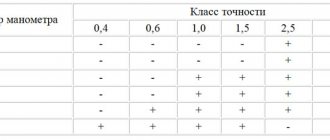

Class - accuracy - measuring device

The accuracy class of a measuring device is a generalized characteristic of the device, determined by the limits of permissible main and additional errors, as well as other properties of the device that affect the accuracy, the values of which are established in the standards for certain types of measuring instruments. The accuracy class characterizes the properties of instruments in terms of accuracy, but is not a direct indicator of the accuracy of measurements performed using these instruments. For example, the accuracy class of voltmeters characterizes the limits of permissible basic error and permissible changes in readings caused by an external magnetic field and deviations from normal values of temperature, alternating current frequency and some other influencing quantities.

The accuracy class of a measuring device is a number that corresponds to the largest error allowed by the standards. The accuracy class is expressed as a percentage of the upper limit of measurement of the device. For example, a Class 1 thermometer may have an error tolerance of 1% of the upper scale limit.

The accuracy class of a measuring device is determined by the largest permissible error in percentage of the value corresponding to the limiting value of the device scale.

The accuracy class of measuring instruments is standardized as a generalized characteristic of measuring instruments, determined by the limits of permissible main and additional errors, as well as other properties of measuring instruments that affect their accuracy, the values of which are established by standards for the corresponding types of measuring instruments.

The accuracy class of a measuring device is its characteristic, which determines the degree of measurement accuracy and the limits of the main error. For thermotechnical control devices of refrigeration units, the accuracy class is numerically equal to the maximum value of the given main error, expressed as a percentage.

What characterizes the accuracy class of measuring instruments.

The given permissible error determines the accuracy class of the measuring device.

The value of which quantity determines the designation of the accuracy class of the measuring device.

The limit values of the main and additional errors determine the accuracy class of the measuring device, which is set in two ways: by the magnitude of the absolute error and by the value of the largest permissible basic reduced error in the form of an absolute number that coincides with the permissible error limit for the final value of the working part of the scale.

In physical and chemical research, the first path is tantamount to increasing the accuracy class of measuring instruments or moving to more precise measurement methods. The second way seems more accessible, but it is only suitable for measuring extensive quantities. In addition, to successfully use this technique, you need to be sure that the absolute measurement error does not correlate with the mass of the sample being studied and, therefore, with the extensive property being measured. Thus, if the absolute error in measuring the enthalpy of combustion for a calorimeter of a given design is approximately constant for a given range of values 100 - 5000 J, in order to reduce the relative error of determination, samples that provide large heat release should be burned.

The maximum error of these measurements is known and is determined by the accuracy class of the measuring instruments used.

For various experimental work, it is very important to correctly select the accuracy class of the measuring instruments used. The accuracy of a device is understood as its property, which characterizes the degree of approximation of the readings of a given device to the actual values of the measured value.

Typically, the accuracy of a device is specified by the accuracy class of the device or is indicated in its passport. Obviously, the more accurate the device, the smaller its error and the higher the cost.

The permissible signal/interference ratio also depends on the accuracy class of the measuring device.

A ( / is the measurement error, which is determined by the accuracy class of the measuring device; DH is the permissible measurement error of the modeled value.

Particularly specific are the requirements imposed by some standards regarding the accuracy class of measuring instruments used during testing.

Choice - exemplary device

The choice of a model device is made: a) by the type of current; b) according to its nominal value; c) according to accuracy class.

When choosing standard instruments for verification, it is necessary to take into account a number of general requirements, the fulfillment of which is essential to ensure the correctness of the results. The reference device must be more accurate than the one being verified. As a general rule, the accuracy class of the reference device must be at least 3 times higher than the accuracy class of the device being verified.

When choosing a reference device, it is necessary to take into account that the upper limit of measurement of the reference device must be equal to or greater than the upper limit of measurement of the device being verified. In addition, the main error of the reference device should be 4 times less than the main error of the device being tested.

When choosing a reference device, it is necessary that the upper limit of measurement of the reference device be greater than or equal to the upper limit of measurement of the device being verified.

When choosing standard instruments, certain conditions must be met under which the intrinsic error of the standard instruments will not have a noticeable impact on the assessment of the errors of the instruments being verified.

When choosing a reference device based on its nominal value, it is necessary that its upper limit of measurement be equal to or close to the upper limit of measurement of the device being verified; otherwise, the relative (but not given) errors of the reference device may be unacceptably large.

When choosing a standard instrument according to its accuracy class, it is necessary that its permissible (reduced) error be at least 3 times less than the permissible (reduced) error of the device being verified.

When choosing a standard instrument for checking a specific type of measuring instrument, it is necessary not only to take into account its accuracy characteristics, but also to analyze the consistency of the adopted model of the measured quantity with the actual law of its change

When determining the reliability of verification, it is necessary to take into account the influence of the verification error component due to the inadequacy of the accepted and real model of the parameter being verified. . When selecting reference devices, their scales should not exceed the final scale value of the device being tested.

When selecting reference devices, their scales should not exceed the final scale value of the device being tested.

When choosing a reference device for verification work, it is necessary that its upper limit of measurement be equal to or slightly greater than the upper limit of measurement of the device being verified. The accuracy class of the reference device is recommended to be at least 3 times higher than the accuracy class of the device being verified.

When working with electrical measuring instruments, preparation for verification in most cases consists of selecting suitable reference devices and including them together with the device being verified in the circuit of the corresponding verification installation. In some cases, it is necessary to do other preparatory operations, for example, before determining the characteristics of a galvanometer with a light reading, it is necessary to install it accordingly and adjust the lighting devices. In preparation for verification, the balance of the moving part of the indicating instruments is also determined and the electrical strength of the insulation of current-carrying parts is tested or its resistance is measured.

Verification of the device consists of four parts: 1) external inspection of the device; 2) selection of a reference device and preparation for verification; 3) verification of instrument readings and 4) documentation of verification.

| Installation for checking spring pressure gauges using a standard deadweight pressure gauge. |

When calibrating any device, the readings of the device being verified are compared with the readings of the standard one. When choosing a standard device for verification, the following requirements are taken into account: 1) the upper limit of the standard device must exceed the upper limit of the device being verified; 2) the maximum absolute error of the reference device must be at least four times less than the maximum absolute error of the device being verified.

You should pay attention to a common mistake when, instead of a five-fold margin of accuracy, standard instruments are used, in which the number indicating the accuracy class is five times less than the accuracy class of the device being tested. This error is a consequence of identifying the concepts accuracy class and reduced error

Since the permissible error limit of a device depends not only on its accuracy class, but also on the measurement limit, the latter should be taken into account when choosing a reference device.

Electrostatic instrumentation

These devices operate on the principle of interaction of charged electrodes, which are separated by a dielectric. Structurally, they look almost like a flat capacitor. At the same time, when the moving part moves, the capacity of the system also changes.

The most famous of them are devices with linear and surface mechanisms. They have a slightly different operating principle. For devices with a surface mechanism, the capacitance changes due to fluctuations in the active area of the electrodes

Otherwise, the distance between them is important

The advantages of such devices include low power consumption, GOST accuracy class, fairly wide frequency range, etc.

The disadvantages are the low sensitivity of the device, the need for shielding and breakdown between the electrodes.

Registration of electrical quantities in emergency modes

GOST R 8.674-2009 state system for ensuring the uniformity of measurements (GSI).

general requirements for measuring instruments and technical systems and devices with measuring functions 1.6.20. To automatically record emergency processes in the electrical part of the power system, automatic oscilloscopes must be provided.

The placement of automatic oscilloscopes at objects, as well as the selection of electrical parameters recorded by them, as a rule, should be done in accordance with the recommendations given in Table. 1.6.2 and 1.6.3.

In agreement with power systems (district energy departments), recording devices with accelerated recording in case of an accident may be provided (for recording electrical parameters that are not monitored using automatic oscilloscopes).

What are they used for?

Various types of instrument transformers are found both in small matchbox-sized devices and in large power installations. Their main purpose is to reduce primary currents and voltages to the values required for measuring devices, protective relays and automation. The use of step-down coils provides protection for the lower and higher rank circuits, since they are separated from each other.

Reducing agents are divided according to characteristics of operation and are intended for:

- measurements. They transmit secondary current to devices;

- protection of current circuits;

- applications in laboratories. Such reducing agents have a high accuracy rating;

- repeated conversion, they belong to intermediate instruments.

Measurement

An instrument transformer is necessary to reduce the high current of the main voltage and transfer it to measuring devices. Connecting standard devices to a high-voltage network would require cumbersome installations. It is neither economically profitable nor advisable to sell instruments of this size.

The use of step-down transformers allows the use of conventional measuring devices in normal mode, which expands the range of their applications. Due to the reduced voltage, they do not require additional modifications. The transformer separates the high-voltage network voltage from the supply voltage of the devices, ensuring safety from use. The accuracy of electrical energy metering depends on their class.

Protection

In addition to powering measuring instruments, step-down transformers supply voltage to protection and automatic blocking systems. Because voltage drops and surges occur in the network electrical network, which is detrimental to high-precision circuit equipment.

In power plants, equipment is divided into power and secondary, which controls the processes of the primary device connection circuit. High-voltage equipment is located in open areas or devices. Secondary equipment is located on relay strips inside distribution cabinets.

The intermediate element for transmitting information between power units and measuring, control, monitoring and protection devices are step-down or instrument transformers. They separate the primary and secondary circuits from the harmful effects of power units on sensitive measuring instruments, and also protect operating personnel from damage.

Specifications

According to the documentation, on network diagrams, voltmeters are usually designated by a circle with an inscribed Latin letter “V”. In Russian laughter, it can be replaced by the Russian letter “B”. Moreover, the first number after the letter in the marking reflects the type of device and the specifics of its use. For example, B2 is a voltmeter for direct current, B3 is for alternating current, B4 is for pulsed current, etc.

You may be interested in: Types of household and industrial electrical switches

Device V3-38 for use in AC networks

The assessment of device performance includes the following components:

- Measuring range. It is limited to the smallest and largest indicator that the device can change. Modern devices have a range from millivolts to kilovolts. Industrial analogues are capable of measuring both lower and higher voltages;

- Accuracy of measurements. Not every home tester is characterized by increased measurement accuracy. As already said, this depends on its internal resistance. New voltmeters with relatively small sizes have small measurement errors;

- Frequency range. Shows the sensitivity of the device to certain signals with different frequencies recorded in the network;

- Temperature and other factors. These parameters determine the indicators at which the device has the minimum measurement error available to it;

- Actually the internal resistance itself (impedance). The higher this parameter, the more accurate the voltmeter is.

Digital devices have almost completely replaced analogue ones.

Important! The technical characteristics of analog devices strongly depend on the sensitivity of the magnetoelectric device. The lower its total deflection current, the more high-resistance resistors can be used

Features and Specifications

Type approval of measuring instruments

Multimeters differ from each other not only in their operating principle, but also in their ability to measure certain quantities. Any multifunctional device has basic and additional functions.

Basic operating modes include:

- ammeter;

- voltmeter;

- ohmmeter

In this case, it is possible to measure both variable and constant signal values. Additional modes make it possible to check the device’s capacitance, inductance, frequency, temperature and pn junction. Some meters are mobile oscilloscopes, so you can also observe the waveform. But a cheap device does not always have few functions. Often devices that have basic functions are more expensive than other functional testers. This is explained by the quality of the measurement and the type of protection used in the device.

When selecting a tester, you should pay attention to the following functions:

- AC and DC voltage;

- AC and DC power;

- electrical resistance measurement;

- checking photocells;

- continuity test, which occurs in low-resistance resistance testing mode, accompanied by an audible signal;

- testing transistors, measuring current gain;

- checking the capacity of radioelements;

- inductance measurement;

- temperature determination - usually using a remote thermocouple.

A high-quality multimeter must be equipped with protection for measurement modes. In the event of an incorrectly selected level, it should protect the device from possible damage. In addition, popular functions are auto power off, memory of measured results, automatic selection of test limit and backlight

It is worth paying attention to the shape of the tester and what material the device body is made of.

Limits

As mentioned earlier, the measuring device, thanks to standardization, already contains random and systematic errors. But it is worth remembering that they depend on the measurement method, conditions and other factors. In order for the value of the quantity to be measured to be 99% accurate, the measuring instrument must have minimal inaccuracy. The relative one should be about a third or a quarter less than the measurement error.

Basic method for determining error

When setting the accuracy class, first of all, the limits of the permissible main error are subject to standardization, and the limits of the permissible additional error are a multiple of the main one. Their limits are expressed in absolute, relative and reduced form.

The reduced error of a measuring instrument is relative, expressed as the ratio of the maximum permissible absolute error to the standard indicator. Absolute can be expressed as a number or binomial.

If the SI accuracy class is determined through absolute, then it is denoted by Roman numerals or Latin letters. The closer the letter is to the beginning of the alphabet, the smaller the permissible absolute error of such a device.

Accuracy class 2.5

Thanks to the relative error, you can assign an accuracy class in two ways. In the first case, the scale will show an Arabic numeral in a circle, in the second case, a fraction, the numerator and denominator of which indicate the range of inaccuracies.

The main error can only occur under ideal laboratory conditions. In life, you have to multiply data by a number of special coefficients.

Additional occurs as a result of changes in quantities that in some way affect the measurements (for example, temperature or humidity). Exceeding the established limits can be identified by adding up all the additional errors.

Random errors have unpredictable values due to the fact that the factors influencing them are constantly changing over time. To take them into account, they use the theory of probability from higher mathematics and keep records of previously occurring cases.

Example of error calculation

The statistical value of a measuring instrument is taken into account when measuring a constant or a quantity that is rarely subject to change.

Dynamic is taken into account when measuring quantities that often change their values over a short period of time.

Rationing

Accuracy classes of measuring instruments tell us information about the accuracy of such instruments, but at the same time it does not show the accuracy of the measurement performed using this measuring device. In order to identify in advance the error in the instrument readings, which it will indicate during measurement, people normalize the errors. To do this, they use already known normalized values.

Rationing is carried out according to:

Formulas for calculating absolute error according to GOST 8.401

Each device from a specific group of devices for measuring dimensions has a certain value of inaccuracies. It may differ slightly from the established standardized indicator, but not exceed the general indicators. Each such unit has a passport in which the minimum and maximum error values are recorded, as well as coefficients that have an impact in certain situations.

Read also: Fiolent milling cutter MFZ 1100

All methods of standardizing measuring instruments and designating their accuracy classes are established in the relevant GOSTs.

Classification of the meter by phase

Depending on what type of electrical network is installed in the house (single-phase or three-phase), you must purchase the appropriate meter:

- Single-phase metering device - installed in a single-phase (two-wire) network with a voltage of 220 V. Such electrical networks are mainly installed in apartments, individual residential buildings, small shops, and offices.

- Three-phase metering device - installed in a three-phase network with a voltage of 380 V or more. Such electrical networks are installed in large cottages, industrial facilities, large stores, restaurants, administrative buildings and warehouses, in a word - in large facilities.

A Question of Choice

To install an electric meter in a private house or apartment, models that have a class of at least 2 are suitable.

In addition, when going to the store to buy an electric meter, you should know exactly the following characteristics:

- Phase of the electrical network. If the electrical network connected to the meter is single-phase, then the device must also be for a single-phase network. A three-phase electric meter can also be installed to track electricity usage, but such devices tend to be more expensive. When the meter is installed to measure three-phase current, the corresponding inscription must be indicated on it. Single-phase devices are not used to calculate three-phase current.

- The load under which this device will be operated. Depending on the maximum load that will be connected to the electricity metering device, a model is selected, on the body of which this indicator is indicated. For a standard load used in a private home, electric meter models designed for a maximum current of 60 A are used. If you plan to connect powerful electric heating boilers, then an electric meter is selected with an indicator of at least 100 A.

- If the electricity supplier can sell electricity at 2 tariffs, then the tariff of the meter is also taken into account when purchasing. Two-tariff devices allow you to save significantly on electricity bills. When using electricity at night, such a meter will record consumption separately. If the electricity supplier allows such payment, then installing a multi-tariff meter will allow you to use electricity more efficiently.

- Mounting method. Allows you to install the device in an existing box, or in place of a device that was previously installed.

The Art of Choice

How to choose the right electric meter for your apartment? Which is the best type on the market? The assessment should be made on technical characteristics.

Household metering devices are manufactured single-phase and three-phase. Single-phase ones are designed for a voltage of 0.22 kilovolts. Networks for such a meter consist of one phase and zero. They are used for apartments, private houses, garden buildings and garages.

Three-phase devices operate at a voltage of 0.4 kilovolts. Installed on networks of phases “A”, “B”, “C” and “zero”. They are used for buildings with a load above the average value: houses, cottages and garages, stuffed with energy-intensive equipment - heaters, refrigerators, pumps, electric furnaces, air conditioners.

Three-phase meters can operate at a voltage of 0.22 kilovolts. Single-phase ones cannot cope with a network load of 0.4 kilovolts.

The accuracy classes of electricity meters for apartments are legally established at 2.0.

Electricity meter suppliers offer a two-tariff power consumption mode. Night tariffs reduce the financial burden on the consumer. If in a residential building at night from 23:00 to 07:00 appliances with an average electricity consumption of 30% of the daily volume are used, then the transition to payment according to a two-tariff mode is justified.

Let's give an example. In the Chelyabinsk region in the first half of 2017, under the “single tariff” (Ts) regime, electricity costs a private consumer 2.92 rubles/kWh. The “two tariffs” mode is calculated taking into account the daily price Td of 3.36 rubles/kWh. and night price Tn 1.75 rub/kWh.

Daily consumption (Es) consists of daytime (Ed) and nighttime amounts (En). The total is 100 percent consumption.

Es = Ed+ En = 100%

The cost of daily electricity in a single-tariff mode is equal to Es * 100.

With a two-tariff regime, the costs will be

Ed*Td + En*Tn = Ts*100

Let's substitute Ed=100-En.

(100-En)*Td + En*Tn = 100*Ts

It remains to simplify the expression and obtain a formula for calculating the nightly percentage of electricity consumption.

En=100*(Td-Ts)/(Td-Tn)%

Substituting the tariff values of the guaranteeing supplier into the formula, we get 27% - the percentage of nightly electricity consumption that justifies the cost of installing a two-tariff meter in apartments and houses in the Chelyabinsk region.

Knowing the price of electricity for each mode for his own region, the consumer is able to calculate the percentage of night load and determine the rationality of installing a two-tariff meter.

The payback of an electricity meter also depends on the tariff policy in the region. Let be:

Tsot – meter price for one tariff;

Tsdt – meter price for two tariffs;

Juice – Payback period;

Em, Edm, Etm – monthly daily, day and night volumes of electricity.

Juice = (Tsdt-Tsot)/(Em*Ts-Edm*Td – Etm*Tn).

With monthly daytime consumption of 170 kWh and nighttime consumption of 70 kWh, the payback period will be:

Juice = (1500 - 700)/(240*2.92 - 170*3.36 - 70*1.75) = 77 months.

Seventy-seven months is half the interval between state verifications. The payback rate is not impressive. With an increase in the electrical load in the house, the period will decrease.

So, with a monthly electricity consumption of 300 kWh, including 150 kWh. during the day and 150 kWh. at night, the payback period will decrease tenfold, to 7 months.

Household conclusion: it is preferable to turn on energy-intensive devices (washing machine, boiler) between 11 pm and 7 am.

What are the accuracy classes?

The error of the electric meter is determined by its design feature and is regulated by the manufacturer. Calibration is carried out at the factory, after which the readings are entered into the product passport. The operating and verification periods of meters are established by law depending on the design features.

The table below shows average statistical data on service life.

After this period, operation is prohibited; the device must be replaced or sent for verification. Now the owners must monitor the deadlines. If you do not comply with this standard, the owner may be fined.

Responsibility for using an expired electric meter lies with the owner. To carry out verification, the device is dismantled and transferred to a specialized laboratory, where a comprehensive examination is carried out and the measurement error is checked.

If the metering device meets the factory specifications, then the laboratory workers give a conclusion about the suitability of the device for further use, which is recorded in the product passport. A faulty electric meter is repaired or written off.

So, according to the PUE, the maximum permissible error of induction electricity meters is 2. However, according to the law for 2020, from July 1, “smart meters” will have to be installed at the expense of the state. Based on this, it follows that the owner will not need to purchase an electric meter and know what error it has, 1 or 2, which is better. This will be done by organizations that replace metering devices.

Electricity metering is mandatory for all consumers. So, for legal entities, individuals with three-phase input and other large consumers, three-phase electricity meters. If it has such electrical installations.

Depending on the power consumption, electricity meters with the following accuracy class are used:

- For business entities connected to a 35 kV network and a power of up to 670 kW, an electricity meter with an error of at least 1.0 is installed.

- To connect a load with a voltage of 110 kV or more, the accuracy class of the electricity meter must be 0.5S.

- Accounting for electricity consumption at loads above 670 kW, devices are used with an accuracy of 0.5S and allow recording hourly loads, as well as being able to integrate into an accounting and memory system capable of storing data for up to 90 days.

All electricity meters used for commercial metering on high-voltage lines cannot be directly connected. To measure the consumed electricity in this case, as well as when consuming currents over 100A, transformer switching meters are used.

For connection voltages of 110 kV or more, as well as for powers above 670 kW, metering devices with an accuracy class of 0.5 and 0.5S are used. The consumer needs to know what accuracy class the meter should have and 0.5 and 0.5S what is the difference between these indicators.

The main differences are as follows:

- An error of 0.5 does not allow all electricity to be taken into account, which leads to a larger amount of under-accounted electricity compared to 0.5S.

- The difference in readings is 0.75%.

- Meters with an error of 0.5 do not pass verification and are rejected.

- If the device fails or reaches the end of its service life, it is necessary to replace such meters with devices with an error of 0.5S.

IMPORTANT! The readings on the device depend on the accuracy class of the electric meter and the current transformer

Types of electricity meters

Induction

Induction is a device familiar to almost everyone. Their characteristic feature is a constantly rotating wheel behind transparent glass. It spins at different speeds and depends on the electricity consumption. The higher it is, the faster the wheel spins.

The readings can be seen on special reels with the numbers depicted. Its operating principle is as follows. The design has 2 coils. One of them is a voltage coil. It limits alternating current and also serves as a kind of barrier to various types of interference.

Its other function is to create a magnetic flux, which is equivalent to the voltage passing through it. The second coil is called the current coil. It also produces a magnetic flux, but only it is proportional to the strength of the current.

Both magnetic fluxes eventually penetrate through a special aluminum disk. Since they have a parabolic trajectory, they pass through the above-mentioned obstacle 2 times. Due to this, forces arise that cause the aluminum disk to spin.

As a result, the axis on which it is located acts on those same drums with numbers through a gear-screw drive. Thus, the readings depend on the rotation speed of the aluminum disk, and this, in turn, depends on the magnetic fluxes that are created by the coils.

As a result, the higher the voltage in the electrical network, the larger the numbers on the reels will be. Such meters are quite widespread even in the age of high technology.

Their advantages include:

- High reliability.

- Durability.

- Absolute independence from random voltage surges.

- Low price.

However, they have several disadvantages:

- Low accuracy class.

- The actual absence of any protection against electricity theft.

- High electricity consumption by the meter itself.

- Inevitable increase in error at low loads.

- Large overall dimensions.

Electronic

Electronic ones are more profitable these days and are used somewhat more often. They are superior to induction ones in terms of accuracy and make it possible to take into account such an indicator as multi-tariff.

This type of meter operates by converting an analog signal that comes from an electric current sensor. The device turns it into a digital code, which is numerically equal to the energy consumed. Then the received code is decrypted in the microcontroller and after that the readings can be seen on the digital screen.

An electric type meter has a much larger number of advantages than its induction counterpart, these include:

- High class of accuracy.

- Multiple tariffs.

- Measuring the consumption of all types of electricity.

- Storing all readings.

- Ease of information availability.

- When attempting to steal, unauthorized access is recorded.

- Possibility to take readings from the device remotely.

- Small overall dimensions.

A few disadvantages include:

- High sensitivity of the device to voltage changes.

- Relatively high cost

- Difficult to maintain and repair.

Related Posts

- How to use a multimeter correctly

- Calculation of resistor resistance for LEDs: online calculator

- How to check grounding

- Correct choice of current transformer according to GOST

- Current and voltage transformers

- How to check basic battery parameters with a multimeter

- Surge protection: overview of available options and effective devices (90 photos)

- Electric meter verification: verification period and verification interval

- Uninterruptible power supplies for heating boilers of any type

- How to measure the resistance of a phase-zero loop?

- Three-phase voltage relay

- Technical characteristics and connection diagram of Neva electricity meters

- Check the electric meter: simple methods for checking electricity meters (115 photos)

- All the nuances of measuring voltage with a multimeter

- Quality of electrical energy at the enterprise

- How to choose a surge protector with a surge protector

- Calculation of the resistance of parallel connection of resistors

- Voltage regulator

- Sewage metering unit: features, measuring instruments

- How a hair hygrometer works

- Adjustable voltage stabilizer

- Technical characteristics of meters CE 101

- Methods for testing board parts with a multimeter

- How to measure current with a multimeter?

- Calculation of a resistor for an LED: how to choose a current-limiting element

Read with this

- How to use a multimeter correctly

- Calculation of resistor resistance for LEDs: online calculator

- How to check grounding

- Correct choice of current transformer according to GOST

- Current and voltage transformers

- How to check basic battery parameters with a multimeter

- Surge protection: overview of available options and effective devices (90 photos)

- Electric meter verification: verification period and verification interval

- Uninterruptible power supplies for heating boilers of any type

- How to measure the resistance of a phase-zero loop?