General information

Iron-carbon alloys are a group of iron-based compounds saturated with additional components, the main one of which is carbon.

Areas of application:

- Assembly of industrial equipment, machines, ships, aircraft, various mechanisms.

- Manufacturing of tools for processing wood, metal, concrete, plastic.

- Assembly of metal structures.

Iron-carbon alloys are divided into 2 large groups:

- Steel. A compound of carbon and iron. The mass fraction of carbon can reach 2.14% of the total amount. More often, its content does not exceed 1.5% of the total mass. Carbon steels are a strong, malleable, deformable structural material.

- Cast iron. An alloy based on carbon and iron. The content of the first component can reach 6.67% of the total amount. More often, its mass fraction does not exceed 5%. The properties of the material depend on the structure.

Types of cast iron:

- Grey. The carbon included in the alloy is in the form of graphite. The material lends itself well to processing with tools and has high casting properties.

- White. Poorly processed. Most or all of the carbon is contained in the composition in the form of cementite. It is characterized by high hardness and poor weldability. Most often used to produce malleable cast iron.

- Highly durable. Carbon in such cast iron is contained in the form of spherical graphite, which is formed due to the crystallization process. Used for the production of parts that will be subject to heavy loads.

- Half-hearted. Carbon is contained in the form of graphite and cementite. Parts with increased wear resistance are made from it.

- Malleable. It is obtained by casting and heat treatment of white cast iron. Used for assembling agricultural machinery and cars.

A separate group should include special cast irons, the second name of which is ferroalloys. They contain manganese and silicon. Used for steel production. With their help, you can remove harmful impurities that impair technical characteristics.

Malleable cast iron figurine (Photo: Instagram / antikevro)

Iron-carbon alloys

1.1. Iron

Iron belongs to the main chemical element in the group of ferrous metals.

Iron does not occur in its pure form in nature, but occurs in the form of oxides that form the so-called iron ore with varying iron content. The crystal lattice of iron is bcc, but it changes with increasing temperature. When heated to a temperature of 150 ... 250 ° C, pure iron, interacting with oxygen, becomes covered with an oxide film. Technically pure iron is ductile. With insignificant mass fractions of impurities (no more than 0.01%), ductility sharply decreases. Pure iron does not find practical use due to its low mechanical properties.

The metallurgical industry produces several types of technically pure iron for scientific research: pure, electrolytic, carbon, technical.

These grades of pure iron have different mechanical properties. For example, tensile strength σв = 180 ... 320 MPa (18 ... 32 kgf/mm2), relative elongation δ = 30 ... 50% depend on the type of iron. The ductility of iron depends on the test temperature.

When heated slightly, pure iron becomes brittle. Research has shown that iron has three zones of fragility:

- up to 270 °C - cold-brittle iron;

- 540 ... 720 °C - blue-brittle iron;

- 1,080 ... 1,265 °C - red-brittle iron.

The brittleness properties of iron manifest themselves depending on the type of atomic crystal lattice and its parameters. Chemical elements (impurities) increase or decrease the brittleness temperature of iron. For example, oxygen increases, and carbon and manganese decrease the brittleness temperature. In addition, practice shows that the strength and ductility of iron depend on the method of production of the samples under study. Cast samples have reduced strength and ductility compared to samples obtained by deformation (rolling, forging). Wrought iron is stronger than cast iron.

Iron in the solid state, depending on the temperature, can be in two modifications: α-iron and γ-iron. When heated and cooled, allotropic transformations occur, as a result of which the atomic lattices are rearranged. In addition, an important factor is the ability of iron to dissolve carbon, nitrogen and hydrogen, as well as various metals. In this case, substitutional solid solutions are formed with metals, and interstitial solutions with carbon, nitrogen and hydrogen.

Carbon, which dissolves in both α-iron and γ-iron, plays a special role in the formation of interstitial solid solutions. The highest solubility of carbon in γ-iron is 2.14% (on the Fe-Fe3C phase diagram, the critical temperature is 1,147 °C).

It is almost impossible to obtain pure iron. Currently, iron is obtained with a mass fraction of various impurities from 0.01%. For example, Armco iron - industrial iron produced in open-hearth furnaces and used for scientific research - has a mass fraction of impurities of 0.1 ... 0.2%.

Practice shows that carbon, when alloyed with iron, contributes to a sharp increase in mechanical properties - hardness, wear resistance, elasticity and strength increase. Plasticity and toughness decrease. In this regard, alloys of iron with carbon and other elements have found widespread use in practice.

1.2. Characteristics of iron-carbon alloys

An iron-carbon alloy is an alloy of iron that is saturated with carbon and other chemical elements during blast furnace smelting or another metallurgical process. Iron-carbon alloys are the main structural materials and represent a large group, both in terms of production volume and the variety of different grades.

Iron-carbon alloys, according to their physical, chemical and mechanical properties, are divided into two large groups: steels and cast irons.

Steel is an alloy of iron and carbon, in which the mass fraction of carbon is up to 2.14% (theoretically). In practice, the mass fraction of carbon is usually 1.3 ... 1.5%. Carbon steel is a deformable, malleable and strong structural material, the tensile strength of which reaches 1,150 MPa, hardness - 285 HB and elongation - 32%. The steel has good machinability, weldability and pressure treatment.

Cast iron is an alloy of iron and carbon, in which the mass fraction of carbon is 2.14 ... 6.67% (theoretically). In practice, cast irons with a carbon mass fraction of 2.5 ... 5.0% are used. The properties of cast iron depend on its structure, i.e., on the interaction of carbon with iron.

Depending on the structure, cast iron will have certain physical and mechanical properties. If it has a grain structure, cast iron will have high hardness and strength, as well as high machinability.

Most commercial pig iron is processed into steel.

1.3. Phases and structures of iron-carbon alloys.

An iron-carbon alloy, depending on physical conditions (temperature, pressure), can be in three phase states:

- liquid phase,

- semi-liquid phase,

- solid phase.

Each of these phases, despite the homogeneity of the chemical composition, has different physical and mechanical properties. When studying the properties of iron-carbon alloys, of scientific and practical interest are the various structures of the solid phase, which, when interacting with carbon, form iron (for example, the chemical compound cementite, solid solutions of austenite and ferrite, mechanical mixtures of pearlite and ledeburite).

Cementite is a chemical compound of carbon with iron (iron carbide) Fe3C. The structure of cementite is a complex orthorhombic atomic crystal lattice with a weak metallic bond. The temperature of the beginning of cementite melting is 1,147 °C, the end of melting is 1,600 °C. Cementite with various chemical elements found in iron-carbon alloys forms substitutional solid solutions. Under certain conditions (temperature and high pressure), cementite breaks down into free carbon (graphite).

Cementite is a ferromagnetic material, has no allotropic changes, and at a temperature of 217 ° C loses its magnetic properties. The amount of carbon in cementite is always constant and amounts to 6.67%. Cementite is the hardest (700 ... 800 HB) and brittle structural component of iron-carbon alloys; it cuts glass and cannot be processed by cutting. The plasticity of cementite is zero. When fractured, cementite has a fine-grained or needle-like structure, a white shiny color and is a typical structure of white pig iron.

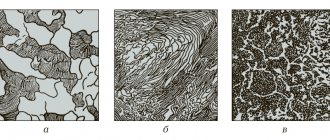

Rice. 1. Microstructure of carbon steels: a - hypoeutectoid steel - ferrite + pearlite; b - eutectoid steel - pearlite; c - hypereutectoid steel - pearlite + secondary cementite

Ferrite is a solid solution of intercalated carbon in α-iron. This is low-carbon iron with a carbon mass fraction of up to 0.02%. Ferrite has a hardness of 60 ... 80 HB, tensile strength σв = 250 MPa (25 kgf/mm2), elongation at break δ = 50% and is the microstructure of low-carbon steels, which consists of large light grains.

Austenite is a solid solution of interstitial carbon in γ-iron.

The maximum carbon concentration in austenite is 2.14%, hardness is 170 ... 220 HB. Austenite is formed at a temperature of 727 °C and has an unstable structure; it disintegrates when cooled. The austenite structure has high mechanical (strength, ductility, toughness, hardness) and technological properties.

Perlite is a mechanical mixture of a solid solution of ferrite and the chemical compound cementite. This mixture is called eutectoid (easily disintegrating). Perlite has a fine-plate or granular structure.

The mass fraction of carbon in pearlite is 0.83%, hardness is 200 ... 240 HB, tensile strength σв = 1,100 ... 1,150 MPa (110 ... 115 kgf/mm2). Pearlite is an unstable structure; at a temperature of 727 °C it decomposes into austenite.

Ledeburite is a mechanical mixture of austenite and cementite. Ledeburite (eutectic) contains 4.3% carbon and melts at a constant temperature of 1,147 °C.

Steel with a carbon mass fraction of 0.83% is called eutectoid, less than 0.83% is hypoeutectoid, and more than 0.83% is hypereutectoid. The microstructures of eutectoid (pearlite), hypoeutectoid (ferrite + pearlite) and hypereutectoid (pearlite + secondary cementite) steels are shown in Fig. 1.

Cast iron with a carbon mass fraction of 4.3% is called eutectic, with a carbon mass fraction of less than 4.3% - hypoeutectic, with a carbon mass fraction of more than 4.3% - hypereutectic (Fig. 2).

Rice. 2. Microstructure of white cast iron: a - hypoeutectic cast iron - pearlite + ledeburite + cementite; b - eutectic cast iron - ledeburite; c - hypereutectic cast iron - ledeburite + primary cementite

Industrial production

Iron-carbon alloys are produced by metallurgical plants from various components. The basis is iron with carbon. Stages of the production process:

- Preparation of consumable raw materials (ore). It is sorted by piece size and chemical composition. Low-grade ores are enriched with the required components. Waste rocks are removed.

- Fuel preparation. Coke coal undergoes a screening procedure. It is needed to remove foreign impurities from the fuel, which can lead to heat losses during ore smelting.

- Flux preparation. Substances that will be used for the production of cast iron are crushed. At the same time, fines are sifted out and foreign impurities are removed.

- Loading consumables and ore into the blast furnace. First, it is filled with coke, ore is laid out on top, and another layer of coke is poured on top of it. Heated air is blown inside to maintain the melting temperature of the metal. When coke burns, a large amount of carbon dioxide is released, which passes through the coke residues, forming the compound CO. During the reduction process, the iron gains hardness. Gradually the carbon begins to dissolve. Liquid cast iron is fed to special ladles, from which it is poured into molds.

Large blast furnaces are used to produce cast iron. Their height can reach 30 m, and their internal diameter is 12 m.

Blast furnace (Photo: Instagram / viktormacha)

Manufacturing technologies

As you know, cast iron is produced in special blast furnaces. The main raw material for its production is iron ore. The manufacturing process consists of the reduction of iron ore oxides and the resulting production of another material - cast iron. For its production, fuels such as coke, thermoanthracite, and natural gas are used.

To produce one ton of pig iron, about 550 kilograms of coke and approximately a ton of water are required. The volume of ore loaded into the furnace will depend on the iron content in it. As a rule, ore is used, which contains at least 70% iron. The thing is that it is not economically feasible to use a lower concentration.

The first stage in the production of cast iron is its smelting. Ore is poured into the blast furnace, and then coking coal, which is necessary to pump and maintain the required temperature inside the furnace shaft. During combustion, these components take an active part in the ongoing chemical reactions as iron reducers.

Meanwhile, flux is immersed in the furnace, which acts as a catalyst. By accelerating the melting of rocks, it thereby supports the rapid release of iron. It is important to know that before loading into the furnace, the ore undergoes the necessary pre-treatment. It is crushed in a crushing plant because smaller particles melt faster. It is then washed to remove non-metal particles. Next, the raw material is fired, as a result of which sulfur and other foreign components are extracted from it.

At the second stage of production, natural gas is supplied through special burners into the filled and ready-to-use furnace. Coke is involved in heating the raw materials. Carbon is released, which combines with oxygen to form an oxide. It, in turn, promotes the recovery of iron from ore.

As the volume of gas in the furnace increases, the rate of the chemical reaction decreases. It may even stop completely when a certain gas ratio is reached. Carbon penetrates the alloy and combines with iron to form cast iron. Unmelted elements remain on the surface and are soon removed. Such waste is called slag. It is used to make other materials.

Alloy components

Technical characteristics of iron-carbon alloys depend on the type and amount of alloying additives:

- Carbon. The composition is present in the form of cementite, graphite, iron carbide. This component is introduced specifically to give the material hardness, strength, and change technical characteristics for the better.

- Manganese, silicon. Useful impurities that are specially introduced into the alloy (a certain part of them comes from the ore). They reduce the fragility and hardness of alloys, increasing its strength and wear resistance.

- Phosphorus, sulfur. Harmful impurities for iron-carbon alloys. Manufacturers are trying to reduce their number. With a high content of these impurities, fragility and hardness increase, casting properties deteriorate, and shrinkage appears when the molten metal cools.

Alloy features

The main feature of cast iron is hidden in the process of its manufacture. The fact is that for different types of this alloy the melting point reaches 1200ºC, while for steel it is 1500ºC. This factor is affected by too high a carbon content. Iron and carbon atoms do not have very close bonds with each other.

When smelting occurs, the carbon atoms cannot be completely embedded in the molecular lattice of the iron, causing the cast iron alloy to become brittle. In this regard, it is not used in the production of parts that will be constantly subject to load.

This material belongs to the ferrous metallurgy industry and its characteristics are similar to steel. Products made of cast iron and steel are widely used in everyday life, and it is entirely justified.

If we compare the characteristics of these metals, we can draw the following conclusions:

- The cost of steel products is higher than the cost of cast iron.

- Differences in color: cast iron is dark and matte, while steel is light and shiny.

- Steel is less susceptible to casting, but, unlike cast iron, it is easier to forge and weld.

- Steel has greater strength than cast iron alloy.

- Steel is heavier in weight.

- It has a lower carbon content than cast iron.

Classification

Steel is classified according to different criteria. By chemical composition:

- High carbon - more than 0.65% C.

- Medium carbon - from 0.25% to 0.65% C.

- Low carbon - less than 0.25% C.

By structure:

- hypereutectoid;

- eutectoid;

- hypoeutectoid;

- ledeburite.

By purpose:

- Instrumental. Used in the manufacture of working parts and accessories for electrical tools and industrial equipment.

- Structural. They are used in the manufacture of metal structures, parts of industrial equipment, and machines.

Steel in rolls (Photo: Instagram / mmz_sim)

Steel classification

Steels are characterized or classified according to many characteristics:

Classification by chemical composition

- carbon steels - classified depending on the carbon content in %: low carbon (< 0.25%C)

- medium carbon (0.25-0.65%C)

- high carbon (> 0.65%C)

- alloy steels - classified depending on the total content of alloying elements in%: low alloy (< 2.5%)

- medium alloyed (2.5-10%)

- highly alloyed (> 10%)

If the Fe content is less than 45%, then it is an alloy based on the element with the highest content. If the Fe content is more than 45%, then it is steel.

Classification by purpose

- structural - used for the manufacture of machine parts and mechanisms, carbon content <0.8%. Structural ones are divided into cemented ones, with a carbon content of <0.3%, and improved ones, with a carbon content of >0.3%. The main classification and groups of structural steels can be found here

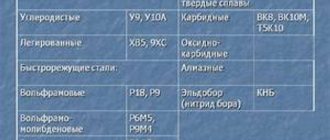

- instrumental - used for the manufacture of measuring and cutting tools, hot and cold deformation dies. Carbon content >0.8%;

- with special properties: electrical, with special magnetic properties, heat-resistant, wear-resistant, etc.

Classification by structure

Oberghoffer classification - according to structure at equilibrium

Initially, this classification contained only 4 types of steels:

- hypoeutectoid

- eutectoid

- hypereutectoid

- ledeburite (having eutectic in the cast state)

Later additions were made:

- ferritic

- austenitic

Equilibrium state - the state of an alloy or steel after slow cooling, most often after annealing

Guillet classification - according to structure after normalization (heating and cooling in air)

- pearlite

- martensitic

- ferritic

- austenitic

- carbide

There can also be mixed classes: ferrite-pearlite, austenite-ferritic, etc.

Classification of steels by quality

A quantitative indicator of quality is the content of harmful impurities - sulfur and phosphorus:

- ordinary quality (S≤0.05, P≤0.04)

- quality steels (S, P ≤0.035)

- high quality (S, P ≤0.025)

- especially high quality (S≤0.015, P≤0.025)

Classification by smelting method

- in open hearth furnaces

- in oxygen converters

- in electric furnaces: electric arc, induction, etc.

Classification by degree of deoxidation

- boiling (kp)

- semi-calm (ps)

- calm (sp)

For expanded characteristics and properties (technological, physical... chemical composition) of some steel grades, see here.

Properties

Characteristics of iron-carbon alloys:

- Density - up to 7.9 g/cm3.

- Melting point - up to 1520 °C.

- Specific heat capacity - 462 J/(kg °C) at an ambient temperature of no more than 20 °C.

- Specific heat of fusion - 84 kJ/kg.

- Thermal conductivity coefficient is 30 W/(m K) at a temperature of 100 °C.

- The coefficient of linear thermal expansion is 11.5·10-6 1/°C.

Iron-carbon alloys are produced by industrial enterprises. These include different types of steel and cast iron. They are used in various industries.

Advantages and disadvantages

This material, like any other, has its strengths and weaknesses.

The advantages of cast iron include the following factors:

- Sometimes it is even compared in terms of characteristics to steel, because certain types of it are characterized by increased strength.

- Retains temperature for a long time: when heated, heat is distributed evenly throughout it and remains unchanged for a long time.

- It is an environmentally friendly material, which is why it is often used in the manufacture of utensils in which food will be directly cooked.

- Does not react to acid-base environment.

- It is a durable material.

- The longer a product made from this material is used, the better its quality becomes.

- This material is absolutely harmless to the human body.

The disadvantages include the following factors:

- It can become rusty even if water is kept in it for a short time.

- It is a very expensive material, but despite this, it fully justifies itself. Quality, practicality and reliability are the main features of products made from this alloy.

- Gray cast iron is characterized by low ductility.

- White is very fragile and is most often melted down.

Alloy theory

Pure metals are relatively rarely used in mechanical engineering, since they do not provide the necessary complex of mechanical and technological properties of parts made from them.

Alloys consisting of two or more elements (two metals, such as copper and zinc, or a metal and a non-metal, such as iron and carbon) are widely used. The elements included in the alloy are called components.

Alloys are produced by fusing components, sintering, electrolysis and sublimation. The components included in the alloy, in the liquid state, almost always dissolve in each other, forming a liquid solution. The atoms of such a solution are uniformly mixed with each other. The properties of alloys depend mainly on the interaction of the components during solidification. When alloys solidify, a solid solution, chemical compound or mechanical mixture is formed.

Solid solution. During the transition to the solid state in alloys, the homogeneity of the distribution of atoms of various components, and therefore the property of solubility, is preserved. When an alloy crystallizes, the atoms of the components enter into a single cell of the crystal lattice, so the resulting grains are homogeneous and identical in composition. The solid solution, like pure metal, has a uniform crystal lattice. In the crystal lattice of a pure metal, all nodes are occupied by atoms of one component, and in the lattice of a solid solution - by atoms of the components that make up the alloy. In solid solutions, the solubility of the components is not limited at any quantitative ratio (copper with nickel).

The properties of alloys that form solid solutions change smoothly and differ from the properties of the components from which they are composed. They are distinguished by valuable properties. They are harder and stronger than their constituent components, have good ductility, high electrical resistance that does not change with temperature changes, and increased resistance to corrosion. Due to their high ductility, such alloys are well processed under pressure.

Chemical compound. During crystallization, the components of some alloys can enter into a chemical bond, forming a chemical compound. For example, iron and carbon form the chemical compound Fe3C - iron carbide (cementite); copper with magnesium - Cu2Mg; magnesium with lead - Mg2Pb, etc.

A chemical compound, like a solid solution, has a homogeneous structure. Its crystal lattice includes atoms of both components. However, in the crystal lattice of a chemical compound, unlike a solid solution, the atoms of each component are in a strictly defined quantity and are always located in the same way. For example, the chemical compound of iron with carbon Fe3C always consists of three iron atoms and one carbon atom, the Mg2Pb compound always has two magnesium atoms and one lead atom. Thus, a chemical compound has a constant composition and is expressed by a chemical formula, but the composition of solid solutions varies within wide limits; a solid solution cannot be expressed by a chemical formula. The crystal lattice of a chemical compound differs from the lattices of its constituent components, therefore, when an alloy is formed, it is considered as an independent component. For example, steel is an alloy, one component of which is iron, and the other is the chemical compound Fe3C (cementite).

Chemical compounds have very high hardness and good electrical resistance. Sometimes their hardness is 10 times higher than the hardness of pure components. For example, iron and carbon form the chemical compound Fe3C, the hardness of which is 10 times higher than the hardness of iron. Chemical compounds of tungsten and titanium with carbon (carbides), characterized by very high hardness, are used to make cutting tools. Unlike solid solutions, chemical compounds are characterized by high fragility and are unsuitable for pressure treatment.

Mechanical mixture. Individual components in the solid state do not dissolve in each other (to form a solid solution) and do not enter into a chemical reaction with each other (to form a chemical compound). During crystallization, each of these components creates its own crystal lattice, unique to it alone. Mixing with each other at a constant temperature and a certain percentage, they form a mechanical mixture, in which individual components are visible when examined under a microscope. Thus, a mechanical mixture of Pb - Sb is formed at a temperature of 246 ° C and the ratio of components: Pb -87%, Sb - 13%.

Mechanical mixtures have good casting properties. This especially applies to eutectic alloys, which have greater fluidity and a lower melting point than their constituent components.

Knowledge of the structure of alloys facilitates their selection in the manufacture of machine parts and the development of technological processes. When studying the processes occurring in metals and alloys when their temperature and composition change, concepts such as component, system, and phase are used.

, a system is a collection of substances or bodies between which energy and mass can be exchanged without hindrance. The system can be a chemical element (sulfur, aluminum, hydrogen), a chemical compound (Fe3C, water, table salt), an alloy of two or more metals (copper-nickel, tin - lead - antimony), an aqueous solution (sugar in water) , a mixture of gases (air consisting of nitrogen, oxygen, carbon dioxide and five inert gases).

A phase is a part of a system that has a homogeneous structure and is separated from other parts by an interface. A phase can include any number of components that make up the system. The system may contain one or more phases. Single-component systems “sulfur”, “aluminium”, “table salt” at room temperature have one solid phase, the “water” system under the same conditions contains one liquid phase, and the “hydrogen” system - one gaseous phase. At temperatures below zero, the “water” system is also single-phase, having one solid phase - ice. At zero degrees, this system is two-phase, since at this temperature liquid (water) and solid (ice) phases coexist.

The two-component system “sugar solution in water” is single-phase, that is, it has one liquid phase if the solution is unsaturated. The same system will be two-phase with a saturated solution containing undissolved sugar crystals, which are the second (solid) phase. The liquid phase in this case will contain two components (water and sugar), and the solid phase only one (sugar).