Characteristics of steel grade VSt3sp

VSt3sp - Structural carbon steel of ordinary quality, welds well, welding is carried out without heating and without subsequent heat treatment, welding methods: manual arc welding, automatic submerged arc welding and gas protection, KTS, ESW. For thicknesses greater than 36 millimeters, heating and subsequent heat treatment are recommended; it is prone to flake sensitivity, and there is no tendency to temper brittleness. Machinability by cutting in the hot-rolled state at HB 124 σB = 400 MPa Kυ hard alloy. = 1.8 and Kυ b.st. = 1.6, has found its application in load-bearing elements of welded and non-welded structures and parts operating at positive temperatures. Shaped and sheet products (5th category) - for load-bearing elements of welded structures operating under variable loads: with a thickness of rolled products up to 25 mm in the temperature range from -40 to +425 ° C; for rolled products with thickness over 25 mm - from -20 to +425 °C, subject to delivery with guaranteed weldability. Forging at temperatures from 1300 to 750 0C, cooling is carried out in air. Calm steel has a dense structure and good mechanical properties. It is less prone to negative reactions to welding heat and to aging. The features of a homogeneous microstructure give the alloy maximum corrosion resistance and ductility.

Characteristics of steel grade BSt3ps

BSt3ps - Structural carbon steel of ordinary quality, welds well, welding is carried out without heating and without subsequent heat treatment, welding methods: manual arc welding, automatic submerged arc welding and gas protection, KTS, ESW.

Welding methods for BSt3ps steel:

- manual arc welding

- manual argon arc welding

- automatic submerged arc welding

- mechanized welding with a consumable electrode in a carbon dioxide environment

- electroslag welding

- contact welding

According to GOST 27772-88, steel grade St3ps5 in its characteristics and properties is an analogue of steel for building structures S245, steel BSt3ps is an analogue of steel for building structures S275. For thicknesses greater than 36 millimeters, heating and subsequent heat treatment are recommended; it is not prone to flake sensitivity and there is no tendency to temper brittleness. Machinability by cutting in the hot-rolled state at HB 124 and σв=410 MPa, Kυ hard alloy. = 1.8 and Kυ b.st. = 1.6, has found its application in load-bearing elements of welded and non-welded structures and parts operating at positive temperatures, and is actively used in general construction solutions. This grade of steel is used to produce parts and components of freight cars, power transmission line supports, excavators and forestry equipment, offshore structures, road bridges, building structures, oil and gas platforms. Forging is carried out at temperatures from 1300 to 750 0C, cooling is carried out in air.

Interpretation of steel grade VSt3sp

Interpretation of steel: The letter B at the beginning denotes a group of steel that determines the tensile strength criteria for the chemical composition. Steel, in the name starting with the letter B, the strength is 20-30 MPa lower than steel of group A. The following letters St. indicate that the steel is of ordinary quality, although most steels are high quality. The numbers from 0 to 6 are the conventional brand number depending on the chemical composition and mechanical properties. Typically, the higher the number, the more carbon and the greater the strength. In our case, 3 indicates the carbon content in the alloy is 0.14–0.22%. The letters after the brand number indicate the degree of deoxidation: cn - calm.

Interpretation of steel grade BSt3ps

Interpretation of steel: The letter B at the beginning denotes a group of steel that determines the tensile strength criteria for the chemical composition. Steel with a name starting with the letter B comes with a guaranteed chemical composition, strength is 20 MPa lower than steel of group A, and may also differ in mechanical properties from group A. Letter St. indicate that the steel is of ordinary quality, although most steels are high quality. The numbers from 0 to 6 are the conventional brand number depending on the chemical composition and mechanical properties. Typically, the higher the number, the more carbon and the greater the strength. In our case, the number 3 indicates the carbon content in the alloy is 0.14–0.22%. The letters after the brand number indicate the degree of deoxidation: ps - semi-calm.

Supply of VSt3sp

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

| B03 - Metal forming. Forgings | GOST 8479-70; |

| B20 - Classification, nomenclature and general standards | GOST 380-2005; |

| B22 – Long and shaped rolled products | GOST 8239-89; GOST 8278-83; GOST 8282-83; GOST 8283-93; GOST 2879-2006; GOST 2591-2006; GOST 2590-2006; GOST 8510-86; GOST 19772-93; GOST 19771-93; GOST 11474-76; GOST 8509-93; GOST 9234-74; GOST 8281-80; |

| B23 - Sheets and strips | GOST 103-2006; GOST 82-70; GOST 19903-74; |

| B33 - Sheets and strips | GOST 10885-85; |

| B34 - Tapes | GOST 503-81; |

| B62 — Steel pipes and connecting parts for them | GOST 20295-85; GOST 10705-80; GOST 10706-76; GOST 8734-75; GOST 24950-81; |

Supply of BSt3ps

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

| B03 - Metal forming. Forgings | GOST 8479-70; |

| B20 - Classification, nomenclature and general standards | GOST 380-2005; |

| B22 – Long and shaped rolled products | GOST 5267.0-90; GOST 5781-82; GOST 8239-89; GOST 8240-97; GOST 8510-86; GOST 8509-93; GOST 10884-94; GOST 30136-95; GOST 9234-74; GOST 4781-85; GOST 10551-75; GOST 25577-83; GOST 5422-73; GOST 535-2005; GOST 19240-73; GOST 19425-74; GOST 2590-2006; GOST 11474-76; GOST 2879-2006; GOST 2591-2006; GOST 30565-98; |

| B23 - Sheets and strips | GOST 14637-89; GOST 16523-97; GOST 8568-77; GOST 14918-80; GOST 19903-74; GOST 103-2006; |

| B24 - Tapes | GOST 3560-73; GOST 6009-74; |

| B34 - Tapes | GOST 19851-74; |

| B42 - Rails. Overlays. Linings. Crutches | GOST 8142-89; GOST 5812-82; GOST 16277-93; |

| B62 — Steel pipes and connecting parts for them | GOST 12132-66; GOST 10705-80; GOST 10706-76; GOST 3262-75; GOST 24950-81; GOST 8696-74; GOST 10707-80; GOST 20295-85; |

Impact strength of steel VSt3sp

| Delivery condition, heat treatment | +20 | after mechanical aging | -20 |

| Sheet cross section 5-9 mm | 78 | 39 | 39 |

| Sheet cross section 10-25 mm | 68 | 29 | 29 |

| Sheet cross section 26-40 mm | 49 | ||

| Wide strip with a longitudinal section of 5-9 mm | 98 | 49 | 49 |

| Wide strip with a longitudinal section of 10-25 mm | 78 | 29 | 29 |

| Wide strip with a longitudinal section of 26-40 mm | 68 | ||

| Long and shaped rolled steel with a longitudinal section of 5-9 mm | 108 | 49 | 49 |

| Long and shaped rolled steel with a longitudinal section of 10-25 mm | 98 | 29 | 29 |

| Long and shaped rolled steel with a longitudinal section of 26-40 mm | 88 |

Supply of BSt3sp

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

| B03 - Metal forming. Forgings | GOST 8479-70; |

| B20 - Classification, nomenclature and general standards | GOST 380-2005; |

| B22 – Long and shaped rolled products | GOST 2591-2006; GOST 535-2005; GOST 5422-73; GOST 5781-82; GOST 30136-95; GOST 8239-89; GOST 8240-97; GOST 8509-93; GOST 10884-94; GOST 2879-2006; GOST 9234-74; GOST 5267.0-90; GOST 25577-83; GOST 11474-76; GOST 4781-85; GOST 8510-86; GOST 19240-73; GOST 19425-74; GOST 30565-98; GOST 2590-2006; |

| B23 - Sheets and strips | GOST 14918-80; GOST 8568-77; GOST 16523-97; GOST 14637-89; GOST 19903-74; GOST 103-2006; |

| B24 - Tapes | GOST 3560-73; GOST 6009-74; |

| B34 - Tapes | GOST 19851-74; |

| B42 - Rails. Overlays. Linings. Crutches | GOST 5812-82; GOST 8142-89; GOST 16277-93; |

| B62 — Steel pipes and connecting parts for them | GOST 24950-81; GOST 10705-80; GOST 10706-76; GOST 12132-66; GOST 20295-85; GOST 8696-74; GOST 3262-75; GOST 10707-80; |

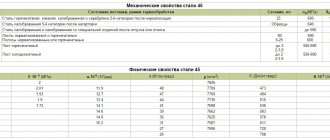

Mechanical properties of steel VSt3sp

Mechanical properties of VSt3sp steel according to GOST 380-94 regulations is sold in the form of hot-rolled steel with a cross-section of up to 20 mm, from 20 mm to 40 mm, over 40 mm to 100 mm, and also over 100 mm. Yield strength – 175, 205, 225, 235 and 245 MPa. Tensile strength 370-480 MPa. Relative elongation after rupture 24, 26, 28%.

Mechanical properties of VSt3sp steel according to GOST 16523-89 regulations in the form of hot-rolled and cold-rolled sheets. The cross-section is made up to 2mm inclusive, and more than 2mm and up to 4mm inclusive. The relative elongation after rupture is 26%. Below is the data in tabular form:

| Heat treatment, delivery condition | Section, mm | σ0.2, MPa | σB, MPa | δ5, % | δ4, % |

| Hot rolled products | <20 | 245 | 370-480 | 26 | |

| Hot rolled products | 20-40 | 235 | 370-480 | 25 | |

| Hot rolled products | 40-100 | 225 | 370-480 | 23 | |

| Hot rolled products | >100 | 205 | 370-480 | 23 | |

| Hot rolled sheets | <2,0 | 370-480 | 20 | ||

| Hot rolled sheets | 2,0-3,9 | 370-480 | 22 | ||

| Cold rolled sheets | <2,0 | 370-480 | 22 | ||

| Cold rolled sheets | 2,0-3,9 | 370-480 | 24 |

Interpretation of steel grade BSt3sp

Interpretation of steel: The letter B at the beginning denotes a group of steel that determines the tensile strength criteria for the chemical composition. Steel with a name starting with the letter B comes with a guaranteed chemical composition, strength is 20 MPa lower than steel of group A, and may also differ in mechanical properties from group A. Letters St. indicate that the steel is of ordinary quality, although most steels are high quality. The numbers from 0 to 6 are the conventional brand number depending on the chemical composition and mechanical properties. Typically, the higher the number, the more carbon and the greater the strength. In our case, 3 indicates the carbon content in the alloy is 0.14–0.22%. The letters after the brand number indicate the degree of deoxidation: cn - calm. In terms of price, calm steels have become more expensive than semi-calm and boiling steels. Mild steel is steel obtained as a result of deoxidation. It is obtained by deoxidation with aluminum, manganese and silicon. The level of oxygen in it is so reduced that during metal processing no reaction occurs between carbon and oxygen, and the presence of non-metallic slags and their inclusion is reduced to a minimum. Calm steel has a dense structure and good mechanical properties. It is less prone to negative reactions to welding heat and to aging. The features of a homogeneous microstructure give the alloy maximum corrosion resistance and ductility.

Mechanical properties of VSt3sp at elevated temperatures

| Test temperature, °C | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 |

| Hot rolled billet dimensions 140x120 mm | |||||

| 20 | 220 | 445 | 33 | 59 | 154 |

| 300 | 205 | 199 | |||

| 500 | 180 | 285 | 34 | 80 | 119 |

| Hot-rolled sheets and shapes up to 30 mm thick | |||||

| 20 | 205-340 | 420-520 | 28-37 | 56-68 | |

| 200 | 215-285 | ||||

| 300 | 205-265 | ||||

| 400 | 155-255 | 275-490 | 34-43 | 60-73 | |

| 500 | 125-175 | 215-390 | 36-43 | 60-73 | |

| A sample with a diameter of 6 mm and a length of 30 mm is forged and normalized. Strain rate 16 mm/min, strain rate 0.009 1/s | |||||

| 700 | 73 | 100 | 57 | 96 | |

| 800 | 51 | 63 | 95 | 95 | |

| 900 | 38 | 65 | 84 | 100 | |

| 1000 | 25 | 43 | 79 | 100 | |

| 1100 | 19 | 31 | 80 | 100 | |

| 1200 | 14 | 25 | 84 | 100 | |

Characteristics of steel grade BSt3sp

BSt3sp - Structural carbon steel of ordinary quality, welds well, welding is carried out without heating and without subsequent heat treatment, welding methods: manual arc welding, automatic submerged arc welding and gas protection, KTS, ESW. For thicknesses greater than 35 millimeters, heating and subsequent heat treatment are recommended; it is not prone to flake sensitivity and there is no tendency to temper brittleness. Machinability by cutting in the hot-rolled state at HB 124 σB = 400 MPa Kυ hard alloy. = 1.8 and Kυ b.st. = 1.6, has found its application in the design of load-bearing elements of welded and non-welded structures and parts operating at positive temperatures; BSt3sp steel has relatively high toughness and ductility, slightly higher than that of BSt3ps steel. Forging at temperatures from 1300 to 750 0C, cooling is carried out in air. BSt3ps steel is not prone to temper brittleness and is magnetic.

Mechanical properties of VSt3sp forgings

| Section, mm | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 | HB |

| Normalization | ||||||

| <100 | 175 | 353 | 28 | 55 | 64 | 101-143 |

| 100-300 | 175 | 353 | 24 | 50 | 59 | 101-143 |

| <100 | 195 | 392 | 26 | 55 | 59 | 111-156 |

| 100-300 | 195 | 392 | 23 | 50 | 54 | 111-156 |

Interpretation of steel grade VSt3ps

Interpretation of steel: The letter B at the beginning denotes a group of steel that determines the tensile strength criteria for the chemical composition. Steel, in the name starting with the letter B, the strength is 20-30 MPa lower than steel of group A. The following letters St. indicate that the steel is of ordinary quality, although most steels are high quality. The numbers from 0 to 6 are the conventional brand number depending on the chemical composition and mechanical properties. Typically, the higher the number, the more carbon and the greater the strength. In our case, 3 indicates the carbon content in the alloy is 0.14–0.22%. The letters after the brand number indicate the degree of deoxidation: ps - semi-calm.

Impact strength VSt3sp

| Delivery condition, heat treatment | +20 | after mechanical aging | -20 |

| Sheet cross section 5-9 mm | 78 | 39 | 39 |

| Sheet cross section 10-25 mm | 68 | 29 | 29 |

| Sheet cross section 26-40 mm | 49 | ||

| Wide strip with a longitudinal section of 5-9 mm | 98 | 49 | 49 |

| Wide strip with a longitudinal section of 10-25 mm | 78 | 29 | 29 |

| Wide strip with a longitudinal section of 26-40 mm | 68 | ||

| Long and shaped rolled steel with a longitudinal section of 5-9 mm | 108 | 49 | 49 |

| Long and shaped rolled steel with a longitudinal section of 10-25 mm | 98 | 29 | 29 |

| Long and shaped rolled steel with a longitudinal section of 26-40 mm | 88 |

Characteristics of steel grade VSt3ps

VSt3ps - Structural carbon steel of ordinary quality, welds well, welding is carried out without restrictions, welding methods: RDS, ADS submerged and gas shielded, ESW and KTS. For thicknesses greater than 36 millimeters, heating and subsequent heat treatment are recommended; it is not prone to flake sensitivity and there is no tendency to temper brittleness. Machinability by cutting in the hot-rolled state at НВ 124 and σв=400 MPa, Kυ hard alloy. = 1.8 and Kυ b.st. = 1.6, has found its application in load-bearing and non-load-bearing elements of welded and non-welded structures and parts operating at positive temperatures. Shaped and sheet metal (category 5) up to 10 mm thick for load-bearing elements of welded structures operating under variable loads in the range from -40 to +425 °C. Rolled products from 10 to 25 mm - for load-bearing elements of welded structures operating at temperatures from -40 to +425°C, subject to delivery with guaranteed weldability. Forging at temperatures from 1300 to 750 0C, cooling is carried out in air.

Physical properties of steel VSt3sp

| Temperature | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 1.94 | 7850 | ||||

| 100 | 1.92 | |||||

| 200 | 1.87 | |||||

| 300 | 1.83 | |||||

| 400 | 1.78 | |||||

| 500 | 1.67 | |||||

| 600 | 1.59 | |||||

| 700 | 1.46 | |||||

| 800 | 1.2 | |||||

| 900 | 0.99 |

At a temperature of +20 0C, the density of steel is 7850 kg/m3

Foreign analogues of steel grade St3sp

| USA | A284Gr.D, A57036, A573Gr.58, A611Gr.C, GradeC, K01804, K02001, K02301, K02502, K02601, K02701, K02702, M1017 |

| Germany | 1.0038, 1.0116, DC03, Fe360B, Fe360D1, RSt37-2, RSt37-3, S235J0, S235J2G3, S235JR, S235JRG2, St37-2, St37-3, St37-3G |

| Japan | SS330, SS34, SS400 |

| France | E24-2, E24-2NE, E24-3, E24-4, S235J0, S235J2G3, S235J2G4, S235JRG2 |

| England | 1449-2723CR, 1449-3723CR, 3723HR, 40B, 40C, 40D, 4360-40B, 4360-40D, 4449-250, 722M24, Fe360BFU, Fe360D1FF, HFS3, HFS4, HFW3, HFW4, S235J2G 3, S235JR, S235JRG2 |

| European Union | Fe37-3FN, Fe37-3FU, Fe37B1FN, Fe37B1FU, Fe37B3FN, Fe37B3FU, S235, S235J0, S235J2G3, S235JR, S235JRG2 |

| Italy | Fe360B, Fe360BFN, Fe360C, Fe360CFN, Fe360D, Fe360DFF, Fe37-2, S235J0, S235J2G3, S235J2G4, S235JRG2 |

| Belgium | FE360BFN, FE360BFU, FED1FF |

| Spain | AE235BFN, AE235BFU, AE235D, Fe360BFN, Fe360BFU, Fe360D1FF, S235J2G3, S235JRG2 |

| China | Q235, Q235A, Q235A-B, Q235A-Z, Q235B, Q235B-Z, Q235C |

| Sweden | 1312, 1313 |

| Bulgaria | BSt3ps, BSt3sp, Ew-08AA, S235J2G3, S235JRG2, WSt3ps, WSt3sp |

| Hungary | Fe235BFN, Fe235D, S235J2G3, S235JRG2 |

| Poland | St3S, St3SX, St3V, St3W |

| Romania | OL37.1, OL37.2, OL37.4 |

| Czech | 11375, 11378 |

| Finland | FORM300H, RACOLD03F, RACOLD215S |

| Austria | RSt360B |

- Structural steel

- Tool steel

Mechanical properties of VSt3ps steel

| Test temperature, °C | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) |

| Hot rolled billet dimensions 140 x 120 mm | |||||

| 20 | 220 | 445 | 33 | 59 | 154 |

| 300 | 205 | — | — | — | 199 |

| 500 | 180 | 285 | 34 | 80 | 119 |

| Hot-rolled sheets and shapes up to 30 mm thick | |||||

| 20 | 205-340 | 420-520 | 28-37 | 56-68 | — |

| 200 | 215-285 | — | — | — | — |

| 300 | 205-265 | — | — | — | — |

| 400 | 155-255 | 275-490 | 34-43 | 60-73 | — |

| 500 | 125-175 | 215-390 | 36-43 | 60-73 | — |

| A sample with a diameter of 6 mm and a length of 30 mm is forged and normalized. Deformation speed 16 mm/min, strain rate 0.009 1/s | |||||

| 700 | 73 | 100 | 57 | 96 | — |

| 800 | 51 | 63 | 95 | 95 | — |

| 900 | 38 | 65 | 84 | 100 | — |

| 1000 | 25 | 43 | 79 | 100 | — |

| 1100 | 19 | 31 | 80 | 100 | — |

| 1200 | 14 | 25 | 84 | 100 | — |