Carbon steel, due to its affordable cost and high strength characteristics, is one of the most widely used alloys. From such steels, consisting of iron and carbon and a minimum of other impurities, various engineering products, parts of stakes and pipelines, and tools are made. These alloys are also widely used in the construction industry.

Carbon steel calibrated wheel is most often used in shipbuilding and mechanical engineering

Compound

Depending on the amount of carbon, carbon and alloy steel are divided. The presence of carbon gives the material strength and hardness, and also reduces viscosity and ductility. Its content in the alloy is up to 2.14%, and the minimum amount of impurities due to the manufacturing process allows the bulk to consist of iron up to 99.5%.

High strength and hardness are what characterize carbon steel.

Impurities that are constantly included in the structure of carbon steel have a small content. Manganese and silicon do not exceed 1%, and sulfur and phosphorus are within 0.1%. An increase in the amount of impurities is characteristic of another type of steel, which is called alloyed.

The lack of technical ability to completely remove impurities from the finished alloy allows the following elements to be included in carbon steel:

- hydrogen;

- nitrogen;

- oxygen;

- silicon;

- manganese;

- phosphorus;

- sulfur

The presence of these substances is determined by the steel melting method: converter, open-hearth or other. And carbon is added on purpose. If the amount of impurities is difficult to regulate, then adjusting the level of carbon in the composition of the future alloy affects the properties of the finished product. When the material is filled with carbon up to 2.4%, steel is classified as carbon.

Characteristic

The characteristics and structure of the metal are changed using heat treatment, through which the required surface hardness or other requirements for the use of the steel structure are achieved. However, not all structural properties can be adjusted using thermal methods. Such structurally insensitive characteristics include rigidity, expressed by the elastic modulus or shear modulus. This is taken into account when designing critical components and mechanisms in various fields of mechanical engineering.

In cases where the calculation of the strength of an assembly requires the use of small-sized parts that can withstand the required load, heat treatment is used. This effect on “raw” steel makes it possible to increase the rigidity of the material by 2-3 times. The metal that is subjected to this process is subject to requirements regarding the amount of carbon and other impurities. This steel is called high quality.

Classification of carbon steels

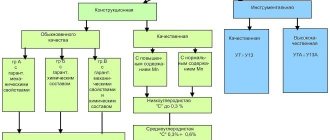

According to the direction of application of products, carbon steel is divided into tool and structural.

The last of them is used for the construction of various buildings and frame parts. Tools are used to make durable tools for performing any work, including metal cutting. The use of metal products in the household required the classification of steel into different categories with specific properties: heat-resistant, cryogenic and corrosion-resistant.

According to the method of production, carbon steels are divided into:

- electric steel;

- open hearth;

- oxygen converter.

Differences in the structure of the alloy are due to the presence of different impurities characteristic of a particular smelting method.

The relationship of steel to chemically active environments has made it possible to divide products into:

- boiling;

- semi-calm;

- calm.

Carbon content divides steel into 3 categories:

- hypereutectoid, in which the amount of carbon exceeds 0.8%;

- eutectoid, with a content of 0.8%;

- hypoeutectoid – less than 0.8%.

It is the structure that is a characteristic feature in determining the state of the metal. In hypoeutectoid steels, the structure consists of pearlite and ferrite. Eutectoid ones have pure pearlite, while hypereutectoid ones are characterized by pearlite with admixtures of secondary cementite.

By increasing the amount of carbon, steel increases strength and reduces ductility. The viscosity and brittleness of the material also have a great influence. As the percentage of carbon increases, the impact strength decreases and the fragility of the material increases. It is no coincidence that when the content is more than 2.4%, metal alloys are already classified as cast iron.

According to the amount of carbon in the alloy, steel is:

- low carbon (up to 0.29%);

- medium carbon (from 0.3 to 0.6%);

- high carbon (more than 0.6%).

High carbon steel: characteristics, properties, grades and markings

High-carbon steel, due to a number of undeniable advantages that it has, is successfully used for the production of products used in many industries.

Meanwhile, the use of steels in this category is not always advisable, so it is very important to have a good understanding of the properties and quality characteristics of such alloys.

Features of the material

Any steel, as is known, is an alloy of iron and carbon, to which various alloying elements can be added.

The division of steels into low-, medium- and high-carbon types depends on the amount of carbon present in their composition.

This element, which has a serious impact on the characteristics of the finished alloy, can be contained in steels from 0.02 to 2.14%. In steels classified as high-carbon, the amount of this element in the composition starts at 0.6%.

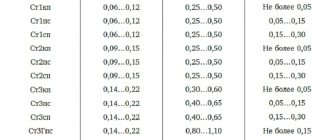

Steel grades and the proportion of various elements in their composition

One of the distinctive features that high-carbon steels have is that products made from them are difficult to weld; welding leads to cracks appearing in the weld zone.

This is explained by the fact that such materials, having a certain chemical composition, have a tendency to form hardened zones in those places where the metal is exposed to thermal effects.

Due to this feature of high-carbon steels, welding products made from them should only be done using electrodes with low thermal power. The welding arc used to connect products made of high-carbon steels must be of the recovery type.

The use of an oxidizing arc in such cases will lead to the fact that carbon will be burned out of the steel composition, and, as a result, the metal in the weld area will become more porous. Meanwhile, such a negative effect can be avoided if the products to be joined are preheated to a temperature of 200–2500.

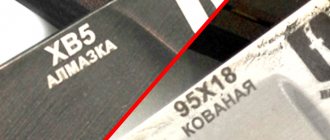

Marking

When designating carbon steels of ordinary quality, the letters St are used, which are accompanied by numbers characterizing the carbon content. One digit shows the quantity multiplied by 10, and two digits by 100. When guaranteeing the mechanical composition of the alloy, B is added before the designation, and compliance with the chemical constituents is B.

At the end of the marking, two letters indicate the degree of deoxidation: ps - semi-quiet, kp - boiling state of the alloys. For calm metals this indicator is not indicated. An increased amount of manganese in the structure of the product is designated by the letter G.

When designating high-quality carbon steels used in the manufacture of tools, the letter U is used, next to which a number is written confirming the percentage of carbon in a 10-fold amount, regardless of whether it is two-digit or single-digit. To highlight higher quality alloys, the letter A is added to the designation of tool steels.

Examples of designation of carbon steels: U8, U12A, St4kp, VSt3, St2G, BSt5ps.

Production methods and quality differences

According to production methods, alloys are divided into three types:

- open hearth;

- convector;

- in electric furnaces.

The production method and quality division are indicated in the metal certificate and can be indicated letter-wise at the end of the marking. For example, VD is electric arc remelting, Sh is slag remelting.

Open hearth furnaces with the lowest quality are used for reworking and rolling of group A. Electric furnaces produce an alloy of high and very high quality.

Production

The metallurgical industry produces metal alloys. The specificity of the process for producing carbon steel is the processing of cast iron billets with the reduction of suspended matter such as sulfur and phosphorus, as well as carbon, to the required concentration. The differences in the oxidation technique by which carbon is removed allows us to distinguish different types of smelting.

Oxygen converter method

The basis of the technique was the Bessemer method, which involves blowing air through liquid cast iron. During this process, carbon is oxidized and removed from the alloy, after which the iron ingots gradually turn into steel. The productivity of this technique is high, but sulfur and phosphorus remained in the metal. In addition, carbon steel is saturated with gases, including nitrogen. This improves strength but reduces ductility, making the steel more prone to aging and high in non-metallic elements.

Given the low quality of steel produced by the Bessemer method, it was no longer used. It was replaced by the oxygen-converter method, the difference of which is the use of pure oxygen, instead of air, when purging liquid cast iron. The use of certain technical conditions during purging significantly reduced the amount of nitrogen and other harmful impurities. As a result, carbon steel produced by the oxygen-converter method is close in quality to alloys melted in open-hearth furnaces.

The technical and economic indicators of the converter method confirm the feasibility of such smelting and make it possible to replace outdated methods of steel production.

Open hearth method

A feature of the method for producing carbon steel is the burning of carbon from cast iron alloys not only with the help of air, but also by adding iron ores and rusty metal products. This process usually takes place inside furnaces, to which heated air and combustible gas are supplied.

The size of such melting baths is very large; they can hold up to 500 tons of molten metal. The temperature in such containers is maintained at 1700 ºC, and carbon burning occurs in several stages. First, due to excess oxygen in flammable gases, and when slag forms above the molten metal, through iron oxides. When they interact, slags of phosphates and silicates are formed, which are subsequently removed and the steel acquires the required quality properties.

Steel melting in open hearth furnaces takes about 7 hours. This allows you to adjust the desired composition of the alloy when adding different ores or scrap. Carbon steel has long been manufactured using this method. Such stoves, in our time, can be found in the countries of the former Soviet Union, as well as in India.

Electrothermal method

It is possible to produce high-quality steel with a minimum content of harmful impurities by melting it in vacuum furnaces of electric arc or induction furnaces. Thanks to the improved properties of electric steel, it is possible to produce heat-resistant and tool alloys. The process of converting raw materials into carbon steel occurs in a vacuum, due to which the quality of the resulting workpieces will be higher than the previously discussed methods.

The cost of such metal processing is more expensive, so this method is used when there is a technological need for a high-quality product. To reduce the cost of the technological process, a special ladle is used, which is heated inside a vacuum container.

Classification by degree of deoxidation

According to the degree of deoxidation, carbon alloys are divided into the following types:

- boiling;

- calm;

- semi-calm.

Boiling alloys of ordinary quality are released from the furnace immediately after adding the deoxidizer. In some cases, deoxidation is carried out in a ladle. As a result, many air bubbles form under the crust.

For tool alloys, the deoxidation reaction begins before the spill and ends completely when poured into the ladle.

Boiling steels are used for the production of ingots, slabs and blooms - large-section rolled products. Subsequently, they are melted down into high-quality metal in electric furnaces or converted into rolled products of a smaller diameter - round, square. During processing, air escapes and the grain is pulled lengthwise, increasing the mechanical properties of the steel. Semi-quiet steels are characterized by increased malleability.