Purpose and principle of operation

It is the process of machining and cleaning holes.

At first glance, it is similar to drilling and countersinking. But it is used at a later stage, and also has a completely different purpose. After the groove is formed, there are almost always serious deviations in the tolerance level and quality from the initial parameters specified in the drawing. This is a feature of the tool and the human factor. Perfect accuracy is simply impossible to achieve. But the finishing process brings the product as close as possible to the bar specified according to the scheme. And here it becomes clear what sweeping is and what the process is used for. This is an opportunity to achieve the required level of quality. Align the geometry, get rid of burrs and irregularities on the metal. Accordingly, the procedure is especially relevant if a high accuracy class is required for the product being processed. Yes, it is quite possible to reach the eighth or seventh grade with ordinary drilling. Countersinking will allow you to get closer to the fifth, and in some cases even the fourth class. But above that is the job of finishing. The tool itself has a large number of teeth. Thanks to the high speed of circular movements, as well as longitudinal feed, the rod scrapes out any irregularities, and also removes the walls of the hole in the smallest value. Literally tenths of a millimeter are ground off per pass, allowing you to get closer to the ideal parameters indicated in the drawing.

Therefore, metalworking mechanical reaming is the only way to achieve good accuracy indicators even outside the production workshops.

Device and characteristics

There are a significant number of species and types. But there are almost always basic design elements that remain unchanged. Let's look at them in detail:

- Working part. It is divided into several zones, each of which performs its own functions. The main one is considered to be the fence; it contains cutting edges that have high levels of sharpness. Due to their location, they pick up small amounts of metal from the inner surface. The calibrating part already has many teeth connected into one continuous strip. With its help, calibration occurs. And the final part is the back, this is the fastening element that is adjacent to the neck. This will be discussed further below.

- Neck. A kind of jumper. It allows you to connect the upper and lower structures together.

- Tail. This element is needed to fix the tools in the source. For production standards, this is the machine chuck. At home, a gate drill, for example.

This is the general design of the sweep. But let's focus on certain aspects.

Material

Of course, these are always steels with the highest hardness ratings. But a specific choice should always be based on the resource with which you will have to work. Select rods based on the surface density of the object. In principle, in the vast majority of cases, high-strength alloy steel 9ХС is used; it is usually used for any quality tools. And also some parts of the structure are made from high-speed alloys, such as P9.

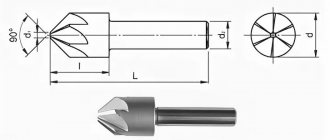

Dimensions

They are different. Of course, the holes in production can be of completely different sizes. Thus, conical rods are often placed in the length range of 55-170 millimeters with a spread of 7-46 millimeters. And cylindrical analogues have great variability: length from 80 to 360 mm, and diameter 3-50 mm.

Machine tools for deployment are often highly standardized. They have their own size numbering in numbers from 1 to 6, which corresponds to a range from 1 to 120 mm.

Teeth

The number of incisors affects the final quality. But at the same time, each individual cutting equipment often has less hardness and completely. And also with a large number of edges, problems arise with the removal of metal shavings. Accordingly, if you want to know what reaming a hole is, a photo of a cutting tool can give all the information. The many teeth are highly accurate factory tools, and for simple work, 4 solid edges are usually used. In principle, the top bar is considered to have 14 teeth, but there are some models where their number reaches 16 pieces. But this is subject to high requirements for finished hardware up to class 1 accuracy. Of course, such rods are simply not used at home.

Tool selection factors

Effective use of a reamer depends on the correct selection of the type, size and other characteristics of the tool and the hole being machined (type, location, workpiece material, etc.). So, for manual countersinking, you need to manually select a tool with a square shank for the wrench. Floating countersinks and tools with straight flutes cannot be used to work with intermittent holes with slotted veneers. Processing of this type of holes is carried out with a countersink with screw grooves.

To ream holes of increased length, where the standard tool size is not enough, mounted countersinks on a long mandrel are used. The type of tool attachment affects the choice of length and design. It is also necessary to take into account the length of the hole and the type of metal-cutting equipment on which the processing is performed.

Economic factors also influence the choice of tool. For mass production of parts, it is advisable to use rigid countersinks or special types. At the same time, for small and medium-sized series, the best option would be to use universal designs - these are adjustable tools or countersinks with inserted working edges.

The tool material is selected, as a rule, taking into account the material of the workpiece being processed. To work with hard parts, countersinks with carbide plates are used.

GOST

There are several standards that regulate product quality. Thus, GOST 29240-91 is responsible for the standard variety, as well as size ranges. And if you understand models that have an allowance, then you will have to be guided by a completely different regulatory document. Or more precisely - GOST 11173-76. A very common procedure at home. When the source of supply becomes not a machine, but an ordinary hand-held device. And in this case, we need to pay attention to GOST 7722-77. But another document, numbered 1672-80, already regulates the standards in one-piece machine-type models. That is, just the factory settings.

Application of sweeps

It is almost impossible to achieve high precision and surface quality when using a conventional drill. This is due to the peculiarities of the working part, which has a relatively small number of cutting edges. The use of the products in question can significantly improve the quality of the hole and bring all indicators to the required levels. The scope of application of the tool is extensive:

- Mechanical engineering industry.

- Production of precision products.

- Manufacturing of household appliances and various electronics.

- Machine tool industry.

Note that the wrench used is suitable for various hand tools. In addition, the machine-type product is suitable for almost all cartridges and can be used when performing intermediate operations.

In conclusion, we note that preference should be given exclusively to products from well-known manufacturers. This can be attributed to the fact that they guarantee high quality production and a long service life of the product. However, due to quality control at each stage of production and the use of high-quality materials, the cost of the product increases significantly.

Classification of scans, what types and types there are

Now let's talk more specifically about the variety of different tools. Not only the accuracy class obtained as a result largely depends on them. But also the methodology of the procedure itself, the possibilities of operation, methods of application.

By type of hole

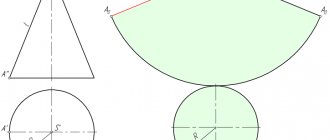

This is the most popular type of division. And we have already mentioned it indirectly. There are cylindrical and conical options. The former have the same diameter along the entire length of the recess. And the latter, in turn, narrow. Moreover, the actual angle of inclination is allowed to vary greatly. And you need to select your own individual model for it. Separately, it is worth mentioning the stepped reamers, which allow you to achieve high quality work. The peculiarity of the equipment is that it can be divided into two levels of allowance or more.

According to processing accuracy

There are two broad categories in this section. The first ones are usually called drafts. And they are not too much ahead of their counterparts after countersinking in terms of final quality. Therefore, they are often used as manual options. They have no special use in production. But the second type is finished, usually machine-made analogues. And when they work correctly, they achieve very high accuracy class indicators.

By clamping method

The tail varies in its structure. For manual mode, this is almost always a square base. To be easily inserted into the gate mechanism. But the machine versions, which are installed in the cartridge, are divided into two more categories. The first is for conical models, the second, as it becomes clear, for cylindrical ones.

Practical guidelines for drilling holes

It is better to divide the boring operation into several stages: roughing and finishing. The allowance is divided accordingly and tools of two categories are used:

Reaming holes - process

- The allowance for a rough pass is 0.1-0.15 mm, for a finishing pass – 0.1-0.05 mm.

- To increase processing efficiency, the adjacent end surface is ground. The procedure allows you to use each tooth of the reamer during processing.

- For cast iron parts, the end of the hole must be machined so that the tool does not become dull.

- A clean deployment operation requires smooth execution. The smaller the feed, the better the quality of the surface. The speed is set to low.

- The metal-cutting tool is removed from the hole smoothly, avoiding rotation in the opposite direction, which can disturb the surface.

- The use of coolant will help improve the durability of the working element and the quality of processing. When deploying steel parts, coolant with the addition of oil is supplied to the cutting zone.

- Cast iron is processed using kerosene or compressed air.

To control the accuracy of finished holes, smooth plug gauges and bore gauges are used.

Reamers fall into the category of precision and expensive instruments. Requires compliance with operating and storage conditions in special wooden cells.

Related video: Adjustable sweep

Kinds

WE went through the main species diversity, which divides all instruments into only three groups. But in reality there are much more types. Let's try to take all of them into account.

One-piece

They are often made from tool steel. But there are options made from high-speed metal. These are the simplest, but at the same time reliable equipment. They have become widespread due to their low price niche. You can buy them for 25-50 rubles.

Mounted

These are more expensive and complex specimens. They are produced in the form of an oblong hollow rod equipped with cutting edges on the sides. Their length and quantitative factor are situational; there are different models. The cavity inside is designed for mounting on the tail section. And with the help of the backdrop, the hardware is installed in the machine chuck.

Combined sweep, application

This tool has two working surfaces at once. Accordingly, he can perform finishing processing at different levels, which saves time and resources. At the same time, it is also possible, in principle, to combine two different related procedures. So, with the help of one rod you can immediately carry out countersinking, as well as the final cleaning itself. A convenient choice, but also more expensive compared to conventional analogues.

Unregulated

It is not possible to set the required diameter with this hardware. It is always strictly fixed. This means that the area of operation of one specific sample is significantly narrowed. Suitable in cases where, in principle, there are few quantities in production. And they are all typical. Then it is permissible to choose your own hardware for each type. And if you have to deal with different hole sizes every time, then it is better to use the following device.

Adjustable

By analogy, it becomes clear that this sample is capable of changing diameter. But it’s worth clarifying right away that the range of its capabilities is strictly limited and often quite narrow. But still, within small limits, it can easily replace a dozen of its brothers that do not have the ability to adjust. This is beneficial if there are dozens or hundreds of different types of recesses in production. Then each group will need one of its own hardware. But its cost is often several times higher than that of similar models. On average it reaches 3 thousand rubles.

Awl

This is a special type that belongs to general groups with great reserve. In fact, this is precisely an awl-shaped rod. May have a different number of edges. They are also often found on the market with a removable handle. Not suitable for hard materials. Yes, hardware does a good job with soft plastic, wood, even soft types of metals. It works exclusively in manual mode, which is understandable. After all, it doesn’t even have a mounting part for the cartridge, only a handle that needs to be taken in the hand.

Cylindrical

These are already types of developments based on the shape of the working part. And the first of them is in the shape of a cylinder. It is logical to assume that it is used only if the width of the groove is uniform along the entire length. And this is the most common standard. Such products are mass produced. Depending on the quality and brand, the cost varies from 50 to 100 rubles. And production usually purchases them in huge quantities. And almost every second master keeps a dozen similar products in his own garage.

Conical

Already a rarer type, which is usually not used manually. Designed for holes that taper to one side. The angle is different, which often complicates finishing. And it becomes much more difficult to go through a countersink. It is noteworthy that these hardware products are not at all inferior in price to their common counterpart. And they even win, usually conical products are 30-40% cheaper than cylindrical ones. In principle, this is logical, because their production requires less material.

Stepped

This sample has two or more stages. In fact, the hardware visually resembles its conical counterpart. But the thickening towards the base is not smooth, but as if in steps. The more there are, the higher the quality of processing carried out by the designated species. True, only professional machines work with a large number of steps. In addition, with many transitions, the manufacturer often softens the composition of the steel, making it less hard.

Manual

A large group of products that are united by the fact that they work without a machine. Accordingly, the tail is adapted for a crank and has a square base. But such specimens do not exceed the threshold diameter of 50 millimeters. The restrictions appeared due to the fact that turning thicker hardware would be seriously difficult. After all, the friction force also increases. And if the machine can cope with this without any complications, then in the manual version this technique will not work.

Machine

This is already the type for installation in a cartridge.

And there are a huge number of different varieties. The ranges of standard sizes are varied. But they are often reduced to certain standards, which, for simplicity, are designated by one number. There are also plenty of internal classifications. According to the material of production, the number of cutting edges (there are up to 16 teeth), according to fasteners, the shape of the grooves.

Now, if you are asked, name the types of scans based on processing accuracy, method of use or other parameters - you know exactly what you need to answer.

Deployment Processing Features

When drilling, there is a possibility that the dimensions will differ significantly from those that needed to be obtained. This is due to the fact that at the time of machining there is high pressure on the workpiece, the material and the cutting part itself can heat up and deform. This is why many people decide to use a reamer to achieve high quality holes.

The features of the processing carried out include the following points:

- You can achieve processing accuracy that will correspond to a quality in the range from 6-9. Such precise holes are required when obtaining critical products.

- The roughness index can be in the range from 0.32 to 1.25 microns.

- Considering the features of devices intended for deployment, we note that there are about 4-14 cutting edges on the surface. Due to this, the quality of processing and dimensional accuracy are significantly improved. It is the large number of cutting edges that determines that no deformation of the tool or workpiece occurs during cutting.

- When processing a hole, the product rotates around its axis, and it is also given a reciprocating motion. This ensures the removal of edges that could reduce the quality of the surface.

In general, we can say that the drill in use does not differ significantly from the product in question. In both cases there is rotation and reciprocating motion. However, in the case of deployment, the processing carried out is finishing and involves a high rotation speed.

How to choose the right products

First of all, you should pay attention to the cost factor. Professionals usually do not purchase individual hardware, but immediately buy a complete set, which contains many different variations. At the same time, you will still need your own products for different purposes. For deep holes, you need an extension rod, and if you need an intermittent channel, you will need a floating one. Each model has its own strict purpose. For example, what is an end reamer used for - to work with diesel landing slots, clean injectors, repair sockets in the engine. A very specific type that makes no sense to use for other purposes.

If you plan to do it manually, look at the square tail, and if you plan to do it by machine, look at the cylindrical or conical one. The size range is always based only on the hole size requirements.

What you need to know

Even when I work manually, there is an opportunity to insure myself against a lost axle. It would seem that without a machine it would still be impossible to clearly fix the center and maintain it. But there is a way - you just need to purchase a type of equipment with a coaxial shaft. And then the human factor will be leveled out. True, the model does not provide other advantages of machine processing, please keep this point in mind.

Manufacturers

At the moment there are not many prominent brands on the market that are worthy of mention. Among foreign companies, I would like to specifically mention Bahco and Licota, and Rock FORCE also deserves attention.

But our domestic manufacturer often sets more reasonable prices with good quality. TECHMASH or Russian Instrument, as well as AvtoDelo - these companies will be able to give a serious competitive fight to foreign companies.

Well, our review has come to an end. Now you know exactly what sweeps are used for. And you can easily choose the most effective and suitable products for yourself.