Shiny coated parts are widely used in the interior and exterior of automobiles. They radically change the appearance, giving the appearance of individual elements a modern and presentable look. Galvanic chrome plating of parts is also used to extend the service life of plastic and metal, since the created layer protects them from scratches, corrosion and other damage. However, over time, the elements treated in this way also become unusable - they lose their shine, wear out, become chipped and rust. In this case, a good alternative to completely replacing them would be to restore the parts by chrome plating. This technology allows you to completely recreate the appearance and integrity of the coating, saving money on the purchase of expensive components.

Features of galvanic chrome plating

This method of processing parts is used to increase decorativeness and improve the operational properties of individual parts of the machine. Also, the chromium layer increases the service life of plastic and metal products. The technology itself is quite simple. Its essence lies in the application (diffusion saturation or precipitation) of chromium when the part is immersed in an electrolytic solution and exposed to electric current. The main composition is chromium-containing substances. This may be hexavalent chromium in the form of chromic anhydride or a trivalent compound represented by chromium chloride or sulfate.

Depending on what aesthetic and physical properties need to be imparted to the coating, one of the following popular methods of chrome plating parts is selected:

- "Milk Chrome" It is formed when the electrolyte is exposed to a current density of 15–25 A/dm2 at a temperature range from +65 to +80 °C. Characterized by low hardness. However, it has a pleasant shine, elastic and non-porous.

- "Shiny Chrome" It is created by supplying a current with a density of 30–100 A/dm2 into a bath with a solution at a temperature of +45 to +60 °C. It has a high hardness index, which ensures its durability. It also has a characteristic mirror shine.

- "Hard chrome." Produced using the traditional method at low temperatures (up to +40 °C) under the influence of a current density of more than 100 A/dm2. This type of coating has the highest level of hardness.

Galvanic chrome plating of parts in Moscow prices

It is important to note that both plastic and metal elements can be coated with a chrome-plated composition.

This activity should be carried out exclusively in a well-ventilated area, since during the work the air flows can be significantly enriched with chemical elements, as a result of which they can radically affect human health. If they get on a person’s skin, then, accordingly, dangerous burns may remain. Among other things, cases of chemical burns occur very often. That is why galvanic chrome plating of parts in Moscow at a low price should be trusted only to professionals in their field. There is no need to risk your own health, or it is very important to scrupulously follow the most basic and simple rules regarding safety precautions. It is advisable to carry out this procedure called galvanic chrome plating of auto parts in Moscow, the prices for which will suit everyone, in a garage or a well-ventilated area. It is very important to protect your skin and eyes well.

Preparing parts for chrome plating

Modern technologies for chrome plating of parts, regardless of their essence and methods of implementation, require high-quality preparation of the processed products. This process has several stages:

- thorough surface grinding followed by polishing;

- washing and wiping parts from dust and dirt;

- insulating the internal space of the product (sealing holes);

- fixing the workpiece on a special suspension;

- surface degreasing and washing;

- pickling in a salt bath and re-washing the part.

How does chrome film plating work?

Chrome plating of car elements with film is invariable in its sequence. After selecting the film you are interested in and discussing your personal wishes, the parts are prepared before pasting:

Preparation:

- Thorough cleaning of car parts from various contaminants using special means and solution;

- Degreasing the surface;

- Polishing painted parts to a characteristic shine.

Pasting:

- Uniform application of the film to the surface;

- Eliminates air for better results;

- Removing excess material.

Fixation:

- Using a special tool, the film is securely fixed to the surface in certain places;

- The finished work is also fixed with hot air to provide additional security.

Examination:

- Visual inspection of the resulting result;

- Eliminate imperfections, if any.

Chrome plating process

To understand how chrome plating of a part occurs, you need to understand in detail the main stages of its implementation. After preparation, the product undergoes the following types of processing:

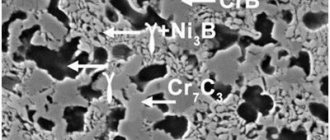

- Applying the base layer. Very often, before chrome plating, the part is etched or coated with other metals (nickel, copper). This significantly increases the strength of chrome, and also enhances its shine and resistance to weathering.

- Galvanization in a bath. The main stage of chrome plating involves processing the product in a special solution. The part is placed in a bath with an electrolytic composition heated to a certain temperature. After this, a current of a certain strength and density is supplied to the container. The temperature regime is maintained at the same level. The duration of galvanization is determined by the thickness of the layer that needs to be created.

- Post-processing. The chrome surface has small pores. To strengthen the resulting layer, it is coated with special varnishes and oils. After this, heat treatment is carried out, keeping the chrome-plated part at +200 °C for some time.

Chrome plating of car parts. Technological process of work + video instructions.

You've probably noticed shiny silver parts on many tuned and not only cars. Due to such accents, car enthusiasts want to distinguish their car from the rest and provide a good protective coating for both metal and plastic parts. This effect is achieved by chrome plating car parts. Very often, deflectors, side mirrors, moldings, radiator grilles and other elements of the car body structure are treated with chrome.

With prolonged use, such coatings lose their former appearance, and the need for their restoration arises. In this case, the car owner has two options. The first is to go to a car repair shop and order a service from specialists, as many people do. The second is self-repair of the coating, which is chosen by car enthusiasts either for economic reasons or if they have a desire to independently perform chrome plating of car parts with their own hands at home. So that in the future you can tune your cars for minimal money.

At its core, chrome plating is the process of saturation with chromium by diffusion or its deposition on parts in an electrolyte under the influence of an electric current.

This coating helps protect metal surfaces from corrosion and gives them a beautiful shiny appearance after polishing.

To perform all the technology at home, you need to understand that this is a complex and scrupulous process that requires good preparation of the surface of the part and strict adherence to all instructions.

What equipment and consumables are needed?

To apply chromium to the metal surfaces of car parts, you will need a certain list of equipment and materials for the work.

To assemble a chrome applicator, you will need:

- plastic or propylene bath. You can use plastic buckets or glass containers (for example, jars).

- acid-resistant heater for heating the electrolyte to the required temperatures.

- thermometer, with a measurement scale from 1 to 100 degrees Celsius.

- a rectifier that can produce a voltage of 12V and a current of up to 50 amperes. For these purposes, you can use a device for charging a car battery; it is quite suitable for processing small parts.

- clamp for hanging the part. This will ensure uniform treatment of all surfaces, since it will not stick to the walls of the container into which it is immersed.

- a cathode in the form of a clamp and an anode in the form of a rod or plate.

Related article: How to paint a plastic bumper from a spray can. Step-by-step instruction.

This is the main kit for assembling the installation for this work. It should be remembered that the process of chrome plating of machine parts is harmful, so the working area must be well ventilated. Also, if you decide to work in a garage, be sure to take care of personal protective equipment: a respirator, gloves, safety glasses and clothing.

The size of the electrolyte containers will depend on the volume of parts you are going to process. If possible, in order to save money, try to choose the most optimal size so as not to waste extra material.

Also, to store the solution and avoid its evaporation, it is advisable to come up with a tightly closing lid, or a separate sealed container for storing the material.

What does the electrolyte consist of?

The electrolyte is prepared from the following components:

- distilled water (with a little salt).

- chromic anhydride with a concentration of 220-250 g/l.

- sulfuric acid with a concentration of 2.2-2.5 g/l.

Additionally, you will need: hydrochloric acid, solvent type 646, clean sheet lead.

The electrolyte preparation process is as follows:

- We fill the container with heated water to 45 - 60 degrees Celsius, or heat it in the container.

- Pour in and gradually stir chromic anhydride at the rate of 250 g per 1 liter of water.

- Pour and stir sulfuric acid at the rate of 2.5 g per 1 liter of water.

- We drive the resulting solution through an electrolytic field over a time interval of about 3 hours. The current strength is set to about 6.5 amperes per 1 liter of solution. When the solution is ready, it will change color to burgundy.

- Let the electrolyte stand for about a day.

Technological process of galvanic chrome plating of parts

You need to understand that chromium can be applied to a metal part only if it consists of copper, brass or nickel. To treat a steel surface, you must first apply a copper, brass or nickel substrate to it.

The technology for chrome plating parts is as follows:

- First you need to prepare the part. To do this, it is cleaned and degreased using a solvent, for example 646.

- Heat the electrolyte to a temperature of 45 - 60 degrees Celsius.

- Next, the part to activate the surface is placed in a solution of hydrochloric acid for a period of 15 - 20 minutes, depending on the condition of the surface. Hydrochloric acid is diluted with water in a ratio of 100 grams/liter.

- After this, we rinse the parts in water and immerse them using a fixative in a bath of electrolyte. Usually the suspension is made of copper wire, on which the part is hung. The minus clamp from the rectifier is connected to this wire. Next to the container, using copper wire, we attach a lead anode, to which the plus from the power supply is supplied.

- After a period of 20–40 minutes, the parts are removed from the container and washed in water. After complete drying, you can polish the surface.

Related article: How to polish a car body by hand? Complete instructions for carrying out work.

What defects occur during chrome plating?

If the coating turns out to be defective, there is no need to be upset; the applied layer can be removed in a solution of hydrochloric acid by diluting it with water in a ratio of 100 - 200 grams/liter. After which the procedure can be repeated, taking into account errors.

The main defects include:

- chipped chrome film. This is usually a consequence of poor surface preparation, in particular degreasing, which leads to poor adhesion of the material and the surface.

- chrome beads on the edges. This is an indicator of the high current density in these places. You can try installing screens in problem areas.

- dullness of the coating. There are three methods to solve the problem: increase the electrolyte temperature, slightly reduce the current, or add more chromic anhydride.

Video example of chrome plating parts.

How can you restore chrome on plastic?

In order to chrome-plate plastic parts of a car, you can use a slightly different method of applying a metallized coating.

The technology of work in this case will be as follows.

- We put the part on a stand for more convenient work, maybe a metal one.

- If the plastic part is completely cleared of paintwork, you must first apply a bonding primer to it. Before applying the primer, you need to matt the surface with P800 - 1000 abrasive and degrease it. Usually 2–3 layers of primer are applied. Dry the painted part at room temperature for 6 – 7 hours.

- We carry out fire treatment of the primed surface.

- We prepare sprayers with manual air pumping into which the materials necessary for the work will be filled. And we pump air.

- We wash the surface of the part with distilled water.

- We spray an activator onto the surface, like a chemical. activator reagent ST.2516.

- Again, rinse the surface with distilled water.

- At the same time, we spray chemical reagents of the META-CHROME type from one container and reducing agents AB.101 and AB.202 and carry out the metallization process.

- Rinse the surface with distilled water.

- Using a hairdryer, remove the drops and dry the surface of the plastic part. Next, leave the part to dry for 1.5 – 2 hours at room temperature.

That's all, you can additionally varnish the surface.

Here is a video example of the work.

Cost of work in auto repair shops

If you decide not to do the work yourself, but go to a workshop, then you need to know how much chrome plating of parts costs from specialists. For example, to cover 4 20-inch wheels with chrome, it will cost you at least $500. The formula works here: the larger the order, the cheaper the work. Some companies even have a minimum check rule, which is $200 or more.

Terms and prices for chrome plating of parts

Typically, the entire cycle of work takes several days to complete. With a large volume of parts, it can take months, since each product undergoes chrome plating separately. The number of components will also affect the cost. When calculating the price, other factors will be taken into account: processing area, source material of the product (silumin, iron, etc.), general condition of the part. The result of properly performed galvanic chrome plating will be a perfectly smooth, mirror-shiny surface that will last at least 20 years.

Why do you need chrome plating?

The shiny chrome finish always attracts the attention of passersby. Even an unprepossessing car, after being decorated with a silver-colored part, acquires an original design. In addition, with the help of such elements you can emphasize the peculiarity of the body finish and protect them from the aggressive effects of moisture.

But in addition to the design idea, chrome plating also has a practical side. A part treated with a special substance receives a durable protective layer that prevents the formation of corrosion. The chrome surface is easier to maintain, as it is glossy, and the mirror effect will immediately show where dirt needs to be removed.

In every car you can find at least one element processed in this style. However, some motorists strive to express themselves and are not content with the factory equipment of their cars. In some cases, the coating is applied to those parts that have been damaged by rust, but technically they can still be used in the car. After processing, such a spare part becomes like new.

Before considering the entire processing technology, it is worth paying attention to the fact that this is a labor-intensive and rather dangerous procedure. The metal is treated with chromium ions. For this purpose, chemicals hazardous to health, such as acid, are used. Chrome plating is accompanied by the effect of electricity on the surface being treated, so most people prefer to have this work performed by specialists (for example, if there is a plant with a galvanizing shop nearby). But for lovers of handmade work, we will consider the entire procedure step by step.

Chrome painting

You can do chrome plating at home in several ways - by covering parts or body elements with film, or by doing catalytic, galvanic or chemical chrome plating yourself.

Covering a car with chrome film is an easy to implement and inexpensive solution. Its advantages are a wide range of film shades (from gold to pearlescent), and the ability to remove worn-out coatings. The film also performs a protective function, preventing scratches and abrasions from appearing on the surface of the body.

Also, do-it-yourself chrome plating at home is often done by painting with catalytic chrome paint. Such compositions are applied with a spray gun and dry at room temperature, but at the end you get only a decorative reflective effect (the reflectance coefficient for high-quality paints is up to 95%), and do-it-yourself catalytic chrome plating does not provide the protective properties characteristic of coatings obtained by galvanization.

Do-it-yourself chrome plating of parts using the painting method consists of the following steps:

Painting compositions with a chrome effect, in addition to metal surfaces, allow you to chrome plating plastic parts at home; they are also suitable for processing glass, foam plastic, and wood.

Basic methods of chrome plating

To give the product its characteristic silver finish, four chrome plating methods are used:

- Surface metallization is a procedure similar to painting. To do this, you will need an appropriate set of reagents, as well as a sprayer powered by a compressor. As a result, a thin metal layer is applied to the surface of the product.

- Galvanization of a part is a process in which chromium molecules are layered on the surface of the product. The peculiarity of this process is that it is suitable not only for parts made of cast iron, steel, brass or copper. It can be used to process plastic and wood. Given this versatility, this technique is more expensive and time-consuming. It is not suitable for home use because many processes during product processing must be controlled automatically. For example, you need to strictly adhere to the temperature regime (for about 8 hours), or control the concentration of the saline solution. Without sophisticated equipment this is extremely difficult to do.

- Sputtering in a vacuum chamber;

- Diffusion under high temperature conditions.

The easiest way is to perform the first procedure. To carry it out, there are ready-made reagent kits that have detailed mixing instructions. They are produced, for example, by Fusion Technologies. Such kits do not require complex galvanic installations, and the solution can be applied to surfaces made of any materials, including glass and ceramics.

The last two methods can only be performed in the factory. Electroplating is also more often used in factories, but some are able to provide the necessary conditions for an appropriate reaction in garage conditions. It is suitable for processing small parts.

As for the method under consideration, for which the electrolyte mentioned above is used, its effect will be observed only in the case of copper, brass or nickel parts. If there is a need to process conventional products, an additional layer of sputtered molecules of the corresponding non-ferrous metals is applied to them before chrome plating.

Chrome plating of car parts

The chrome part stands out on the surface of the body with its shine. This is one of the budget tuning options - unlike airbrushing, where the entire car is repainted, chrome plating is not accompanied by fundamental changes in the car's exterior - you will get a catchy, aggressive look of the car by transforming only a small part of it - the wheels, spoiler or radiator grille.

After chrome plating, your car will look more solid.

The chrome plating process allows you to apply a coating to the entire surface of the body, however, such repainting has a negative impact on road driving safety - the car shines under the sun's rays, which blinds drivers of passing vehicles. To avoid problems with the traffic police, it is rational to chrome only some elements of the body.

This article presents the technology of chrome plating at home. We will look at methods for producing chrome coatings - the use of chrome film, galvanic, chemical and catalytic chrome plating, and find out what equipment is needed for their implementation. Methods for caring for and restoring chrome parts will also be discussed.

Features of car chrome cleaning

Restoring a car's chrome can be quite difficult in advanced cases. It is worth remembering that different parts of the machine are exposed to different influences:

- door handles lose their luster due to sweat marks from the palms;

- wheel rims are subject to dynamic loads;

- Radiator grilles resist oncoming air flow and “catch” mechanical particles of dust, insects, and shock loads when clinging to branches, grass or road barriers.

Therefore, before cleaning and polishing, it is necessary to assess the condition of the chrome and then use comprehensive cleaning methods.

It is worth remembering that the vast majority of substances that cause corrosion are most active in a dissolved state. That is why chrome parts should be coated with water-repellent agents.

Also, it is worth removing bitumen stains as quickly as possible - they easily destroy chrome, leaving yellow stains.

After removing pockets of rust, the chrome coating must be coated with a protective compound.