Authors: S.V. Kislov, P.V. Balash (SPC Mineral Coating Technologies LLC), V.G. Kislov (NPO Geoenergetics LLC), A.V. Skazochkin (Kaluga branch of RANEPA).

Published in the journal Chemical Technology No. 8/2016

In recent years, the industrial use of mineral coatings has been actively developing, imparting high anti-corrosion, wear-resistant, anti-abrasive, anti-friction properties to parts, devices and mechanisms operating in various industries. In many cases, it is the properties of the metal surface of the part that enable long-term and reliable operation of the parts. Active practice over the past five years has allowed us to accumulate a significant amount of information on the use of multifunctional mineral coatings on parts of friction pairs used by enterprises in various industries (shipbuilding, metallurgy, oil and gas production, mechanical engineering, energy, etc.).

The basis of the original technology of mineral coatings for increasing the wear resistance of metal parts was created in Russia in the period 2009–2013. [1]. After experimental and operational confirmation of the properties of mineral coatings created at the Scientific and Production Center "Mineral Coating Technologies" (NPO "Geoenergetics"), specialists from the Federal Institute for Research and Testing of Materials (VAM, Germany) [2], Russian State University of Oil and Gas named after I.M. Gubkin, MIEM NRU HSE [3–5], the stage of active use of technology by industrial enterprises in Russia and the EU began.

The essence of the technology is to create a modified layer (5...50 μm deep from the metal surface) by plastic deformation of the surface using ultrasonic, mechanical and other types of influence that accompany the diffusion of ultrafine particles of minerals of natural origin into the bulk of the metal [2, 3].

The practical advantages of mineral coating technology are obvious:

- the technology does not change the geometric dimensions of parts;

- mineral layers can be created locally on the surface;

- during the process of creating layers, the part does not heat up;

- all technological operations are carried out in air at room temperature [3].

Mineral coatings significantly increase the wear resistance of friction pairs, provide anti-corrosion and anti-abrasive protection, and reduce the coefficient of friction. In the process of practical application, mineral coatings were created on the surface of parts made of various types of steel, titanium, cast iron, bronze, and copper. In addition, it turned out that parts with mineral layers work well, demonstrating an advantage over all currently existing coatings, in sea water, salt fog, abrasive dust, hydrogen sulfide, at high humidity, in the presence of various acids and other aggressive environments; at high temperatures (up to 1100°C), as well as under thermal cyclic loads in a wide temperature range.

These advantages of the technology led to the creation by specialists of the Scientific and Production Center "Technology of Mineral Coatings" (SPC TMP) of mineral coatings on metal parts, which successfully work on such objects as special equipment of the Russian Navy; floating nuclear power plant "Akademik Lomonosov"; Kamchatka (Mutnovskaya) geothermal station; CHPP of JSC Mosenergo; several metallurgical plants.

Currently, experimental studies have been carried out and about 80 types of mineral materials are used to create multifunctional mineral coatings.

Main types of mineral materials used to create coatings [6]

Number of varieties

| Serpentinites Mg6[Si4O10](OH)8 | 28 |

| SiO2 series | 18 |

| Al2O3 series | 10 |

| Jadeite NaAlSi2O6 | 4 |

| Graphite | 2 |

| Diamonds | 3 |

| Micas [for example, KMg3AlSi3O10(OH)2] | 4 |

| Zircon Zr[SiO4] | 2 |

| Baddeleyite ZrO2 | 1 |

| Eudialyte | 1 |

| Olivine Mg1.8Fe0.2[SiO4] | 3 |

| Forsterite series Mg2SiO4 | 4 |

| Combined substances | 10 |

We can highlight the specifics of natural materials, which may contribute to achieving the unique parameters of parts with mineral coatings [6]:

- minerals were formed under the influence of high pressures and temperatures that are unattainable during industrial production;

- minerals are obtained from rocks containing a significant amount of impurities, which in some cases can be useful and improve the properties of the natural material;

- minerals contain up to hundreds of different atoms of various substances in one molecule, and the atoms can be combined into groups that can change their allotropic states with different effects on the surface of the part during operation.

Taking into account the specific characteristics of such substances is difficult, which necessitates the need for special techniques when determining and predicting their physicochemical properties.

The selection and processing of rock is carried out by the Scientific and Production Center "Technology of Mineral Coatings" according to many parameters, including both an assessment of the material composition of the rock and its various physical, chemical and mechanical characteristics that affect the properties of the created mineral coatings.

Issues of theoretical explanation of the effects that arise when metals are alloyed with ultrafine particles of minerals of natural origin are still in the nature of assumptions. In addition to the reason mentioned above, another reason is the change in the properties of minerals during grinding [6]:

- increase in specific surface area, increase in surface activity;

- transition of a substance into a new modification;

- morphization of crystalline substances;

- dehydration and hydration.

Another possible option for the mechanism of action of natural mineral materials in friction units was proposed in [7]. It concerns the use of serpentinites as the most common surface modifiers of friction pairs to solve the problem of hydrogen wear of metal and is as follows. Silicate materials such as serpentine contain siloxane (bridge) Si–O–Si bonds, when broken due to the destruction (crushing) of the mineral, uncompensated Si–O bonds are formed, which are active hydrogen acceptors in the form of H+ or H0. When they interact, compensated silanol groups Si–OH are formed. Thus, when introducing into the lubricant (or when doping the surface) ultrafinely ground serpentine, which has a large specific surface area and a large number of dangling siloxane bonds, the mineral coating technology creates conditions for the binding of active hydrogen located near the surface in the friction zone, i.e. prevents its interaction with metal and prevents hydrogen wear of the latter. In [7], it is assumed that silicates with dangling Si–O–Si bonds are effective adsorbents, absorbers, and acceptors of active hydrogen, and, therefore, can be used to solve the problem of hydrogen wear of metal in friction units.

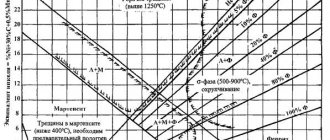

As practice has shown, the use of layered silicates of the serpentinite type is especially effective in friction units with extreme loads, including at high temperatures and pressures (SPC has protocols for the operation of parts with a mineral coating of a rolling mill). In this case, it can be assumed that the thermal decomposition of serpentine leads to the formation of more highly energy-dense and solid phases compared to the original serpentine. It can also be assumed that the finely dispersed material of serpentine decomposition products (apparently, largely amorphized) fills micropores, microcracks, various types of defects, vacancies on the surfaces of the friction unit, which leads to their strengthening [8] and a significant increase in wear resistance.

Let us present the results of a bench test of the durability of the Z-133 thread of a set of threaded connections for pipes made of Magnadur steel with and without mineral coating, carried out in 2021 by NPC TMP together with PKF-GazNefteMash LLC and Kovrov Drilling Equipment Plant LLC. Information about the test was presented in the speeches of the authors of this article at the III International Forum Valve Industry Forum & Expo'2016 - Industrial pipeline fittings for oil, gas, energy, chemistry and housing and communal services in Moscow.

Test details

Drill pipe made of non-magnetic steel Magnadur 501 is produced in German steel mills and is designed to create an axial load on the bit, increase the rigidity and stability of the lower part of the drill string when drilling directional and horizontal wells, as well as to eliminate the influence of ferromagnetism when using telemetry systems inside the pipe .

Composition of standard Magnadur 501 steel: 13.0–16.0% Cr, 18.5–22.0% Mn, 0.25–0.5% Ni, 0.3–0.6% Si, 0.35– 0.60% Mo, 0.32–0.40% N, <0.04% C, <0.006% S, <0.03% P, rest Fe.

The corrosion resistance of stainless steel directly depends on the chromium content: with a chromium content of 13% and above, the alloys are stainless under normal conditions and in mildly aggressive environments, more than 17% are corrosion-resistant in more aggressive oxidative and other environments. The reason for the corrosion resistance of stainless steel is explained mainly by the fact that a thin film of insoluble oxides forms on the surface of a chromium-containing part in contact with an aggressive environment. However, the formation of a protective film of oxides on the surface creates problems when creating reliable wear-resistant coatings using traditional methods.

In addition, the cost of pipes made of non-magnetic steel Magnadur 501 is quite high, and, according to statistics, the number of breakdowns, for example tubing, in some cases reaches 80% of the total number of breakdowns of well drilling equipment. In this case, in most cases (~50%) tubing failures occur associated with the threaded connection [9, 10]. All this indicates the relevance of the problem of increasing the wear resistance and durability of pipes, in particular the oil and gas range.

During testing, wear-resistant mineral coatings were created on sets of nipple-coupling pipe connection samples made of Magnadur 501 steel.

Samples with and without mineral coating were used in the experiments.

The purpose of this work is to determine the service life of a nipple-coupling set for connecting pipes made of Magnadur 501 steel with a mineral coating in comparison with a set without a mineral coating.

Before testing, thread-sealing lubricant RUSMA R-14 TU 0254-068-46977243–2009 was applied to all threaded connections, then the samples (Fig. 1) were screwed together manually using a 0.4 m long wrench.

Rice. 1. Samples for testing the nipple-coupling set

Methods for increasing corrosion resistance.

Of all the designs. The materials that are most resistant to corrosion are plastics, ceramics, glass, rubber, asbestos and concrete. However, in many other performance properties, these materials cannot compete with metals. Highly resistant noble metals are too expensive to be used as the main construction materials of modern technology. The most accessible metal is iron, which has the required physical complex. properties, but low resistance to corrosion. To increase the latter without compromising the mechanical characteristics, Fe is alloyed with other metals, for example, chromium. When alloying a significant amount of chromium and sometimes nickel, stainless steels are obtained. Austenitic steels have the greatest resistance to uniform corrosion if conditions exist to maintain them in a passive state. Austenitic steels are resistant to air, nitrogen solutions, etc. org. acids, sulfuric acid in a certain concentration range, sulfurous acid and alkalis. However, in other environments they are susceptible to pitting, crevice and intergranular corrosion, as well as corrosion cracking. Ni, Al, Cu, Ti and alloys based on them are also important corrosion-resistant materials. Nickel is resistant to hot and cold alkalis, diluted non-oxidizing organic and inorganic acids, as well as air atmosphere. Alloying with copper increases its resistance to corrosion and will restore it. environments, as well as to pitting corrosion in sea water. Alloying with chromium increases resistance to oxidizing environments, and alloying with molybdenum increases resistance to reducing environments; simultaneous alloying with chromium and molybdenum - exposure to both environments. Aluminum has good resistance to corrosion in solutions of acetic and nitric acids, S vapors, SO2 and others. Al is alloyed with small amounts of other metals, mainly to improve its mechanical properties. Copper is resistant to air, sea and fresh (hot and cold) water, and deaerated solutions of non-oxidizing acids. Alloys of Cu with Al (aluminum bronze) and Ni (cupronickel) are used for the manufacture of condenser tubes, and aluminum bronze is also used for pump housings and ship propellers. Titanium and its alloys have high corrosion resistance in sea water, air polluted by industrial emissions, and in a number of aggressive chemical environments (see also Corrosion-resistant materials). In practice, corrosion protection is widely used by surface alloying of inexpensive alloys with good mechanical characteristics. The surface layer of ordinary steel can be converted into an alloy with high corrosion resistance by heating in a powder mixture containing Zn (diffusion galvanizing), Al (alitizing) or Cr (chromium plating), sometimes with special. activating additives. You can also clad a cheap, low-resistant material with a thin layer of a more corrosion-resistant material, for example, by hot rolling two sheets together to the desired thickness of the resulting “bimetal.” The surface of products is modified by applying thin coatings of other metals or alloys suitable for protection against atmospheric corrosion. The composition and method of coating application may vary. Coatings of Zn, Al and their alloys are most often applied to rolled steel by spraying: the coating metal in the form of wire or powder is melted in an electric arc or flame, sprayed with a gas jet and deposited on the prepared surface. Coatings formed by dipping the protected products into a bath of molten Zn or Al are distinguished by good adhesion and uniform thickness. Electrochemical deposition methods are widely used in cases where a coating of a very small and controlled thickness is required, and the product should not heat up too much. This is how Cr, Ni, Sn, Zn, Cd and others are applied. Chrome coatings are decorative and, due to the high ability of chromium to passivate, can have a high protective ability, but, as a rule, they contain cracks and therefore are more often applied over nickel coatings.

Methods for reducing the corrosive activity of the environment. The most common aggressive media are water, aqueous solutions of acids and alkalis, atmosphere, soil. The aggressiveness of aqueous environments depends on the O2 and CO2 dissolved in them, the removal of which is one of the methods of combating corrosion of iron, steel, copper, brass, zinc, and lead. Phys. removal of O2 and CO2 is achieved by heating water under reduced pressure or blowing with an inert gas; chemical removal is achieved by passing iron or steel filings through a layer, treating with a reducing agent (sodium sulfate, hydrazine). In the energy sector and some branches of technology, water is also freed from local corrosion stimulants, for example, chlorides. The aggressiveness of aqueous environments is effectively reduced by small additions (rarely more than 1%) of corrosion inhibitors, the protective effect of which is due to the formation of insoluble corrosion products firmly bound to the surface. Typically, anodic inhibitors are used: hydroxide, carbonate, silicate, borate, phosphates, sodium nitrite and benzoate, and cathodic inhibitors (zinc sulfates, sodium bicarbonate, and some others). Anodic inhibitors in insufficient concentrations cause pitting corrosion. They are more effective when mixed with cathodic inhibitors, and the combined effect often exceeds the sum of the individual effects. In acidic environments, specific, mainly organic inhibitors are used. A special class consists of passivator inhibitors, which transfer the metal to a passive state by shifting its electrode potential to a more positive one. region. These are oxidizing agents, often of the peroxide type, as well as compounds of noble metals, the exchange deposition of which on the protected metal contributes to the achievement of passivation potential. The aggressiveness of the atmosphere greatly depends on its humidity and on whether the area is industrial, rural, marine, etc. (see Atmospheric corrosion). For any metal, depending on the hygroscopicity of its corrosion products and dust particles falling on the surface, there is a certain critical relative humidity, below which it is not exposed to atm. corrosion; for Fe, Cu, Ni, Zn it ranges from 50 to 70%. Therefore, in an open atmosphere, it is advisable to periodically clean the surface of the product from hygroscopic contaminants. The hygroscopicity of steel corrosion products is reduced by alloying with copper in small quantities. For items of historical value, their storage temperature is sometimes artificially maintained slightly above the dew point. In cavities and packaging of valuable products, low relative humidity is maintained using moisture absorbers. Volatile corrosion inhibitors are also very effective, for example, cyclohexylamine carbonate or nitrate, which, slowly evaporating, are deposited on the protected surface to form an independent adsorption film. However, while protecting steel, such inhibitors can increase corrosion of other metals. Therefore, to protect products containing various metals from corrosion, special compounds are needed. Packaging materials (paper, cardboard, film) containing a suitable corrosion inhibitor are common. The aggressiveness of the industrial atmosphere is determined mainly by fuel combustion products and other emissions (SO2, CO2, H2S, NO2, NH3, soot, suspended salts). Of these, the main stimulator of corrosion is SO2, which turns into sulfuric acid on the metal surface in a humid atmosphere. In closed volumes, org. vapors act as corrosion stimulants. acids (formic, acetic, propionic) released from some types of wood, plastics, adhesives, paints. The only way to reduce the aggressiveness of the industrial atmosphere is to eliminate emissions, condition the premises and filter the incoming air. The corrosive aggressiveness of soil is determined by its O2 content, humidity, electrical conductivity, and pH (see Underground corrosion). In acidic soils, pieces of lime near a metal buried in the soil can for a long time create a pH sufficient to maintain the metal in a passive state.

Protective insulating coatings. Among organic insulating coatings, paint and varnish are widely used for protection against atmospheric corrosion; for underground structures, thick coatings of coal pitch, bitumen, and polyethylene, combined with cathodic electrochemical protection. To improve adhesion, the surface for coating is prepared: thorough (mechanical or chemical) cleaning from dirt and corrosion products, special chemical or electrochemical treatment (phosphating, chroming, anodizing). Continuity is increased by using multilayer (usually three-layer) coatings. The first (primer) layer requires max. adhesion to metal and good protective characteristics achieved by introducing pigments with inhibitory properties (red lead, zinc chromate). The final coating thickness usually does not exceed 0.75 mm. The use of modern synthetic materials instead of natural oils allows you to increase the service life of the coating by 3-5 times. Some plastics, such as epoxy and polyurethane resins, effectively protect metal in the form of thin coatings; others (polyvinyl chloride, polyesters, some fluoro-polyolefins, polyethylene) are used as relatively thick coatings. Thick and especially reinforced coatings can be considered as corrosion-resistant linings. Among inorganic protective coatings, glassy enamels are important, used primarily. to protect cast iron and steel products (tanks, bathtubs, household appliances) from exposure to the atmosphere, water and other environments. The interior surfaces of steel pipelines, hot and cold water tanks, petroleum storage tanks and some chemical products can be protected with cheap cement coatings. A special class consists of the so-called. conversion protective coatings, which consist of stable compounds based on the metal being coated (phosphate, chromate, oxide), obtained by chemically. or electrochemical processing. They are used primarily. as a base for paint and varnish coatings.

Electrochemical protection is based on the characteristic dependence of the rate of corrosion processes on the electrode potential of the metal. Cathodic protection is widely used to reduce the corrosion rate of underground structures (pipelines, communication cables, pile and steel foundations), ship hulls, overpasses, and offshore drilling wells. Typically, cathodic protection is used in neutral environments, when corrosion occurs with oxygen depolarization, and, therefore, under conditions of increased cathodic polarizability of the metal. There are two options for cathodic protection. In the first option, the required shift of the electrode potential is achieved by cathodic polarization using external. current source and auxiliary inert anodes (protection with imposed current); in the second - by contacting it with massive electrodes made of a more electronegative metal, which, dissolving anodically, ensure the flow of cathodic current to the structure being protected (galvanic protection). Alloys are used as “sacrificial” anodes. The first option is used to protect extended structures, usually in combination with insulating coatings, in environments with both low and high electrical resistance. Its advantage is the ease of regulating the protective current and maintaining the protective potential even when the insulating properties of the coating change over time. However, when using cathodic protection with an imposed current, another metal structure located near the protected one can serve as a conductor and be subject to increased corrosion. The galvanic version of cathodic protection is usually used for corrosion protection of small structures with good coverage and low current consumption or for local protection. Typically, there is no corrosion of adjacent metal structures. Anodic protection, used in acidic environments, is applicable to metals and alloys that can be passivated and remain passive over a relatively wide range of their potentials (most transition metals and alloys based on them, including stainless and carbon steels). The metal is passivated and maintained in a passive state by polarizing its external appearance. anode current. Due to the low current value, its penetrating ability is high and even surface areas remote from the cathode can be protected. More often, however, this method is used to protect containers containing aggressive chemical products.

Test procedure

The parts were transported to the MS-4 coupling and screwdriver machine and installed in the machine (Fig. 2). The position of the flywheel relative to the stationary frame (point 0) was noted, screwed all the way and unscrewed to point 0.

Rice. 2. Scheme of installation of samples in the machine

Make-up conditions:

- make-up speed – 6 rpm;

- number of make-ups – 400 cycles;

- make-up torque – no more than the nominal fastening torque of the lock thread according to TU 1324-00186528288–2010.

So, for a pipe D = 168 mm, d = 83 mm, with a 3-133 thread, the nominal fastening moment is 31.8 kNm.

The following make-up moments were set on the MS-4 machine:

- first make-up – 10 kNm (1000 kgf);

- second make-up – 21 kNm (2000 kgf);

Test results

The first set [sample N (nipple) without coating – sample M (coupling) without coating] withstood 30 screwing and unscrewing, then jamming occurred. After unrolling, traces of thread sticking are visible (destruction of the thread along the fourth thread, Fig. 3).

Rice. 3. Nipple-coupling pair of the first set after testing

The second set [sample N with mineral coating – sample M with mineral coating] withstood the planned number of test cycles - 400 screwing and unscrewing. After unscrewing, it was established that only the thrust ends of the samples were damaged (Fig. 4).

Rice. 4. Nipple-coupling pair of the second set after testing

It can be concluded that wear-resistant antifriction mineral coatings can be successfully created on the complex surface of a threaded joint.

The results of testing a set of pipe samples (nipple-coupling) made of Magnadur 501 steel showed that with a mineral coating, the number of screwing-unscrewing cycles is more than an order of magnitude greater than that of a set of samples made of the same steel without a mineral coating.

Considering the condition of the mineral-coated threads after 400 make-up and break-out cycles, we can predict the good condition of this pair even after 1000 cycles.

When planning a large number of make-up and break-out operations (more than 100 cycles), it is recommended to create wear-resistant mineral coatings on the end surfaces of these parts.

Mineral coatings are a promising technological tool for increasing the wear resistance of various parts, assemblies and mechanisms, including those made of chromium-containing corrosion-resistant steels for use in various industries, including valve engineering, compressor technology and the oil and gas industry.

Bibliography

- RF patent No. 2421548. A method for forming a combined mineral surface layer on metal parts, protecting them from the effects of aggressive environments and with specified tribological properties.

- Kislov S., Kislov V., Ostrovsky P. and Woydt M. Localized hardening and structuring of steel by a simple process//53 Tribologie Fachtagung “Reibung, Schmierung und Verschleiβ” der GfT in Gottingen, Gottingen, 24.09–26.09.2012, Herstellung: Druckservice Zillekens, Band 2, p.49/1–49/7.

- Kislov S.V., Kislov V.G., Skazochkin A.V., Bondarenko G.G., Tikhonov A.N. Effective mineral coatings for hardening the surface of metallic materials//Metals. 2015. No. 4.

- Kislov S.V., Kislov V.G., Balash P.V., Skazochkin A.V., Bondarenko G.G., Tikhonov A.N. Increasing the wear resistance of threaded connections of steel pump-compressor pipes when applying a mineral coating // Oil and Gas Business. 2015. No. 4. Electronic access: [https://ogbus.ru/years/42015/]/

- Kislov SV, Kislov VG, Balasch PV, Skazochkin AV, Bondarenko GG and Tikhonov AN Wear resistance of a metal surface modified with minerals//Materials Science and Engineering/IOP Conf. Series: Materials Science and Engineering 110 (2016). Electronic access: [https://iopscience.iop.org/article/10.1088/1757899X/110/1/012096/pdf].

- Grushev V.V., Lazarev S.Yu. Industrial applications of mineral coatings and ultrasonic processing. Chita: ZabGU, 2012.

- Heinicke G. Tribochemistry. M.: Mir, 1987.

- Yushkin N.P. Mechanical properties of minerals. L.: Nauka, 1971.

- Prokofiev A.A. Technological improvement of corrosion resistance of threads of pump-compressor pipes. Dis…. Ph.D. tech. Sci. M.: Mos. state industrial univ., 2013.

- Saroyan A.E., Subbotin M.A. Operation of tubing columns. M.: Nedra, 1985.

Chemical resistance of aluminum and its alloys.

The standard electrode potential of aluminum is -1.66V, i.e. it is a fairly active metal. However, due to its tendency to passivate, aluminum can be resistant in many environments.

In its normal state, the surface of aluminum is covered with a layer of oxide with a thickness of 5 to 100 nanometers. The film is firmly adhered to the metal and covers it with a continuous layer. A film on aluminum is formed at pH=3-9. The corrosion resistance of aluminum is higher for the most pure aluminum (AB1 and AB2) with an aluminum content of 99.9-99.85%, respectively, and lower for technically pure A00 and A0 with an aluminum content of 99.7-99.6, respectively. Duralumin (duralumin, 2-7% copper) has low corrosion resistance. Silumin casting alloys (0.8-13% silicon) hold up well in oxidizing environments.

Aluminum struts:

• In atmospheric conditions;

• In environments containing H2S, SO2, NH3;

• In water when heated;

• In solutions of salts with oxidizing properties - chromate, nitrate;

• In concentrated solutions of nitric and sulfuric acids (have oxidizing properties);

• In dilute sulfuric acid at 20o C;

• In oleum up to 200o C;

• In phosphoric acid at room temperature;

• In acetic acid with a concentration of 1-99% by weight at temperatures up to 65o C;

• In boiling acetic acid only at concentrations of 98-98.8% mass;

• In formaldehyde;

• In dry hydrogen chloride.

Aluminum is unstable:

• In neutral solutions of salts containing halides - fluorides, chlorides, bromides, iodides;

• In sulfuric acid of medium concentration;

• In boiling acetic acid up to 98% mass and above 98.8% mass;

• In drop-liquid and vapor mercury (corrosion of aluminum in acetic acid begins in the presence of mercury 0.000004% wt;

• In alkalis (with hydrogen depolarization);

• In hydrofluoric acid;

• In contact with copper, iron and their alloys.