Hunting skis are a mandatory and very important piece of equipment for every professional hunter and fisherman.

Skis intended for hunting have little in common with ordinary (recreational) or sports models, and even to a person who is poorly versed in them, the differences will be clearly visible.

The sliding surface of sports skis is much larger and thanks to it, falling through in loose snow is excluded

Unfortunately, not every store offers a similar product at a reasonable price, much less skis that are 100% suitable and comfortable, so this equipment is strictly individual. In this regard, homemade skis are increasingly in demand among experienced hunters. Currently, experienced masters of “skiing” can offer hunters the following popular products: camo skis or boot skis. The working surface of skin skis is covered with pieces of skins, making it easier to glide over the snow and help climb uphill. However, with these positive qualities, there are also disadvantages such as greater weight and complexity in manufacturing.

Came skis

How to choose the size of hunting skis

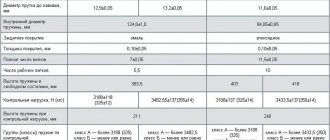

The highest quality skis are custom-made skis, since their size is calculated based on parameters such as the weight and height of the hunter, the hunting area and the quality of the snow. Loose snow requires a larger support area - approximately 50 cm² per kilogram of weight. But hard crust allows you to move safely with a smaller supporting area - about 40-43 cm². The length of the skis should in no way be below the shoulders or above the top of the owner’s head. This is what experienced hunters say, but still, when maneuvering in the thickets, many of them prefer short skis.

The front end of the skis has holes that allow them to be used as sleds and for ease of transportation.

As for the width, it is usually equal to the distance of 20-24 cm. To ensure reliable support, the width is made larger if the hunter is heavy. But it is still not advisable to make skis that are too wide, since it will be difficult to pass between the trees. To avoid scooping up snow with skis, the toe is always 35-40 mm. wider than the heel. The thickness of the cargo area is usually 12-13 mm if the skis are glued with camus. But if flax (the backbone of the animal) is placed under the camus, then the thickness can be reduced slightly, to 9-10 mm.

Bending

You need to make 2 bends: front and back. At the initial stage, wood can be bent by heating, firing and steaming. After this, each is placed in a special bending machine. It is necessary to ensure that there is no distortion, otherwise the material will be damaged.

Steaming is convenient to carry out when the ski is already secured in the machine. This will help you get the best result. You need to cool it in the cold, but this can only be done after successful bending. When the material has completely cooled under the required conditions, it is necessary to inspect it for distortions; if there are any, the skis will move incorrectly.

Selection and preparation of wood when making skis

Wood suitable for making skis is chosen depending on the location of the fishery: Amur lilac, Manchurian walnut, and Maka akotnik are popular in the Far East. These species have light wood that is quite strong and lightweight. Hunters on this side of the Urals use maple, spruce, and aspen to make skis. The most reliable skis are made from birch. This wood has all the necessary qualities to make an excellent, durable ski. Aspen and spruce products have better movement and are lighter, but their strength is low.

For an avid hunter, 3 pairs of skis made from this wood are not enough for a season.

Having decided on the type of wood, it should be selected: only a straight-grained specimen, without moving knots and with a complete absence of rot, is suitable. When harvesting a tree, you need to listen to the advice of experienced craftsmen and cut the desired specimen in August. The wood is placed in a place with good ventilation until the end of September. Then you need to cut down all the bark and leave the material to mature for another year. The most suitable place is the attic, but closer to the chimney. To make blanks, piles are split along the layer. On average, one trunk produces 3 pairs of skis. In the process of an inexperienced master there will always be a couple of spoiled materials, so a supply will never hurt.

Material

The first step in making good hunting skis with your own hands is to choose high-quality material.

Typically, the materials used are trees such as walnut, willow, aspen, and balsa wood. They have very important qualities for high-end skis: flexibility, strength and lightness.

It is worth remembering that the wood must be without signs of rotting or knots. Many experienced experts advise taking boards for skiing at the end of summer. It’s no longer so hot outside, and there’s no cold yet.

To make high-quality skis for hunting with your own hands, their surface needs to be covered with camus. This is this type of material. It can be made from the skin of both elk and deer.

This material helps the skis not to roll down when going uphill and protects them from snow sticking.

«>

On the bottom surface of the skis you need to make a small groove from tip to heel. Its width and depth should be a couple of centimeters. The entire surface of the skis must be sanded.

Making your own skis

Ski blanks are boards that are centimeter thick. The resulting material is placed in a bucket, arranged with wood chips, filled with water and placed on the stove. Cook the boards over low heat for 2-3 hours. Take them out of the bucket one at a time and gradually bend them on a machine or with homemade devices. This is how the noses are formed. Next, the bend is hardened with a burner until it turns black.

The arch should not be skewed in any way, otherwise the skis will not move correctly.

Then you should remove excess material, rounding the heels and toes. Always saw from the center to avoid chipping. The operation is performed slowly and carefully.

Making kamus

For kamus, the skin is cut off from the animal. Next, the camus is stretched onto boards, fixed with nails, and dried for 10-12 days.

Good pieces of skin of smaller thickness are selected. If the pieces are not large enough, then you can:

- sew them in pairs with coarse thick threads,

- soak in water for 5-6 hours,

- dry slightly so as not to tear when stretched,

- drill holes,

- glue the prepared kamus,

- apply the composition to the surface of the skins from the inside and treat the edges of the ski track so that snow does not stick,

- additionally paint or varnish.

Subsistence

Finished skis need to be protected from moisture absorption, so they are thoroughly fattened. It is very good for this operation to use a mass cooked according to the recipe of the old masters. Pour 400 g of linseed oil into the kettle and bring to a boil. Birch tar is added to it in the same amount and boiled for another 1 hour. Then you will need 200 g of paraffin. After the latter has completely dissolved, the pot is set aside and red wood alcohol (400 g) and formaldehyde (200 g) are poured into it. While the mixture is hot, cover the skis very generously. After the product has been absorbed, the coating is repeated until the wood is completely saturated. Next, the skis are dried and, if desired, covered with drying oil.

Place for mounting fasteners

Much attention should be paid to choosing the location where the mount will be located. To determine where to install the mount, the ski is turned over on its edge and lifted at the loading area with two fingers. If the ski lowers its heel down and forms an angle of 45 degrees with the floor, then the point is chosen correctly. If the result is negative, the search continues. The found point is marked with a transverse line. From the drawn line towards the toe, mark 4 cm and also draw a line. On both lines, mark the center and apply a clenched fist to it, combining its center with the existing one. Dots are marked on the lines on the sides of the fist. Moreover, on the line located closer to the toe, the side points are brought closer together by 1 cm each. It would be a good idea to check the markings a second time. If the result is positive, the marks are burned and longitudinal grooves for the belts are made between them. The depth depends on the thickness of the belts: in the end they must be aligned with the sliding surface. The bases for the bindings, 2 pieces, are made from planks and placed in the center of the ski and shifted 3 cm towards the heels. Make a mark, put it on glue and fix it with self-tapping screws.

Making sticks

Sticks are an indispensable attribute. They will allow you to clear snow and slow down in case of an unsuccessful descent from the mountain. They are made of birch and walnut with blades on the lower ends (upper) claws and rings.

It is good to equip the poles with divisions (marks) every 5-6 cm, which will help in measuring the thickness of the snow cover when skiing. Sticks should be stored in a suspended state and in a ventilated area, tied together in pairs. Today, many people prefer plastic options for ski accessories. Plastic freezes quickly in the cold and it is better to make wooden sticks. The main thing is to prevent moisture from getting into the fastenings. Before storage, poles and skis must be thoroughly cleared of snow, kept in the sun to dry, and checked for the strength of the fastenings and that the screws are not loose.

Knowing the structure of skis and the stages of production, you can make a lightweight, gliding model without any special disadvantages for moving on flat and steep (mountain) snow-covered surfaces with descents, ascents, and slopes.

Fastenings

The fastening is done taking into account the usual hunting shoes. It should be loose enough, but not fly off. It is not advisable to use new leather, as it will creak in the cold and may become stiff. The best option would be a strap made from old reins. For skis, you can purchase straps in advance, and then smoke and fry them. The finished skis are carefully inspected, rubber or birch bark is glued under the foot.

Kamus

While the skis are being made, you should work on the camus. The skin must be skinned from the base of the hoof. Then it dries for a couple of weeks and ski patterns are made from it. The required size of the product is sewn from pieces of skins and glued to the skis.

Glue

Good quality carpenter's glue is not always available, so some hunters prefer to glue skis with homemade glue, prepared according to old recipes and tested over the years. For this you will need chum salmon skin. The fish can be bought fresh in the store, used for food, and the skin can be used for glue. The skin is cleaned of fat and scales and filled with warm water for 1 hour. After softening, roll it onto a rod, wrap it in a wet cloth and place it over the stove, near the coals. Over time, the skin turns into a high-quality adhesive mass.

Ski pole

At the same time as the skis, a ski pole is made from the same material. At the bottom it is made with a spatula, and at the top it is equipped with a claw and a ring. Markings are made on the stick to help determine the thickness of the crust. And the stick itself performs many functions necessary for a hunter: clearing snow, testing the road as a brake, using a stick to tow it, and much more.

Ski storage

For storage, skis are tied in pairs and hung on a special spacer. The room must be ventilated and not damp. Some hunters sew special covers from tarpaulin for skis. Homemade skis are in no way inferior to purchased ones, even better, since they are made to an individual size and taking into account the physiological characteristics of the hunter.

Previous post Loading hunting cartridges

Next entry DIY duck decoy