Popular models of moisture meters

There are a large number of models designed for highly targeted and varied measurements of moisture concentration. Some devices are equipped with additional functionality, for example, determining the temperature of the object of study and the environment, calculating average values for multiple measurements, and measuring air humidity.

The most popular are simple models of moisture meters with a budget price and sufficient capabilities.

The EM4806 device can measure the concentration of water in wood and building materials upon surface contact. The minimum recorded moisture is 5%, the maximum can reach 42%. The moisture meter operates in a wide temperature range, provides data with an error of no more than 2%, and has the most affordable price for the consumer.

The GMH 3830 device uses a probe to measure humidity up to 100% in material at a depth of up to 40 cm. The moisture meter operates at negative (up to – 25 °C) and positive (up to + 50 °C) temperatures.

A moisture meter with the trade name Hydro Pro determines the mass fraction of water in wood in the concentration range from 2% to a maximum content of 65% at a depth of 3.5 cm. The device operates only at positive temperatures, the value of which does not exceed 40 °C.

The range of measuring instruments for wood allows each consumer involved in its amateur or professional processing to select the most acceptable model. In general, contactless devices are noticeably more expensive than other devices. Having assessed your needs and opportunities, it makes sense to talk with a consultant and make an informed choice.

Brief overview of moisture meter models

- "EMCO" MP500 series. Digital display, 1 mAh battery, non-contact measurement. Price – 1,500 rubles.

- "Valcom" series EM4806. Small (about 100 g) mobile needle surface moisture meter. Price – 1,480 rubles.

For the private sector or small enterprise, these two devices (or those with similar characteristics) will be quite sufficient.

Conclusion - the choice of a moisture meter for wood is made individually. There cannot be only one correct recommendation. Every owner (entrepreneur) knows the working conditions and what kind of wood they have to deal with, so you should purchase a model “to suit” your interests. And as already said, it is advisable to have at least two devices.

Needle meters

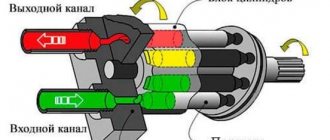

The contact method of deep humidity measurement is carried out using needle devices, the action of which is based on the conductometric determination of the electrical conductivity of the object of study.

Rigid thin metal needles are introduced into lumber and wood raw materials, which record the value of electrical resistance. The value is converted into a humidity indicator, which can be immediately seen on the display.

To obtain completely reliable information, the result must be checked with the special attached tables that take into account the influence of the medium temperature on the measurement accuracy.

To examine wooden boards, moisture meters with short needles are often used, which allows some marketers to present the devices as surface devices. In fact, they are not, because the defining elements are the needles inserted into the wood. The depth of surface damage when taking measurements with such a device is less than when using a conventional needle device.

Conductometric determinations make it possible to record moisture concentrations whose values are greater than 5%. To study objects with a lower concentration of water molecules, you need a high voltage source with characteristics from 500 to 1500 volts, which is impossible to achieve when using portable moisture meters.

Purpose and types of moisture meters

Standard methods for identifying the mass fraction of water in wood raw materials are based on determining the weight of the sample before and after drying when it reaches a constant weight. The procedure is carried out in several stages and requires careful execution and a long time.

In practice, there is often a need to quickly determine the moisture content of raw materials or wood products, which can be done using special compact meters.

There are several types of devices that differ in operating principles. Definitions could be as follows:

- optical;

- radiometric;

- inductive;

- infrared;

- ultra-high frequency;

- combined action.

The devices differ in the accuracy of measurements, the range of concentrations to be recorded, and the type of impact on wood.

How to choose?

First of all, when choosing any device, including a moisture meter, you need to clearly understand what you are going to use it for. If the hygrometer is intended to measure the moisture content of wood building materials, a cheaper and simpler needle moisture meter will suit you. If you are going to work not only with wood, but also with its, so to speak, derivatives - chipboard, MDF, sawdust, as well as plasterboard, alabaster and other materials, you better choose a more advanced and accurate model among non-contact devices.

Pay attention to the country and manufacturer. It is believed that the best quality measuring instruments are supplied to us by the Old World (Europe)

But among Russian and Chinese factories there are many whose products meet all international standards. They were mentioned above.

Carefully look through the passport of the intended purchase. All the main technical characteristics of the product must be indicated there, including the maximum measurement error. The best option is considered to be devices in which this figure does not exceed 3%. The cost and dimensions of the device also affect its commercial attractiveness. Agree, would you rather buy a compact device that is comfortable to hold and use than a more bulky analogue? There is nothing to say about the price - why pay more? And, of course, additional devices and improvements to the device are a pleasant bonus.

Instruments for surface measurements

Devices that record the dielectric constant of an object can work when placed on the surface of wood. The material does not undergo mechanical damage, so the method is suitable for working with finished products.

Reading of the required values when implementing the dielcometric method of determination occurs using a radio frequency generator, which produces waves with a frequency from 3 MHz to 30 MHz. When the contact part of the device is pressed against wood, the signal penetrates into the depth of the material to a distance of up to 30 mm. Based on the signal attenuation, the microprocessor records the dielectric constant and recalculates it into a humidity indicator.

Any performer can use the device without special training. It is enough to enter information about the type of wood, lean the device against the surface of the object with the contact part, press the button and look at the number that appears on the display of the moisture meter. The device provides accurate moisture content information at concentrations greater than 1%. If the mass fraction of water in the wood is less, the readings may have an error.

Purpose and types

A moisture meter is an electronic device designed to determine the moisture content as a percentage of the mass of the object being tested.

According to their purpose, such devices are classified as follows: for wood and bulk materials, for soil and soil, as well as other building materials.

Moisture meters for wood are used in woodworking and processing enterprises, in furniture and construction industries.

Using a moisture meter allows you to control the quality of the lumber used

Based on their design, moisture meters are classified as follows:

- needle - have two sharp electrodes that are immersed in a wooden surface, after which a measurement is performed;

- non-contact – they work without immersion in the material being tested; for this, just touching it is enough;

- surface measurement - similar in design to needle models, but differ in that when they are used, the needles of the device are only slightly immersed in the surface of the material being tested;

- depth measurement - massive instruments for professional use, when examining large volumes of lumber, sawdust and products made from them (fuel briquettes, pellets, etc.).

Needle type device, model “Testo 606-1”

Needle moisture meters for wood

Needle models, called conductometric devices, are calibrated for specific types of wood that differ in their resistivity.

When an electrical pulse passes, the meter compares the readings contained in it for a specific type of wood with the result obtained, which is reflected on the display.

The advantages of devices of this type are the following indicators:

- ease of use;

- high measurement accuracy;

- relatively low cost.

Disadvantages are also present, these include the following indicators, such as:

- during measurements, the surface of the material or product being tested is damaged;

- the measurement limit does not allow measuring humidity when its level is below 4%.

Dielectric type device, model “Testo 616”

Non-contact moisture meters for wood

Devices operating on a non-contact principle have a radio frequency generator in their design; they are called dielectric moisture meters.

When using devices of this type, it is necessary to apply a special contact surface to the measurement object or move it to a certain distance, which depends on the model of the device and the type of measurements being performed.

The advantages of meters of this type are the following indicators:

- the wood is not damaged during measurements;

- low percentage of error in the results obtained;

- The presence of memory makes it easier to use when taking measurements.

Disadvantages include high cost and the inability to carry out repairs on your own.

Using a dielcometric model when checking the moisture content of board materials (chipboards)

Types of moisture meter models

The main difference between all wood moisture meters is in the type of sensors and the principle of measuring moisture content. The technical side of the issue is unlikely to be interesting to the reader, and many will not understand it (dielectric constant, indirect calculation of resistance). Therefore, we will analyze the feasibility of purchasing moisture meters of various modifications from a practical point of view.

Needle (conductometric)

General characteristics:

- Humidity measurements are made only at positive temperatures. At 0 0C and below, the error increases sharply.

- Reading accuracy – ±0.2%.

- Limit (maximum) – 35%.

Surface measurement

The sensors in such moisture meters are short needles that are immersed shallowly in the wood. Such devices are compact and easily fit in your pocket. Considering the depth of the sensors, the main purpose is to measure the moisture content of the board.

Depth measurement (probe)

The dimensions of such moisture meters are larger, but they allow you to work with a wide range of wood samples - timber, logs, thick boards, piled wood chips or sawdust. The readings from the device give an accurate idea of the liquid content throughout the entire structure of the material. The only thing required is careful use. Carelessness leads to breakage of the needle, which is then unlikely to be removed from solid wood.

Non-contact (dielcometric)

The set of such moisture meters includes sensors that are either mounted on the surface of the wood or built into the body of the device, and it is placed on the controlled sample. Such models are the only possible option for measuring the moisture content of parquet (piece or board), laminate, plywood and other materials characterized by high density.

And it is hardly advisable to pierce such samples with probes, understanding that after measurements there will be irremovable traces. The sensors are not immersed in wood, but are fixed on its surface without damaging the material.

When choosing such a model, you should clarify what types of wood the device can work with (range of settings).

GMH 3830

This device is universal. It can be used to take moisture measurements not only in wood, but also in materials such as:

- cardboard and paper;

- cork and textiles;

- concrete and aerated concrete;

- brick, plaster, etc.

Advantages:

- shows the direct value of the moisture content in %;

- user-friendly interface;

- good temperature compensation;

- ease of maintenance;

- automatic shutdown.

The disadvantage is the high price.

As a conclusion, we note that you should select a moisture meter individually, taking into account the specific situations in which you will use it. Happy shopping!

general information

Without knowing what types of moisture meters the industry produces, it is impossible to make the optimal choice. The fact is that the devices differ in their operating principle, but in fact they have to work with different workpieces. Wood is a general concept. This category of building materials includes logs, timber, boards, plywood, and so on. It will not be possible to determine humidity with the same moisture meter in all samples without exception. In principle, everything is possible, but in some cases the error will be such that the data from the measurement results will tell us absolutely nothing.

If you have to work with wood constantly, with its various species and preparations, then it is worth purchasing at least a couple of different types of moisture meters. It will be cheaper than one universal one, but at a high price.

How to choose?

Weighing moisture meters can be used to study not only solids, but also air. Devices operating on this principle are accurate. However, they are used mainly in laboratories, since they require the use of other precision equipment. Hair instruments are suitable for working with gases, but they cannot be used to study solids and non-aqueous liquids. A conductometric moisture meter works simply and quickly, but it will not measure very low (less than 5%) humidity.

The needle device is not suitable for furniture and finishing wood. Scanning tips will leave ugly marks in the material. It is imperative to take into account the degree of error and the measurement range (the highest measured level).

Internal memory plays a very important role. Even non-specialists can benefit from comparing measurements taken at different times. The body of a good moisture meter is durable and lined with rubber. It is recommended to give preference to devices with batteries or a rechargeable battery rather than those with mains power. Of course, you should carefully study reviews about a specific model.

Peculiarities

Everyone knows that wet objects and materials weigh much more than their dry counterparts. The traditional method of determining the degree of moisture is based on this - during the drying process, the material is weighed several times, the difference in mass provides the basis for calculating the level of moisture content in the object. Why is this method inconvenient? It requires too much time and extra effort.

Nowadays, compact devices - moisture meters (or hygrometers) - easily cope with this task. What are their advantages? Firstly, they make measurements easy and simple; they do not require bulky equipment or laboratory conditions. Secondly, you can choose the measuring location yourself - by the way, evenly dried wood is considered to be of the highest quality; the pattern of water distribution in the material can be determined only by several samples in different areas of the lumber. Thirdly, accessibility to a wide range of users and a variety of device types.

Advantages of contactless devices

Such devices implement non-destructive analysis of the material, which is important in the examination of decorative wood panels. This method is achieved through sensors installed on the working part of the device. They replace the probes of contact models, but record data at a distance. Moreover, some representatives of this class provide scanning at a depth of up to 5 cm. It is advisable to use a non-contact wood moisture meter precisely in cases where the study of the lower threshold of values is required. Also, the advantages of contactless devices include the ability to analyze the temperature and humidity of the air.

Testo 606-2

The device combines three functions: measuring the moisture content of concrete, mortar screed and brick; measuring temperature and air humidity. The model's body is protected from moisture, so it can be used outdoors in bad weather. The humidity measurement range is from 7 to 22.1%. All indicators provide accurate data. The device was assembled according to high technology standards, which made it possible to make the model truly high-quality. It is suitable for long-term work and is very comfortable in the hand due to its small size and light weight.

Pros:

- Convenient and easy to use;

- High accuracy of results;

- Informative display;

- Measures moisture, temperature and moisture in the air;

- Product durability;

- Responsive keys;

- Waterproof housing.

Minuses:

- High price.

Advantages of use and types of moisture meters

The use of a compact device has its undeniable advantages, the main one being high quality analysis. Such devices are relatively inexpensive, and you will not experience any difficulties when handling them.

The moisture meter only requires a battery to operate.

What can be written down as a minus for him? Well, perhaps the need to make a small hole in the material being tested with a probe. This can be difficult if you are planning, for example, to check a finished product made of expensive wood. You will have to look for an inconspicuous place to conduct the analysis. Well, there is one more insignificant drawback - the device will not provide accurate information about humidity less than 4%. Although, if there is 4%, then this is a normal figure.

Moisture meters are available in different versions depending on the principle of analysis

Needle moisture meters for measuring wood moisture

Such devices are actively used in professional woodworking. Humidity measurement occurs in the thickness of the material at a depth of up to 4 cm. The operating range of the device is from 5 to 50%.

Needle Moisture Meter

Moisture meters for surface analysis

In such devices, the probes are short in length. These are compact devices for pocket carrying for household purposes. With their help it is easy to measure the moisture content of the board.

Probe penetration depth – up to 1 cm

Wood moisture meters for deep measurements

Deep instruments will show the condition of timber, logs and thick boards. They are also used to determine the moisture content of wood chips and sawdust used in the production of pressed boards. The main problem in using this professional device is the fragility of the long needle.

In order not to break the needle, certain skill is required during analysis.

Surface or dielectric moisture meters

Modern developments make it possible to study the moisture content in objects without violating their integrity. This is exactly how dielcometric moisture meters work. Non-contact wood moisture meters are simply placed on top of the product without damaging its integrity. This is very convenient if you need to analyze furniture or parquet made of expensive species.

A similar device can measure the moisture content of plywood and laminate

Rating of the best moisture meters

| Nomination | place | Name of product | price |

| Rating of the best moisture meters | 1 | LASERLINER MoistureMaster Compact 082.333A | 20 146 ₽ |

| 2 | MEGEON 20550 | 20 330 ₽ | |

| 3 | TESTO 606-1 | 9 500 ₽ | |

| 4 | CEM DT-172 | 6 100 ₽ | |

| 5 | MEGEON 20725 | 2 490 ₽ | |

| 6 | CONDTROL Hydro-Test 3-14-022 | 1 990 ₽ |

LASERLINER MoistureMaster Compact 082.333A

Rating: 4.9

The German-Chinese moisture meter LASERLINER MoistureMaster Compact 082.333A is distinguished by its simplicity and reliability. Using this professional instrument, it is possible to determine humidity in different materials with high accuracy (0.2% error). Experts note a large measurement range (0-66.5%) and a wide range of applications. Builders use the device to control the moisture level of cement screed, concrete, and gypsum plaster. For carpenters, the moisture meter is interesting because it stores 56 types of wood. For instant data processing and a 12-segment backlit indicator, the model takes first place in our rating.

Users praise the moisture meter for its high accuracy, rapid analysis and unpretentiousness. The only drawback is the high price.

Advantages

- high build quality;

- precise measurements;

- wide scope of application;

- rapid determination of humidity.

Flaws

- high price.

Features of contact models

This is a traditional type of moisture meter, which is equipped with special needle probes that perform the measurement. The operating principle of such models is based on the conductometric method. That is, the calculation of indicators is carried out directly through the value of electrical resistance that occurs between the probes. During operation, a needle wood moisture meter is brought close to the object under study, after which the environmental data is analyzed. The information is then converted into percentage moisture content. The essence of this method is that the electrical resistance changes depending on humidity levels.

The advantages of contact devices include design simplicity, ease of setup and handling, as well as high measurement speed. On the other hand, wood moisture meters are not always accurate when working with material whose moisture content is up to 5%. Moreover, especially for wood, it is desirable that the probes be small.

Working principle of the moisture meter

Previously, wood moisture content was determined exclusively according to GOST. This method is quite complicated and takes a lot of time. It involves separating a small piece of wood, weighing it and drying it in a special drying cabinet. To find out the moisture content, the sample is reweighed in its dried form and the results are compared. As a rule, the sample must spend at least 24 hours in the drying cabinet, but in practice the drying time can last up to three days.

Despite the accuracy of the result, this method has many disadvantages. Firstly, this is, of course, the timing of the research. Secondly, for the experiment it is necessary to separate a piece. When it comes to a finished product, this is, of course, unacceptable.

There is only one salvation - a moisture meter for wood. This small device produces the required result in a matter of seconds. The principle of its operation is quite simple. It is based on the value of the electrical resistivity of the wood. Depending on the humidity, this value changes. In addition to the speed of research, the advantage is the fact that there is no need to damage the product by separating a particle from it.

A wood moisture meter measures the moisture content of a product as a percentage. The only drawback of this device is that it can produce a small error. It ranges from 2-10%. As for the first measurement method (according to GOST), the error does not exceed 1%.

This error occurs for two reasons. The first reason is the product of local measurement. However, this can be solved by taking measurements in several places. The second reason is that the electrical resistivity of wood depends not only on its moisture content, but also on another factor, namely the density of the material. The fact is that each type of wood has its own density. This is important to consider when working with the device.

Overview of species

Currently, you can find several types of hygrometers (depending on the method for determining the level of water content in the material).

- Conductivity meter. Measures electrical conductivity and calculates the degree of humidity based on deviation from the standard.

- Dielmeter. Measures the dielectric constant and, based on the difference with the reference value, determines the water content.

- Infrared and microwave meters. In the first case, the degree of reflection of infrared rays is determined, in the second, the degree of absorption of high-frequency radiation. These types of hygrometers cannot be classified as compact products - they are installed permanently at large woodworking enterprises.

Needle-shaped

Another name for conductometers is needle moisture meters. They got it from two electrode needles that are dipped into wood to measure the current between them. The length of the needles can vary from 1.5 to 2.5 cm, the distance between them depends entirely on the manufacturer.

Contactless

Dielcometric or non-contact (induction) hygrometers work on a different principle - the test sample is placed in an artificially created EM field. This generates a high frequency electric current. Its strength depends on the humidity of the environment in which it is formed.

CMT DMM-001

The universal model of the moisture meter allows it to be used to measure the moisture of wood, drywall and concrete. It has very small dimensions and an insignificant weight of 86 grams. Thanks to this indicator, you can carry the device in your pocket and not notice it. The case is made of fairly durable plastic, which is completely protected from moisture getting inside. Moreover, it can withstand temperature changes and minor mechanical shocks. The device measures humidity in wood from 5 to 50%, and in plasterboard and concrete from 1.5 to 33%. The model produces an insignificant error of 0.3%. The display is bright and it is easy to see current information.

Pros:

- Waterproof housing;

- The case can withstand light mechanical shocks and temperature changes;

- Small percentage of error;

- Bright display;

- Little weight;

- Convenience and ease of use.

Minuses:

- High price.

Basic selection options

The main characteristic of the device is the range of measured indicators. This is the range of humidity coefficients that the device will, in principle, be able to record. There are models that are capable of determining readings on a scale from 0 to 100%

But here it is important to understand that models with narrow ranges most often turn out to be more accurate and productive, since they are designed for a less extensive amount of data processing. In addition, the target material does not always require a wide range of examination.

This depends on the area in which you plan to use the wood moisture meter. How to choose a device based on this indicator? For lumber, for example, they are usually limited to a range from 1 to 45-50%. This “corridor” contains the optimal humidity for building materials. But for forestry workers who carry out taxation, it is important to have a universal model for recording extreme values. The error of the apparatus should also be taken into account. On average, it is in the range of 0.1-3.5%, but even in this case it is not always necessary to strive for the highest values. Accuracy up to 0.1-0.2% is usually required in highly specialized areas of construction or industry.

How to use?

How to correctly measure the degree of dryness of wood and other materials using a moisture meter? Is it necessary to calibrate and configure the device during operation? How to correctly interpret different-sized device readings at different measurement locations? We will try to answer these questions. So how do you measure moisture with a needle moisture meter?

Mark several areas for measurements, immerse the electrodes of the device into the thickness of the wood and turn it on. The display should show the moisture content level. Perform similar actions on all selected places. As you can see, there is nothing complicated about this.

If you purchased a non-contact moisture meter, you can determine the moisture level of the wood as follows: place the sample within reach of the electromagnetic field that the device creates and wait a little. A microprocessor built inside the device will measure the strength of the high-frequency current that appears in the EM field and display the results on the display. Calibration of moisture meters is necessary if you measure the humidity of different materials with the same device. The technical data sheet and operating instructions provide tables for such measurements.

For information on how to choose the right moisture meter, see below.

Additional moisture meter options

In some cases, certain functions can be very useful. What else can be measured?

- Average humidity value. If you have to check large volumes of wood, the device itself will give the final result. Therefore, you don’t have to take several measurements in different places and do calculations.

- Environmental parameters – temperature, humidity. In the case of processing wood in a drying chamber, organizing its long-term storage, these options are very necessary. They will help control local conditions and regulate the process.

Photos of the best moisture meters for wood

Best models

If you need to measure grain moisture, the Fauna-M model is suitable. This is a microprocessor device designed for oilseeds and grains. “Fauna-M” can be used during harvesting, and when monitoring the quality of harvested grain, and during storage, and during express analyzes during processing. The device operates in a dielectric method, and the measurement results are displayed on an alphanumeric display with backlight. There is a sensor that determines the temperature of the grains; There is also a setting that compensates for errors caused by temperature changes.

By adjusting the calibration of the device, you can adapt it to a specific type of grain crop. Even in the most difficult cases, the measurement error will not exceed 1.5%. The system is designed to work with:

- wheat;

- soybeans;

- peas;

- sunflower;

- rapeseed;

- triticale;

- mustard;

- flax;

- 8 more crops;

- optionally with chickpeas, safflower and other grain plants.

Testo 606-1 is a moisture meter for measuring the water content in wood and building materials. The model is included in the federal state register. Its memory contains characteristic curves for various types of controlled substances and wood species. You can successfully explore:

- beech;

- cement beacons;

- maple;

- concrete mixture;

- brickwork;

- pine;

- plaster;

- larch;

- mortar;

- spruce.

Thanks to the Hold option, reading measurements is simplified. The moisture meter from Testo lights up the screen and performs self-diagnosis if necessary. Other features worth noting:

- cover for protected storage;

- carrying strap;

- proprietary calibration protocol included;

- weight 0.09 kg;

- dimensions 0.119x0.046x0.025 m;

- error no more than 1%;

- measurement every second.

Condtrol Hydro-Tec is also an excellent moisture meter for working with wood and concrete. The device works very quickly. The design allows you to set the moisture content in the range of 2-65% in layers up to 0.02 m deep. The built-in sample library contains 20 types of wood, but not randomly, but divided into 9 groups. The manufacturer claims that Hydro-Tec is professional grade.

Therefore, it is readily used in woodworking, furniture, parquet, molding, window and door industries. The company warranty is given for 2 years. The device is included in the federal register. Requires a pair of AAA batteries to operate. The measurement takes no more than 1 second; and the relative air humidity during operation should not exceed 85%, permissible temperatures - 5-40 degrees above zero.

For wood and grain, Gann Hydromette Compact from Germany can be used. The German product can also work with sawn wood, fiber and particle boards no thicker than 0.025 m, gypsum and plaster. This needle-type moisture meter allows you to take into account the temperature of the material according to the table included in the delivery set. The moisture content of the plaster is indicated as a percentage of the dry mass. A 9 V dry cell or a rechargeable battery is used for power supply.

Separation by purpose

Each moisture meter is designed to work with specific materials. Water saturation occurs differently for different objects; if you use a device for wood with grain, it will not show accurate data.

Moisture meters are in great demand among furniture makers, carpenters and builders, and at logging enterprises. If the board is not dried enough, it may become deformed in the future. Wood moisture content is measured using needle devices. Typically, wood moisture meters have several modes, so they can be used with different species at once.

Moisture meters are no less necessary in the food industry and in agriculture, where these devices are used to determine the moisture level of bulk materials. To determine the moisture content of grain, they most often resort to devices with a container.

To decide whether to water the soil, a moisture meter is also used. To accurately measure soil moisture, prepare a fresh hole in advance, since the device cannot go deeper than 10 centimeters.

In the construction industry, these devices allow you to determine the moisture level of building materials. Universal devices work with a large number of materials - from concrete to lathing.

What are moisture meters used for?

Electronic moisture meters have come into use relatively recently. Before their invention, humidity levels were determined according to state standards. The research took a lot of time and required compromising the integrity of the samples. With the advent of electronic sensors, everything has become much simpler and faster: they measure the electrical resistance of a material and produce a result in a matter of seconds.

Electrical resistance depends on the amount of water in the wood

The moisture meter has an error of up to 4%, which should be taken into account if you are measuring, for example, a trunk. For accurate results, you need to take measurements in at least three places, at the ends and in the middle of the workpiece. It must be remembered that wood species have different densities. This factor can also affect the measurement error.