Welding, regardless of the specific type and method, is a rather dangerous process.

The organs of vision are most at risk. Therefore, welding helmets with highly tinted glass have been created that can provide complete eye protection. However, using conventional masks comes with one difficulty: the problem of igniting the welding machine. The fact is that until the welding arc is ignited, practically nothing can be seen through the mask. You have to start the welding machine blindly; one careless movement, especially when working with thin metal, can completely render the workpiece unusable. If you do not use a mask, then bright light will negatively affect eye health. To solve this problem, chameleon welding masks were created. It got its name from the presence of special light filters in its structure. In normal condition, when the welding machine is turned off, the degree of darkness is 4 DIN, this value is sufficient to ensure normal inspection. As soon as the welding arc starts, the degree of darkness instantly increases to levels from 9 to 13 DIN.

A chameleon-type welding helmet allows you to solve two problems at once: eye protection and ease of operation when the welding machine is turned off. It is for this unique ability that masks of this type have gained their popularity among both amateurs and professionals. But a “chameleon” mask is much more difficult to choose than a classic one. There are many manufacturers that produce chameleon masks for welding. In addition to differences in technical characteristics, they may differ in purpose, for example, for classical gas welding, for semi-automatic welding, in an environment of protective inert gases, etc. In order to choose the right mask for the required type of work, you need to know their differences. It is also worth noting that the production of chameleon-type welding masks is strictly regulated by state standards.

Classification

The state standard, in accordance with which masks are produced, obliges all manufacturers to apply markings to the outer surface of the product. Since the main difference between a “chameleon” and a regular classic mask is the ability to automatically adjust the darkening, the classification occurs according to the technical parameters associated with this property.

The marking consists of four digits separated by a fractional symbol. Each number represents a specific characteristic. It can take values in the range from one to three, where one indicates the highest level of quality, three the lowest. In addition, you also need to know the designation of each number.

1. The first digit indicates the optics class of the product. It determines the quality of vision through the glass of a mask with a light filter. The main components that influence changes in this parameter are the quality of the original glass, the light filter and the film used.

2. The second number tells us the degree of light scattering. This parameter indicates the degree of haze of the image obtained through the glass of the mask. The quality of this characteristic is determined by the purity of the liquid crystals used.

3. The third number determines the uniformity of the degree of darkness. The fact is that the glass in chameleon-type welding helmets is darkened unevenly. The parameter value indicates how much the darkest zone can differ from the lightest.

4. The last digit shows the value of the angular dependence. Its value tells us how dependent the light filter is on the angle of flashes entering the field of view of the mask.

Replacing batteries in the Chameleon mask

Unfortunately, the CR2032 battery did not last long. Despite the fact that current consumption is measured in microamps, after some time the filter did not work again.

Of course, a question like “What should I do?” didn't even arise. It was necessary to install a more powerful power source. The most suitable option is two 1.5V elements of size AA or AAA. They can be placed in a special battery compartment, which is commercially available. I didn’t have one, so I had to saw off the battery compartment from my favorite TV remote control.

I sawed off the part where the contacts for the batteries are located from the printed circuit board. I cleaned everything unnecessary (microcircuit and wiring) and soldered two stranded wires to the contacts. The end was lightly covered with what was at hand. It turned out to be a good battery compartment for two AA elements.

The battery compartment is attached to the mask with two M2.5 bolts. The holes are drilled in the center, so the mount does not interfere with the installation of batteries in the compartment. Can be mounted anywhere. The wires should be as short as possible. I secured the compartment at the top, above my head. In this case, the overall balancing is not disturbed, and there is free access to the compartment for replacing batteries. During idle periods, you can even remove one battery from the compartment. For the purpose of, so to speak, global economy...

Well, that's all.

In order to know how to set up the mask and how to check its performance, it is better to refer to the operating instructions. Important to remember:

Operating principle of chameleon type welding helmets

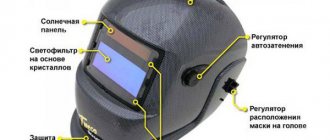

The welding helmet is very similar to other products of a similar role when considered in terms of design. "Chameleon" consists of several main components:

- body - is the basis for the entire structure, as a rule, it is made of fire-resistant durable material, which protects the head from metal splashes and the effects of high temperatures;

- light filter - this component is responsible for automatically adjusting the dimming level (some models also support manual adjustment);

- motherboard - without this component, automatic adjustment is impossible; it is a small chip that runs on battery power;

- power source - thanks to it, the system board operates; a lithium-ion battery is used to power it; if the welding helmet is equipped with two power sources, then most often the second is a solar battery.

In the normal state, without exposure to light from the welding machine, the glass of the mask is slightly darkened. It is covered with a layer of darkening film and several layers of liquid crystals. They are the ones who create the light filter. In a quiet state, the light filter does not work, but as soon as a flash from the welding machine enters its field of view, the signal is instantly sent to the system board, as a result of which the glass is automatically darkened. The entire process described takes a fraction of a second. After the welding machine turns off, the glass does not brighten immediately. Different models perform this process with different times, in any case it does not exceed five seconds. This property allows you to increase the level of security in case of emergency situations. On most popular models, this parameter can also be adjusted.

How to test a Chameleon mask without welding

When you hold down the Test button for five seconds, the filter should darken. If there is no such configuration function, you need to check Chameleon in other ways. The sensors are triggered by a powerful light beam. The filter is turned towards the light source at least three times, the screen should darken in all cases. Light protection reacts to:

- radiation from the sun (the filter should darken and open after an exposure interval, because the flow is of constant intensity);

- red spirals of incandescent lamps (darkening persists throughout the entire period of being near the emitter; it operates at an alternating current frequency);

- a spark from a silicon lighter (the filter darkens sporadically when the wheel knocks out a spark);

- remote control for household appliances (sensors react to infrared radiation pulses, the light output of the remote control is uniform);

- smartphone screen during flash.

If the filter does not respond, check the power supply: change the batteries or batteries, charge the solar panels. The sensitivity of the filter is checked with an incandescent lamp. If the spiral is equally visible at different settings, the regulator does not work.

Approximate technical characteristics of chameleon-type welding helmets

Chameleon masks for welding have the following technical characteristics. The specific value of a particular parameter may change depending on the specific mask model. The general meanings are:

- glass dimensions have a universal standard: 110x90x9 (length, width and thickness), however, there are specialized models in which this parameter can take other values;

- The darkening level in standard mode for almost all models is 4 DIN;

- the degree of darkness in operating mode can take values in the range from 9 to 13 DIN;

- the response speed of the light filter can be from several ten-thousandths to three hundredths of a second;

- adjustment of the degree of darkening can be carried out both jerkily and smoothly;

- Almost every model has two sensors at its disposal;

- lithium-ion batteries and solar panels are used as power sources;

- the body is made of durable material that is resistant to high temperatures and open flames;

- The weight of the product is approximately half a kilogram.

Problems with the Chameleon mask

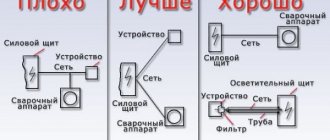

There is the following problem: when argon arc welding at 60...80A of steel strips, previously cleaned with an angle grinder, the Korund ASF 4/9-13 mask turns off for a tenth of a second.

This happens rarely and most often when passing seams inside corners. Nevertheless, I manage to catch the “rabbits”, then, naturally, my eyes turn red and pain appears. Question: is the problem with the mask or is it my “crooked little hands” that are to blame? Naturally, it is impossible to give a definite answer to this question. But there are several recommendations, because Chinese chameleon masks have been sold for several days and a lot of experience has been accumulated in their use. Take more interest from fellow welders.

- Option number one: the optical sensor “does not see” the arc when welding in hard-to-reach places (or you cover the photocell with your hand). Adjust the sensitivity using the tuning knob. If it doesn't help, try using a regular filter. If you don’t want to burden yourself with selecting a light filter when welding at low/high currents, look for a mask with an electromagnetic arc sensor. Even such good PPE as Speedglas opens if you cook it “around the corner.”

- Option number two: the dimming is very slow, set the adjustment knob to maximum.

- The problem may also be this: simple cheap masks behave quite correctly when working with conventional inverters (without a set of “cool” welding functions). But as soon as you switch to professional equipment with the function of smooth ignition and arc extinction at a predetermined time, problems begin to appear. When ignited, the mask works normally, but after a while, when the arc flares up more strongly, subsecond shutdowns occur. This can be explained this way: the electronics adjust to the brightness of the light flux once, and then, when its intensity increases, it does not work a second time, because it is not adapted to such changes.

svarka-master.ru

How to use a chameleon welding helmet

Before using the product for its intended purpose, you must read the instructions for use, which are always present in the original packaging. Before starting welding work, you need to perform the following manipulations.

1. Conduct a full technical inspection for defects, breakdowns or defects. If the mask is to be used for the first time after purchase, you need to remove the protective films from the entire surface. It is also necessary to remove the protective film under the plate; to do this, you need to dismantle it, remove the protection, and install it back. Important: when checking, you should always pay attention to the technical condition of the cable that connects the light filter to the system board and control unit.

2. After inspection, if there are no defects, you can begin setting up the “chameleon”. It is performed in the following order:

- adjust the process of opening and closing the mask using special clamps;

- Next you need to adjust the working angle;

- You can also configure individual parameters, which include: the distance from the glass to the organs of vision, adjust the technical parameters of the product (if required);

3. After all checks and settings have been completed, you need to adjust the dimming level. To do this, you need to use a special control unit.

DIY drawings on a welding helmet

The desire to decorate your working tool is inherent in all professionals. This will not only allow you to realize your creativity, but will also highlight an individual element of protection, which means no one will use it “by mistake.”

For example, you can apply some kind of colorful design to a welding mask. To do this, you just need to find a suitable picture and, after transferring it to paper, make a stencil. Next, the design is applied using a can of paint.

If it is possible to use a spray gun, then the task is greatly simplified. As you gain experience, you can try to apply more and more complex multi-layer designs.

How to charge batteries in masks of this type?

The method for charging the battery depends on its type. If the mask uses a regular lithium-ion power source, then it can be charged using a regular household outlet of two hundred and twenty volts. Almost always, a charging adapter is included with the product.

If solar batteries are used as a power source, then the “chameleon” needs to be charged in the sun, or in bright, targeted light. If the mask is equipped with two types of batteries at once, then the charging process can be combined.

Carrying out maintenance

Welders should inspect the Chameleon at least once a month. Dirt is removed with a soft rag or cotton cloth. Cleaning products with aggressive, oily and abrasive bases are not suitable for glass. It is important to remember that filters are fragile and cannot withstand shock loads. To get to the light sensors, the casing is dismantled. This is done when the power supply is turned off, just remove the batteries.

Step-by-step instructions for replacing the protective screen:

- The cartridge latches are moved to the center of the filter and opened.

- The damaged glass is removed along with the rubber gasket, and it is replaced with a new light filter of the Chameleon mask.

- The assembled cartridge is installed in its working position. It should fit tightly.

When replacing the filter, remove the regulator knob and potentiometer. Then the elements are assembled in the reverse order. Be sure to check the sensitivity lever; the delay time adjustment should work perfectly so as not to catch “bunnies”.

What to look for when purchasing?

The most important parameter to pay attention to when purchasing a chameleon welding helmet is the auto-darkening speed. The higher it is, the safer the welder’s visual organs are. It is best to purchase a model in which the light filter is adjusted smoothly, as this has less impact on the eyes and provides additional comfort during use.

The second thing you should pay attention to is the number of batteries. It is best if the welding helmet has two different power sources. This will protect against unexpected battery drain.

Important: despite a fairly large number of important parameters, first of all, when purchasing, you need to be guided by the comfort of using a welding helmet.

The more layers of liquid crystals a product has, the better. However, as they increase, the cost of the welding helmet also increases. Also an important parameter is the weight of the “chameleon”; the mask should not be too heavy.

Welding helmets of this kind are created both at domestic and foreign factories. It is worth mentioning several of the most popular brands: Centaur, Dnepr, Optech, Cosmos, etc.

Selecting a mask

The range of chameleon welding masks is huge. They are made by both domestic and foreign manufacturers. Prices can vary from $20 to infinity. We do not recommend buying the cheapest models, since the quality of their filters leaves much to be desired. Yes, even the cheapest chameleon mask is more comfortable than a regular welding shield, but it will not last you very long. In addition, cheap filters in low-quality masks may not fully protect your health.

Choose masks from the middle price category. They are often the ideal option in terms of price and quality. In our practice, the chameleon welding mask Forte MC has proven itself well, namely the chameleon welding mask Forte MC 1000. The chameleon Bars welding mask, the Centaur SM chameleon welding mask and the Svarog AS chameleon welding mask also cope well with the task.

There are impact-resistant masks on sale that are resistant to falls and mechanical impacts. We recommend purchasing one if you treat the mask as a working tool and do not want to pay much attention to its storage.

By the way, about storage. Some rules still need to be followed. Store the mask in a dark place, such as a garage or closet. Make sure the temperatures are not too high or too low. You must understand that the “chameleon” has a very sensitive filter. This is not simple tinted glass, like in a regular shield. Therefore he needs care. Wipe the mask and glass with a cloth before each use.

Pay attention to how the mask is placed on your head. This could be a helmet or a headband. Usually a helmet is more comfortable, but it is more difficult to find the right size for your head. Before purchasing, be sure to try on the mask and make sure that you will be comfortable working in it.

Light filter in a chameleon: what is it and which is better

That small glass that is installed on the welding helmet is a real miracle of science and technology. It contains the latest achievements in optics, microelectronics, liquid crystals and solar energy. This is the “glass”. In fact, this is a whole multi-layered cake, which consists of the following elements:

- liquid crystal cells (several layers - the more, the better);

Approximate composition of an automatic light filter in a chameleon welding mask (To increase the size of the picture, right-click on it) - UV filter;

- infrared filter;

- polarizing films;

- welding arc detection sensors (from 2 to 4, there are also them, the more, the better);

- protective glass;

- batteries (solar batteries and/or lithium batteries).

The main and main advantage of a chameleon welding mask is that even if it did not have time to work, it will not let in ultraviolet and infrared radiation (if the mask was lowered). And the degree of protection from these harmful effects does not depend in any way on the settings. In any case and with any settings, you are protected from these types of harmful influences.

But this is only if the “pie” contains the appropriate filters and they are of the proper quality. Since it is impossible to check this without special devices, you have to rely on certificates. And masks must have them. Moreover, on the territory of Russia only two centers can issue them: VNIIS and the Federal State Budgetary Institution at the All-Russian Research Institute of Labor Protection and Economics. To be sure that the certificate is genuine, its number can be found on the official website of the Federal Service for Accreditation at this link.

This is a form on the Rossaccreditation website for checking the certificate. You can fill in only the number, leaving all other fields empty (To increase the size of the picture, right-click on it)

The certificate number is entered in the appropriate field and you receive the validity date, information about the applicant, and the manufacturer. A small note: the abbreviation RPE stands for “optical personal protective equipment.” This is what a welder's mask is called in bureaucratic language.

If such a certificate exists, the following message will appear. By clicking on the link you will see the text of the certificate (To enlarge the image size, right-click on it)

The most important thing is that you make sure that this product (by the way, compare both the name and model) is safe for your health.

You may be interested in how to make a gazebo on a metal frame.

Classification of automatic welding filters

Since the light filter and its quality are the key element in this product, you should start choosing a chameleon mask with it. All its indicators are classified according to the EN379 standard and must be displayed on its surface through a fraction.

One of the filters in the chameleon mask. Its classification is indicated in red

Now let’s take a closer look at what is hidden behind these numbers and what they should be. Each position can contain a number from 1, 2, 3. Accordingly, “1” is the best option - first class, “3” is the worst - third class. Now let’s talk about which position displays which characteristic and what it means.

Explanation of EN37 classification

Optical class

It reflects how clearly and without distortion the picture will be visible to you through the filter. Depends on the quality of the protective glass (film) used and the build quality. If "1" comes first, distortion will be minimal. If the values are higher, you will see everything as if through a crooked glass.

Light scattering

Depends on the purity and quality of the optical crystals used. Shows the degree of “turbidity” of the transmitted picture. You can compare it with wet car glass: as long as there are no oncoming traffic, the drops hardly interfere. As soon as a light source appears, everything blurs. To avoid this effect, it is necessary that the second position be “1”.

Uniformity or Homogeneity

Shows how evenly the filter is shaded in different parts. If there is a unit in the third position, the difference can be no more than 0.1 DIN, 2 - 0.2 DIN, 3 - 0.3 DIN. It is clear that it will be more comfortable with uniform darkening.

Angular dependence

Reflects the dependence of dimming on viewing angle. Here, too, the best value is “1” - the first class changes the darkening by no more than 1 DIN, the second by 2 DIN and the third by 3 DIN.

This is what the difference between a high-quality mask and a not-so-good filter looks like in real life.

From all this it is clear that the more units in the filter characteristic, the more comfortable you will be working in a mask. This is what you need to focus on when choosing a chameleon welder mask. Professionals prefer at least the following parameters: 1/1/1/2. Such masks are expensive, but even after working for a long time, your eyes will not get tired in them.

Amateur welders, for occasional work, can get by with simpler filters, but class 3 is considered a thing of the past. Therefore, it’s probably not worth buying masks with such filters.

And one moment. Sellers usually call this entire classification with one term “Optical class”. It’s just that this formulation quite accurately reflects the essence of all the characteristics.

Adjustments of the SpeedGlass chameleon welding helmet (SpeedGlas)

There are several more chameleon settings that allow you to adjust the dimming mode for a given situation. They can be located inside, on the light filter, or they can be placed outside in the form of handles on the left on the side surface of the mask. These are the following parameters:

- Dimming adjustment. Allows you to change the current dimming level. You can make it lighter/darker without interrupting your work if the control is located outside. If it is located inside, you will need to stop, remove the mask and tighten the adjuster. For non-professionals, this is normal: they don’t need development. But even the pros don’t always like external adjustments: they can hit something.

The controls themselves can be in the form of switches, wheels, or can be made in the form of touch switches - Adjusting sensitivity. It is located inside the mask, on the filter. With its help, you can set what the filter will work on: only on the arc, or also on bright light sources. If you work indoors, you can set the sensitivity to high: the filter will darken when an arc occurs. Since there are no other variable light sources, it will not twitch. On the street, with high sensitivity, it can also respond to sun glare. So here you have to reduce the sensitivity.

- Delay in mask clearing. It is necessary to prevent the eyes from receiving light shock from the hot metal after welding is completed. If there is no delay, the filter immediately becomes lighter and the bright glow of the weld pool hits the eyes. It is not dangerous or fatal, but unpleasant. The dimming delay allows you to “push back” the moment of filter brightening for some time. Also, this delay prevents the filter from clearing if you cook with arc separation or if the electrode sticks. So adjustment is necessary.

You may be interested in reading about the types of welds and joints, welding techniques and methods used.