Mechanical engineering and metallurgy cannot do without stainless steel. Reliability, ease of processing, aesthetics and compatibility with other non-metallic elements allow the use of stainless steel in interior design and other areas of art. People are increasingly aware of the presence of stainless steel in everyday life. Many household items are partially made of stainless steel.

A large consumer of stainless steel is the transport engineering industry. Huge volumes of cargo transportation with varying environmental aggressiveness require the use of high-alloy steels of the best grades. Stainless steels of this class allow the creation of multi-purpose containers, with the help of which significant savings are achieved in this area.

Range of products made from stainless steel

Corrosion-resistant steel is used to produce the following products:

- heat-treated etched and polished sheets;

- heat-treated unetched sheets;

- thermally untreated and unetched sheets;

- warm, cold and hot-deformed seamless pipes;

- hot-rolled steel strips for general purposes;

- calibrated hexagons;

- stainless steel circles;

- stainless steel wire (heat-treated and cold-drawn);

- castings with special properties;

- forgings;

- other types for which GOSTs and technical instructions (TU) have been developed.