Most often, powder mixtures of the following compositions are used:

- 49.5% aluminum + 49.5% Al2O3 + 1% NH4Cl;

99% ferroaluminum + 1% NH4Cl;

In all compositions, the aluminizing temperature is maintained at 950...1050 °C, and the holding time for the indicated temperatures is set in the range from 6 to 12 hours. Under such conditions, the depth of the aluminized layer can be 0.25...0.6 mm.

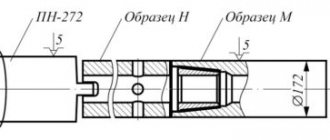

The aluminizing process itself is carried out as follows. Parts and powders are loaded layer by layer into iron or nichrome boxes. During the saturation process, 10-15% of fresh powder mixture is repeatedly added to them. If the mixture contains aluminum oxide, it is first calcined at a temperature of 800-900 °C before loading it into the box. All components of powder mixtures are sifted through a sieve with a mesh size of 0.4-0.5 mm. The box in which aluminizing is carried out must be equipped with a fusible shutter. Along with the parts, two or three control samples, called witnesses, are placed in the box. With the help of such witnesses, you can monitor the progress of saturation.

Figure 1 shows the dependence of the depth of the aluminized layer on steel 10 on the duration of saturation at various temperatures. Aluminizing in molten aluminum.

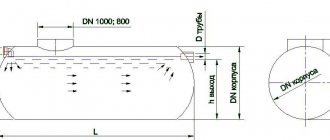

The essence of this method is to soak the parts in a bath of molten aluminum at temperatures of 720 -850 °C. Since some parts can dissolve in liquid aluminum, to prevent this process, 8-12% iron is introduced into the bath. It is undesirable to contain impurities of copper, zinc and silicon in the bath, because they make the process of saturation difficult.

The holding time may vary depending on the type of parts and their purpose from 15 minutes. up to 1 hour Under such conditions, it is possible to obtain aluminized layers with a depth of 0.1...0.3 mm. It should be noted that with this method, an increase in the fragility of the resulting layer can sometimes be observed. Therefore, in order to eliminate such a defect, parts after aluminizing are subjected to annealing at a temperature of 950-1050 °C for 4-5 hours. With such heat treatment, the layer depth can increase by 20-40%.

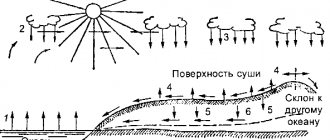

During the aluminizing process, it is recommended to create a layer of flux on the surface of the melt, consisting, for example, of 40% NaCl; 40% KCl; 10% Na3AlF6; 10% AlF3. This flux plays the role of protection and reduces the process of corrosion of the surface of the part. In Figure 2

The dependence of the layer depth of steel 10 on the duration of aluminizing in the aluminum melt at different temperatures is shown.

The aluminized layer is a solid solution of aluminum based on the chemical compound Fe3Al. This phase is more often called the ?-phase. The aluminum concentration in this phase can reach up to 30% or more.

Currently, aluminizing by metallization is gradually developing and expanding. The essence of this method is to spray a layer of aluminum onto the surface of the part, followed by diffusion annealing at a temperature of 900-1000 °C. Before annealing, the part is coated with a coating consisting of 48% silver graphite, 30% quartz sand, 20% clay and 2% ammonium chloride. All components are mixed on liquid glass and applied to the part with a thickness of 0.8-1.5 mm.

The temperature at which saturation occurs is 900-950 °C. The process itself can last 2-4 hours. Under such conditions, it is possible to obtain a layer with a thickness of 0.2-0.4 mm. Aluminizing is most widely used in the production of valves for internal combustion engines, thermocouple covers, etc. In principle, aluminizing can be prescribed for any parts that operate at high temperatures and which, above all, are required to have high scale resistance.

Aluminizing steel

Over the course of several centuries, the basic performance properties of metals have been changed using chemical-thermal effects. Tests indicate that the percentage of certain impurities in a metal can affect its hardness, strength, corrosion resistance and many other qualities. Aluminizing carbon steel is the process of saturating the surface layer of a product with aluminum, which takes place at a certain temperature. The process of aluminizing steel is quite complicated; it requires the installation of certain equipment. Let us consider the features of the work on saturating the surface layer of steel and cast iron with aluminum.

Steel aluminizing process

Aluminizing is a type of diffusion metallization, which is characterized by saturation of the surface layer with aluminum. The protective coating creates an oxide film on the processed products, which increases resistance to high temperatures and prevents corrosion processes. Although this processing method is suitable for most metals and alloys, the most popular is aluminizing steel. Cast iron takes second place.

Aluminizing is characterized by high technological complexity - it is almost impossible to implement at home. Let's consider the features and nuances of the technology.

Aluminizing methods

Aluminizing steel is performed at temperatures from 700 to 1100 °C, depending on the characteristics of the workpiece. There are several methods of surface aluminization:

- in powder mixtures (calorization);

- spraying;

- metallization;

- in a vacuum;

- by immersion.

Each method has advantages and disadvantages. The technical characteristics of the layer will also have different parameters.

Aluminizing steel by immersion is the most preferred method.

Properties and advantages of aluminized steels

Aluminized steel has a number of valuable qualities:

- After chroming, a surface with high adhesion to paint and varnish products is obtained.

- The low cost of coating allows the use of aluminizing as a worthy alternative to expensive heat-resistant coatings.

- Aluminized steel is resistant to mechanical damage.

- At temperatures above 470 °C, an intermediate alloy is formed, which has high resistance to temperature influences.

Laboratory tests have shown that, with equal thickness, the aluminum layer is 2.5 times stronger than zinc.

Aluminizing is a high-tech process that gives the surface of the metal being processed new protective properties. What do you think about technology? Perhaps you think that there are better methods of metallization? Share your thoughts in the comments section.

Purpose of the process

Normalization is designed to change the microstructure of steel; it does the following:

- reduces internal stress;

- through recrystallization, it refines the coarse-grained structure of welds, castings or forgings.

The goals of normalization can be completely different. Using this process, the hardness of steel can be increased or decreased, the same applies to the strength of the material and its toughness. It all depends on the mechanical and thermal characteristics of the steel. Using this technology, it is possible to both reduce residual stresses and improve the degree of machinability of steel using one or another method.

Steel castings are subjected to this treatment for the following purposes:

- to homogenize their structure;

- to increase susceptibility to heat hardening;

- to reduce residual stresses.

Products obtained by forming are subjected to normalization after forging and rolling in order to reduce the heterogeneity of the structure and its banding.

Normalization together with tempering is needed to replace the hardening of products with complex shapes or with sharp changes in cross-section. This will prevent defects.

This technology is also used to improve the structure of the product before hardening, increase its machinability through cutting, eliminate the secondary cement network in hypereutectoid steel, and also prepare the steel for final heat treatment.

Process technology

Preparation, nitrogen saturation and finishing of the top layer of steel and alloys involves several steps:

- Preparatory heat treatment of metal, which consists of hardening and high tempering. At the same time, the inside of the product becomes more viscous and durable. Hardening takes place at a very high temperature of about 940 ° C and ends with cooling in a liquid - oil or water. Temperature conditions for tempering are 600-700 °C, which gives the metal a hardness suitable for cutting;

- Mechanical processing of workpieces, which ends with grinding. After this procedure, the part reaches the desired size;

- Precautionary measures for those parts of products that must be exposed to nitrogen saturation. For this, simple compounds like tin or liquid glass are used, applied in a layer of no more than 0.015 mm by electrolysis. Occurs by the formation of a thin film impermeable to nitrogen;

- Nitriding of steel using the technology described above;

- Finishing parts to the required condition.

, complex-shaped workpieces with thin walls are strengthened at 520 ° C.

Regarding the change in the geometric parameters of products after the nitriding process, it is noted that it depends on the thickness of the resulting nitrogen-saturated layer and the temperatures applied. However, this change is insignificant in any case.

It should be noted that modern methods of metal processing by nitriding are carried out in shaft furnaces. The maximum temperature of which can reach 700 °C, the circulation of ammonia in such furnaces is forced. The muffle can be built into the furnace or replaceable.

The process will go much faster if you introduce an additional muffle. Then the spare muffle with parts is loaded immediately when the first one with processed workpieces is ready. However, the use of this method is not always economically justified, especially when large products are saturated with nitrogen.

Purpose

Normalizing steel has different functions other than increasing its hardness. In some cases, normalization is carried out with the opposite purpose to reduce strength and toughness.

The main goals of metal normalization include:

- Obtaining the result of stress leveling. After processing, the steel has additional parameters, which makes it easier to process it in different ways.

- Reducing the heterogeneity and banding of the structure. In this case, objects are subjected to normalization after forging or rolling using the pressure method.

- Reducing the risk of deformation of parts that have sharp differences in cross-section or a complex configuration.

- Changing the coarse-grained structure of steel to fine-grained. Normalization helps to remove the network of secondary cement in hypereutectoid steel, improving its ability to be processed and hardened.

Methods for improving the quality of the surface layer of parts

To improve surface quality, various hardening methods are used. These methods can improve the quality of parts. Similar methods include finishing processing. The main goal of the methods is to reproduce the necessary requirements for parts and increase their service life.

A surface can be characterized by physical, mechanical properties and microgeometry.

It is an indisputable fact that the quality of the surface properties of various parts (for example, shafts) directly affects the performance of machines. Using a certain type of surface treatment, machine parts are adjusted to the specified physical and mechanical characteristics. Parts become more durable, stable, and solid. Their service life and quality of operation increases. The quality requirements for machines must be fully met. Several methods help solve this problem. Let's take a closer look at their classification:

— heat treatment of the surface (for example, conventional hardening or high-frequency high-frequency currents);

— chemical and thermal methods (cementation, nitriding, planning);

— diffusion metallization (diffusion aluminizing, chrome plating, silicon plating, etc.);

— use of hard alloys and metals (coating with cast and powdered alloys);

— metal application;

- distortion of shape.

Hardening -

An electric current is passed across the surface of the parts. This method is also carried out using a gas flame. Then the inside of the part, after lowering the temperature, turns out to be unhardened. The hardening method makes the surface harder and more resistant to external environmental influences. And the central part remains strong and viscous. The use of a laser beam is also advisable when hardening surfaces.

Cementation —

The main goal of the method is to fill the surface with carbon. This method has been used since the 19th century. The technology is similar to nitriding. Steel is placed in any type of carburizer (solid, gaseous, liquid). Then it is heated. Then the temperature decreases. At the end of carburization, it is recommended to perform hardening, which will leave the central part plastic. Cementation increases the resistance of products to various types of loads, strength and hardness. The temperature during cementation must be at least 800 degrees. Some cementation methods are used at home.

Nitriding —

The method fills the surface of products with nitrogen. Ammonia gas is used for this. The parts are heated at a temperature of 450 degrees. After which the product cools down. Nitriding increases strength and service life and minimizes the appearance of rust.

Cyanidation —

This method combines carbon and nitrogen. Surface filling increases strength, service life and hardness. The temperature range of this method is from 530 degrees. Used for various metals. The result depends on the type of material, temperature and gas concentration.

Diffuse metallization —

Using this method, the surface is saturated with different types of metals. To begin with, the surface of the product is heated very strongly. At this moment, the product is in contact with another metal. The external sides of the product are filled with aluminum, chromium, and silicon. Aluminizing, chrome plating of the product, and siliconization of the product occurs. Various metals are used. The surface of the part is kept at elevated temperature for the required time, after which the temperature is reduced. The temperature regime for diffuse metallization should be at least 900 degrees. As a result, resistance to rust formation increases, layers are strengthened, and temperature limits increase.

Surface coating -

For this method, various durable alloys and metals are used. You can apply spraying. The coating method increases the service life of the product. The filler material is usually powder. It is used to enhance properties and improve performance. In this case, plasma spraying is used, which is carried out using a laser.

Surface plastic deformation (SPD) —

It is considered the easiest and most productive. It increases the performance and safety of machines. Using this method, the strength and service life of products is increased. The part becomes as hard as possible. And all existing irregularities are minimized. PPD reduces the roughness Ra. Rounded vertices increase in radius. The length of the profile support also increases.

Hardening allows you to set certain properties and requirements for the product and its surface.

This method of deformation is divided into: shot processing, hydro-vibro-impact processing; electromagnetic, ultrasonic hardening, etc. It allows you to create different structures of the material and impart special properties. Products with different shapes and volumes can be subject to deformation.

Finishing method —

This includes fine-tuning, lapping, super-grinding, polishing. When using this method, slight deviations in the volume, size and shape of the product are possible. But these deviations do not in any way affect the quality of the product or the success of its operation. Particular attention is paid to the roughness of the product.

Abrasive finishing —

The ultimate way to improve part quality. Actively used in industry. To carry it out, special pastes, machines, and manual grinding are used. Small changes in the size and shape of the surface of parts are possible: Ra = 0.16...0.01 microns. This method combines mechanical, chemical and physico-chemical processes. This method is used quite often. In some cases, abrasive finishing is the only possible method of improving the surface quality of a product.

Super finish —

The product is polished using grinding and cylindrical stones. Using this method makes it possible to reduce the roughness to Ra = 0.1...0.012 microns. The supporting surface area is used almost completely (90%). In this case, there is no change in the volumes and shapes of the surfaces of the product. Fine-grained stones are used for grinding. They are lubricated with kerosene mixed with turbine oil. Processing speed up to approximately 2.5 m/s). The impact on the part is minimized. For superfinishing, simple equipment and universal machines are used. This method has very high productivity and excellent surface quality of products. The performance properties of the product increase with the use of this method. The only thing is that it is not always possible to eliminate the errors of previous treatments.

Polishing -

It is used to reduce surface irregularities without changing the dimensions and appearance of the part. With the help of polishing, it becomes possible to remove a minimal and thin layer from the product. This method is also the final stage in processing. The task of polishing is to achieve a roughness equal to Ra = 0.1...0.012 µm. For this method, sanding tools are used - cloth, felt, etc. Special pastes are applied to the instruments. Hand polishing makes the product smooth and perfect. When grinding products in drums and vibrating containers, abrasive cloths, as well as free abrasives, are used. When polishing I often use electrocorundum and silicon carbides. Also, boron, chromium oxide, iron, aluminum, GOI pastes, diamond and CBN skins - all this polishes the surface of products.

16.08.2019

7 2878

Back to list Next news

Sulfocyanation

This treatment is more reminiscent of the cyanidation process. The surface is saturated not only with carbon and nitrogen, but also with sulfur. Sulfocyanated parts have, to a greater extent, the same characteristics as cyanidated parts. Sulfocyanated parts performed best in mechanisms under medium loads. Thanks to a slightly different cyanidation scheme, seizing and enveloping of the metal is prevented.

The normal melting point of the mixture is 560-580 degrees. The processing of steel alloys is carried out mainly in liquid media, but it is also possible in gas media. Since sulfocyanated parts have a little more strength, their use is justified as piston rings, cast iron bushings, and various pump spare parts.

Types of metal heat treatment

There are 3 main types of metal heat treatment:

- annealing;

- hardening;

- vacation.

There is also thermochemical treatment, which refers to combined methods of imparting properties of increased hardness and wear resistance to the material.

Annealing

The essence of annealing is that the metal is heated to a certain temperature, held for the required period of time, and then slowly cooled to normal room temperature.

Most often, annealing is performed to solve the following problems:

- increase in mechanical properties of the material;

- bringing the material to a homogeneous state;

- improved plasticity;

- increasing the level of resistance;

- reducing the internal resistance of the material for subsequent forging.

Annealing is a process that is divided into several types, depending on the nuances of the procedure:

- diffusion;

- complete or incomplete;

- spheroidization;

- isothermal;

- normalization.

There are more annealing methods, but these are the main and most commonly used.

Also, the full annealing procedure involves improving the properties of the material for processing and getting rid of internal resistance. Full annealing is used to process:

- steel with a minimum amount of carbon;

- hypoeutectoid alloy.

In the full process, the product is brought to a critical temperature (point A3) and after the required period of time is cooled to room temperature. Since the specific temperature parameters depend on the type of materials used. As a result, the holding time also directly depends on the type of alloy undergoing this technological process.

With incomplete annealing, the ultimate goal is different - to create, if possible, a softer and more ductile material. In this case, the heating temperature can reach 770 degrees. Cooling is divided into 2 stages: first in the oven, and then in the open air.

An isothermal type of annealing is used for high-chromium steels. This method saves significant production time because one of the cooling stages uses an accelerated process. There is no need to wait until the steel cools down with the furnace.

Metal hardening

During hardening, the product is heated to critical levels. As a result, subsequent cooling is not carried out gradually and naturally, but abruptly and forcibly. In this case, to reduce the temperature, substances such as compressed air, water mist, and liquid polymer quenching medium are used. in addition to strength, the metal receives lower parameters of viscosity and elasticity.

Hardening methods:

- Using one medium is a simple method, which, however, has limitations on the material used. Rapid cooling occurs and temperature unevenness occurs. Metal with a high carbon content cannot be processed in this way, since such material can be destroyed by aggressive influence.

- Multi-stage hardening - first the metal is heat-treated, and after reaching the required temperature it is placed in a salt bath. The temperature is equalized and only then is the material cooled using oil, air or fog.

- Light hardening. With this method, the material is first kept in a salt bath with the addition of sodium chloride. Then it is cooled in a bath with caustic sodium and caustic potassium.

- Self-vacation. With this method, the part is pulled out of the cooling system before the temperature drops. At this time, a high temperature will still remain in the center of the workpiece or part. After the tempering of the part is completed, it is cooled completely by immersion in a special environment.

- Isothermal hardening. An analogue of step hardening with a longer exposure time in a salt bath.

Aluminized metals and alloys

Aluminizing is not only a way to protect the surface. Oxide film is an excellent base for paint and varnish coatings. The main metals that are subjected to aluminization are:

- Carbon steel. With a high carbon content in the metal, the diffusion of aluminum is difficult, so low- and medium-carbon steels are mainly processed.

- Alloy steel. Processing this metal is associated with certain difficulties, however, if all technological requirements are met, a wear-resistant protective layer can be obtained.

- Cast iron. Cast iron is processed less frequently. The goal is to change the physical properties of the surface layer of cast iron.

The manufacturing process of stainless steel involves aluminizing alloy or carbon compounds.

In addition to the above metals, a protective layer is applied to the following materials:

Essentially similar heat treatment processes

In addition to normalization, the following operations can be added to the list of heat treatment of steels:

- annealing;

- vacation;

- hardening;

- cryogenic treatment and several others.

The annealing operation provides a high-quality, finer structure of pearlite; this occurs because furnaces are used to cool the parts. The purpose of this operation is to reduce the heterogeneity of the structure, remove stress, and increase machinability.

The principles underlying the hardening operation are identical to those of normalization, but there are some differences. For example, when hardening, much higher temperatures and high cooling rates are used. Hardening leads to improved strength characteristics, hardness, etc. But often workpieces that have undergone hardening are characterized by reduced viscosity and high fragility.

Tempering of parts is used after the hardening operation. Tempering reduces brittleness and internal stress. In this case, the temperature range is lower than that used in normalization. The parts are cooled in air. As the temperature increases, the tensile strength and hardness decrease and at the same time the impact strength increases.

Steel carburization technology, its essence and purpose - methods and videos

Depending on the specific application of various metals and alloys, additional processing is often carried out. This allows you to highlight (strengthen) certain properties of the sample. What is steel carburization, why is it needed, in what cases is it advisable to carry it out - the reader will learn about this in an accessible form from this article.

There are various methods of chemical-thermal treatment of materials. One of them is cementation. This technology is used for low-carbon and alloy steels, the content of element “C” in which does not exceed 0.25%.

The purpose is to increase such characteristics of the alloy as wear resistance, strength, and hardness.

For implementation, special furnaces are most often used, where the process takes place at high temperatures - about 945 (±15) ºС.

Depending on the dimensions and design features of the product, it is kept in such conditions for several hours. In essence, this is a complex treatment of a part (chemical + thermal) in order to give it hardness.

Pastas

The technology is the simplest, but not always applicable. For parts that have a complex configuration, with various protrusions, grooves, and the like, it is clearly not suitable.

The technique is the surface application of cement paste onto the sample. Its layer is chosen to be large compared to the calculated depth of carbon penetration into the steel (about 7 times).

Conditions - the temperature regime is set depending on the type of paste, ranging from 900 to 1,000 ºС.

Such carburization of steel can be carried out at home, if you have a drying cabinet with the required parameters.

Gas environment

One of the most effective techniques that is widely used in industry. It significantly simplifies the carburization process, reduces steel processing time and increases productivity. The main condition is to choose the right mixture according to the carbon content and the optimal temperature regime.

Methodology - products are loaded from a carburizing furnace into which gas is supplied.

Fluidized bed

This method is only partially reminiscent of the previous one.

Methodology - so-called corundum is placed in the furnace, on the gas distribution grid. Endogas (a mixture into which methane is introduced) is supplied from below and, rising, dilutes it, as a result of which the smallest fractions begin to move along with the flow to the product being processed. At high temperatures, diffusion of corundum particles occurs, and as a result, saturation of the surface layer of the sample with carbon.

Feature - the degree of cementation is easy to adjust by changing the gas supply. This technology makes it possible to uniformly saturate the steel over the entire area.

Experts recommend using this method, taking into account the costs and low complexity, for small-scale production of blanks.

Solid carburizer

As a saturating medium for this cementation technology, coal, peat or charcoal semi-cokes with granules from 3 to 10 mm are used with the obligatory addition of substances that initiate the process (activators).

Methodology - the samples to be processed are placed in a metal container on a sand seal. They are positioned so that they can be covered on all sides with a layer of carburizer. Therefore, contact of products with the walls of the tank or with each other is not allowed.

Carburization conditions – temperature 925 (±25) ºС. The holding time depends on the layer of the saturating medium. Determined at the rate: per 0.1 mm – 1 hour of heat treatment. The process can be accelerated by increasing the heating to 975 - 980 ºС. This reduces the time of the technological operation, but increases energy costs and reduces the quality of the finished product. A mesh will form on its surface, which will have to be removed.

In some cases this is quite difficult, for example, if the product is characterized by relief.

Application of aluminizing

The properties imparted to the product largely determine the scope of application of the technology of chemical-thermal treatment under consideration. In production, aluminizing of steels is used to change the following properties of the processed steel:

- High scale resistance. This property is associated with the process of formation of a protective film on the surface of the product when it is heated.

- High protection against oxidative processes.

- High anti-corrosion properties. As a result of aluminizing, the product can be used even when exposed to sea water.

- When considering the hardness of the surface layer, you need to pay attention to the fact that the maximum achieved value is about 500HV.

When considering the advantages and disadvantages of aluminizing steel, it should be noted that exposure to high temperature causes a rearrangement of the atomic lattice, as a result of which the surface layer becomes brittle.

When processing critical parts using this chemical-thermal method, firing is carried out for several hours. Therefore, the process of adding aluminum is characterized by a long duration.

Aluminizing steel 20