If we characterize the concept of yield strength briefly, then in the strength of materials the yield strength

is the stress at which plastic deformation begins to develop. Yield strength refers to strength characteristics.

According to [1], fluidity

is macroplastic deformation with very low

hardening

dτ/dγ.

Physical yield strength

is a mechanical characteristic of materials: stress corresponding to the lower position

of the yield point

in

the tensile diagram

for materials having this site (figure),

σ

T =

P

T/

F

0. Here

P

T is the yield stress load, and

F

0 is the initial cross-sectional area of the sample.

Yield strength

establishes the boundary between the elastic and elastic-plastic deformation zones.

Even a small increase in stress (load) above the yield point

causes significant deformation. [2]

Metal fluidity

Knowledge of the mechanical properties of a material is extremely important for the designer who uses them in his work. It determines the maximum load on a particular part or the structure as a whole, if exceeded, plastic deformation will begin, and the structure will lose its strength and shape and may be destroyed. Destruction or serious deformation of building structures or elements of transport systems can lead to large-scale destruction, material losses and even casualties.

The yield strength is the maximum load that can be applied to a structure without deformation and subsequent failure. The higher its value, the greater the load the structure can withstand.

Metal fluidity

In practice, the yield strength of a metal determines the performance of the material itself and products made from it under extreme loads. People have always predicted the maximum loads that the structures they erect or the mechanisms they create can withstand. In the early stages of industry development, this was determined experimentally, and only in the 19th century did the creation of the theory of strength of materials begin. The issue of reliability was solved by creating a multiple safety margin, which led to heavier and more expensive structures. Today it is not necessary to create a model of a product of a certain scale or full size and conduct experiments on destruction under load on it - computer programs of the CAE (calculation engineering) family can accurately calculate the strength parameters of the finished product and predict the maximum load values.

How is the strength test performed?

Initially there were no special events. People took an item, used it, and as soon as it broke, they analyzed the breakdown and reduced the load on a similar product. Now the procedure is much more complicated, however, until now the most objective way to find out PP is the empirical way, that is, experiments and experiments.

All tests are carried out under special conditions with a large amount of precise equipment that records the condition and characteristics of the experimental material. Usually it is fixed and experiences various influences - tension, compression. They are performed by instruments with high precision - every thousandth of a newton of the applied force is noted. At the same time, each deformation is recorded as it occurs. Another method is not laboratory, but computational. But usually mathematical analysis is used in conjunction with testing.

Definition of the term

The sample is stretched on a testing machine. In this case, first it lengthens in size, and the cross-section becomes narrower, and then a neck is formed - the place where the thinnest diameter is, this is where the workpiece will rupture. This is true for ductile alloys, while brittle alloys, such as cast iron and hard steel, stretch very slightly without necking. Let's take a closer look at the video:

The value of the yield strength of the material

With the development of atomic physics in the 20th century, it became possible to calculate the value of the parameter theoretically. This work was first done by Yakov Frenkel in 1924. Based on the strength of interatomic bonds, he, through calculations that were complex for that time, determined the amount of stress sufficient to initiate plastic deformation of bodies of simple shape. The value of the yield strength of the material will be equal to

ττ=G/2π. , where G is the shear modulus, which determines the stability of bonds between atoms.

Stretching materials

The tensile yield strength determines at what value the stress will remain unchanged or decrease despite elongation. That is, this parameter will reach a critical point when a transition from the elastic to plastic region of deformation of the material occurs. It turns out that the yield strength can be determined by testing the rod.

Calculation of the yield strength value

The ingenious assumption Frenkel made in his calculations was that the process of changing the shape of the material was considered to be driven by shear stresses. For the onset of plastic deformation, it was assumed that it was sufficient for one half of the body to move relative to the other to such an extent that it could not return to its initial position under the influence of elastic forces.

Physical Yield Strength Graph

Frenkel suggested that the material tested in the thought experiment has a crystalline or polycrystalline structure, characteristic of most metals, ceramics and many polymers. This structure presupposes the presence of a spatial lattice, in the nodes of which atoms are arranged in a strictly defined order. The configuration of this lattice is strictly individual for each substance, as are the interatomic distances and the forces connecting these atoms. Thus, in order to cause plastic shear deformation, it will be necessary to break all interatomic bonds passing through the conventional plane separating the halves of the body.

At a certain stress value equal to the yield stress , the bonds between atoms from different halves of the body will break, and a number of atoms will shift relative to each other by one interatomic distance without the possibility of returning to their original position. With continued exposure, such a microshift will continue until all the atoms of one half of the body lose contact with the atoms of the other half

In the macrocosm, this will cause plastic deformation, change the shape of the body and, with continued exposure, lead to its destruction. In practice, the line of the beginning of destruction does not pass through the middle of the physical body, but is located in the locations of material inhomogeneities.

Proof of Yield

A large number of metals and alloys, when tested at tensile strength, demonstrate a yield diagram with an absent or weakly defined “yield plateau”. For such materials they speak of a conditional yield strength. It is interpreted as the stress at which deformation occurs within 0.2%.

Proof of Yield

Such materials include alloy and high-carbon steel alloys, bronze, duralumin and many others. The more plastic the material is, the higher its residual deformation index. Examples of ductile materials include copper, brass, pure aluminum and most low-carbon steel alloys.

Yield strength of steel

Steel, as the most popular mass structural material, is under particularly close attention of specialists in calculating the strength of structures and the maximum permissible loads on them.

During their operation, steel structures are subjected to combined loads of tension, compression, bending and shear that are large in size and complex in shape. Loads can be dynamic, static and periodic. Despite the most difficult conditions of use, the designer must ensure that the structures and mechanisms he designs are durable, reliable and have a high degree of safety for both personnel and the surrounding population.

Yield strength of steel

Therefore, increased demands on mechanical properties are placed on steel. From the point of view of economic efficiency, the company strives to reduce the cross-section and other dimensions of its products in order to reduce material consumption and weight and thus increase performance characteristics. In practice, this requirement must be balanced with the safety and reliability requirements set out in standards and technical specifications.

The yield strength of steel is a key parameter in these calculations because it characterizes the ability of a structure to withstand stress without permanent deformation or failure.

Alloy check

Before launching into production, tests are carried out to study the properties of the metal alloy. Metal samples are subjected to various loads until all properties are completely lost.

The loads are:

- Statistical load.

- Testing the endurance and fatigue of steel.

- Stretching an element.

- Bend and torsion testing.

- Combined bending and tensile endurance.

For these purposes, special machines are used and conditions are created that are as close as possible to the operating mode of the future structure.

Testing

To carry out tests on a cylindrical sample with a cross-section of twenty millimeters and a calculated length of ten millimeters, a tensile load is applied. The sample itself has a length of more than ten millimeters so that it can be securely grasped, and a length of ten millimeters is marked on it and this is what is called the calculated length. The tensile force is increased and the increasing elongation of the sample is measured. For clarity, the data is plotted on a graph. It is called a conditional stretch diagram.

With a small load, the sample elongates proportionally . When the tensile force increases sufficiently, the limit of proportionality will be reached. After passing this limit, disproportionate elongation of the material begins with a uniform change in the tensile force. Then a limit is reached, after which the sample cannot return to its original length. When passing this value, the test part changes without increasing the tensile force. For example, for steel rod Art. 3 this value is equal to 2450 kg per square centimeter.

Unexpressed flow point

If, under constant force, a material is capable of deforming on its own for a long time, then it is called ideally plastic.

During testing, it often happens that the yield point is not clearly defined, then the definition of the conditional yield strength is introduced. This means that the force acting on the metal caused a deformation or permanent change of about 0.2%. The value of the residual change depends on the ductility of the metal.

The more ductile the metal, the higher the residual deformation value. Typical alloys in which such deformation is not clearly expressed are copper, brass, aluminum, and steels with low carbon content. Samples of these alloys are called densified.

When a metal begins to “flow,” as experiments and research demonstrate, strong changes occur in its crystal lattice. Shear lines appear on its surface and the layers of crystals shift significantly.

After the metal spontaneously stretches, it passes into the next state and again acquires the ability to resist. Then the alloy reaches its strength limit and the weakest area clearly appears on the part, where a sharp narrowing of the sample occurs.

The cross-sectional area becomes smaller and this is where rupture and destruction occur. The magnitude of the tensile force at this moment drops along with the value of stress and the part breaks.

High-strength alloys can withstand loads of up to 17,500 kilograms per square centimeter. The tensile strength of ST.3 steel is in the range of 4–5 thousand kilograms per square centimeter.

Plasticity characteristic

The ductility of a material is an important parameter that must be taken into account when designing structures. Plasticity is determined by two indicators:

- residual elongation;

- narrowing upon rupture.

Permanent elongation is calculated by measuring the total length of the part after it has broken. It consists of the sum of the lengths of each half of the sample. Then the ratio to the original conditional length is determined as a percentage. The stronger the metal alloy, the lower the elongation value.

Residual narrowing is the percentage ratio of the narrowest point of the rupture to the original cross-sectional area of the rod under study.

Fragility index

The most brittle metal alloys are considered to be tool steel and cast iron. Fragility is the inverse property of plasticity, and it is somewhat conditional, since it strongly depends on external conditions.

Such conditions may be:

- Ambient temperature. The lower the temperature, the more fragile the product becomes.

- The rate of change of applied force.

- Ambient humidity and other parameters.

When external conditions change, the same material behaves differently. If a cast iron bar is clamped on all sides, it will not break even under significant loads. And, for example, when there are grooves on a steel rod, the part becomes very fragile.

Therefore, in practice, it is not the concept of the brittleness limit that is used, but the state of the sample is determined as brittle or rather ductile.

Material strength

This is a mechanical property of the workpiece and is characterized by its ability to withstand loads without completely collapsing. For the test sample, conditions are created that best reflect future operating conditions and a variety of influences are applied, gradually increasing the load. An increase in impact forces causes plastic deformations in the sample. In plastic materials, deformation occurs in one, pronounced area called the neck. Brittle materials can fail in several areas at the same time.

Steel is tested to accurately determine various properties in order to obtain an answer about the possibility of its use in certain conditions during construction and the creation of complex structures.

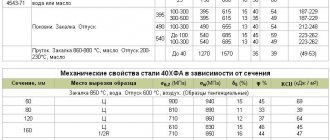

The fluidity values of various steel grades are included in special Standards and Specifications. There are four main classes. The fluidity value of products of the first class can reach up to 500 kg/cm2, the second class meets the load requirements of up to 3 thousand kg/cm2, the third - up to 4 thousand kg/cm2. and the fourth class can withstand up to 6 thousand kg/cm2.

Influence of carbon content on the properties of steels

According to the physicochemical principle of additivity, the change in the physical properties of materials is determined by the percentage of carbon. Increasing its proportion to 1.2% makes it possible to increase the strength, hardness, yield strength and threshold cold capacity of the alloy. A further increase in the proportion of carbon leads to a noticeable decrease in technical indicators such as weldability and ultimate deformation during stamping operations. Low carbon steels exhibit the best weldability.

Tensile strength

Let's look at how this characteristic of mechanical properties is determined. Strength is the ability of a material, under certain limits and conditions, to withstand various impacts without collapsing. Mechanical properties are usually determined using conventional stress-strain diagrams. Standard samples should be used for testing. Test instruments are equipped with a device that records the diagram. Increasing loads above normal causes significant plastic deformation in the product. The yield strength and tensile strength correspond to the highest load preceding the complete destruction of the sample. In plastic materials, deformation is concentrated in one area where a local narrowing of the cross section appears. It is also called the neck. As a result of the development of multiple slips, a high dislocation density is formed in the material, and so-called nucleation discontinuities also arise. Due to their enlargement, pores appear in the sample. Merging with each other, they form cracks that propagate transversely to the tensile axis. And at a critical moment the sample is completely destroyed.

Nitrogen and oxygen in the alloy

These non-metals from the beginning of the periodic table are harmful impurities and reduce the mechanical and physical characteristics of steel, such as the viscosity threshold, ductility and brittleness. If oxygen is contained in amounts greater than 0.03%, this leads to accelerated aging of the alloy, and nitrogen increases the fragility of the material. On the other hand, the nitrogen content increases strength by reducing the yield strength.

Microstructure of an alloy containing nitrogen and oxygen

Tensile strength of steel

Steel structures have long replaced other materials, as they have excellent performance characteristics - durability, reliability and safety. Depending on the technology used, it is divided into brands. From the most common with a PP of 300 MPa, to the hardest with a high carbon content - 900 MPa. This depends on two indicators:

- What heat treatment methods were used - annealing, hardening, cryotreatment.

- What impurities are contained in the composition. Some are considered harmful, they are discarded for the purity of the alloy, and others are added to strengthen them.

Manganese and silicon additives

An alloying additive in the form of manganese is used to deoxidize the alloy and compensate for the negative effects of harmful sulfur-containing impurities. Due to its similar properties to iron, manganese does not have a significant independent effect on the properties of the alloy. Typical manganese content is about 0.8%.

Silicon has a similar effect; it is added during the deoxidation process in a volume fraction not exceeding 0.4%. Since silicon significantly worsens such a technical indicator as the weldability of steel. For structural steels intended for welding, its proportion should not exceed 0.25%. Silicon does not affect the properties of steel alloys.

Table of fluidity of clay soils

| Soil classification | Consistency | IL turnover rate |

| Sandy loam | hard | ≤ 0 |

| plastic | 0 ≤ IL ≤1 | |

| fluid | IL >1 | |

| Clays and loams | hard | IL ≤ 0 |

| semi-solid | 0 ≤ IL ≤0.25 | |

| refractory | 0.25 < IL ≤0.5 | |

| soft plastic | 0.5 < IL ≤0.75 | |

| fluid-plastic | 0.75 < IL ≤1 | |

| fluid | IL >1 |

Impurities of sulfur and phosphorus

Sulfur is an extremely harmful impurity and negatively affects many physical properties and technical characteristics.

The maximum permissible content of this element in the form of brittle sulfites is 0.06%

Sulfur impairs the ductility, yield strength, impact strength, wear resistance and corrosion resistance of materials.

Phosphorus has a dual effect on the physical and mechanical properties of steels. On the one hand, with an increase in its content, the yield strength increases, but on the other hand, viscosity and fluidity simultaneously decrease. Typically the phosphorus content ranges from 0.025 to 0.044%. Phosphorus has a particularly strong negative effect with a simultaneous increase in the volume fraction of carbon.

What is PT for valves?

These products are an integral part of reinforced concrete, intended, as a rule, to resist tensile forces. Usually steel reinforcement is used, but there are exceptions. These products must work together with the mass of concrete at all stages of loading a given structure without exception, and have plastic and durable properties. And also meet all the conditions for the industrialization of these types of work. The mechanical properties of steel used in the manufacture of reinforcement are established by the relevant GOST and technical specifications. GOST 5781-61 provides for four classes of these products. The first three are intended for conventional structures, as well as non-prestressed rods in prestressed systems. The yield strength of reinforcement, depending on the class of the product, can reach 6000 kg/cm2. So, for the first class this parameter is approximately 500 kg/cm2, for the second - 3000 kg/cm2, for the third - 4000 kg/cm2, and for the fourth - 6000 kg/cm2.

Alloying additives in alloys

Alloying additives are substances intentionally introduced into the composition of an alloy to purposefully change its properties to the desired levels. Such alloys are called alloy steels. Better performance can be achieved by simultaneously adding several additives in certain proportions.

The influence of alloying elements on the properties of steel

Common additives are nickel, vanadium, chromium, molybdenum and others. With the help of alloying additives, the values of yield strength, strength, viscosity, corrosion resistance and many other physical, mechanical and chemical parameters and properties are improved.

Ways to increase strength characteristics

There are several ways to do this, two main ones:

- addition of impurities;

- heat treatment, for example, hardening.

Sometimes they are used together.

General information about steels

All of them have chemical and mechanical properties. Below we’ll talk in more detail about ways to increase strength, but first, let’s present a diagram showing all the varieties:

Also watch a more detailed video:

All of them have chemical and mechanical properties. Below we’ll talk in more detail about ways to increase strength, but first, let’s present a diagram showing all the varieties:

Carbon

The higher the carbon content of a substance, the higher the hardness and the lower the ductility. But the composition should not contain more than 1% of the chemical component, since a larger amount leads to the opposite effect.

Manganese

A very useful additive, but with a mass fraction of no more than two percent. Mn is usually added to improve machinability. The material becomes more susceptible to forging and welding. This is due to the displacement of oxygen and sulfur.

Silicon

Effectively increases strength characteristics without affecting ductility. The maximum content is 0.6%, sometimes 0.1% is enough. Combines well with other impurities; together, they can increase corrosion resistance.

Nitrogen and oxygen

If they get into the alloy, but worsen its characteristics, they try to get rid of them during manufacturing.

Alloying Additives

You can also find the following impurities:

- Chrome – increases hardness.

- Molybdenum – protects against rust.

- Vanadium – for elasticity.

- Nickel – has a good effect on hardenability, but can lead to brittleness.

These and other chemicals must be used in strict proportions according to the formulas. In the article we talked about tensile strength (short-term resistance) - what it is and how to work with it. They also gave several tables that you can use while working. To finish, let's watch the video:

To clarify the information you are interested in, please contact our managers by phone;; 8 (800) 707-53-38. They will answer all your questions.

Metal melt fluidity

The fluidity of a metal melt is its ability to completely fill the casting mold, penetrating into the smallest cavities and relief details. The accuracy of the casting and the quality of its surface depend on this.

Liquid metal for processors

The property can be enhanced by placing the melt under excess pressure. This physical phenomenon is used in injection molding machines. This method can significantly increase the productivity of the casting process, improve the surface quality and uniformity of castings.

Testing a sample to determine the yield strength

To carry out the standard tests, a cylindrical sample with a diameter of 20 mm and a height of 10 mm is used, fixed in the test apparatus and subjected to tension. The distance between the marks applied on the side surface of the sample is called the calculated length. During the measurements, the dependence of the relative elongation of the sample on the magnitude of the tensile force is recorded.

The dependence is displayed in the form of a conditional stretch diagram. At the first stage of the experiment, an increase in force causes a proportional increase in the length of the sample. Upon reaching the limit of proportionality, the diagram turns from linear to curvilinear, and the linear relationship between force and elongation is lost. In this section of the diagram, when the force is removed, the sample can still return to its original shape and dimensions.

For most materials, the values of the proportional limit and the yield strength are so close that in practical applications the difference between them is not taken into account.

Physical characteristics

Yield strengths refer to strength indicators. They represent macroplastic deformation with rather small strengthening. Physically, this parameter can be represented as a characteristic of the material, namely: stress, which corresponds to the lower value of the yield area in the graph (diagram) of tension of materials. This can also be represented in the form of the formula: σТ=PT/F0, where PT means the yield stress load, and F0 corresponds to the initial cross-sectional area of the sample in question. PT establishes the so-called boundary between the elastic-plastic and elastic deformation zones of the material. Even a slight increase in stress (above PT) will cause significant deformation. The yield strength of metals is usually measured in kg/mm2 or N/m2. The value of this parameter is influenced by various factors, for example, heat treatment mode, sample thickness, the presence of alloying elements and impurities, type, microstructure and crystal lattice defects, etc. The yield strength changes significantly with temperature. Let's consider an example of the practical meaning of this parameter.