Sharp cutting discs cut wood quickly, evenly, without chipping at the edges. When the teeth become dull, the wood tears and burns. In order for the circular saw to work quickly and for a long time, you need to regularly sharpen carbide circular saws. This can be done using special equipment or using a grinder.

The harder the wood, the faster the cutting edge wears off. If you do not sharpen the saw blade in time, the teeth will break, the wear of the carbide plates will be great, and the service life of the circular saw will be reduced. Due to heavy loads when working with a blunt instrument, the circular saw overheats and can burn out.

Sharpening carbide circular saw blades

Circulating saws - what are they?

A saw blade, when properly sharpened and set with teeth, is capable of high-quality and accurate sawing of the workpiece in any cutting direction relative to the fibers.

There are several types of cutting blades for a circular saw:

Carbide circular saw - characteristics

- Discs with a base and cutting area made of solid metal;

- Discs with a solid metal base and coating of hard structure materials on the teeth;

- Metal blades with carbide tipped.

High-quality cutting of workpieces is impossible when the teeth are worn out or dull. An accompanying phenomenon of working with a blunt tool will be excessive load on the engine, the risk of jamming, and unsafe cutting operations. Circular saws need to be sharpened.

For cutting hardwood, it is permissible to use only discs that have special grooves. Technological breaks in the blade prevent general deformation of the tool during possible heating during operation. This eliminates the appearance of a vibration background and deterioration of the cut line.

This is interesting: Do-it-yourself circular grinder: drawings and assembly

General rules for sharpening a circular saw

To sharpen the disks for a circular saw, you need to prevent them from wearing out too much, namely, the radius of rounding of the cutter should not be more than 0.2 mm. The following basic rules are followed:

- The main edges are processed first, of which the front faces wear out the most.

- In extreme cases, if the side edges are heavily worn, they are corrected.

- No more than 0.15 millimeters of the thickness of the saw metal is removed at a time.

- When finishing edges with an electric tool, overheating of the metal is not allowed, in which case its properties will deteriorate.

- To ensure the maximum service life of the saw, when it can be sharpened up to 30 times, you should sharpen both edges: the front and back, removing the same amount of metal.

- Sharpening circular saws with tools not intended for this purpose, such as a grinder and a metal cutting disc, is not allowed.

After the basic sharpening operations, you can refine the teeth with fine sandpaper. The quality of tool sharpening is checked under working conditions. If everything is in order, the cutting of the material will be clean, smooth, without visible defects or blackening.

Methods for processing disc blades

To shape the cutting edge, any sharpening machine is suitable where the design of the equipment is not of great importance .

Of course, the sharpening angles of disk plates with carbide tips are obtained more accurately using specialized equipment. However, its cost is very high, so a conventional grinding machine is used, which has the ability to change the inclination of the corundum disk. To sharpen a circular disk yourself, you must strictly fulfill several basic conditions:

- Usually the top edge is subject to deformation. Sometimes the rounding of the edges reaches 0.3 mm. Therefore, sharpening starts from the top.

- Processing is carried out taking into account the leading edge and its rear part.

- The operation is repeated at least 25 times. The thickness of the metal being removed should not be more than 0.05-0.15 mm.

- The quality of processing must be exactly the same over the entire surface being processed.

- After sharpening is completed, it can be fine-tuned manually using fine-grain sandpaper.

Methods for sharpening circular saws

Any sharpening machine can be used to form a new cutting edge. It is important to initially choose the right sanding wheel and use it to sharpen the edge. To do this, it is necessary to use corundum or diamond models.

The best option is to use special equipment designed to perform this work. But due to its high cost, in many cases its acquisition is impractical. An alternative method is to use a grinding machine with the ability to change the angle of the corundum disc.

Under no circumstances should you sharpen by hand yourself. Firstly, it will take a lot of time. Secondly, the result obtained will not meet the standards. If it is not possible to sharpen a saw blade for wood yourself, it is recommended to use the services of specialized companies.

Do-it-yourself professional sharpening of circular saws is performed according to the following rules:

- the main deformation occurs at the upper edge of the tooth. The edges are rounded from 0.1 to 0.3 mm. It is from this place that processing must begin;

- sharpening is carried out along the leading and trailing edges. This will ensure the possibility of repeating the procedure up to 25 times;

- the removal amount should not exceed 0.05-0.15 mm;

- The level of processing of the front and rear edges should be the same.

After sharpening the discs for wood is completed, it is recommended to finish it with fine-grained sandpaper. This can be done manually or using a special machine.

Experts advise using special corundum disks, the end surface of which has a specially shaped groove. It will make the procedure easier.

Necessity of the procedure

Circular saws are needed both in private households and in production. When building a house, creating furniture, cutting boards, timber - a similar tool is required everywhere. Properly sharpening a circular saw requires practical skill and knowledge.

Circular saws compare favorably with other cutting tools:

- chain;

- saber;

- longitudinal.

Disc circular devices have significant productivity, and their service life is also much longer. Sharpening circular saws is an important necessary step; without it, the tool will not work fully. Thanks to various attachments with carbide tips, as well as pobedit coatings, cutting can be carried out with both wood and metals.

To sharpen discs with different attachments, special equipment is required. If the disk is treated “scientifically”, this will greatly extend its service life.

Timely sharpening of circular saws is carried out when there are several obvious signs.

- The engine begins to experience unnecessary loads. The reason is simple - the teeth are dull and additional resources are required to process the material. There is a danger: if the disk is damaged, if there is no engine shutdown relay, the machine may fail.

- If chips and chips form on the cut, and the cut itself becomes too wide, then this is a sure sign that the tool should be repaired.

- A foreign smell of burnt material appears, and dark spots are visible on the cut line.

- The time required to process a part increases.

When to sharpen a circular saw

There are very definite signs by which one can judge the condition of the instrument. Saw sharpening is necessary when the following clearly appears:

- During operation, smoke appears, a specific smell of burnt wood, the casing covering the saw teeth begins to heat up quickly.

- When moving the tool along the workpiece, you need to apply significant effort, as if pushing the saw forward.

- After cutting the material and visually inspecting the sawn edge, black deposits or many chips, fiber burrs, and chipped areas are visible.

- When you carefully examine the saw teeth through a magnifying glass, you can see that the cutting parts have rounded edges rather than sharp ones.

All this requires immediate cessation of work, otherwise there is a high risk of damage to the material and wear of the circular saw to a state where sharpening will no longer help it.

Home processing of toothed blades

To process a circular saw, it is not at all necessary to have a special machine for sharpening circular saws with your own hands. To secure the canvas in a certain position, you can use a flat stand, which has several nuances:

- The surface should be flush with the center of the sharpening wheel.

- The sharpening plane should be at an angle of 90 degrees relative to the gear wheel.

- To create different inclinations, the device must have a swivel joint.

To select the desired angle, make a mark with a colored marker. The device must be installed in a powerful vice. Even the slightest movement of the special stand is not allowed.

Originally posted 2018-03-28 15:29:34.

Principles and angles of sharpening circular saws

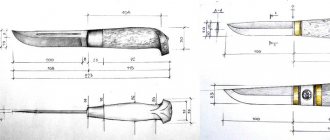

The saw has four main sharpening angles for the circular saw blade along the working part. The angles under consideration, as well as the tooth shape itself, can be called the main performance characteristics. Each tooth can be characterized as follows:

- front and back angle;

- cutting angles of the front and back surfaces.

The values of the above parameters depend on the purpose of the sawing device and the type of workpiece material.

Circular saw tooth surfaces

Based on the above parameters, several saws can be distinguished:

- for performing longitudinal cutting. In this case, the rake angle should be from 15° to 25°.

- when performing cross cutting, the considered indicator should be from 5° to 10°.

- The universal version is recommended to be sharpened at an angle of 15°.

The type of material being processed also determines what characteristics the tooth should have. As a rule, the harder the material, the more difficult it is to machine. That is why it is recommended to sharpen the cutting teeth to a lesser extent.

With prolonged use of a carbide saw, significant wear occurs on the uppermost cutting edge. When considering the tooth plane, it is worth noting that most wear occurs on the front surface.

Types of Circular Saw Teeth

Sharpening circular saws at home

You can sharpen the saw yourself without using a special sharpening machine, which is expensive and is rarely used for its intended purpose due to the use of carbide material when creating the cutting edge. However, you cannot simply hold the circle in your hands, since you need to achieve certain cutting parameters to ensure the required performance indicator.

To fix the gear wheel in a strictly specified position, an ordinary flat stand is used. It has the following features:

- The surface of the flat stand should coincide with the level of the axis of the sharpening disc.

- We place the toothed wheel on the stand so that the sharpening plane is perpendicular to the saw blade.

- The device in question for teeth located at a certain angle is equipped with a rotary hinge.

Read also: Safety precautions when sawing

The device in question makes it possible to fix the element being processed in relation to the abrasive material used. Using a colored marker, marking lines are drawn that allow you to select the correct angle. A vice is also needed in which the created fixing device is attached.

Sharpening carbide-tipped tools

Sharpening circular saws with pobedit tips often causes problems. Processing with standard abrasives takes a very long time, and if the material is overheated, it can be “tempered.” Of course, processing with a diamond tool will be much faster, but its cost is very high. It will be much more economical to purchase a victorious disk.

Each master approaches solving this problem purely individually. To obtain the correct sharpening angles for carbide-tipped circular saws, you will definitely need a machine.

This is interesting: How to choose a wood sander

Tool sharpening training

We teach sharpening of tools. There are several options for learning to sharpen: a week course, a month course, a two month course, including an internship as an assistant master.

To cut wood, specialized power tools are used, as well as toothed discs, which become dull over time and cannot cope with their tasks. To avoid having to buy a new cutting attachment, you can sharpen circular saw blades yourself. The principle of sharpening is not difficult, and everyone can cope with it if they have instructions for implementing this process.

Read also: What is a lux meter for?

Methods

You can sharpen the instrument yourself (if it does not have a pobedit coating) at home. And also in such cases, you can use a simple machine on which you can successfully sharpen any edges. It is very important to choose the right circle.

They come in the following types:

- corundum;

- diamond

It is best to use a unit in which the disc can be positioned at different angles.

Equipment for sharpening tipped discs is not cheap and can only be found in specialized technical centers.

It is forbidden to move the sharpening yourself:

- it costs extra labor;

- the accuracy of manual movement will be poor;

- If you do not have the skill to sharpen wheels, it is recommended to turn to professionals.

There are rules:

- the main defect occurs on the edge from above, that is, the edges are rounded within 0.11-0.31 mm - this is the starting point from which sharpening should begin;

- Both the front and rear parts should be processed, this should be done at least 26 times;

- size does not exceed 0.051-0.151 mm;

- front and back edges are processed identically;

- After the end of the cycle, the finishing process should be carried out, that is, clean the surface with “zero” sandpaper.

The work of creating a new configuration requires compliance with regulations and has its own complexity.

- Familiarize yourself with the requirements, in particular, clarify the number of revolutions. It is clear that for metal this figure will be noticeably lower. Wooden elements are processed with a large number of revolutions.

- The material from which the soldering is made can withstand heavy loads, its service life is significant, but even it sooner or later receives defects, chips and cracks appear.

- A sure sign that the material is beginning to “tire” is the appearance of microburrs and roughness on the surface. Defects will appear in these places after some time.

To carry out sharpening correctly, you should know what types of teeth there are:

- straight;

- tooth with a bevel on the back;

- trapezoidal;

- cone-shaped;

- concave.

How to sharpen:

- The disc should be thoroughly cleaned using alcohol or chemicals;

- all working planes are processed;

- it is permissible to remove metal 0.051-0.151 millimeters;

- sharpen perhaps no more than twenty-five times;

- you can sharpen using a special file, if you have practical experience;

- It is recommended to sharpen carbide teeth using separate equipment;

- Victory tips can only be “taken” using a special machine that contains a diamond wheel.

Markers should be made to mark the starting point. The teeth are arranged in such a way that they are in a single plane. After completing the sharpening cycle, each tooth is tested and processed separately.

There are several types of tooth alignment.

- Wavy, each tooth is straightened at a certain angle of inclination, thus creating a semblance of a wave.

- Protective, two teeth have angles of inclination, the third tooth is present without inclination. This method is effective even when working with mahogany and oak.

- Classic, when the teeth are variable - angles of inclination to the left and right.

- Frontal.

- Rear.

- A tilt is made at the frontal plane.

- A tilt is made at the rear plane.

There is another parameter - the sharpening angle, but it usually “works” as an additional tool.

For manual sharpening you will need:

- wooden blocks (2 pieces, size 52x32 mm);

- drill, screwdriver;

- screwdriver bit;

- a hacksaw for processing ceramics;

- marker;

- ruler;

- screws or self-tapping screws.

The middle of the bars is cut out, they are fixed on a solid plane using self-tapping screws. A mark is made on the bars so that a crown for processing ceramics is then placed in the sawn markings, which, in turn, is attached to a screwdriver.

The surface of the stand coincides with the surface of the disc. The circle lies on a stand, the sharpening plane should be at an angle of 90 degrees to the saw blade. This simple device is equipped with a swivel unit. Such reliable fastening allows you to evenly process all the teeth of the tool. Using a marker, you make markings, which makes it possible to correctly determine the angle of inclination.

Types of circular saw tooth settings

Before sharpening the circular saw, you need to check whether the teeth are set.

To do this, measure the width of the tooth with a caliper, and then make a small cut in a piece of hardwood and measure its width. If the circulation disc is set apart, then the cut should be wider than the tooth. Otherwise, the saw teeth must be set apart before sharpening operations. The complexity of the setting process is due to the need to move the teeth to the side at the same distance. This can be achieved by using a factory-made device for wiring circular saws. Each tooth should be started from the middle of its size. For wood materials of different densities, the degree of teeth set should be different, but without going into details, we can say that the teeth are set wider for sawing soft wood than for hard wood.

There are three main wiring methods:

- Stripping type wiring. This method boils down to the fact that after two teeth the tooth remains in its place without change, the rest are deflected in different directions. This saw preparation is good for working with solid wood.

- A variant of the classic setting, when the saw teeth alternately move to the right and then to the left. This universal method can be used for almost all types of saws.

- The so-called wavy layout, the distinctive feature of which is that the teeth are not set at a strictly defined distance from the center, but at different distances with a deviation of 0.3–0.7 millimeters.

Types of sharpening cutting teeth

To better understand how circular saws are sharpened, you need to study the features and structure of those parts of the tool through which the material is cut. Cutting teeth are the main element involved in sawing wood.

They are made of carbide metal. The cutting teeth consist of 4 working flat surfaces: front (a), rear (b) and two side planes (c), which have an auxiliary role. By means of one main (1) and two additional (2 and 3) cutting edges, intersection lines are formed for each specified working plane.

Depending on its configuration, a circular saw may have different types of cutting teeth:

- Straight tooth type. Often used for accelerated longitudinal sawing. They do not have ideal cutting quality.

- Beveled (oblique) type of teeth. They have a characteristic angular cut on the right and left rear surfaces. In some cases, the blades have teeth with different bevel sides, which alternate along the entire circumference of the saw. Using such discs you can cut wood, chipboard and various plastics. A large bevel angle ensures a high-quality cut without chipping the cutting edge.

- Trapezoidal type of teeth. The cross-section of the cutting surfaces is trapezoidal in shape. This configuration allows you to work without dulling for a long period of time. Often the disc has straight teeth that alternate with trapezoidal ones. In such cases, the trapezoidal element plays the main role in rough cutting, while the straight tooth type is used for finishing.

- Conical teeth type. They have a cone-shaped appearance. As a rule, they perform an auxiliary function for preliminary cuts on the laminate. The conical type of teeth is used to process the specified floor covering. This saw allows you to avoid chipping the material, as often happens when using the main saw.

Tooth material and shape

Saw blades are steel blades whose tips are high-temperature welded cutters.

As a rule, these parts of the tool are made of sintered tungsten-cobalt alloy (grades VK, VK6, VK15, etc.). Hard alloys are also used. But it should be taken into account that the strength depends on the grain size of the carbide phase.

The soldering itself (tooth) has the following planes:

- Front;

- Rear;

- Two side (auxiliary).

That is, intersecting, they form two cutting edges:

- Home;

- Auxiliary.

What teeth are there on cutting attachments?

At the heart of any cutting device are teeth, the quality of their sharpening affects efficiency and productivity. The teeth on the attachments are made directly from carbide materials. To increase the service life, pobedit soldering is applied to the teeth, which allows you to extend the life of the working attachment by 5-6 times.

The number of cutting teeth on a wheel depends on its diameter. The teeth consist of a front and a back part, which differ in design, as well as a side part. Teeth according to their appearance (geometry) are classified into the following types:

- Straight - a type of teeth used for longitudinal cutting of sheet material

- Trapezoidal shape - the cutting links have a trapezoidal shape, which is an advantage - they need sharpening very rarely

- Bevel links are the most common type of teeth and are characterized by the presence of an angular bevel on the back or front. This design allows sawing not only wood, but also other types of materials such as fiberboard, chipboard, plywood and even plastic.

- Conical - they have the shape of a cone, but their main drawback is that they quickly become dull, so they need frequent sharpening. They are used not only for transverse, but also longitudinal cutting of sheet material

Manufacturers also produce circular saw blades with active and passive links. Depending on the type of teeth, the process of sharpening them differs. To properly sharpen the teeth on a circular saw, you will need to correctly determine the sharpening angle.

How to sharpen a saw blade - rules

The main point in working with soldered teeth is the accurate determination of the degree of wear. Therefore, before starting work, you need to check all the teeth without exception. A metal template will provide the main assistance in this.

The rules for sharpening can be formulated as follows:

- If the cutting edge of the tooth is rounded and the distance between the corner of the template and the tip of the edge becomes 0.1-0.2 mm, then the front or front part of the soldering is sharpened.

- If the edge is more rounded, then you need to remove not only the front, but also the upper part of the soldering.

- If the saw has teeth set, then the angle of inclination is first restored, and then the edge is restored.

- If the teeth have different front angles of inclination of the edge, then first sharpen one inclination, and then correct the inclination of the other angle.

Differences in working teeth by geometric shape

The tooth has several working planes. The front plane “A” together with the rear “B” at the intersection form the main cutting edge “1”. At the intersection of the plane's thin lines with the side "B" auxiliary edges "2" and "3" are formed.

Schematic representation of a blade cutting edge

To effectively work with materials, various types of cutting teeth have been developed.

- Basic shape – straight tooth

Designed for rough and fast cutting. The cut quality is low, so it is not suitable for fine work and jointing of hard materials.

This shape of the cutting edge allows you to make smooth, precise cuts and is well suited for composite materials, for example, chipboard with double-sided lamination. There are practically no chips left on hard surfaces. Teeth with a beveled back surface are excellent at cutting hard workpieces, but at the same time they become dull faster. The slope alternates, so a canvas with this shape is called alternately beveled. Both the trailing and leading edges can be beveled.

The main advantage is slow dulling. Such working teeth alternate with straight ones, working in a complex manner. The trapezoid is slightly higher than the main tooth, and, as it were, cuts through the material “roughly,” making it easier for the straight edge to work. Used for cutting plastics and materials with durable double-sided laminate.

Discs with conical teeth are auxiliary. With their help, a preliminary cut is made in the laminate to prevent the formation of chips when cutting. Not used as a stand-alone tool.

In addition, the front plane of the teeth may have a concave shape. These saws are designed for cross cuts. The concave plane and sharp edge cut the transverse fibers of the material like a sickle.

Sharpening circular saws with your own hands video

There are discs with alternating active and passive teeth. Passive ones have a negative sharpening angle.

Sharpening using a machine

If it is possible to purchase a special machine, then the process in question can be carried out with maximum efficiency. This device is compact in size and can be used at home.

Particular attention is paid to the choice of abrasive wheel. In this case, we note the following nuances:

- Carbide blades are difficult to sharpen.

- When choosing, you should pay attention to wheels made of CBN, with diamond chips or green silicon carbide.

The sharpening process when using professional equipment is very simple. The disk is secured using a special clamp. It was created taking into account the design features of the circle. We will pay special attention to the fact that when using special machines it is very easy to sharpen circular saws while maintaining the required parameters. In this case, the error is minimal. This is due to the fact that the design has a special angle indicator meter. In order not to be mistaken at the time of work as to which teeth have already been processed, you should use a marker to mark the starting point.

How to sharpen a disc with a machine

For high-quality work, sharpening machines with special devices are used. The simplest one can be made from a grinder - you just need to secure it with clamps, and the work table can be made from chipboard.

At home, a coarse-grained disc is used for rough processing and shaping of the tooth, and a medium-grained disc for preparing the cutting edge. Diamond for finishing.

Before sharpening a circular saw blade for wood, it is degreased. The tooth from which sharpening begins is marked with a marker and secured to the machine. The edges are sharpened one by one; the transition to processing the next surface occurs when all the saw teeth are processed.

Sharpening with a diamond blade

Professional equipment from thousand to 1.5 million rubles

Professional sharpening machines are intended for use in repair shops of large sawmills or service companies specializing in working with such tools. All of them are equipped with industrial controllers with the ability to select a processing program for a specific saw blade model.

| № | Model | Max. diameter (mm) | Drive Power (W) | Weight, kg) | Control type | Price, rub.) |

| 1 | MF1263 | 630 | 300 | 260 | machine | 165 000 |

| 2 | Unimac 600A 288,000 | 630 | 300 | 250 | automatic | 288 000 |

| 3 | GRIGGIO GA U5 | 400 | 560 | 115 | automatic | 451 000 |

| 4 | OS-2M | 1500 | 1 100 | 270 | automatic | 525 000 |

| 5 | OTOMAT-96 | 750 | 1 000 | 850 | machine | 1 500 000 |

Important Features

So that readers do not get lost in the wilds of the modern market for accessories for circular saws, we have prepared 5 main criteria that will help you make your choice. Let's consider them in order of importance.

External diameter

The outer or outer diameter of the disk should not exceed the dimensions of the circular saw casing, otherwise it will not be possible to install it in the seat. Increasing the parameter leads to an increase in the depth of cut. The characteristics vary from 65 to 500 mm.

Landing diameter

Landing, or internal diameter - the size of the hole in the center of the equipment. Determines whether the saw blade will fit on the spindle. The most popular sizes: 16 , 20 , 22 , 30 and 32 mm. But the full range is much wider - from 11 to 50 mm.

Manufacturers may install pins on the saw seat for additional fixation . In this case, you need to choose a disk with appropriate holes .

Number of teeth

As the number of teeth increases the processing speed decreases , but the cleanliness of the cut improves . And vice versa: the fewer teeth, the faster the work goes , but the cut becomes less and less accurate . The characteristic has its own classification, presented in the table:

| № | Name | Number of teeth, pcs |

| 1 | Big | 80-90 |

| 2 | Average | 40-80 |

| 3 | Small | 10-40 |

Tooth sharpening angle

Sharpening inclination is the angle of deviation of the cutting edge of the tooth from the radius of the saw blade. The picture clearly shows how a characteristic can influence the work process. The angles are:

Standard : 5-15 °. Universal sharpening. Suitable for all types of cuts.

Positive : 15-20 °. Ideal for rip sawing due to its gripping effect.

Negative : from to - 5 °. Used for cross cutting, does not form chips.

Disc thickness

The standard parameter is 3.2 mm. The thinner the disk, the more it heats up and the faster it fails. The large thickness guarantees a long service life of the equipment, but slows down the work. In this case, the excess consumption of material increases due to the wide cut.

What to consider when processing

The operating principle of the sharpening disc has its own characteristics, as well as its structural design. The materials for its manufacture are based on nitrogen and boron compounds, which increase not only the accuracy of processing, but also the resistance to high temperatures that characterize the process itself. It must be taken into account that wheels have different diameters and are suitable for different tools and types of materials, so you need to carefully select the required model in accordance with the existing tool to be processed.

Types of saws

If the disk is properly sharpened and the teeth are set according to the pattern, then it can process the workpiece in any direction relative to the wood fibers.

There are these types of tools:

- saw with carbide blades;

- discs made of solid metal;

- discs with teeth treated with hard material;

- discs with heavy-duty soldered teeth.

Hardwoods are processed with discs that have special grooves. Technological breaks prevent tool deformation and prevent it from overheating during the production cycle. Vibration and background noise are also significantly reduced, and the quality of the line formed by the cut is improved. The saw has teeth that are machined at a certain angle, each tooth has several cutting edges.

There is a main edge, additional ones are mated to it, and intersecting planes are formed:

- A;

- IN;

- WITH.

The planes themselves also vary in different mates.

To use saws correctly and productively, you must consider the material you are working with.

The teeth can be straight, they are usually used for preliminary cutting of material . These teeth provide a low level cut. However, the productivity of such teeth is quite high.

Beveled teeth provide a more precise line and are suitable for cutting materials such as:

- plywood;

- PVC sheets;

- chipboard;

- Fiberboard.

The teeth ensure an even cut without the material crumbling.

There are also discs that have a bevel at the leading edge of the cutter, and there is also a bevel with a trailing edge . Options for alternating different teeth with different bevels are possible. Such tricks ensure a clean cut, but you should remember: the denser the material, the faster such teeth become dull.

Trapezoidal tooth – this tooth configuration ensures long tool life. Often a complex design is used, when trapezoidal and straight teeth alternate. The latter make the primary cut, which allows straight-shaped teeth to “polish” the cut.

Typically, such a tool is used in cutting laminate flooring, as well as PVC sheets.

Cone-shaped tooth - these teeth are auxiliary and are designed to work with materials that have a laminated surface. They ensure correct cutting without the formation of any chips.

Teeth of this configuration are practically not used independently.

Sickle-shaped tooth - in this case, the teeth are bent, which makes it possible to accurately cut the material across the wood fibers.

Option 2 - how to make a sharpening machine from a grinder and a drill

In addition to an emery machine, you can use a grinder or angle grinder to make a contactor. An appropriate diamond-coated sharpening disc is installed in the spindle of this tool, and the power tool itself is fixedly attached to the base. The principle of manufacturing the conductor is as follows:

- Take a frame made of chipboard or fiberboard measuring 50x80 cm. The components will be located on this frame

- Initially, you should fix the angle grinder motionless using clamps. The tool spindle should be positioned at right angles to the frame

- A movable frame is made and placed at the end of the tool, on which discs for sharpening will be installed.

- Frame mobility is achieved through the use of furniture slides

- A bracket is made on the frame to secure the sharpened equipment

The finished product is shown in the photo below.

How to use, as well as the features of working on a homemade machine for sharpening the equipment of circular saws, is shown in the video.

Read also: Dimmer for adjusting light

The result of the work done is the following - restoration of the integrity of the disk with teeth, which allows you to continue working with power tools when processing wood. The methods discussed in the material are suitable for sharpening saw blades of tools such as grinders, circular saws and stationary circular saws. If the principle of performing the work is clear, then there will be no difficulties with the manufacture of a special machine and its operation.

Signs of wear

Saw sharpening is a common activity, as is DIY chain sharpening. You can entrust the device with carbide, pobedit tips to specialists. This is due to the fact that pobedit tips have increased hardness, which makes it impossible to sharpen with a regular file. This will require an expensive diamond grinding tool.

The first thing you need to do is determine the current condition of the saw wheels. Chainsaw blades and chains show certain signs of wear. If you are aware of them, you will easily know that the sharpness of the circular saw has deteriorated significantly.

- The temperature on the motor housing of your circular saw has started to rise significantly.

- To cut a workpiece, you have to put in more physical effort with your hands. A similar phenomenon is typical for dull chainsaws.

- Smoke may occasionally come out of the engine.

- When processing workpieces, an unpleasant burning aroma is formed.

- Dark spots form on the edges of the saw blade. This is soot. It can also appear on the surface of chainsaw chains.

- The wooden workpiece begins to move jerkily around the machine, although during normal sharpening the movements should be smooth.

- There is some extraneous noise when the machine is operating.

- The geometry of the teeth of the saw blades of your circular saw is disrupted.

How to determine wear?

Checking the saw blade for wear is an important issue that should be given special attention. Deep damage makes it impossible to sharpen the wheel. There are three main signs by which you can understand that the saw needs to be sharpened or replaced:

- The protective casing becomes very hot and produces smoke. The circular saw has a special casing that indicates that the saw has become dull due to heat. In particularly difficult situations, smoke may appear from it.

- Sometimes the saw design involves a mechanical feed (if you need to manually adjust the pressure force). In such a situation, wear can be noticed if the pressure has to be increased.

- If, when sawing wood, carbon deposits and a strong unpleasant odor are formed on the workpiece.

All the situations described above tell the user that it is time to sharpen the device.

Determining the degree of wear and sharpening angle

Circular saws, sooner or later, lose their performance characteristics during operation; it is possible to effectively extend the service life of the tool if it is sharpened again correctly. This operation is simple; in many cases you can do the work yourself.

First of all, you should have an idea: what parameters the working disk of the unit has. The second most important parameter is the sharpening angle, what parameters the tooth itself has.

Before you start working, you should test the tool to understand how relevant its restoration is. The disc should be inspected by removing it from the machine. An important indicator is the change in size, this can be seen even with a cursory examination.

Discs that are treated with special materials require a special approach. The tipped disc allows you to significantly increase the service life of the cutting tool. It can work with any type of tree, even material of increased hardness.

The “knobs” themselves are made of heavy-duty steel of the following grade:

- 9HF;

- 50 HVA;

- 65G.

Some other grades of steel are also used.

This material stands out for its strength and wear resistance, but it also requires preventive treatment.

To begin work, it is advisable to have the required template, according to which you can adjust the geometry of the cutting surface. Usually the template is made of tin or cardboard.

The teeth themselves have a standard prescribed in GOST 9768-78, however, each manufacturer has differentiation in inclination angles and shapes.

In the absence of a template, you will need to determine the parameters of the teeth yourself. There is a tool for this - a pendulum protractor. With this tool you can accurately set the sharpening angle.

Another option is to take a new disk and use it as a template . You should take a sheet of thick cardboard and draw precise outlines on it with a pencil. Then, using a pendulum angle gauge, the exact configuration of the soldering should be established. this sample; you can work with it in the future , using it as a standard.

After finishing the work, it will be necessary to test the resulting sample by comparing it with the standard. The angle of inclination in such saws ranges from 15 to 25 degrees .

If the model is transverse, then the differentiation can be from 5 to 10 degrees. If the model is universal, then the tilt angle is only 15 degrees.

Something to keep in mind when starting work: the rake angle may have a negative value. Similar models are used for working with PVC sheets, as well as soft metals.

How to determine the sharpening angle of a circular saw

The best option would be to have an initial template according to which you can correct the geometry of the cutting edge. Often it is made of thin-walled stainless metal, less often - of thick cardboard.

Carbide teeth are manufactured in accordance with GOST 9769-79. But their geometry and geometric dimensions are determined by the manufacturer based on the purpose of the saw. If there is no template, you need to independently determine the required sharpening angles. To do this, it is recommended to use a pendulum inclinometer.

Do-it-yourself template making technology.

- Take a new disc with soldering, which is completely identical to the dull one.

- Draw precise outlines on a hard sheet of cardboard.

- Using a pendulum goniometer, determine the initial geometry of the carbide tips.

- Enter the data on the template.

In the future, it can be used for self-sharpening on a machine or provided as a sample for companies providing similar services.

Additionally, it is recommended to compare the obtained data with the reference ones. In rip saws, the rake angle is usually 15°-25°. For transverse models, this figure ranges from 5° to 10°. In universal models, the rake angle is 15°.

It is important to remember that the rake angle can be negative. Similar models are used for cutting plastic sheets and non-ferrous metals.

Read also: How to remove the cover from a light switch

Expert advice

Experience is a useful thing, thanks to which you can avoid a number of mistakes typical for beginners. Therefore, paying attention to the advice of experts is very useful if you want to achieve a positive result for yourself when turning a circular saw.

- Always use safety glasses. For some reason, many people ignore this rule, which is why the masters themselves then suffer. Therefore, before you start sharpening, be sure to wear all the necessary protective equipment;

- Do not attempt to remove more metal than required. Remove just enough to remove all existing cracks, burrs and irregularities;

- During turning, be sure to keep the disk in a constant position;

- If the disc has not been sharpened for a long time, you will have to remove a larger layer of metal;

- Keep all teeth identical in shape and height.

Initially, it seems that sharpening is a technologically complex process. But with a little experience, you will be able to sharpen circular saw blades easily.

How can you sharpen a circular saw?

Sharpening discs is impossible without the use of a special tool. For these purposes you can use:

- Special wheels for sharpening saws, made on the basis of diamond abrasives.

- A regular file for sharpening a saw, but you also need to have a vice to secure the saw and a wooden block used as a guide.

- Processing on professional equipment is the fastest and highest quality method of sharpening, but requires large material costs to purchase the tool.

Sharpening saw blades with carbide teeth

Tooth angles for sharpening saw blades

Pobedit tips are sharpened using a special machine or a homemade attachment for a grinding wheel. The device is a clamp in which the disc is clamped, maintaining certain sharpening angles relative to the emery. A diamond wheel is considered the best for sharpening a pobedit.

A marker marks any point as a reference point. Position the main working surface of the tooth against the grindstone so that they are in the same plane. Grind each tooth in turn until the entire circle is completed. Rearrange the disk with the auxiliary plane to the grinding wheel. They grind a different plane for each tooth. This is how the carbide-tipped discs are completely sharpened step by step.

Related video: Sharpening a circular saw using an electric sharpener

Signs that sharpening is needed

The tooth on a circular saw wears out faster on dense or damp wood. The working edge experiences more resistance and friction. Saw blades should be sharpened when the first signs of dullness appear:

- it takes more effort to cut wood;

- dark spots appear at the cut site;

- the smell of burnt wood is felt;

- the part being cut moves unevenly, jerkily;

- the engine hums louder;

- the motor casing gets hot;

- the edge of the tooth became rounded and curved.

If you do not pay attention to these signs, then breakage of the teeth and smoke from the burnt out drive will follow. The cutting plane on wooden parts will be uneven and torn. A dull tooth does not cut, but tears the wood fibers and presses grooves into it.

Recommendations

And finally, some advice from experts:

- the frontal part should be monitored more closely;

- when working with massive elements, the side planes are subject to heavy loads;

- radius rounding no more than 0.21 mm;

- It’s best to process the teeth both front and back;

- metal removal parameters should not exceed 0.151 mm;

- the disk is cleaned before starting work, all relevant corners should also be checked;

- sharpening the teeth at the desired angle requires practical experience; in the absence of this, it is better to take the disc to a workshop;

- wheels with diamond coating should be cooled using a special coolant;

- a unit designed for sharpening circular knives is capable of working with a workpiece in only one plane;

- the teeth should not be allowed to wear to the point of rounding by more than 0.21 mm, otherwise it will be difficult to do normal sharpening;

- Usually the disk has a resource of no more than 36 sharpenings, and it does not matter on which unit the processing takes place;

- It is important to ensure that the metal does not receive defects during processing (chips, cracks, nicks), their appearance can provoke further destruction of the material.

The following video shows how to sharpen carbide-tipped circular saws.

How to sharpen a blade on a circular saw with pobedit tips

Craftsmen often buy wheels that have increased wear resistance due to the presence of special pobedite soldering. These soldering extends the service life of the consumable, but does not make it last forever. The pobedite layer is applied to the links using a special solder. Due to soldering, the geometric shape of the tooth becomes more complicated, and therefore the sharpening process also becomes more difficult. Restoring the sharpness of the teeth must be carried out taking into account precise exposure.

To sharpen the teeth on a carbide-tipped blade, you will need to smooth the cutting edge to 0.3 mm. To perform high-quality sharpening of carbide-tipped teeth, experts recommend using special equipment for this, as well as diamond-coated grinding wheels. If you use an abrasive wheel, it will quickly wear off before the soldered disc can be sharpened.

When restoring the sharpness of links, the following factors are taken into account:

- Saw blades must be sharpened not only on the front, but also on the rear plane. You need to start directly from the front

- When sharpening, the pobedit tip should be in close contact with the diamond sharpening wheel.

- The contact time should be no more than 5 seconds. It is necessary to take into account the time in order to avoid overheating of the metal. If the metal overheats, it will harden and decrease in hardness.

When sharpening, you must also take into account that the thickness of the material being ground should not be more than 0.15 mm. If the procedure is carried out correctly, then at least 30 sharpenings are carried out until the disk with pobedit tips is completely worn out.

You need to make your own decision about the rationality of restoring the sharpness of tipped discs, since the cost of a diamond-coated grinding wheel is sometimes more expensive than electrical drive equipment.

Read also: Determination of hardness by the Vickers method

Geometry of cutting elements

The working element of the saw - the tooth - has a certain geometric shape with the presence of not one, but several cutting edges. There is always one main edge and additional ones formed by the intersection of planes “A”, “B” and “C” in certain combinations. To work with different materials, it makes sense to select discs with the most suitable shape of cutting teeth.

Straight tooth

A saw blade with such a working zone is intended for rough cutting of lumber. The cut is rough, of low quality, and the operations are carried out relatively quickly.

Beveled tooth

The front plane of the cutting edge, made in this form, ensures cuts with an accurate and even line. The saw is ideal for working with composite type materials: plywood, chipboard (with single-sided and double-sided lamination). After cutting blanks of solid lumber, it is chipped, practically no chips are observed.

There are discs with a beveled leading edge of the cutter, some with a beveled trailing edge, or a variant with alternating teeth (variably beveled blade). When working with a tool with a beveled surface of the trailing edge of the cutting element when cutting hard wood, a clear, high-quality cut is observed, but the saw quickly becomes dull.

Trapezoidal tooth

The main advantage of such a saw is the slow wear of the disc due to the absence of the need for frequent sharpening on a sharpening machine. Typically, the entire blade line consists of alternating cutting elements - straight and trapezoidal teeth working in tandem. The taller trapezoid tooth roughs the cut, allowing the main straight edge to cut more easily. The tool can be used for cutting plastics and hard laminates.

Conical tooth

An auxiliary type of tool designed for cutting materials with a laminated surface prior to the main cut. The operation is carried out to avoid the appearance of chips on the front part of the product. This saw blade is not used as an independent working unit.

Crescent tooth

Blades with a concave tooth shape are convenient for cutting material in the transverse cutting direction relative to the location of the fibers.

- The movement of the workpiece on the work table during cutting occurs with the use of great physical force;

- Cracks and chips are observed along the cut line;

- During operation, the engine overheats;

- There is a burning smell in the air;

- The material burns, which appears as dark areas along the cut line.

If any of these signs are detected, you must immediately begin sharpening your circular saws yourself. Also, before carrying out work, you can check the sharpness of the saw, focusing on tactile sensations or visually using a magnifying glass. The permissible rounding radius of the cutting angle should correspond to a value of 0.1-0.2 mm. When cutting large workpieces, all working edges wear out.

Carbide tooth geometry

The teeth of saws, both solid ones made of high-speed steel and those equipped with carbide tips, have a specific shape. Some have the shape of an isosceles triangle, others are crescent-shaped, and others are generally made like a trapezoid. This tooth shape meets several objectives.

Firstly, each mold has several surfaces that form the cutting edges. Secondly, the type depends on the purpose of the tool: a small, even tooth is suitable for cutting thin sheet materials, and a trapezoid is suitable for working with hard wood. Thirdly, the duration of use depends on the shape: the trapezoid lasts longer than the straight or crescent type.

For household use the following discs are usually used:

- Straight teeth - for rough cutting of material. The main advantage is fast cutting of the material.

- Inclined and crescent teeth - designed for working with thin materials.

- Beveled teeth are used for finishing cuts of material.

- Trapezoidal type - saws for long-term work with materials of different densities.

- Conical teeth are suitable for finishing work on materials with a smooth, glossy finish.

As you can see, it is very difficult to sharpen such discs yourself without knowledge of sharpening technologies. The most difficult thing is to maintain the “correct” angle, so that both the geometry of the cutting edge and the shape of the tooth itself are achieved on all teeth.

Improper sharpening of a circular saw blade, at best, results in an uneven cut with crooked edges. And in the worst case, due to the beating that appears, the electric saw itself will have to be repaired.

Carbide tips requiring sharpening and a new saw