Basic information

Young's modulus (also called the longitudinal modulus of elasticity and the modulus of elasticity of the first kind) is an important mechanical characteristic of a substance. It is a measure of resistance to longitudinal deformation and determines the degree of rigidity. It is designated as E; measured in n/m2 or in Pa.

This important coefficient is used when calculating the rigidity of workpieces, assemblies and structures, and in determining their resistance to longitudinal deformations. Substances used for the manufacture of industrial and building structures, as a rule, have very large E values. And therefore, in practice, E values for them are given in gigaPascals (1012 Pa)

The value of E for rods can be calculated; for more complex structures it is measured during experiments.

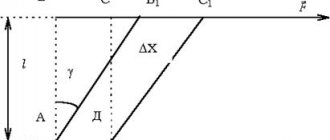

Approximate values of E can be obtained from the graph constructed during tensile tests.

Tensile test schedule

E is the quotient of normal stress σ divided by relative elongation ε.

E=α/ε

Hooke's law can also be formulated using Young's modulus.

Methods for determining and monitoring strength indicators of metals

The development of metallurgy and other related areas for the production of metal objects is due to the creation of weapons. At first they learned to smelt non-ferrous metals, but the strength of the products was relatively low. Only with the advent of iron and its alloys did the study of their properties begin.

The first swords were made quite heavy to give them hardness and strength. Warriors had to take them in both hands to control them. Over time, new alloys appeared and production technologies were developed. Light sabers and swords came to replace heavy weapons. At the same time, tools were created. With increasing strength characteristics, tools and production methods were improved.

Types of loads

When using metals, different static and dynamic loads are applied. In the theory of strength, it is customary to define the following types of loads.

- Compression - an acting force compresses an object, causing a decrease in length along the direction of application of the load. This deformation is felt by frames, supporting surfaces, racks and a number of other structures that can withstand a certain weight. Bridges and crossings, car and tractor frames, foundations and reinforcement - all these structural elements are under constant compression.

- Tension - the load tends to lengthen the body in a certain direction. Lifting and transport machines and mechanisms experience similar loads when lifting and carrying loads.

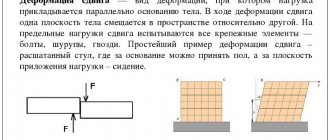

- Shear and shear - such loading is observed in the case of forces directed along the same axis towards each other. Connecting elements (bolts, screws, rivets and other hardware) experience this type of load. The design of housings, metal frames, gearboxes and other components of mechanisms and machines necessarily contains connecting parts. The performance of devices depends on their strength.

- Torsion - if a pair of forces acting on an object are located at a certain distance from each other, then a torque occurs. These forces tend to produce torsional deformation. Similar loads are observed in gearboxes; the shafts experience just such a load. It is most often inconsistent in meaning. Over time, the magnitude of the acting forces changes.

- Bending – a load that changes the curvature of objects is considered bending. Bridges, crossbars, consoles, lifting and transport mechanisms and other parts experience similar loading.

In the middle of the 17th century, materials research began simultaneously in several countries. A variety of methods have been proposed for determining strength characteristics. The English researcher Robert Hooke (1660) formulated the main provisions of the law on the elongation of elastic bodies as a result of the application of a load (Hooke's law). The following concepts were also introduced:

- Stress σ, which in mechanics is measured in the form of a load applied to a certain area (kgf/cm², N/m², Pa).

- Elastic modulus E, which determines the ability of a solid body to deform under loading (applying force in a given direction). Units of measurement are also defined in kgf/cm² (N/m², Pa).

The formula according to Hooke's law is written as ε = σz/E, where:

- ε – relative elongation;

- σz – normal stress.

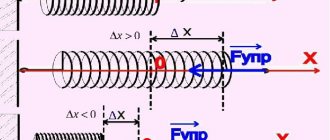

Demonstration of Hooke's law for elastic bodies:

From the above dependence, the value of E for a certain material is derived experimentally, E = σz/ε.

The modulus of elasticity is a constant value that characterizes the resistance of a body and its structural material under normal tensile or compressive load.

In the theory of strength, the concept of Young's modulus of elasticity is adopted. This English researcher gave a more specific description of the methods of changing strength indicators under normal loads.

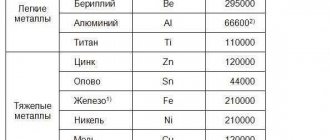

The elastic modulus values for some materials are given in Table 1.

Table 1: Modulus of elasticity for metals and alloys

| Name of material | Elastic modulus value, 10¹² Pa |

| Aluminum | 65…72 |

| Duralumin | 69…76 |

| Iron, carbon content less than 0.08% | 165…186 |

| Brass | 88…99 |

| Copper (Cu, 99%) | 107…110 |

| Nickel | 200…210 |

| Tin | 32…38 |

| Lead | 14…19 |

| Silver | 78…84 |

| Gray cast iron | 110…130 |

| Steel | 190…210 |

| Glass | 65…72 |

| Titanium | 112…120 |

| Chromium | 300…310 |

Physical meaning of Young's modulus

During a forced change in the shape of objects, forces are generated inside them that resist such a change and strive to restore the original shape and size of elastic bodies.

If the body does not resist changing shape and remains in a deformed form after the end of the impact, then such a body is called absolutely inelastic, or plastic. A typical example of a plastic body is a block of plasticine.

Types of deformation

R. Hooke studied the elongation of rods made of various substances under the influence of weights suspended from the free end. The quantitative expression of the degree of change in shape is considered relative elongation, equal to the ratio of absolute elongation and original length.

As a result of a series of experiments, it was found that absolute elongation is proportional with the elasticity coefficient to the original length of the rod and the deforming force F and inversely proportional to the cross-sectional area of this rod S:

Δl = α * (lF) / S

The inverse of α is called Young’s modulus:

1/α = E

Relative deformation:

ε = (Δl) / l = α * (F/S)

The ratio of tensile force F to S is called elastic stress σ:

ε=α σ

Hooke's law, written using Young's modulus, looks like this:

σ = ε/α = E ε

Now we can formulate the physical meaning of Young’s modulus: it corresponds to the stress caused by stretching a rod-shaped sample twice, provided its integrity is maintained.

In reality, the vast majority of samples fail before they have stretched to twice their original length. The value of E is calculated using the indirect method for small deformations.

Stiffness coefficient for elastic deformation of the rod along its axis k = (ES) / l

Young's modulus determines the magnitude of the potential energy of bodies or media subjected to elastic deformation.

General concept

The modulus of elasticity (also known as Young's modulus) is one of the indicators of the mechanical properties of a material, which characterizes its resistance to tensile deformation. In other words, its value shows the ductility of the material. The greater the elastic modulus, the less any rod will stretch, all other things being equal (load magnitude, cross-sectional area, etc.).

In the theory of elasticity, Young's modulus is denoted by the letter E. It is an integral part of Hooke's law (the law on the deformation of elastic bodies). Connects the stress arising in the material and its deformation.

According to the international standard system of units, it is measured in MPa. But in practice, engineers prefer to use the dimension kgf/cm2.

The elastic modulus is determined experimentally in scientific laboratories. The essence of this method is to tear dumbbell-shaped samples of material using special equipment. Having found out the stress and elongation at which the sample failed, divide these variables by each other, thereby obtaining Young's modulus.

Let us immediately note that this method is used to determine the elastic moduli of plastic materials: steel, copper, etc. Brittle materials - cast iron, concrete - are compressed until cracks appear.

Additional characteristics of mechanical properties

The modulus of elasticity makes it possible to predict the behavior of a material only when working in compression or tension. In the presence of such types of loads as crushing, shear, bending, etc., additional parameters will need to be introduced:

- Stiffness is the product of the elastic modulus and the cross-sectional area of the profile. By the value of rigidity, one can judge the plasticity not of the material, but of the structure as a whole. Measured in kilograms of force.

- Relative longitudinal elongation shows the ratio of the absolute elongation of the sample to the total length of the sample. For example, a certain force was applied to a rod 100 mm long. As a result, it decreased in size by 5 mm. Dividing its elongation (5 mm) by the original length (100 mm) we obtain a relative elongation of 0.05. A variable is a dimensionless quantity. In some cases, for ease of perception, it is converted to percentages.

- Relative transverse elongation is calculated similarly to the point above, but instead of length, the diameter of the rod is considered here. Experiments show that for most materials, transverse elongation is 3-4 times less than longitudinal elongation.

- The Punch ratio is the ratio of the relative longitudinal strain to the relative transverse strain. This parameter allows you to fully describe the change in shape under the influence of load.

- The shear modulus characterizes the elastic properties when the sample is exposed to tangential stresses, i.e., in the case when the force vector is directed at 90 degrees to the surface of the body. Examples of such loads are the work of rivets in shear, nails in crushing, etc. By and large, the shear modulus is associated with such a concept as the viscosity of the material.

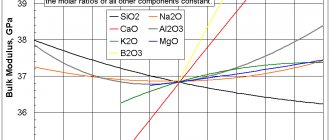

- The bulk modulus of elasticity is characterized by a change in the volume of the material for uniform, versatile application of load. It is the ratio of volumetric pressure to volumetric compressive strain. An example of such work is a sample lowered into water, which is subject to liquid pressure over its entire area.

Young's modulus values for some materials

The table shows the E values of a number of common substances.

| Material | Young's modulus E, GPa |

| Aluminum | 70 |

| Bronze | 75-125 |

| Tungsten | 350 |

| Graphene | 1000 |

| Brass | 95 |

| Ice | 3 |

| Copper | 110 |

| Lead | 18 |

| Silver | 80 |

| Gray cast iron | 110 |

| Steel | 200/210 |

| Glass | 70 |

The longitudinal elastic modulus of steel is twice the Young's modulus of copper or cast iron. Young's modulus is widely used in formulas for strength calculations of structural elements and products in general.

Table of material elasticity indicators

Before moving directly to this characteristic of steel, let us first consider, as an example and additional information, a table containing data on this value in relation to other materials. The data is measured in MPa .

Modulus of elasticity of various materials

As you can see from the table above, this value is different for different materials, and the indicators also differ, if we take into account one or another option for calculating this indicator. Everyone is free to choose exactly the option for studying indicators that suits them best. It may be preferable to consider Young's modulus, since it is most often used specifically to characterize a particular material in this regard.

After we have briefly reviewed the data on this characteristic of other materials, we will move directly to the characteristics of steel separately.

First, let's look at the hard numbers and derive different indicators of this characteristic for different types of steels and steel structures:

- Modulus of elasticity (E) for casting, hot-rolled reinforcement from steel grades called St.3 and St. 5 equals 2.1*106 kg/cm^2.

- For steels such as 25G2S and 30KhG2S this value is 2*106 kg/cm^2.

- For periodic wire and cold-drawn round wire, there is an elasticity value equal to 1.8 * 106 kg/cm^2. For cold-flattened reinforcement the indicators are similar.

- For strands and bundles of high-strength wire the value is 2·10 6 kg/cm^2

- For steel spiral ropes and ropes with a metal core, the value is 1.5·10 4 kg/cm^2, while for cables with an organic core this value does not exceed 1.3·10 6 kg/cm^2.

- The shear modulus (G) for rolled steel is 8.4·10 6 kg/cm^2.

- And finally, Poisson’s ratio for steel is equal to 0.3

These are general data given for types of steel and steel products. Each value was calculated in accordance with all physical rules and taking into account all existing relationships that are used to derive the values of this characteristic.

Below will be given all the general information about this characteristic of steel. Values will be given both by Young's modulus and by shear modulus, both in some units (MPa) and others (kg/cm2, newton*m2).

Steel and several different grades

| Material | Elastic modulus indicators (E, G; N*m2, kg/cm^2, MPa) |

| Steel | 20.6*10^10 newton*meter^2 |

| Carbon steel | E=(2.0…2.1)*10^5 MPa; G=(8.0…8.1)*10^4 MPa |

| Steel 45 | E=2.0*10^5 MPa; G=0.8*10^5 MPa |

| Steel 3 | E=2.1*10^5 MPa; G=0.8*10^5 MPa |

| Alloy steel | E=(2.1…2.2)*10^5 MPa; G=(8.0…8.1)*10^4 MPa |

The elasticity values of steel vary, since there are several modules at once , which are calculated and calculated in different ways. You can notice the fact that, in principle, the indicators do not differ greatly, which indicates in favor of different studies of the elasticity of various materials. But it’s not worth going too deep into all the calculations, formulas and values, since it’s enough to choose a certain elasticity value in order to focus on it in the future.

By the way, if you do not express all the values in numerical ratios, but take it immediately and calculate it completely, then this characteristic of steel will be equal to: E = 200,000 MPa or E = 2,039,000 kg/cm^2 .

This information will help you understand the very concept of modulus of elasticity, as well as become familiar with the main values of this characteristic for steel, steel products, and also for several other materials.

It should be remembered that the elastic modulus indicators are different for different steel alloys and for different steel structures that contain other compounds. But even in such conditions, you can notice the fact that the indicators do not differ much. The elastic modulus of steel practically depends on the structure. and also on carbon content. The method of hot or cold processing of steel also cannot greatly affect this indicator.

Material tensile strength

This is the limit of the stress that occurs, after which the sample begins to fail.

Static tensile strength is measured under prolonged application of deforming force, dynamic - under short-term, impact nature of such force. For most substances the dynamic limit is greater than the static limit.

Tensile strength tool

In addition, there are limits to the material's compressive and tensile strength. They are determined experimentally on a test bench, by stretching or compressing samples with powerful hydraulic machines equipped with precise dynamometers and pressure meters. If it is impossible to achieve the required pressure hydraulically, a directed explosion in a sealed capsule is sometimes used.

Methods for determining the elastic modulus

The elastic modulus can be determined in two ways:

- mechanical, samples are used for it;

- ultrasonic, which does not destroy the samples.

Mechanical method

Mechanical testing is carried out in accordance with standard SP 24452-80.

PHOTO: pinterest.co.uk Mechanical strength testing of concrete

Materials and tools

Square or round samples are accepted for testing; their ratio between height and width (section) must be equal to four. Products in series of 3 pieces are sawn or cut from finished structures or cast in molds in accordance with standard 10180-78. After this, they are placed under a damp cloth until testing begins.

Tests are carried out on special equipment - a press, consisting of devices placed in different directions in relation to the faces of the concrete sample. Indicators are attached to the metal frames or support inserts to measure the level of deformation.

PHOTO: tdzhil.ru A certain batch of samples is needed for testing

PHOTO: masterabetona.ru Press for testing

Allowable tensile stress in some materials

From life experience we know that different materials resist changes in shape in different ways. The strength characteristics of crystalline and other solids are determined by the forces of interatomic interaction. As interatomic distances increase, the forces that attract atoms to each other also increase. These forces reach a maximum at a certain amount of stress, equal to approximately one tenth of Young's modulus.

Tensile test

This value is called theoretical strength; when it is exceeded, the destruction of the material begins. In reality, destruction begins at lower values, since the structure of real samples is heterogeneous. This causes an uneven distribution of stresses, and destruction begins from those areas where the stresses are maximum.

Values of σrast in MPa:

| Materials | σrast | |

| Bor | 5700 | 0,083 |

| Graphite | 2390 | 0,023 |

| Sapphire | 1495 | 0,030 |

| Steel wire | 415 | 0,01 |

| Fiberglass | 350 | 0,034 |

| Structural steel | 60 | 0,003 |

| Nylon | 48 | 0,0025 |

These numbers are taken into account by designers when choosing the material for parts of a future product. Strength calculations are also carried out using them. For example, cables used for lifting and transport operations must have a tenfold safety margin. They are periodically checked by hanging a load ten times greater than the cable's rated load capacity.

The safety margins built into critical structures are also multiple.

Characteristics of AISI 304 stainless steel

Grade 304 AISI is the most versatile and most widely used of all stainless steel grades. Its chemical composition, mechanical properties, weldability and corrosion/oxidation resistance provide the best choice in most applications at a relatively low cost. This steel also has excellent low temperature properties. If intercrystalline corrosion occurs in high temperature zones, its use is also recommended.

Russian analogue of 304 AISI according to GOST - 08Х18Н10, 304 L AISI - 03Х18Н11.

Application area

304 AISI is used in all industrial, commercial and domestic areas due to its good anti-corrosion and temperature resistance. Here are some of its uses:

- Tanks and containers for a wide variety of liquids and solids;

- Industrial equipment in the mining, chemical, cryogenics, food, dairy and pharmaceutical industries.

Differentiation of the 304 AISI brand

During the production of steel, the following special properties can be specified, which predetermines its use or further processing:

- Improved weldability;

- Deep drawing, Rotary drawing;

- Stretch forming;

- Increased strength, cold hardening;

- Heat resistance C, Ti (carbon, titanium);

- Mechanical restoration.

Chemical Composition (ASTM A240)

| C | Mn | P | S | Si | Cr | Ni | |

| 304 AISI | 0.08max | 2.0 | 0.045 | 0.030 | 1.0 | 18.0 to 20.0 | 8.0 to 10.50 |

| 304L AISI | 0.03 max | max | max | max | max | 18.0 to 20.0 | 8.0 — 12.0 |

Typical Annealed Properties

The properties stated in this publication are typical of one plant's production and should not be regarded as guaranteed minimum values for the entire specification.

Mechanical properties at room temperature

| 304 AISI | 304L AISI | |||

| Typical | Min | Typical | Min | |

| Rp m Ultimate strength (tensile), N/mm2 | 600 | 515 | 590 | 485 |

| Rp0.2 Elastic Limit, (0.2%), (yield), N/mm2 | 310 | 205 | 310 | 170 |

| A5 relative elongation, % | 60 | 40 | 60 | 40 |

| Brinell hardness - HB | 170 | — | 170 | — |

| Fatigue strength, N/mm2 | 240 | — | 240 | — |

If necessary, the strength of austenitic steel can be increased as follows:

- adding nitrogen to steel (eg 304LN AISI);

- form strengthening of steel at the factory (repeated skin-pass rolling; cold-working; stretching; pressure).

Nitrided stainless steel is used particularly in applications such as large tanks, columns and shipping containers, where the higher design strength (Rp0.2) of the steel allows for reduced wall thickness and savings in material costs.

Other applications for form-hardened austenitic steel include, for example, various forming plates for the vehicle industry, welded pipes, keg hoops, chains, strips and support elements.

Properties at high temperatures

All these values apply to 304 AISI only. No values are given for 304L AISI because its strength decreases noticeably above 425°C.

Tensile strength at elevated temperatures

| Temperature, °C | 600 | 700 | 800 | 900 | 1000 |

| Rp m Ultimate strength (tensile), N/mm2 | 380 | 270 | 170 | 90 | 50 |

Minimum values of elastic limit at high temperature (1% deformation in 10,000 hours)

| Temperature, °C | 550 | 600 | 650 | 700 | 800 |

| Rp1.0 1.0% plastic deformation (yield), N/mm2 | 120 | 80 | 50 | 30 | 10 |

Maximum recommended service temperatures (scaling temperature)

Continuous exposure 925°C intermittent exposure 850°C

Properties at low temperatures (304 AISI, 304L AISI)

| Temperature, °C | -78 | -161 | -196 |

| Rp m Ultimate strength (tensile), N/mm2 | 1100/950 | 1450/1200 | 1600/1350 |

| Rp0.2 Elastic Limit, (0.2%), (proof of yield), N/mm2 | 300/180 | 380/220 | 400/220 |

| Impact strength, J | 180/175 | 160/160 | 155/150 |

Corrosion resistance

Acidic environments

Examples are given for some acids and their solutions (most general values):

| Temperature, °C | 20 | 80 | ||||||||||

| Concentration, % by weight | 10 | 20 | 40 | 60 | 80 | 100 | 10 | 20 | 40 | 60 | 80 | 100 |

| Sulfuric acid | 2 | 2 | 2 | 2 | 1 | 0 | 2 | 2 | 2 | 2 | 2 | 2 |

| Nitric acid | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 1 | 2 |

| Phosphoric acid | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 1 | 2 |

| Formic acid | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 2 | 1 | 0 |

Code: 0 = high degree of protection - Corrosion rate less than 100 mm/year; 1 = partial protection - Corrosion rate from 100m to 1000 mm/year; 2 = non resistant - Corrosion rate more than 1000 mm/year.

Atmospheric influences

Comparison of 304 grade with other metals in various environments (Corrosion rate based on 10 year exposure).

| Environment | Corrosion rate (mm/year) | ||

| AISI 304 | Aluminum-3S | carbon steel | |

| Rural | 0.0025 | 0.025 | 5.8 |

| Marine | 0.0076 | 0.432 | 34.0 |

| Industrial Marine | 0.0076 | 0.686 | 46.2 |

Heat Treatment

Annealing

High temperature from 1010°C to 1120°C and rapid release (cooling) in air or water. The best corrosion resistance is obtained when annealing at 1070°C, and rapid cooling.

Vacation (stress relief)

For 304L AISI - 450-600°C for one hour with a slight risk of sensitization. A lower tempering temperature of 400°C maximum should be used.

Hot working (forging interval)

Initial temperature: 1150 - 1260°C. Final temperature: 900 – 925°C.

Any hot processing must be accompanied by annealing.

Please note: The time to achieve uniform heating is longer for stainless steels than for carbon steels - approximately 12 times.

Cold Processing

304 AISI, 304L AISI, being extremely strong, elastic and ductile, easily finds many applications. Typical processes include bending, stretch forming, deep drawing and rotary drawing.

The forming process can use the same machines and often even the same tools as for carbon steel, but it requires 50-100% more force.

This is due to the high degree of hardening during forming of austenitic steel, which in some cases is a negative factor.

About bending

Approximate bending limits are obtained when s=sheet thickness and r=bending radius:

- s < 3mm, min. r = 0;

- 3mm < s < 6mm, min. r = 0.5 s, bending angle 180°;

- 6mm < s < 12mm, min. r = 0.5·s, bending angle 90°.

The back straightening is greater than that of carbon steel, which is why “the bending should be correspondingly greater.” When bending a regular right angle by 90°, we obtain the following straightening indicators:

r = s reverse straightening approx. 2°; r = 6·s reverse straightening approx. 4°; r = 20 s reverse straightening approx. 15°.

For austenitic stainless steel, the minimum recommended bending radius is r = 2 s.

It should be noted that the following minimums are recommended for ferritic stainless steel: s < 6 mm, - min r = s, 180°; 6 < s < 12mm, — min r = s, 90°.

Deep drawing and rotary drawing

In clean deep drawing on a press, the workpiece is not subjected to “braking”, and the material is allowed to flow freely in the tools. In practice this happens very rarely. For example, when drawing household utensils, there is always also an element of stretch forming.

The material subjected to deep drawing must be as stable as possible, i.e. it should have a low degree of hardening during molding, and the Md 30(N) indicator should clearly be “minus”. For stainless cutlery, the same so-called rules are usually used. sub-analyses of rolled stainless steel, as well as in the manufacture of pans using the deep drawing method.

Rotary drawing on a lathe, as the name itself suggests, is a forming process with turning. Typical applications are buckets and similar conical products of symmetrical rotation, which are not usually polished.

About stretch molding

In the stretch forming process, the workpiece is subjected to “braking” during stretching. The walls become thinner and, in order to avoid ruptures, it is desirable to provide the steel with increased hardening properties during forming. When performing more complex operations (for example, two bowls are pulled out from a dishwasher table blank at a time), the Md 30(N) indicator of the steel should clearly be “on the plus side”.

Welding

Weldability – very good, easy to weld.

| Welding process | Thickness without weld | Including weld | Protective environment | ||

| Thickness | Coating | ||||

| Bar | Wire | ||||

| Resistance -spot (spot) -seam (seam) | <2mm | ||||

| TIG | <1.5mm | >0.5mm | ER 308 l(Si) W.Nr 1.4370 ER 347 (Si) | ER 308 l(Si) W.Nr 1.4370 ER 347 (Si) | Argon Argon + 5% Hydrogen Argon + Helium |

| PLASMA | <1.5mm | >0.5mm | ER 310 | ER 308 l(Si) W.Nr 1.4370 ER 347 (Si) | Argon Argon + 5% Hydrogen Argon + Helium |

| MIG | >0.8mm | ER 308 l(Si) W.Nr 1.4370 ER 347 (Si) | Argon + 2% CO2 Argon + 2% O2 Argon + 3% CO2 + 1% H2 Argon + Helium | ||

| SAW | >2mm | ER 308 L ER 347 | |||

| Electrode | Repairs | E 308 E 308L E 347 | |||

| Laser | <5mm | Helium. Sometimes Argon, Nitrogen. | |||

Typically, post-weld heat treatment is not required. However, where there is a risk of intergranular corrosion, additional annealing is performed at 1050-1150°C. For grades 304L AISI (low carbon) or 321 AISI (Ti stabilization), this condition is preferable (heating the weld to 1150°C followed by rapid cooling). The welding seam must be mechanically and chemically cleaned of scale and then passivated with etching paste.

Safety factor

To quantify the safety factor during design, a safety factor is used. It characterizes the product’s ability to withstand overloads above rated loads. For household products it is small, but for critical components and parts that, if destroyed, can pose a danger to human life and health, it is made multiple times.

Margin of safety

Accurate calculation of strength characteristics makes it possible to create a sufficient safety margin and at the same time not to overweight the structure, worsening its performance characteristics. For such calculations, complex mathematical methods and sophisticated software are used. The most important designs are calculated on supercomputers.