Accuracy class bolts, nuts, A, B, C high-strength fasteners

| Catalog / accuracy class bolts, nuts A, B, C high-strength fasteners |

Fasteners are manufactured with rough, normal and high accuracy or accuracy classes C, B and A, respectively.

Each accuracy class has its own manufacturing tolerances.

For non-design installation connections, fasteners of accuracy class C should be used, and for connections that accept design forces, fasteners of accuracy classes B and A should be used.

Accuracy class of bolts, nuts A, B, C high-strength fasteners:

Fasteners accuracy class C

Bolts and nuts of accuracy class C are placed in holes whose diameter is 2...3 mm larger than the diameter of the bolt rod. In this case, ease of installation of bolts into holes is achieved with some discrepancy between the walls of the holes of adjacent connected structural elements. When an external force is applied to such a connection, significant movements occur due to the difference in the diameters of the bolt and hole, as well as the non-simultaneous entry into operation of all bolts of the connection. For this reason, bolts of accuracy class C are installed structurally without calculations.

Fasteners accuracy class B

Bolts and nuts of accuracy class B are installed in holes whose diameter is 1-1.5 mm larger than the diameter of the bolt rod. Therefore, such connections are less deformable compared to connections with bolts of accuracy class C and require higher accuracy when forming holes in the connected structural elements.

Fasteners accuracy class A

Bolts and nuts of accuracy class A are installed in holes that are drilled to the design diameter in the assembled elements and their diameter is 0.25 - 0.30 mm greater than the diameter of the bolt rod, and the bolts themselves have only a minus tolerance on the diameter of the rod.

Such bolts and nuts are made by turning and therefore have a high cost. When a load is applied to such a connection, all the bolts begin to work almost simultaneously and therefore the connection has little deformation, but requires high precision in the execution of holes in the parts being connected. Terms of sale :

- Sales of metal products wholesale and retail;

- Cashless payment by transferring funds from a bank account;

- Possibility of deferred payments;

- Free consultations from our specialists;

- We provide packaging services according to customer requirements;

- We are ready to produce products of any complexity to order according to customer drawings.

Delivery terms:

- Products are delivered from the warehouse based on availability;

- If necessary, we can provide a storage service;

- We are ready to provide a discount on delivery according to the terms of partnership programs of transport companies;

- Possibility of self-pickup of goods from warehouses.

Guarantees:

- All products are certified and released after technological control;

- Hardware, fasteners, ropes, mesh, wire, electrodes and other metal products comply with GOST and TU;

- Possibility of returning goods in accordance with the legislation of the Russian Federation;

Delivery within the Russian Federation: Moscow, St. Petersburg, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Yekaterinburg, Ivanovo, Izhevsk, Yoshkar-Ola, Kazan, Kaluga, Kirov, Kostroma, Krasnodar, Kurgan, Kursk, Lipetsk, Omsk, Orenburg, Penza, Perm, Pskov, Rostov-on-Don, Ryazan, Samara, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Stavropol, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk, Ufa, Chelyabinsk, Yaroslavl, etc.

The information presented on this website contains a catalog of reference information on more than 3,000 types of metal products, is for informational purposes only, and can be used in various areas of enterprise activity.

Not Found

16. Screws of accuracy classes A and B

Screws with a cylindrical head (GOST 1491-80), with a semicircular head (GOST 17473-80), with a semi-countersunk head (GOST 17474-80), with a countersunk head (GOST 17475-80).

Dimensions, mm

| GOST 1491-80 | GOST 17474-80 Version 1 |

| d= 1…20 mm; d1=d | |

| GOST 17473-80 | GOST 17475-80 |

| d= 1…20 mm; d1=d | |

| Thread d | 2 | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | |

| Thread pitch | large | 0,4 | 0,45 | 0,5 | 0,7 | 0,8 | 1,0 | 1.25 | 1,5 | 1,75 | 2,0 |

| small | — | — | — | — | — | — | 1,0 | 1,25 | 1,25 | 1,5 | |

| D, D1 | 3,8 | 4,5 | 5,5 | 7,0 | 8,5 | 10 | 13 | 16 | 18 | 24 | |

| D2 | 3,8 | 4,7 | 5,6 | 7,4 | 9,2 | 11,0 | 14,5 | 18,0 | 21,5 | 28,5 | |

| k | 1,3 | 1,6 | 2,0 | 2,6 | 3,3 | 3,9 | 5,0 | 6,0 | 7,0 | 9,0 | |

| k1 | 1,4 | 1,7 | 2,1 | 2,8 | 3,5 | 4,2 | 5,6 | 7,0 | 8,0 | 11 | |

| k2, no more | 1,2 | 1,5 | 1,65 | 2,2 | 2,5 | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | |

| f | 0,5 | 0,6 | 0,75 | 1,0 | 1,25 | 1,5 | 2,0 | 2,5 | 3,0 | 4,0 | |

| R | 2,0 | 2,4 | 2,9 | 3,6 | 4,4 | 5,1 | 6,6 | 8,1 | 9,1 | 12,1 | |

| R1 | 4,2 | 5,4 | 6,0 | 8,0 | 9,4 | 12 | 15 | 19 | 22,5 | 30 | |

| t, | no less | 0,6 | 0,7 | 0,9 | 1,2 | 1,5 | 1,8 | 2,3 | 2,7 | 3,2 | 4,0 |

| no more | 0,85 | 1,0 | 1,3 | 1,6 | 2,0 | 2,3 | 2,8 | 3,2 | 3,8 | 4,6 | |

| t1 | no less | 0,75 | 0,9 | 1,0 | 1,6 | 2,1 | 2,3 | 3,26 | 3,76 | 3,96 | 4,76 |

| no more | 1,05 | 1,3 | 1,4 | 2,0 | 2,5 | 2,7 | 3,74 | 4,24 | 4,44 | 5,24 | |

| t2 | no less | 0,8 | 1,0 | 1.2 | 1,6 | 2,0 | 2,4 | 3,2 | 4,0 | 4,8 | 6,4 |

| no more | 1,0 | 1,2 | 1,45 | 1,9 | 2,3 | 2,8 | 3,7 | 4,5 | 5,4 | 7,2 | |

| t3 | no less | 0,4 | 0,5 | 0,6 | 0,8 | 1,0 | 1,2 | 1,6 | 2,0 | 2,4 | 3,2 |

| no more | 0,6 | 0,73 | 0,85 | 1,1 | 1,35 | 1,6 | 2,1 | 2,6 | 3,0 | 4,0 | |

| n | no less | 0,56 | 0,66 | 0,86 | 1,06 | 1,26 | 1,66 | 2,06 | 2,56 | 3,06 | 4,07 |

| no more | 0,70 | 0,8 | 1,0 | 1,2 | 1,51 | 1,91 | 2,31 | 2,81 | 3,31 | 4,37 | |

17. Screw lengths according to GOST 1491-80, GOST 17473-80, GOST 17475-80

Dimensions, mm

| ℓ | Thread length b at d (the sign x marks screws with threads along the entire length of the rod), not less | |||||||||||

| 2 | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 18 | 20 | |

| 3 4 5 6 | X | X | X | - XXX | — — — X | — | — | — | — | — | — | — |

| 8 9 10 11 | X | X | X | |||||||||

| 12 14 16 20 | X 10 10 10 | X 11 11 11 | XX 12 12 | XXX 14 | XXX 16 | X | X | — — — X | — — — X | |||

| 25 30 35 40 | — | 11 — — — | 12 12 — — | 14 (22) | 16 (25) | 18 (28) | X 22 22 22 | XX 26 26 | XX 30 30 | - XXX | ||

| 42 (64) | ||||||||||||

| 46 (70) | ||||||||||||

| 45 50 55 60 | — | — | — | 16 16 — — | 22 (34) | 26 (40) | 30 (46) | 38 (58) | ||||

| 65 70 75 80 | — | — | ||||||||||

The extended thread length shown in parentheses is the preferred length.

18. Screw lengths according to GOST 17474-80

Dimensions, mm

| ℓ | Thread length b at d (x marks mark screws with threads along the entire length of the rod), not less | |||||||||

| 2 | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | |

| 3 4 5 6 | X | — x XX | - XXX | — — XX | — — — X | — | — | — | — | |

| 8 9 10 11 | X | X | X | X | X | — — XX | ||||

| 12 14 16 20 | X 10 10 10 | XX 11 11 | XXX 12 | XXX 14 | X | X | — — XX | |||

| 25 30 35 40 | — | 11 — — — | 12 12 — — | 14 14 14 14 | 16 | 18 | XX 22 22 | XXX 26 | X | - XXX |

| 45 50 55 60 | — | — | — | 22 | 26 | 30 | XXX 38 | |||

| 65 70 75 80 | 38 | |||||||||

GOSTs also provide for other designs, non-recommended diameters and lengths, d = 1 ... 1.6 mm; d = 20 mm; ℓ = 90 ... 120 mm, as well as an “extended” thread length. Diameter d1 is equal to the outer diameter of the thread or the diameter of the rod for rolling metric threads according to GOST 19256-73. Example of a screw designation

accuracy class A, thread diameter d = 12 mm, with large thread pitch, with tolerance range 6g, length ℓ = 50 mm, strength class 5.8, uncoated:

Screw A.M12-6g x 50.58 GOST 1491-80

The same, with a fine thread pitch, strength class 10.9, made of steel 40X, with coating 01 9 microns thick:

Screw A.M12 x 1.25 - 6g x 50.109.40X.019 GOST 1491-80

Thread - according to GOST 24705-81. Runaway and undercut threads - according to GOST 10549-80. Technical requirements - according to GOST 1759.0-87. Maximum deviations of screw sizes are given in table. 19.

19. Maximum deviations of screw sizes

| Dimensions | Limit deviations for accuracy classes | ||

| A | IN | ||

| Rod diameter d1 | h13 | h14 | |

| Head diameter: D | h12 | h14 | |

| D1 | h14 | js15 | |

| D2 | h14 | ||

| Head height: | k | h13 for d < 5 h14 for d > 5 | h14 |

| k1 | js14 | js15 | |

| Screw length ℓ | js15 | js17 | |

20. Set screws with a square head and a shoulder of accuracy classes A and B (according to GOST 1488-84)

Dimensions, mm

D1 = (0.90 … 0.95)S

| Thread d | 5 | 6 | 8 | 10 | 12 | 16 | 20 |

| d1 | 5 | 6 | 8 | 10 | 12 | 16 | 20 |

| S | 5 | 7 | 8 | 10 | 12 | 17 | 22 |

| k | 3,5 | 5,5 | 5,5 | 7 | 8 | 10 | 13 |

| e | 6,5 | 9 | 10 | 13 | 16 | 22 | 28 |

| D | 7,5 | 11 | 14 | 16 | 20 | 25 | 30 |

| k1 | 2 | 2 | 2 | 3 | 3 | 4 | 5 |

| ℓ | b (the x sign means thread along the entire length of the rod) | ||||||

| 14 | X | X | — | — | — | — | — |

| 16 | X' | X | X | — | |||

| 20 | 16 | X | X | X | |||

| 25 | 16 | X | X | X | |||

| 30 | 16 | 18 | 22 | X | X | — | |

| 35 | 26 | 30 | — | ||||

| 40 | 26 | 30 | X | ||||

| 45 | 26 | 30 | 38 | ||||

| 50 | — | 18 | 22 | 26 | 30 | 38 | X |

| 55 | — | — | 26 | 46 | |||

| 60 | — | — | 26 | 46 | |||

| 65 | — | — | . | 46 | |||

| 70 | — | — | — | 46 | |||

GOST provides for ℓ up to 110 mm. Example of a screw designation

accuracy class A, thread diameter d = 10 mm, with tolerance range 6g, length ℓ = 25 mm, strength class 14H, uncoated:

Screw A.M10-6g x 25.14N GOST 1488-84

The same strength class 45N, made of steel 40X, with coating 01 6 microns thick;

Screw A.M10-6g x 25.45H.40X.016 GOST 1488-84

Thread - according to GOST 24705-81. Mechanical properties of screws made of carbon and alloy steels - in accordance with GOST 25556-82, of other materials - in accordance with GOST 1759.0-87. Tolerances for dimensions, deviations in shape and location of surfaces in accordance with GOST 1759.1-82. Other technical requirements are in accordance with GOST 1759.0-87.

21. Screws with a cylindrical head and a hexagonal socket wrench, accuracy class A (according to GOST 11738-84)

Dimensions, mm

| d | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 30 | 36 |

| d1 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 30 | 36 |

| D | 5,5 | 7,0 | 8,5 | 10 | 13 | 16 | 18 | 24 | 30 | 36 | 45 | 54 |

| k | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 30 | 36 |

| S (limit trip no D11) | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | 14 | 17 | 19 | 22 | 27 |

| e, no less | 2,9 | 3,5 | 4,6 | 5,8 | 6,9 | 9,2 | 11,5 | 16,2 | 19,6 | 21,9 | 25,4 | 31,2 |

| D1 (limit trip according to js17) | 3,2 | 3,8 | 4,9 | 6,1 | 7,2 | 9,7 | 12,0 | 16,7 | 20,4 | 22,7 | 26,2 | 32,0 |

| t, not less | 1,3 | 2,0 | 2,5 | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 15,5 | 19,0 |

| W, not less | 1,15 | 1,4 | 1,9 | 2,3 | 3,0 | 4,0 | 4,8 | 6,8 | 8,6 | 10,4 | 12,9 | 15,3 |

GOST also provides for non-recommended thread diameters. Example of a screw designation

thread diameter d = 12 mm with tolerance range 5g, length ℓ = 40 mm, strength class 8.8, uncoated:

Screw M12-6g x 40.88 GOST 11738-84

the same strength class 10.9, made of steel 40X, with coating 01 6 microns thick:

Screw M12-6g x 40.109.40X.016 GOST 11738-84

Thread - according to GOST 24705-81. The lengths of screws and threads are given in table. 22.

22. Screw lengths according to GOST 11738-84, mm

| Rod length ℓ | Thread length b at d (the sign x marks screws with threads along the entire length of the rod) | ||||||||||

| 4 | 5 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 30 | 36 | |

| 6 | X | — | — | — | — | — | — | — | — | — | — |

| 8 | X | — | — | — | |||||||

| 10 | X | X | — | — | |||||||

| 12 | X | X | X | — | |||||||

| 14 | X | X | X | X | |||||||

| 16 | X | X | X | X | X | — | — | — | |||

| 20 | X | X | X | X | X | X | — | — | |||

| 25 | X | X | X | X | X | X | X | — | |||

| 30 | 20 | 22 | X | X | X | X | X | X | |||

| 35 | 20 | 22 | 24 | X | X | X | X | X | — | — | |

| 40 | 20 | 28 | X | X | X | X | — | — | |||

| 45 | — | 28 | 32 | X | X | X | X | X | |||

| 50 | 28 | 32 | 36 | X | X | X | X | ||||

| 55 | — | — | — | 28 | 32 | 36 | X | X | X | X | X |

| 60 | 44 | X | X | X | |||||||

| 65 | 44 | X | X | X | |||||||

| 70 | 44 | 52 | X | X | |||||||

| 75 | — | 28 | 44 | 52 | X | X | X | ||||

| 80 | 28 | X | X | X | |||||||

| 90 | — | 60 | X | X | |||||||

| 100 | 60 | 72 | X | ||||||||

| 110 | It is allowed to produce screws with a diameter of the smooth part of the rod d1 equal to the diameter of the rod; rolling metric threads - according to GOST 19256-73. The shape of the bottom of the hexagonal recess is arbitrary. Tolerances for dimensions, deviations in shape and location of surfaces are in accordance with GOST 1759.1-82. | 36 | 44 | 52 | 60 | 72 | X | ||||

| 120 | 36 | 84 | |||||||||

| 130 | 36 | 84 | |||||||||

| 140 | — | 84 | |||||||||

| 150 | — | 44 | 52 | 60 | 72 | 84 | |||||

| 160 | — | 44 | |||||||||

| 170 | — | — | |||||||||

| 180 | — | — | |||||||||

| 190 | — | — | |||||||||

| 200 | — | — | |||||||||

Technical requirements - according to GOST -1759.0-87. The mechanical properties of the screws must correspond to strength classes 8.8 and 12.9. It is allowed to produce screws with mechanical properties corresponding to strength classes 5.6; 6.8 and 10.9

The requested URL /bottom.php was not found on this server.

Additionally, a 404 Not Found error was encountered while trying to use an ErrorDocument to handle the request.

Differences between bolt GOST 7805-70 and bolt GOST 7798-70

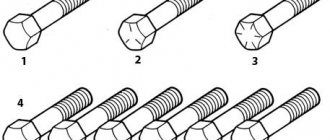

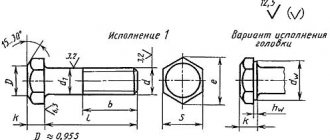

Metric fasteners (which include bolts, nuts, screws, washers) are an integral part of fasteners. Hex head bolts have GOST standards 7805-70 and 7798-70. At the same time, there are 4 options for their execution, as well as different accuracy classes.

Bolts manufactured in accordance with GOSTs 7805-70 and 7798-70 of the 1st and 4th versions do not contain holes. Bolts of versions 2 and 3 have through holes, both in the threaded part of the rod and in the head. GOSTs prescribe the following parameters and design of bolts: rod diameters, thread diameters, bolt hole diameters, as well as turnkey dimensions. Domestic bolts are divided into accuracy classes:

- Class A – increased accuracy class.

- Class B – normal accuracy.

- Class C – rough accuracy.

GOSTs 7805-70 and 7798-70 apply only to bolts that have accuracy class A or B.

GOST 7805-70 describes bolts of accuracy class A, having a thread diameter of up to 48 mm. Thus, according to this standard, bolt version 2 has one hole in the threaded part of the rod. In this case, the size of the hole diameter varies, starting from 1.0, 1.2 ... etc. up to 8.0 mm. Bolt version 3 of the same standard has a radial hole of various diameters: 1.0, 1.2, 2.0, ... 5.0 mm. For thread diameters from 36 mm to 48 mm, bolts with threads with a pitch of 2 mm are produced. GOST 7805-70 prescribes the manufacture of bolts from stainless austenitic steel (grades A2 and A4 with strength classes 50, 70 and 80) and carbon steel. It is recommended to manufacture products with strength class 4.8, 5.6, 5.8, 6.8, 8.8 or 10.9.

Bolts with accuracy class B and thread diameter sizes from 6 mm to 48 mm are described by GOST 7798-70. As in the previous standard, version 2 bolts have one hole in the threaded part of the rod, however, according to GOST 7798-70, the range of diameter sizes is narrower: 1.6, 2.0, 2.5, ..., 8.0 mm.

Type 3 bolts have three radial holes in the head with a diameter range from 2 to 5 mm. Bolts are made from carbon steel, which has a strength class of 4.8, 5.8, 8.8 or 10.9).

Bolts in GOSTs 7805-70 and 7798-70 differ in accuracy classes and ranges of diameters and lengths. The main difference between them is that GOST 7805 applies only to bolts with accuracy class A, and GOST 7798 applies to bolts of accuracy class B. In most assembly plants at the moment, the normal accuracy of bolts is sufficient, so the GOST 7798-70 bolt is more it is in demand and popular, and it is also a little cheaper to produce.

Tolerances for bolts, screws, studs and nuts (ISO 4759-1:2000)

Applies to fasteners with standards: ISO, DIN, DIN ISO, DIN EN ISO.

| 1 | 2 |

| 3 | 4 |

| 5 | 6 |

| 7 | 8 |

| 8 | 10 |

| 11 | 12 |

| 13 |

| № | Name of size or tolerance | Designation dimension or tolerance | Additional Information | Nominal size | Product accuracy class A (formerly m) | Product accuracy class B (formerly mg) | Product accuracy class C (formerly g) | Notes | |

| 1 | Straightness | t | l—nominal length | d ≤ 8 | 0.0020 l + 0.05 | 2 x (0.0020 b + 0.05) | |||

| B - thread length | d > 8 | 0.0025 l + 0.05 | 2 x (0.0025 b + 0.05) | ||||||

| 2 | Thread length | bolt and screw | b | P - thread pitch | 0…+2P* | * 2P tolerance is applied only if ls and lg are not defined in the standard | |||

| ls — minimum length of unthreaded part | |||||||||

| lg—maximum length of unthreaded part | |||||||||

| hairpin | e | js 16 | js 17 | js 17 | |||||

| 3 | Thread tolerance | screw | 6H | 7H | |||||

| bolt and screw | 6g | 8g | |||||||

| 4 | Bolt and screw head height | External spindle* | k | k < 10 | js 14 | js 15 | js 16 | * There are no recesses inside the head | |

| k ≥ 10 | js 17 | ||||||||

| Internal spindle** | k | ≤ M5 | h 13 | h 14 | ** The head has a recess for tightening | ||||

| > M5 | h 14 | ||||||||

| 5 | Head diameter | bolts, nuts | dk | h 13 | h 14 | — | |||

| screws | dk | h 13 | h 14 | — | |||||

| 6 | Nut height | m | ≤ M12 | h14 | h17 | ||||

| > M12 ≤ M18 | h15 | ||||||||

| >M18 | h16 | ||||||||

| 7 | Nominal length | l | l ≤150 | js 15* | js 16 | js 17 | *for screws l > 50 js 16 | ||

| l >150 | 2 x js 17 | ||||||||

| 8 | Symmetry tolerance | bolts and screws | s:d; dk:d | (s), (dk) | 2IT 13 | 2IT 14 | 2IT 15 | *Tolerance for symmetry of the head relative to the axis of the rod in diametric terms | |

| n:d | (d) | 2IT 12 | 2IT 13 | 2IT 14 | Tolerance for slot symmetry relative to the rod axis in diametrical terms | ||||

| screw | s:d | (s) | 2IT 13 | 2IT 14 | 2IT 15 | Tolerance for the symmetry of the hexagon relative to the hole axis in diametric terms | |||

| n:d | (d) | 2IT 13 | 2IT 14 | 2IT 15 | Tolerance for slot symmetry relative to the thread axis in diametric terms | ||||

| 9 | Diameter of the smooth part of the rod equal to the nominal diameter of the thread | ds | h13 | h14 | ± IT 15 | ||||

| 10 | Spline width* | n | ≤ 1 | +0,06…+0,20 | — | — | *depth of spline and internal hexagon, see standard | ||

| > 1 ≤ 3 | +0,06…+0,31 | ||||||||

| > 3 ≤ 6 | +0,07…+0,37 | ||||||||

| 11 | Key size | External spindle | s | s ≤ 32 = h13 | s ≤ 19 = h14 | ||||

| s >19 ≤ 60 = h15 | |||||||||

| s > 32 = h14 | s > 60 ≤ 180 = h16 | ||||||||

| s > 180 = h17 | |||||||||

| 12 | Key size | Inner spindle | s | s 0.7= EF8 | * Tolerance range for set screws | ||||

| s 0.9 = JS9 | |||||||||

| s 1.3 = K9 | |||||||||

| s 1.5—2 = D10(D9*) | |||||||||

| s 2.5 = D11(D10*) | |||||||||

| s 3 = D11 | |||||||||

| s 4 = E11 | |||||||||

| s 5—14 = E12 (E11*) | |||||||||

| s >14 = D12 | |||||||||

| 13 | Corner | 90۫ | ≤ M39 | ±1° | ±1° | ±2° | |||

| >M39 | ±1/2° | ±1/2° | ±1° | ||||||

| 1 Appendix: Accuracy classes in terms of standards - bolts, screws and studs | 84, 85, 444s, 478, 479, 480, 561, 564, 609, 610, 653, 787, 835, 912, 931, 933, 938, 939, 940, 960, 961, 963, 964, 965, 966, 966, 966 6912, 7380, 7513, 7516, 7971—7983, 7984, 7985, 7991 | 444B/609 ≥ M12/610 ≥ M12/931, 933, 960 and 961 > M24 L > 10d > 150 mm | 95, 96, 97, 186, 188, 261, 316, 318, 444A, 525, 529, 558, 571, 601, 603, 604, 605, 607, 608, 6914, 7968, 7969, 7990, 11014 | ||||||

| 2 Appendix: Accuracy classes in terms of standards - nuts | 439, 466, 467, 917, 934, 935, 936, 937, 979, 980, 982≤M12, 985≤M12, 986, 1587, 6330, 6331 | 439, 562, 934, 935, 936, 980≥M16, 982≥M16, 985≥M16, 1587, 6915, 7965 | 314, 315, 555, 557, 935 | ||||||

Numerical values of tolerances and maximum deviations corresponding to tolerance fields, mm:

| Tolerance fields | Nominal sizes | |||||||||||||

| ≤ 3 | > 3 | > 6 | > 10 | > 18 | > 30 | > 50 | > 80 | > 120 | > 180 | > 250 | > 315 | > 400 | ||

| ≤ 6 | ≤ 10 | ≤ 18 | ≤ 30 | ≤ 50 (40) | ≤ 80 | ≤ 120 | ≤ 180 | ≤ 250 | ≤ 315 | ≤ 400 | ≤ 500 | |||

| Tolerances | IT 12 | 0,1 | 0,12 | 0,15 | 0,18 | 0,21 | 0,25 | 0,3 | 0,35 | 0,4 | 0,46 | 0,52 | 0,57 | 0,63 |

| IT 13 | 0,14 | 0,18 | 0,22 | 0,27 | 0,33 | 0,39 | 0,46 | 0,54 | 0,63 | 0,72 | 0,81 | 0,89 | 0,97 | |

| IT 14 | 0,25 | 0,3 | 0,36 | 0,43 | 0,52 | 0,62 | 0,74 | 0,87 | 1 | 1,15 | 1,3 | 1,4 | 1,55 | |

| IT 15 | 0,4 | 0,48 | 0,58 | 0,7 | 0,84 | 1 | 1,2 | 1,4 | 1,6 | 1,85 | 2,1 | 2,3 | 2,5 | |

| IT 16 | 0,6 | 0,75 | 0,9 | 1,1 | 1,3 | 1,6 | 1,9 | 2,2 | 2,6 | 2,9 | 3,2 | 3,6 | 4 | |

| IT 17 | 1 | 1,2 | 1,5 | 1,8 | 2,1 | 2,5 | 3 | 3,5 | 4 | 4,6 | 5,2 | 5,7 | 6,3 | |

| Tolerance range for external dimensions | a 11 | -0,27 | -0,27 | -0,28 | -0,29 | -0,3 | -0,31 | — | — | — | — | — | — | — |

| -0,33 | -0,345 | -0,37 | -0,4 | -0,43 | -0,47 | — | — | — | — | — | — | — | ||

| from 11 | -0,06 | -0,07 | -0,08 | -0,095 | -0,110 | -0,120 | — | — | — | — | — | — | — | |

| -0,12 | -0,145 | -0,17 | -0,205 | -0,24 | -0,28 | — | — | — | — | — | — | — | ||

| f 8 | -0,006 | -0,01 | -0,013 | -0,016 | -0,02 | -0,025 | -0,03 | -0,036 | -0,043 | -0,05 | -0,056 | -0,062 | -0,068 | |

| -0,02 | -0,028 | -0,035 | -0,043 | -0,053 | -0,064 | -0,076 | -0,09 | -0,106 | -0,122 | -0,137 | -0,151 | -0,165 | ||

| h 8 | 0 / -0,014 | 0 / -0,018 | 0 / -0,022 | 0 / -0,027 | 0 / -0,033 | 0 / -0,039 | 0 / -0,046 | 0 / -0,054 | 0 / -0,063 | 0 / -0,072 | 0 / -0,081 | 0 / -0,089 | 0 / -0,097 | |

| h 9 | 0 / -0,025 | 0 / -0,03 | 0 / -0,036 | 0 / -0,043 | 0 / -0,052 | 0 / -0,062 | 0 / -0,074 | 0 / -0,087 | 0 / -0,1 | 0 / -0,115 | 0 / -0,13 | 0 / -0,14 | 0 / -0,155 | |

| h 10 | 0 / -0,04 | 0 / -0,048 | 0 / -0,058 | 0 / -0,07 | 0 / -0,084 | 0 / -0,1 | 0 / -0,12 | 0 / -0,14 | 0 / -0,16 | 0 / -0,185 | 0 / -0,21 | 0 / -0,23 | 0 / -0,25 | |

| h 11 | 0 / -0,06 | 0 / -0,075 | 0 / -0,09 | 0 / -0,11 | 0 / -0,13 | 0 / -0,16 | 0 / -0,19 | 0 / -0,22 | 0 / -0,25 | 0 / -0,29 | 0 / -0,32 | 0 / -0,36 | 0 / -0,4 | |

| h 13 | 0 / -0,14 | 0 / -0,18 | 0 / -0,22 | 0 / -0,27 | 0 / -0,33 | 0 / -0,39 | 0 / -0,46 | 0 / -0,54 | 0 / -0,63 | 0 / -0,72 | 0 / -0,81 | 0 / -0,89 | 0 / -0,97 | |

| h 14 | 0 / -0,25 | 0 / -0,3 | 0 / -0,36 | 0 / -0,43 | 0 / -0,52 | 0 / -0,62 | 0 / -0,74 | 0 / -0,87 | 0 / -1 | 0 / -1,15 | 0 / -1,3 | 0 / -1,4 | 0 / -1,55 | |

| h 15 | 0 / -0,4 | 0 / -0,48 | 0 / -0,58 | 0 / -0,7 | 0 / -0,84 | 0 / -1,0 | 0 / -1,2 | 0 / -1,4 | 0 / -1,6 | 0 / -1,85 | 0 / -2,1 | 0 / -2,3 | 0 / -2,5 | |

| h 16 | 0 / -0,6 | 0 / -0,75 | 0 / -0,9 | 0 / -1,1 | 0 / -1,3 | 0 / -1,6 | 0 / -1,9 | 0 / -2,2 | 0 / -2,5 | 0 / -2,9 | 0 / -3,2 | 0 / -3,6 | 0 / -4 | |

| h 17 | 0 / -1 | 0 / -1,2 | 0 / -1,5 | 0 / -1,8 | 0 / -2,1 | 0 / -2,5 | 0 / -3,0 | 0 / -3,5 | 0 / -4 | 0 / -4,6 | 0 / -5,2 | 0 / -5,7 | 0 / -6,3 | |

| js 14 | ±0,125 | ±0,15 | ±0,18 | ±0,215 | ±0,26 | ±0,31 | ±0,37 | ±0,435 | ±0,5 | ±0,575 | ±0,65 | ±0,7 | ±0,775 | |

| js 15 | ±0,2 | ±0,24 | ±0,29 | ±0,35 | ±0,42 | ±0,5 | ±0,6 | ±0,7 | ±0,8 | ±0,925 | ±1,05 | ±1,15 | ±1,25 | |

| js 16 | ±0,3 | ±0,375 | ±0,45 | ±0,55 | ±0,65 | ±0,8 | ±0,95 | ±1,1 | ±1,25 | ±1,45 | ±1,6 | ±1,8 | ±2 | |

| js 17 | ±0,5 | ±0,6 | ±0,75 | ±0,9 | ±1,05 | ±1,25 | ±1,5 | ±1,75 | ±2 | ±2,3 | ±2,6 | ±2,85 | ±3,15 | |

| k 6 | +0,006 | +0,009 | +0,01 | +0,012 | +0,015 | +0,018 | — | — | — | — | — | — | — | |

| 0 | +0,001 | +0,001 | +0,001 | +0,002 | +0,002 | — | — | — | — | — | — | — | ||

| m 6 | +0,008 | +0,012 | +0,015 | +0,018 | +0,021 | +0,025 | — | — | — | — | — | — | — | |

| +0,002 | +0,004 | +0,006 | +0,007 | +0,008 | +0,009 | — | — | — | — | — | — | — | ||

| Tolerance range for internal dimensions | D 9 | +0,045 | +0,06 | +0,076 | +0,093 | +0,117 | +0,142 | — | — | — | — | — | — | — |

| +0,02 | +0,03 | +0,04 | +0,05 | +0,065 | +0,08 | — | — | — | — | — | — | — | ||

| D 10 | +0,06 | +0,078 | +0,098 | +0,012 | +0,149 | +0,18 | — | — | — | — | — | — | — | |

| +0,02 | +0,03 | +0,04 | +0,05 | +0,065 | +0,08 | — | — | — | — | — | — | — | ||

| D 11 | +0,08 | +0,105 | +0,13 | +0,16 | +0,195 | +0,24 | — | — | — | — | — | — | — | |

| +0,02 | +0,03 | +0,04 | +0,05 | +0,065 | +0,08 | — | — | — | — | — | — | — | ||

| D 12 | +0,12 | +0,15 | +0,19 | +0,23 | +0,275 | +0,33 | +0,4 | +0,47 | +0,545 | +0,63 | +0,71 | +0,78 | +0,86 | |

| +0,02 | +0,03 | +0,04 | +0,05 | +0,065 | +0,08 | +0,1 | +0,12 | +0,145 | +0,17 | +0,19 | +0,21 | +0,23 | ||

| E 11 | +0,074 | +0,095 | +0,115 | +0,142 | — | — | — | — | — | — | — | — | — | |

| +0,014 | +0,02 | +0,025 | +0,032 | — | — | — | — | — | — | — | — | — | ||

| E 12 | +0,1 | +0,14 | +0,175 | +0,212 | — | — | — | — | — | — | — | — | — | |

| +0,014 | +0,02 | +0,025 | +0,032 | — | — | — | — | — | — | — | — | — | ||

| EF 8 | +0,024 | +0,032 | +0,04 | — | — | — | — | — | — | — | — | — | — | |

| +0,01 | +0,014 | +0,018 | — | — | — | — | — | — | — | — | — | — | ||

| H 9 | +0,025 | +0,03 | +0,036 | +0,043 | +0,052 | +0,062 | +0,074 | +0,087 | +0,1 | +0,115 | +0,13 | +0,14 | +0,155 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| H 11 | +0,06 | +0,075 | +0,09 | +0,11 | +0,13 | +0,16 | +0,19 | +0,22 | +0,25 | +0,29 | +0,32 | +0,36 | +0,63 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| H 13 | +0,14 | +0,18 | +0,22 | +0,27 | +0,33 | +0,39 | +0,46 | +0,54 | +0,63 | +0,72 | +0,81 | +0,89 | +0,97 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| H 14 | +0,25 | +0,3 | +0,36 | +0,43 | +0,52 | +0,62 | +0,74 | +0,87 | +1 | +1,15 | +1,3 | +1,4 | +1,55 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| H 15 | +0,4 | +0,48 | +0,58 | +0,7 | +0,84 | 1 | +1,2 | +1,4 | +1,6 | +1,85 | +2,1 | +2,3 | +2,50 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| JS 9 | ±0,0125 | ±0,015 | ±0,018 | ±0,0215 | ±0,026 | ±0,031 | — | — | — | — | — | — | — | |

| K9 | 0 | 0 | 0 | — | — | — | — | — | — | — | — | — | — | |

| -0,025 | -0,03 | -0,036 | — | — | — | — | — | — | — | — | — | — | ||