Water supply

Author Oksana Knopa

Date

Jan 13, 2016

30

20 871

Share

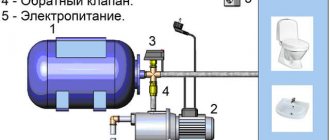

Household devices for an autonomous home water supply system are a vital necessity in the absence of a centralized water supply in a country house or country house. A hydraulic pumping station can be easily installed in a separate special room; water is automatically supplied from a well, river, or well. They are reliable in operation, but if used incorrectly or worn out, malfunctions or breakdown of one or another spare part for pumping stations occur.

- LiveJournal

- Blogger

All owners of wells or boreholes face repairs to pumping stations.

- Common important causes of frequent breakdowns

- Brief analysis of the most popular problems and ways to solve them

- A few notes about adjusting the pressure switch

The pumping station does not gain pressure

If the pumping station does not gain pressure, that is, the turret turns on, works, but cannot reach the set maximum (upper) pressure and, accordingly, does not turn off. The reason for this may be:

- insufficient pump power or wear of its parts;

- water leakage from the system through connections, pipe rupture or plumbing fixture;

- voltage drop in the electrical network;

- air entering the suction pipe of the surface pump.

Now let's look at them in more detail, as well as ways to eliminate them.

Does not gain pressure due to insufficient power or wear of parts

This may be the case if the pump or pumping station is not selected correctly and, according to its characteristics, cannot achieve the specified pressure under these specific conditions: the height and volume of water supply from a well or well, the height and location of plumbing fixtures, the diameter of the water supply system pipes and etc.

In addition, if the pumping station has been in operation for a long time, the cause may be wear of its parts. For example, in a centrifugal pump this may be wear of the impeller and housing or a crack in the plastic funnel (diffuser), and in a vibration pump it may be wear of the rubber valve. In this case, the pump will supply water, but the performance and pressure will not correspond to its original characteristics and it simply will not be able to create the specified maximum (upper) pressure and will work without shutting down.

In order to eliminate the first problem, it is necessary to replace the pumping station with a new or more powerful one, selecting the necessary characteristics, or reduce the specified maximum pressure to a level that it can provide. If parts wear out or break, replace them yourself or take them to a workshop for repairs.

Does not gain pressure due to water leakage from the system

Sometimes, a crazy person cannot gain pressure due to water leaking from the system. This could be a rupture of a pipe or its connections, a faucet or mixer left completely open, a faulty toilet flush, etc. Therefore, if the pumping station has been running for a long time, cannot build up pressure and therefore does not turn off, you need to turn it off yourself, inspect all elements of the water supply system at home and if the above reasons are found, eliminate them.

Insufficient mains voltage

Another reason that the crazy pump does not gain pressure may be a voltage drop in the network, during which the pump cannot develop its full power.

In this case, it is necessary to measure the voltage in the network and if it is less than 220 V, turn off the pumping station, find out the cause of the voltage drop and take measures to normalize it.

Air in the suction pipe

This can happen when using a pumping station with a surface pump without an ejector, in the case when:

- the water level in the well or borehole will drop to the location of the check valve;

- there has been a leak in the pipe or its connection to the pump.

It is necessary to check the water level in the well or well and the tightness of the pipe and its connections.

The pumping station does not pump water: possible malfunctions

Firstly, this can happen if it does not turn on (you turn on the station and it is “silent”). In this case:

- it is necessary to check whether there is voltage in the network, and whether it is supplied to the pressure switch and the crazy pump;

- if there is voltage in the network, it is necessary to check the corresponding circuit breaker in the electrical panel, as well as the integrity of the cable and the voltage supply to the relay. To do this, you can remove its cover and use a probe or tester to find out whether electricity is supplied to its contacts and whether they are burnt;

- if voltage is supplied and the contacts are not burnt and they close and open (that is, the relay is triggered), then the reason may be a malfunction of the electric motor of the pump - the terminals under the boron cover are burnt or the integrity of its winding is damaged, that is, as they say: “the motor burned out” , which can be determined by the characteristic smell of burnt insulation. If the reason is in the electric motor, then it is better to have it repaired by a specialist or replaced with a new one.

If the turretless machine turns on , but does not pump water , then there may be several reasons, depending on its type.

Turret with surface pump (standard version)

If a pumping station with a surface pump does not pump water, then given that it can be equipped with a different type of unit (without an ejector, with a built-in or remote ejector), the reasons may be different. But most often, the following malfunctions may occur:

- lack of water in the pump or in the suction pipeline;

- the tightness of the suction pipeline is broken and air has entered the pump;

- the check valve filter or the valve itself is clogged;

- the water level in the well or well has dropped below the suction pipe;

- the capacitor has failed;

- the pump impeller is “stuck”;

- large wear or breakdown of the impeller;

- very low voltage in the network.

Now let's look at these faults and ways to eliminate them in more detail:

- The bezbashenka does not pump water due to the lack of water in the suction pipe . Before the first start-up of a pumping station with a surface pump without an ejector, the suction pipe and the pump itself must be filled with water, otherwise it simply will not be able to pump water from a well or borehole. If water was filled before start-up, but it later turned out that it was not there, this means that the water goes back into the well or well through a check valve or joints. To eliminate this malfunction, it is necessary to check the check valve and its connection location, as well as the location of the pipe connection to the pump or filter.

- The tightness of the suction pipe connection is broken . If the connection of the suction pipe to the station is not tight, then air may be sucked in. In order to make sure that there is no such reason, it is necessary to wipe dry and inspect all connections. If the connection is not tight, it will leak if there is water in the pipe and pump. It is necessary to check all connections that are on the suction pipe. If a filter is installed at the inlet, you need to check it too.

- The check valve filter or the valve itself is clogged . It may be that the reason that the crazy one does not pump water is that the check valve strainer or the check valve itself is clogged. This can happen, for example, if the well is not deep or has not been cleaned for a long time, and the suction pipe is lowered too low and the check valve is clogged with deposits of sand, clay or silt. In this case, it is necessary to lift the suction pipe together with the check valve and clean its filter.

- The water level in the well or borehole has decreased . A possible reason that the pumping station does not pump water may be a decrease in its level in the well or borehole. If the water level has dropped so that the lower end of the suction pipe with a check valve is in the air, or the distance from it to the level of the pump suction pipe is more than 7-8 meters (depending on the characteristics of the pump), then it’s crazy if it is without a built-in or remote ejector, water will not pump. With a built-in ejector, the station can pump water from a depth of up to 9 m, and with a remote one - up to 40 m. If the check valve at the end of the suction pipe is in the air, then it is necessary to lower the pipe lower, and if the water level in the source (well, well) below 9 m - use a deep-well pump or with a remote ejector.

- The pump impeller is jammed (“stuck”) . Sometimes, after a long break in operation or for other reasons, the electric motor cannot turn the pump impeller when starting. Disconnect the station from the power supply and try to scroll it manually several times. If it is “stuck” due to prolonged inactivity, then this is enough for the pump to start working.

- The capacitor has failed . When turned on, the pump electric motor will make a sound different from a normal operating one (it cannot start, as in step 5), while its rotor and the pump impeller will not rotate. If turning the impeller does not do anything, then you need to check the capacitor, there may be a problem with it and, if necessary, replace it with a new one.

- Wear or damage to pump parts . Due to the content of abrasive particles in the water, wear of the impeller and pump housing can occur. In this case, it may begin to work “for itself” - it will not create the necessary pressure, and in order to eliminate this malfunction, you will have to change the housing and impeller or completely replace it with a new one.

- Very low mains voltage . If the voltage in the electrical network is too low, the pumping station will seem to work (that is, make operating noise), but it may not supply water. At the same time, the sound of the crazy machine itself may differ from the usual one. In this case, it is better to turn it off and identify the cause of the decrease in voltage in the network.

Reckless with a deep-well pump

If water is not pumped by a pumping station with a deep (submersible) pump, then the malfunctions may be as follows:

- the pump is faulty - it does not work or makes a working sound, but does not pump;

- rupture of the connection between the pipe and the pump;

- rupture of a pipe underground on the way from the well (well) to the house;

- the water level in the well or well below the suction valve of the pump has decreased;

- voltage drop in the electrical network.

Now in more detail:

- The pump is faulty - this may be one of the reasons that the pumping station does not pump water. It may not work at all, in which case there is a problem with its electrical part, or it may make a working sound, but not pump water. To determine this, you need to disconnect the pipe from it, lower it into the water and turn it on. The cause of such a malfunction in centrifugal submersible pumps may be wear of the impeller or housing elements due to abrasive particles, and in vibrating pumps it may be wear of the discharge valve or breakage of its axis (core). In order to eliminate such faults, you need to send it in for repairs or do this work yourself if you are confident in your abilities and that you can do it yourself.

- Broken connection between pipe and pump . Sometimes it happens that the reason that the crazy one does not pump water may be a spontaneous disconnection of the pipe from the pump or check valve in the well or well. This can happen due to a pipe rupture at the connection point or a loose clamp, or as a result of an insufficiently reliable connection during installation. This is easy to determine: when working in a well or borehole, the pump will emit a fountain of water. In order to eliminate this malfunction, it will be necessary to reconnect the pipe securely.

- A pipe ruptures underground between a well (well) and a house . In some cases, the cause may be a rupture of a pipe or its connections underground in the gap between the well or borehole and the house. This is one of the most unpleasant reasons, since to eliminate it you will have to dig up the pipe and repair or replace it.

- A decrease in the water level in a well or well, that is, a decrease below the installation depth of a submersible pump (its suction valve). True, the pumping station will not be able to operate for a long time in this mode - the pump will fail. Therefore, it is necessary to monitor the water level or use deep-well pumps that have special float switches that turn off the unit when the water level drops critically, or use a relay with dry-running protection.

- Very low voltage in the electrical network . If the voltage in the network is insufficient, then a crazy pump with a deep pump, as well as with a surface one, can work, but not pump water. If this continues long enough, it may cause the latter to fail.

The lineup

The line of pumping units of this brand has the following classification:

- Pumping station Marina-Speroni RSM 5/25

- APM series units are designed to lift water from deep sources located at a level of up to 30 meters;

- pumping stations of the HC Marina Speroni series have characteristics such as increased power and increased productivity;

- the CAM series of pumping devices represents the most budget-friendly and economical units that can draw water from a depth of up to 9 meters;

- A special feature of Indromat pumping stations is the presence in the design of the units of an electronic control device, which turns off the operation of the unit during a “dry” start.

Pumping station CAM 198/25 Having reviewed all the characteristics of Marina pumping stations, we can say that they have the following advantages:

- low power consumption;

- long period of operation;

- ease of installation and maintenance;

- stability of operation.

The crazy thing doesn't turn off - it doesn't turn off automatically

The pumping station does not turn off if it cannot reach the set maximum pressure in the water supply network (switch-off pressure) or the pressure switch is incorrectly adjusted or faulty, which does not turn off the pump when the set maximum pressure is reached.

In the first case, the pumping station may not be turned off for the following reasons:

- water leakage through connections, plumbing fixtures or pipe rupture in a volume equal to or greater than the capacity of the station pump, so the pump pumps, but cannot raise the pressure in the system to the specified maximum level and the relay, naturally, does not operate;

- very low voltage in the network and the pump cannot develop the necessary power to achieve the set upper pressure;

- malfunction of the mechanical part of the pump;

- air entering the suction pipe of a surface pump without an ejector;

- relay is faulty.

If the pumping station does not turn off when the maximum pressure is reached, then the reason is the pressure switch. You can remove the cover of the pressure relay and inspect the contacts (whether they are burnt or can open) or try to loosen the nuts on the regulators somewhat; they may be too tight, which may also be the reason the relay does not operate. The relay inlet and membrane may be clogged. In order to check this, you need to relieve the pressure in the system and unscrew the nut and remove the relay. If this does not help, replace the relay with a new one.

If the station does turn off, but it takes much longer to reach maximum pressure (shutdown) than before, then it is possible:

- the check valve does not allow water to pass through well (clogged or faulty);

- the mechanical water purification filter installed in front of the crazy tank is clogged;

- small water leak in the system (less than the pump capacity);

- malfunctions in the mechanical part of the pump.

The crazy thing works in jerks - it sharply gains and releases pressure

If the pumping station operates jerkily, that is, it turns on frequently and abruptly and also stops every time a tap or other plumbing fixture is opened, then this may occur for the following reasons:

- the integrity of the rubber chamber-membrane (“bulb”) in the hydraulic storage tank is damaged;

- there is no air pressure in the hydraulic storage tank with the membrane intact;

- pump station pressure switch is faulty

If the integrity of the membrane chamber in the tank is broken, then water will fill that part of it that is intended for pumping air. To find out, just press on the spool core of the fitting intended for pumping air. If, when pressed, water begins to flow out of the fitting, it means that the integrity of the membrane has been compromised and will have to be replaced with a new one.

If water does not flow from the fitting, it is necessary to check and use a pump to raise the air pressure to the required level: 10% less than the minimum pressure in the system (turning on the pump).

If the membrane is intact and the air pressure is normal, then the reason that the pumping station operates jerkily may be a faulty operation of its relay. You can check whether the inlet is clogged and whether the wires are securely fastened in the terminals. If the cause cannot be identified, it is better to replace the pressure switch with a new one.

Setting up the pressure switch

If you are not satisfied with the factory presets of the pressure switch, then you can configure it yourself. All you need for this is a screwdriver and a wrench to adjust the nuts.

It is worth understanding that setting up the relay is a very important and responsible process, since it determines how correctly the maximum response levels will be set, how convenient it will be to operate the pumping station and the time frame for trouble-free operation of both it and its individual components.

The first step is to check the pressure in the reservoir tank. Most often it comes from the factory with a switch-on level of 1.5 bar and a switch-off level of 2.5 bar. You need to check the pressure when the tank is empty and the pumping station is disconnected from the network. To check, you should use a car mechanical pressure gauge, since its body is made of metal, and therefore the accuracy of the reading will be more reliable, which cannot be said about electric or plastic ones. The fact is that their readings can be seriously affected by the air temperature in the room or the battery charge level. It is also recommended that the scale limit of the pressure gauge be as small as possible, since on a scale of 50 atmospheres it will be difficult to measure 1 atmosphere.

To check the pressure in the reservoir, open the cap that covers the spool and connect the pressure gauge. In the future, this procedure should be carried out at least once a month. There should be no water in the tank at this moment, and the pumping station should be disconnected from the 220V network.

Having selected the required operating mode, you should fix it by removing excess air or, conversely, pumping it in additionally. It should be remembered that in no case should the pressure be reduced to less than one atmosphere and, accordingly, pumped. If there is little air in the tank, then the rubber “bulb” with water will touch the walls of the tank, and a large amount will not allow pumping in a lot of water, since a significant volume of the tank takes in air.

The crazy guy can't hold the pressure

a water leak somewhere in the system .

First of all, you need to check the check valve to see if it is letting water back into the well or borehole. Solids may become lodged in the valve, preventing it from closing completely, or the spring may weaken.

If you are convinced that the check valve is working properly, it means that the leak is occurring in the system itself. It is necessary to check the integrity of the pipes and their connections , as well as the connection points of shut-off valves and plumbing fixtures.

the plumbing fixtures themselves can let water through : taps, mixers, toilet flush, etc.

Reckless often turns on

Possible causes and solutions:

- The pumping station often turns on if the air pressure in its hydraulic storage tank is very low or absent at all. In this case, the pumping station will turn on at every, even small, flow of water from the water supply system. Since the liquid is practically not compressible, the lack of air pressure in the tank will lead to the fact that immediately, with any opening of the tap or mixer, the pressure in the system will rapidly drop, which will immediately entail turning on the pumping station. When you close the tap, on the contrary, the pressure instantly rises and the pump immediately turns off. Measure the air pressure in the hydraulic storage tank and, if necessary, add to the required level: it should be 10% less than the lower pressure (pump activation).

- Another reason why the turretless engine often turns on may be the destruction of the membrane of the hydraulic storage tank . In this case, water will come out of the air injection fitting when you press on its core. The membrane chamber can be replaced by first disconnecting the front flange of the tank, which is secured with bolts. When installing a new membrane, it is advisable to cover the points of its contact with the tank and flange with silicone sealant.

- The third possible reason for frequent switching on, if the membrane is intact and the air pressure in the tank is normal, may be that the adjustment of the pressure switch is broken - the difference between the pump switch-on and switch-off pressures (ΔP) is too small. In order to increase the difference, you need to tighten the nut on the smaller of the two regulators clockwise.

If you did not find the answer to your question in the article, ask it through the “Contacts” section of our website or in the comments.

How to correctly set the pump on and off pressure levels?

As mentioned above, pumping stations supplied ready for operation have a relay already configured according to the most optimal parameters. But, if it is assembled from individual elements on site, then the relay must be adjusted, since it is necessary to ensure a normal relationship between the volume of the tank and the power of the pump. There is also a need to change the initial setting. Therefore, in these cases, the procedure should be as follows:

- Having completed adjusting the pressure in the tank, you should turn on the pumping station to pump water. It will turn off once the limit value is reached. Each device has its own maximum pressure and maximum permissible pressure, which cannot be exceeded. This can be determined by the cessation of its growth. Then the pump must be turned off manually. If the maximum value does not coincide with the level given in the instructions for the relay, adjustment should be made by rotating the small nut;

- Lower pressure is measured in the same way. You need to drain the water from the tank and observe the pressure gauge readings. The pressure will gradually drop and when it reaches the lower limit, the pump will turn on. To adjust it, you need to tighten the large nut. The lower pressure indicator should be about 10% greater than the pressure in the tank. Otherwise, the rubber membrane may quickly become unusable.

Typically, the pump is selected with parameters that do not allow the tank to be pumped to the extreme limit. And the pressure that should turn it off is set a couple of atmospheres higher than the switch-on threshold.

It is also allowed to set pressure limits that differ from the values recommended by the relay manufacturer, which allows you to create your own version of the operating mode of the pumping station. When adjusting the pressure with a small nut, it is worth considering that the initial reference point should be the lower level set by the large nut. Rubber hoses and other plumbing fixtures are designed for pressure not higher than that recommended by the manufacturer, which should be taken into account during installation. In addition, excessively strong water pressure is often unnecessary and causes discomfort.