Travelers need a caravan on a long journey; it allows them to take with them all the necessary things, and there may be a lot of them. Industrial trailers are presented in a wide range, but they have one significant drawback - a fairly high price.

- 1 Material for trailer

- 2 DIY car trailer: assembly drawings

- 3 Types of DIY trailers

- 4 Cost of an industrial car trailer for a passenger car

- 5 Tools for making a homemade trailer

- 6 DIY trailer collection

- 7 Do-it-yourself dump-type passenger trailer

- 8 Towbars for cars

- 9 Registration of a homemade trailer in the traffic police

- 10 DIY trailers for cars: video

To save money, you can make a trailer for a car with your own hands; for this you will need to draw up a drawing, buy the necessary material, and have the tools for manufacturing available.

Trailer material

Often, in the garages of car owners, various rubbish lies as unnecessary cargo, which is a pity to throw away, but it has not found any use. We need to dig into these things and see if maybe something will be useful for making homemade items. What may be useful:

- wheels and springs from an old car, disassembled for parts;

- pieces of sheet iron;

- channel or corner;

- various fasteners (nuts, bolts);

- pieces of automotive electrical wiring.

You need to decide for yourself what the load capacity of a car trailer (AT) should be - the car’s passport details indicate what the maximum weight of the trailer is designed for. If some material is missing, you will have to buy it in addition; you also need a plug to connect the car's electrical wiring to the AP.

Sides and bottom

The following materials can be used for cladding:

- steel sheets;

- polycarbonate;

- tree, etc.

The choice here depends solely on your financial capabilities and the operating characteristics of the structure. At the same time, it is advisable to make the corners from steel, no matter what material you choose. Regardless of the type of skin, it is attached to the frame using bolts.

DIY car trailer: assembly drawings

When all the necessary material has been collected, you can begin drawing up the drawing. It’s not very easy to draw a sketch of a future product on paper yourself, so to make the task easier, you can take a ready-made drawing from the Internet as a basis, and make your own adjustments to it as you create the design. The car owner should also remember that the homemade product will have to be registered with the traffic police, and it is important to note that the coupling device can only be used at a factory.

For example, the drawings of the Zhiguli AP can serve as a model for a future trailer, if the vehicle itself is similar in size and carrying capacity to this car model. Any car trailer consists of the following main parts:

- body;

- frames;

- drawbar;

- coupling device.

In any case, the frame must be rigid, so it is made of durable steel. As a rule, the body is also made of ferrous metal, but it can also be made of aluminum or wood.

Sewing the product

Making awnings for passenger trailers requires attention and the presence of correctly measured and neatly cut parts. All awnings are assembled together from several separate pieces, folded at the edges and stitched with two seams spaced 14 mm from the edge. The threads that will be used in sewing must be as strong as possible. The best option is reinforced threads made from polyester. This kind of thread can withstand frequent use, is resistant to stress, cleaning from leaves, dirt and snow.

If the car owner does not have the skills to use a sewing machine, you can resort to soldering the parts of the awning with a construction hairdryer, which can efficiently connect individual pieces of material.

Read also: Vertical drilling machine 2s132 technical characteristics

Types of DIY trailers

A homemade trailer for a passenger car usually has one axle, but it can also be biaxial. The main advantages of a two-axle trailer are:

- road stability;

- large load capacity.

But the biaxial design has its drawbacks, such a trailer:

- more difficult to control, especially during manual maneuvering;

- weighs quite a lot;

- less mobile.

When making crafts, it should be taken into account that a single-axle vehicle must be designed for a load weighing no more than 750 kg. The rules for operating cars with trailers also state that the load on one wheel cannot exceed 700 kg.

Caravans vary according to type of use:

- general purpose, for transportation of goods;

- tourist (motorhomes);

- commercial;

- for transportation of boats and yachts;

- special purpose

Trailers are often equipped with an awning, and motorhomes are also popular among motor tourists, which are very convenient on long journeys. True, to transport such a design, a passenger car must have sufficient carrying capacity; crossovers and SUVs are well suited for towing.

Sheathing options

First, let's talk about making the sides. Namely, about materials that are suitable for extension structures. Let's try to figure out what to make the sides from and how these or those materials differ.

In total, the following options can be distinguished.

- Profile pipe. This way you can make a profile from scratch or build up existing trailer structures. Weld respectively to the vehicle frame or existing sides. A frame is made from a profile pipe, which is mounted on a trailer. Next it is covered with laminated plywood. It is important here that the plywood thickness is at least 9 mm;

- Aluminum or stainless steel. It is a very good material for supervisors because it lasts a long time, does not rust and has excellent characteristics. At the same time, aluminum extensions are expensive, which is why some people are put off by the price;

- Plastic or fiberglass. It's rare, but it does happen. Mainly suitable for creating mobile homes or some kind of mobile residential complexes. The materials are too fragile for loading operations;

- Side profile. An excellent option that is convenient to work with. Available in different suitable sizes and configurations;

- Steel sheets. Here it is also worth making a frame and then sheathing it with steel sheets. The option is cheaper than aluminum and stainless steel, but it will require additional thought about the safety of the metal from the negative effects of corrosion;

- Profiled sheeting. In general, in theory, you can take a galvanized sheet and bend it to the required configuration. But in practice it is easier to take a ready-made metal profile, the ridge of which is equal to C10.

There are quite a lot of materials. You should choose the one that will be practical and beneficial for you. Don’t save, so that later the savings don’t turn into disappointment for you. Manage your budget wisely.

Many people prefer homemade designs because their price is much lower. But the modification becomes somewhat more complicated, since you will need to buy all the materials, components, fasteners, install a lock, hinges, etc. If the latch turns out to be inappropriate for the design, difficulties will arise with fixing the tailgate.

Before you make yourself additional sides, the height of which will meet your requirements, decide on the trailer you will be working on.

Quite often, the following trailers are used as a basis for the modification and installation of extension sides:

- Kurgansky;

- Leader Plus;

- Flint;

- Sturdy;

- Satellite;

- Bee;

- MZSA;

- Taiga;

- VSW;

- KMZ, etc.

If you doubt your decision to do everything yourself, you can always turn to specialists for help. Good craftsmen work in cities such as Samara, Moscow, Volgograd, Nizhny Novgorod, etc. At a minimum, it is worth consulting and deciding whether to do everything yourself, or purchase ready-made structures.

The cost of an industrial car trailer for a passenger car

Industrial trailers have different prices, the price depends on:

- on the complexity of manufacturing;

- dimensions;

- quality of materials used;

- type (purpose);

- configurations

The simplest general purpose trailer will be the cheapest in terms of cost, for example, you can buy a trailer of the LAV-81011 model from on average for 40 thousand rubles. The characteristics in this design are as follows:

- own weight – 175 kg;

- weight of transported cargo – 525 kg;

- The maximum weight of a loaded aircraft is 700 kg.

The trailer has dimensions of 2.9/1.6/1.28 m (length/width/height) and has a very good ground clearance of 167 mm. LAV-81011 is equipped with an awning, its height is 0.45 m. The sides of the body in this model can be folded down or completely removed; there are two modifications.

There are trailers that are much more expensive, for example, a trailer for transporting boats costs on average from 200 to 350 thousand rubles.

Tool for making a homemade trailer

To make homemade products, designers primarily use welding; there are motorists who only use it. Using gas welding, you can not only weld structural parts, but also cut pieces of metal of the required size with a cutter.

Even when assembling a homemade structure, the following is often used:

- angle grinder (grinder);

- automotive tools (spanners and socket wrenches, sockets with wrenches and extensions).

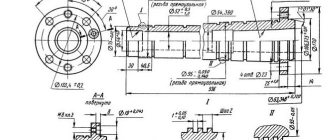

Structure axis

Next we move on to the axle. As a rule, it is installed at the rear of the trailer, at a distance of 40 percent of the length of the entire structure. After all measurements are taken, the frame is turned over on a flat area. Mostly, the axle is assembled and mounted using bots . Installation can begin only after taking control measurements (the center of the axis must coincide with the center of the connecting unit).

DIY trailer collection

Having drawn up the drawings, the DIYers first begin to manufacture the frame. To compose it, a steel channel is very often used, so that the metal can withstand loads well; its cross-section must be at least 25x50 mm. Also, the frame is often made of a metal pipe, but it is more convenient to work with a channel.

The rolled metal is first cut to the dimensions indicated in the drawing, then the sections of the channel profile are welded together. After welding the main body, the frame should be reinforced with additional stiffeners, otherwise the structure will be unreliable.

If you plan to create a trailer on springs, brackets should be welded to the frame. The springs will be attached to the frame base with bolts and nuts, and the axle and springs will be connected using stepladders. The brackets are welded with a slight offset to the rear of the structure, this ensures the greatest stability of the homemade trailer.

Next, you need to weld a drawbar to the frame, and mount a towbar at its end. If the connection point between the trailer and the car is made too long, driving the trailer will not be very convenient, and it will be especially difficult to maneuver in reverse. The drawbar must be welded strictly in the center, otherwise the trailer will pull to the side. Even for a single-axle design, it is necessary to distribute the weight so that the main load of the empty AP falls approximately on the bogies; the heavier the carts, the force on the coupling device will increase, and it will be under constant tension.

At the end of the unit, a part of the coupling device is installed; the towbar can be attached rigidly to the drawbar by welding or with bolts and nuts.

Next you should work on the body; the easiest way is to make it from plywood or wood. The plywood floor is screwed to the base with bolts and nuts; the sides are better made of a more durable material - wood or sheet iron. It would also be a good idea to cover the floor with sheets of iron; plywood can quickly become scratched and become unusable.

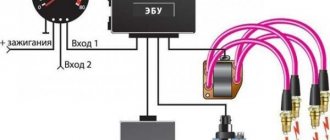

But the assembly of the trailer does not end there; it is still necessary to install the rear lights and connect the wiring. Two-axle trailers are often equipped with brakes; the braking system makes driving the vehicle easier. It is especially important to install brakes on trailers for transporting heavy loads weighing more than 1400 kg.

Where to begin

To begin with, your car must have a towbar; you can buy it here: vseafarkopy - a towbar store in Moscow. The trailer is based on a frame. It is its strength and rigidity that determines the period of operation of the trailer, as well as its ability to transport various types of cargo. To achieve increased frame strength, a welding method should be used when connecting individual elements.

However, if your plans are to make a trailer for a passenger car with your own hands, then you need to start not with this, but with clarifying the parameters related to the length and width of the supporting structure.

The frame dimensions are calculated from the outside of the frame. When measuring the width, you should measure the distance from the inner side walls, and then add two wall thicknesses to them. If the base is between the wheels, then it is also necessary to add two lengths from the wheel to the side.

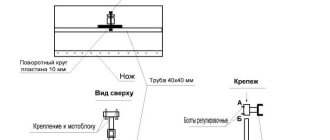

Next we do our first fitting of the support. We lay out the metal profile (pipes with a cross section of 40*40 are ideal) on a flat surface, it is important that the elements are perpendicular to each other. Next, making the trailer with your own hands, we fasten the components using temporary clamps. After that, we take a tape measure and check what parameters we have obtained.

It is important that the length of the frame along the two diagonals matches each other. In this case, a deviation within three percent of the obtained value is allowed. If everything is fine, we weld the structure.

Next, you can add a stiffener, because rectangular and square structures are not very resistant to various types of loads.

Pipes and channels are also suitable for the side frame. True, here the requirements for materials are not as strict as in the case of the frame.

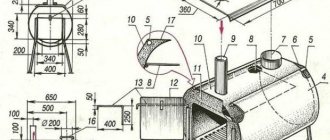

Do-it-yourself dump-type passenger trailer

An AP is often necessary for transporting bulk cargo - river sand, gravel or crushed stone. Unloading construction materials from a regular body is inconvenient - unloading takes a lot of time. You can make the task easier by installing a tipper-type trailer on the body, with a reverse tipping mechanism.

The frame and axle in this design have a movable connection, and a manual body lifting mechanism is installed in front.

You don’t have to install the mechanism, but then you need to weld a support in front. In this embodiment, the body will therefore tip under its own weight when the locking device is removed.

For a homemade dump truck trailer, it is important that its sides tumble.

Towbars for cars

To connect the trailer to the car body, you need to install a tow bar on the car. A towbar for a car consists of parts:

- hinge with excess;

- power beam;

- sockets for connecting wires.

The industry produces towbars of various designs; there are trailer hitches in which the hook is welded to the beam, and together with the hinge it represents a single, monolithic structure. But more often hinges are produced with a removable hook, and this version of the device has the advantage that in case of damage to the coupling joint or wear of the ball, the coupling can always be replaced.

There are also TSUs where the bullet can be removed from the hook and it can be changed separately. Many towbars are equipped with a safety device that prevents complete loss of connection between the car and the trailer; it is necessary for safety.

Methods of fastening the awning structure

The material for the trailer awning provides several mounting options. The car owner can resort to the following methods:

- attach the manufactured structure to the main body using metal rings;

- create eyelets by placing them along the edges of the fabric;

- pull a cable or rope through the rings located above the general structure.

The lugs must be removed by 200 mm, in addition, all rings must be equipped with fasteners.

Cable and rope can be used as a fastening element. Regardless of the method of fastening, the retaining element must consist of a single piece, the edges of which are reinforced with metal tips. When securing the awning, the retaining device must pass through the rings and be tightly stretched.

Registration of a homemade trailer in the traffic police

Any homemade car trailer must be registered with the traffic police; for this you need to provide:

- sales and cash receipts for components and parts purchased for assembling a home-made structure;

- four photos 10 by 15, photos must be from all sides of the trailer;

- personal passport;

- application for registration;

- receipts for payment of state fees.

After registration, license plates are issued for the trailer; technical inspection for trailers with a carrying capacity of up to 3.5 tons is not required if the trailer belongs to a private person.