The pipe welding journal is one of the most important and responsible journals in the construction of oil and gas pipelines, as it contains detailed information on each welded joint, such as the location of the joint, the results of welding control and quality, the names of the elements being welded and other important parameters. The pipe welding log is kept by the foreman or foreman of the welding and installation area and is written by hand daily.

Explanation for the design of a pipe welding journal

Column No. 1

A continuous serial number is written. Example: 1, 2, 3, 4, etc.

Column No. 2

Here we write the date of welding of the joint and the air temperature at which the welding was carried out. Example: 04/10/2020, +8°C.

The air temperature can be viewed in the weather archive; the archive can be found on any good weather forecast site, for example here.

Column No. 3

The diameter and wall thickness of pipes (joints, parts to be welded) are indicated in millimeters. Example: 426x8.

Column No. 4

Here we write down GOST or technical conditions (TU) of pipes, as well as the steel grade and manufacturer. All data is indicated in certificates and passports for pipes and products. Example: TU 14-3R-124-2017, 13HFA, JSC "STZ"

It is not prohibited to fill out column No. 4 with a stamp, since GOST or technical conditions are most often repeated.

Column No. 5

We write down the temperature for drying and heating the joint, if required by the technological map for welding joints. Example: +50°C

A technological map for welding joints is developed for each diameter and wall thickness, as well as steel grade. The technological map must be developed by a Level III NAKS specialist.

Column No. 6

In this column, the assigned joint number is written, as well as the name of the pipeline elements being welded through a fraction. Initially, the numbers are written on the pipe itself (outside and inside), near the joint with indelible paint. When welding horizontally directed bends, the direction indicated is “right” - directed to the right, “left” - directed to the left. Example: single tube/reel l=5m, st. No. 12; coil l=5m/bend 90° straight, st. No. 13.

Column No. 7

We write down the serial numbers of the elements being connected; they are indicated on the pipes and parts (tees, bends), as well as in certificates and passports. Example: 1224/ 3261; 3251/cert. No. 211

If there is no serial number on pipes and parts, the batch number, certificate or passport for the product is written in column No. 7. If this is a coil (part of a pipe), then the number of the pipe from which the coil originated is written down.

Column No. 8

Here we write the connection of the joint to the kilometer, that is, we indicate the kilometer at which the joint is welded. Example: if the joint is located on PK2+55, then indicate 3 km.

Column No. 9

We indicate the picketing reference of the welded joint. If pipeline welding goes in-line, then PC can be specified every 100 meters. If there are any changes along the axis, or the thickness of the pipe wall changes, then in such areas it is necessary to install a PC at each joint. Example: 20+15

One picket has 100 meters, but there are cut pickets (cut) that are more or less than 100 meters. Such pickets are indicated in the working documentation in a longitudinal profile.

Column No. 10

The welding method and the position of the joint are indicated in special letters. Example: RD, B1 - means manual arc welding, vertical position from bottom to top.

Column No. 11

Here we write the brand of electrodes. Example: LB-52U

Welding of pipes must be carried out using electrodes, which are specified in the technological map for welding work agreed with the customer.

Column No. 12

In this column the surname and initials of the foreman or welder are written, and the number of the welders’ arrangement is also indicated. Example: Kechumov Z.I., No. 1

The arrangement of welders is usually drawn up on the second sheet of the welding journal, or on the reverse side of the title page.

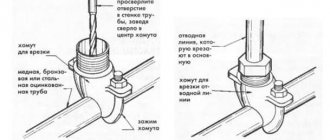

Layout of welders when welding pipes

Column No. 13

The codes of the welders or the brigade code are indicated. Welder codes are written as the product progresses, clockwise, starting from the top. After the code of the welders who welded the root layer, we write the letter K , after the codes of the welders who performed the filling layers, we write the letters ZP we write the letter OB , after the codes of the welders who welded the backing layer, we write the letter P.

Column No. 14

The foreman indicated in column No. 12 puts his signature, confirming that the welding was performed in accordance with the technological map, thereby he is responsible for the welding work performed.

Column No. 15

The foreman or foreman puts his signature only after he is convinced that the parts or pipes being welded comply with the working documentation and is convinced that there is no damage to the pipes or parts. It is also necessary to inspect the weld seam.

The foreman or foreman is responsible for the acceptance of the joint, as well as for the condition of the parts and pipes used.

Column No. 16

Write down the type of welded joint inspection method carried out, the numbers and dates of the conclusions, as well as the inspection results (pass, repair, defective)

Types of control

Closing the log - after the last junction an entry is made (Example):

Journal closed: 05/12/2020

Total welded: 381 joints.

Repaired: 6 joints.

Cut and welded again: 0 joints

The work was carried out by Stroy Kom LLC _____signature_______Morozov M.A.

Contents of the welding log

Filling out the journal in electronic form is strictly prohibited.

This executive document must be constantly on site in paper form and filled out each shift upon completion of work orders by the teams. For each capital construction project, it is necessary to keep a separate log indicating the technical characteristics of the structure, as well as the list and type of required welding connections.

The document in question contains several sections, each of which has its own requirements for completion.

- General information. Information in this section is entered only by a representative of the customer. Contains the details of the parties, addresses and contact details, the name and position of the authorized representative of the customer, as well as the number and date of issue of the power of attorney on the basis of which he performs his functions.

- List of engineering and technical personnel employed at the construction site. To be completed by the contractor's representative. This includes information about engineers, their education and position. The date of certification and the day on which the employee begins to fulfill job obligations are also noted.

- List of welders located on site. As a rule, this section is filled out by the head or foreman of the site. Contains information about welders employed at the site, their level of professional training: rank, personal mark number, work permit to perform high-risk work, as well as information about connecting test and control samples.

The journal also contains the following mandatory items:

- date of;

- name of the parts being welded;

- drawing number of the workpiece;

- record of acceptance of the connected node;

- type of welding filler materials;

- weather;

- employee details, including identification number;

- personal brand number;

- signatures of employees on the execution of the work order;

- responsible for welding work;

- record of the welding supervisor;

- a note on the control check, including any deficiencies identified.

An example of filling out the log is shown in the photo below:

Sections and their completion

Logbook of work according to orders and instructions during the operation of electrical installations

The log of work on welding metal and PE (polyethylene) structures consists of separate blocks.

Title pages

The initial page contains complete information about the production site and the enterprises operating on it.

A standard title page includes the following elements:

- name, legal form of the subcontractor organization;

- description of a construction or industrial facility;

- data of the employee responsible for maintaining housing and communal services;

- information about designers, types of technical documentation;

- registration code for installation or welding work;

- data from the manufacturer of the metal structures being welded, inspection acceptance mark;

- last name, first name, patronymic of the Gostekhnadzor representative;

- start and end dates of document maintenance.

The first page is completed by the person identified by the contractor. Welders enter only technical information about the work being carried out.

List of technical engineers

The list includes data from employees responsible for quality control of technological processes. The list may consist of several names, but most often only 1 engineer is indicated.

The building regulations establish the requirements for such an employee. The project manager is the director of the construction company or the chief engineer.

Team of welders performing the work

This section includes the following data:

- General information. Full names, qualifications, numbers and validity periods of employee IDs are recorded.

- Permit data. A list of works that can be performed by certain welders is indicated. Processes can be standard, low-level, or high-altitude.

- A note on completed tests. The welder provides the samples he has made, and the inspector evaluates the quality of the seams made, indicating the score received.

- Welder's mark. Installed when performing critical work, for example, welding pipelines or tanks operated under high pressure. The number of the specialist’s personal mark is entered in the journal.

Main work table

The page is divided into 13 columns, when filling out which the following order is observed:

- The first column contains the date the work was completed and the work shift number. In the case of welding in the daytime, put the number 1, in the evening - 2, at night - 3.

- The second column contains markings and names of parts being welded. Each welder is responsible for the quality of the welds made.

- The third column describes the joints and the numbers of welded units. Marking is indicated according to the drawing of the object (block).

- The fourth column should contain the receiver's mark. After its installation, the construction stage is considered completed.

- The fifth column contains data on the electrodes used and filler wire. The brand and batch number of consumables are indicated.

- The sixth column (climatic conditions) in a simplified format contains only temperature. Sometimes the presence of precipitation, strong wind or frost is prescribed. The latter option is preferable, because when investigating the causes of an accident, the smallest details are important.

- The seventh column contains information about the welder.

- The next 3 columns contain the name, signature, and mark number of the master responsible for compliance with the technology.

- Columns 11-13 are led by the receiver. The specialist gives an assessment, signature, and, if necessary, indicates any comments.

End of the magazine

The last page of the document indicates the total number of sheets. The data of the head of the enterprise that issued the journal is written down and his signature is affixed. The organization's seal is placed at the bottom of the page.

How to fill out the fields

In the document, the specific names of the columns are clearly and clearly given on the title page; it is difficult to make a mistake here. So, a well-executed document may contain:

- The name of the company that performs the task.

- At what facility the welding work is performed, its address and name.

- Full name and position of the employee who performs the work and enters data on its completion in the journal (this paragraph provides a place for a signature).

- The name of the company that developed the design documentation for the work. There may be a dash in this paragraph if project activities were not carried out, and the employee acted according to ready-made diagrams and drawings.

- Project code.

- Who manufactured the connected structures.

- Full name of the representative of the customer of the welding work performed with the title and signature of the technical supervision officer.

- Dating: beginning and end of journaling.

Important point! Even if two teams of welders from different organizations are working on a construction site at once, they keep separate logs of welding work. And vice versa. When moving to another facility, one organization is required to start a new journal.

After the title page, the financially responsible person should fill out a table with data on the engineering and technical personnel who were involved in welding work. These are mainly engineers and chief engineers. It was these employees who found it necessary to connect metal elements in a specific place and in exactly this way.

The list may consist of one or several lines, it depends on the number of employees involved in the design and development of technical specifications. In any case, it is necessary to record information about employees as completely as possible, indicating their full name, education, category, specialization and position.

Two separate columns are dedicated to the start and end dates of work at the described facility. If a trial takes place, then using these data it will be possible to identify those responsible for the incident. This table must contain information whether the engineer responsible for the correct execution of welding work has a certification mark for this type of construction activity.

In her absence, the manager does not have the right to allow this specialist to monitor the performance of welding work.

After the table with data about engineers, there is data about the welders themselves, who are responsible for the quality of the work done and certify this with their signatures in the last column. In addition to it, the second table on personnel includes information about:

- FULL NAME.

- Qualification level of the employee.

- The number of the personal mark (it is placed on each welded joint made responsibly).

- Welder's certificate (validity period, number, in what spatial position he has the right to weld seams).

- The quality of welding of the provided test samples (satisfactory or unsatisfactory).

The welder's mark is a blank consisting of two lines of numbers 5 mm and 3 mm high, with or without a frame. It helps to determine which employee welded a particular joint. This is especially true for pressure vessels and other metal compounds, on which people’s lives may directly depend.

Requirements for recording inspection results

There are two types of monitoring: daily and periodic.

The first is carried out at the end of the work shift by visual inspection of welded joints. It allows you to identify minor external defects, as well as the presence of foreign alloys. Periodic inspection is more thorough, weekly, weekly. The process uses non-destructive testing methods of welded joints. The date and time of the periodic inspection is chosen by the supervisory authority. The results of the tests are drawn up in accordance with the requirements of the current legislation with the drawing up of a report and making a corresponding entry in the documentation.

The welding log is a very important document, the filling of which requires attention to detail. This is what all inspection authorities check first.

Have you had experience filling out similar documents? Share your acquired skills and impressions in the comments section.