Wells have been used by mankind since ancient times. The technology of their construction has been perfected over centuries and remains almost unchanged. The problems faced by the owners of such structures remain unchanged. One of the most common is reducing the amount of water.

Often the only solution is to deepen the wells to the next aquifer. We will tell you how and in what way the water intake excavation is deepened. You will find out what you will need to stock up on to carry out the work.

When to deepen a well

Not all cases require deepening the well, as this action may not solve the problem of water shortage. There are at least four good reasons why a well needs to be deepened to the next aquifer.

- There is no possibility to dig a new well.

- The depth of the well column has more than ten rings.

- The well partially or completely dries up.

- In one day, the well's filling capacity dropped to one ring.

A well that requires deepening

In almost all other cases, you will need to dig a new well.

Preparatory work

There are several reasons for water loss. Water may drain due to prolonged drought. Also, water may drain due to the close location of an artesian well during periods of high water standing. Before you decide to deepen your well, it is important to determine whether the problem is temporary or not. If the water has gone and it has been gone for a long time, then you will have to dig.

To begin deepening a well, some important procedures must be performed. For example, it is necessary to assess the actual condition of a well. You should also check the soil's ability to hold rings and determine the new groundwater level. These are the main factors to consider before getting started. When all the calculations have been made correctly, then you can begin to deepen the well to its maximum depth. In most cases it can reach three meters.

Note!

Without the correct calculations, deepening a well can be a waste of time and money.

Ring offset

The deepening process itself will be logical if the well has no more than fifteen rings that are not shifted to the side relative to each other. If this displacement is small, then first you will need to align the entire column. To do this, at the beginning of work, install staples at each seam of the water intake column. This will prevent the column from breaking. Moreover, the water-lifting structure should be removed, and if the top has a house, then it is best to remove it.

Reasons for water leaving the well

The water level in the well may not be constant. It depends on a combination of many factors beyond the control of the owner of the structure.

The hydrogeological conditions of the area come first. Prolonged drought in summer and severe frosts in winter can lead to complete drying out of the well. This is a completely normal phenomenon and does not require any human intervention.

The availability of water in a well is influenced by many factors. Perhaps unfavorable weather conditions led to its drying out. Then human intervention is not required; after some time it will be filled with water again

Practice shows that after some time the water will return. Most often, those who dug their wells at the beginning of summer suffer from the consequences of this phenomenon.

At this time there is a peak in the rise of high water, which causes the work to be mistakenly stopped before reaching the real aquifer. Therefore, experts strongly recommend digging a new well during a dry period or late autumn, and even better - in March, before the snow begins to melt.

It often happens that a limited-size aquifer gradually runs out. Moreover, if it does not have regular replenishment, and the operation was quite active. In this case, the question arises, which is better: to deepen the old well or build a new source. In most cases, deepening is more rational as it is the least expensive measure.

The same is done in the event of a sharp drop in the groundwater level in a given area. This occurs when the aquifer or lens cannot be recharged by infiltration of precipitation. In addition, the bottom of the well can become silted, making it impassable for water and forcing it to find other ways to escape.

It also happens that the precipitation level is normal, but there is still no water in the well. In this case, the reason may be the appearance in the immediate vicinity of a new well or borehole with impressive water abundance, which can temporarily “take away” water.

In this case, you need to wait four to five weeks; if the water level has not recovered, you will have to deepen the well shaft.

A silted filter is one of the reasons for the decrease in water flow into the well. It should be cleaned regularly. Even in this case, a large amount of silt and dirt rises from the bottom

And another reason for the disappearance of water can be the wear and tear of the materials in the water intake part of the well shaft. In this case, water will flow poorly due to capillary channels clogged with destroyed material.

In addition, they sometimes become very clogged with dense silt and sandy sediment, which is difficult to distinguish under the water column and to remove. To free the water intake part from contamination, the well will need to be cleaned, repaired and completely sealed.

You can do this yourself!

Almost any well can be deepened with your own hands. To do this, you can install smaller rings, but only if the entire column is smooth and has no displacements or curvatures. A bracket is mounted on the bottom seam. This will prevent rings with a smaller diameter from settling on the barrel. Next, the trunk is dug inside the well into three rings. After this process, new rings are installed and secured with staples. The junction of two columns is also connected using staples. They will not allow the main column to sag in case of soil shrinkage. At the very end of the work, the bottom of the well is covered with pebbles. It will act as a filter. Before starting the well, all new seams should be caulked.

Pumping

So, to complete this work you will need a set of the following tools and materials:

- shovel with a short handle,

- water pump,

- bumper,

- winch for lifting soil,

- ladder, preferably rope,

- a winch that can withstand a load of up to six hundred kilograms,

- lighting,

All this will allow you to complete the work quickly, efficiently and efficiently.

Repair rings

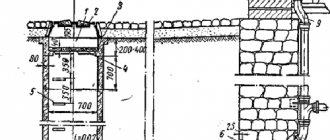

One of the effective means of deepening a well is the use of repair rings. However, they should be smaller in diameter. If the diameter of the rings of an already finished well is one meter, then rings of 0.7 meters should be used for deepening. This is important, otherwise the new rings will not be able to penetrate deeper. In some cases, rings with a diameter of 0.80 meters can be used. But this is only if the shaft does not have ring displacement. The standard height of the rings can be 0.90 or 1 meter.

Scheme of deepening using repair rings

Note!

If the shaft misalignment is large, then it is recommended to use rings of even smaller diameter up to 0.70 meters.

However, in this case the gap between the structures may be too large. It can be leveled with pebbles or stone.

Some, in order to simplify their already labor-intensive work, follow the path of least resistance. They dig up the bottom ring, hoping that the column will sag, and build up with new rings from above. However, as practice shows, this is not entirely the right decision. After all, as the column moves forward, it can hang and cling tightly, so that later you will have to make much greater efforts to somehow get out of this situation. If you deepen the well using the repair ring method, the water level may return to its original state. But such work can be one-time. If you do not want to encounter this, then it is best to deepen the well yourself to the maximum depth and lower the new rings down.

Schematic diagram

So, all of the above work can be divided into several stages:

- The shaft is checked for external protrusions that may interfere with the descent of the rings.

- Using a metal plate measuring 4x40x300 mm, the column is scraped.

- Four such plates should be installed on each seam, securing them with a 12 mm anchor bolt. Holes are pre-drilled.

Note!

This stage is important, since the plates will not allow the columns to break if the supporting layer begins to move during deepening.

- When the column is sufficiently well secured, a bottom filter is selected.

- Then digging for repair rings is carried out until the wall of the new tunnel begins to collapse.

- At this stage, the rings are lowered.

- If necessary, the column can be extended from above.

- To prevent the old column of rings from sliding onto the new repair one, it is recommended to connect them with corner brackets.

- At the very end, the filter is backfilled, as well as all seams are putty.

Note!

The ideal time for carrying out such work is considered to be autumn/winter. It is during this period that the water is at its lowest level. This will allow the new rings to be installed as deep as possible.

Well deepening technology

Repair and deepening of wells is carried out quickly and with maximum effect if modern techniques are used. The work is carried out in several stages. First, find out the possibility of modifying the well in this way and choose a method of resuscitation, which depends on the reasons for the disappearance of water and the composition of the soil. The main processes begin after the sequence of operations has been compiled.

Preparatory work

After the first signs of shallowing of the well appear, you should not immediately begin its restoration.

Wait a few months, the water often returns on its own. It is recommended to modify an existing source in the following cases:

- There is no free space for a new well.

- Pipes and electrical cables are connected to the well, and moving them will require significant financial costs.

- The produced water is of high quality.

- The trunk is quite deep - at least 10 rings.

- The daily intake of fluid is less than one ring or none at all.

Before deepening a well , check its condition.

Construction work can begin if the following conditions are met: the well was recently built, the concrete rings are without distortions, and the log cabins are in good condition. You can even revive a completely dry spring, but to do this you will have to remove a large volume of soil. Refuse modification in the following cases:

- When large quicksand is detected.

- Seasonal fluctuations in water levels are very large.

- The depth of the mine is less than 8 m.

- The well is very old, it will be necessary not only to dig, but also to restore the entire structure.

- If the underground part consists of a log house in which the logs are shifted relative to each other by 5 cm or more.

- The wooden parts of the mine have rotted.

To work you will need the following tools and devices:

- Shovel with a convenient handle for use in confined spaces.

- Pump for pumping out dirty water.

- Axe, crowbar or breaker for passing through hard rocks.

- Winch with a capacity of 500-600 kg for lifting buckets of soil.

- A compact ladder that does not take up much space, such as a rope ladder.

- Light source.

For the worker, prepare special clothing - rubber overalls and boots, a helmet.

Using smaller diameter rings

In this way, you can deepen a well made of concrete rings, built on sandy or other loose soil, by a maximum of 3 m. To carry out the work, you will need smaller repair products so that they move freely in the opening.

The recommended height is 90-100 cm. The outer diameter of the spare parts depends on the degree of curvature of the trunk, therefore, before deepening the well from concrete rings, check the condition of the structure. For a shaft with smooth walls, the gaps between new and old elements should be 20-30 mm. If the opening is 1 m, buy products with an outer diameter of 80 cm. But often the trunk has a curvature. If there are significant irregularities, use rings with a diameter of 700 mm. In this case, at the bottom of the well there will be gaps between the two trunks, which should be filled with stones and rubble.

Also for work you will need a cutting shoe - a shortened ring with a sharp cutting edge.

Before deepening the well with rings, check the reliability of the structure. If you find any gaps in the design, try to eliminate them by aligning the barrel. If this fails, secure the elements together with four metal brackets, which are fastened evenly around the circumference. They are made from metal plates measuring 4x40x300 mm, in which holes with a diameter of 13-14 mm are made. Attach the plates to the adjacent rings and mark the position of the mounting holes on the shaft through the existing ones in the workpieces.

Drill holes according to the marks, then secure the brackets with anchor bolts with a diameter of 12 mm. The installation of fastening devices is very important; they prevent the rings from moving even if the soil moves.

Work on deepening with additional rings is carried out in the following sequence:

- Make sure the bottom can withstand the additional load from the repair rings.

- Pump out all the water from their well.

- Remove the superstructure above the shaft.

- Place a ring with a sharp edge into the well, and a repair ring onto it. Seal the connection points.

- Secure the elements to each other with metal brackets.

- Use a plumb line to check the verticality of the walls of the new shaft.

- Remove the soil from inside the products, first in the middle, then under the shoe, until the shaft settles.

- Repeat the operation until a powerful stream of water appears.

- Check the verticality of the walls of the building.

- Form a bottom filter.

- Fill the gap between the pipe and the wall with small stones and sand.

- Reassemble dismantled buildings and removed equipment.

Instead of concrete rings, you can use plastic pipes or rings reinforced with stiffeners. Pipes can be installed to the very top of the shaft. In this case, samples with threads are used, which allow connecting adjacent elements. Plastic products have a long service life, but they can only be used once.

Application of pipes for filter recess

Produced using special pipes with a diameter of 500 mm.

In such products, holes of 1.5-2 cm are drilled for water to enter. Products can be metal or plastic. It is allowed to use ordinary (non-perforated) elements, and make holes in them yourself. Deepening the well with pipes is carried out in the following sequence:

- Wrap the inside of the pipe with fine-mesh stainless mesh and secure it in this position.

- Install the product vertically in the center of the well and fix it temporarily.

- Mount a tripod with a block above the shaft.

- Pass a rope through the block and attach a bailer to it - a special device for removing soil. It looks like a pointed piece of pipe with a valve.

- Make sure that the bailer is located exactly in the center of the well.

- Lift the device with a rope and check that there is 1.5-2 m of free space under it.

- Release the rope - the device will fall into the well and enter the soil, part of which will fall through the hole into the device.

- Lift the bailer and remove the soil from its cavity.

- Repeat the operation, periodically lowering the pipe into the vacant space.

- After obtaining the desired result, fill the space between the new and old shaft with crushed stone, stone and sand and concrete it.

- Add several layers of crushed stone to the bottom to create a bottom filter.

- Reinstall the buildings and equipment removed at the beginning of the work.

If you close the barrel with a lid, you get a chamber in which the temperature will never drop below zero. It is possible to install a pump and other equipment for water supply to the site.

Digging when deepening a well

A similar scheme for deepening a well involves removing soil from the well and then lowering the rings.

To do this, a worker descends to the bottom and digs a hole. The soil is removed with a bucket and lifted by auxiliary mechanisms, for example, a tripod with a block and a rope, which is connected to a winch. Periodically pump out accumulated water. During the process, do not forget about safety precautions. It is forbidden to dig to a depth of more than 40 cm at a time - there is a danger of sudden lowering of the rings with all the unpleasant consequences.

Remove soil evenly around the perimeter until the structure descends to the depth of the excavation. After this, install an additional ring of the same diameter on top. Seal the joint. Repeat the operation until the influx of water becomes strong.

Sometimes after digging the rings do not come down. To fix the problem, do the following: dig wells with a diameter of 150-200 mm around the well. To do this, use drills - manual, electric, or you can use a drilling rig. The length of the working tool must be at least 4 m. Fill the wells with water, this will loosen the soil. Using blows on the end of the shaft, lower it down until it stops.

If the rings still do not lower, make wooden shields and install them in the well. Prepare 25x150 mm boards from waterproof wood species, such as aspen. The length of the segments should be equal to the distance from the bottom of the already deepened well to the lower end of the shaft, which never sank after digging. Fill the space under the trunk with boards around the circumference. Strengthen the structure with aspen beams, which will create a rigid belt and will not allow the boards to be squeezed inward. The result will be a new ring, not concrete, but wooden, which will last a long time.

Quicksand is not a problem!

Shield for quicksand

In the presence of quicksand soil, work should be carried out extremely carefully. Moreover, it is not advisable to risk your life without effective assistive mechanisms available. It will be possible to achieve the desired result. However, it is possible.

Dredging in floating soils

To achieve the required result and pass a difficult section of soil, you should speed up your work. In this case, an additional ring is used as a load. The technology of the deepening process in this case is similar to that described above. You just need to have special equipment that will allow you to extract a large volume of sand from the mine at one time.

Interlocking concrete rings into a single unit

This is what will allow you to get the job done quickly and efficiently. To complete the job successfully, one important factor plays a role, which is the contact of the repair column with the hard rock of the quicksand. The chance of getting there is small, but it is possible. To do this, you can do the following: A raft made of deciduous trees is laid at the bottom. Afterwards the filter is removed. As a result of these actions, the water inflow will be greater than at the start of repair work. This technology is also used in cases where there is clay quicksand at the base.

Construction and design of the well

The design of the well has not changed for hundreds of years. The structure is a mine, the bottom of which is located in an aquifer.

The walls of the trunk are strengthened from crumbling. For these purposes, stone, wood, or a modern option - reinforced concrete rings can be used. A filter is usually installed at the bottom, which is a backfill of gravel 10-15 cm high. There are more complex multi-layer filters consisting of crushed stone, gravel and sand.

The mine is closed by the so-called well house, which houses a mechanism for raising water. The structure can be equipped with a pump, which greatly facilitates the supply of water.

The figure shows a diagram of the structure of a mine well. Any structure of this type is arranged in a similar way

The main “competitor” of a well is considered to be a well. Each source has its own strengths and weaknesses. In order to choose the best option for you personally, we suggest that you read the comparative review.

However, despite the advantages of a well, many people prefer a traditional water source. With proper operation, the well will last longer than it, while maintaining cleanliness in the mine is much easier than in a tubular borehole.

A structure with a manual water lifting mechanism does not require electricity and can be operated in any conditions, while a well pump is always energy dependent. In addition, the well can be dug and equipped manually, without the use of special equipment and mechanisms. However, problem-free operation of wells is rarely possible.

“Filter” recess method

The "filter" deepening method is another effective method of deepening a well. To do this, you will need to purchase a plastic or metal pipe Ø50 cm and one meter long. It should be perforated and then covered with fine mesh, preferably stainless steel. Then at the bottom of the well you need to dig out the earth with a bailer.

Filter

As the filter deepens, it will settle. Gradually the recess will be completed to the required depth.

To deepen or not to deepen?

Drilling a dry well with your own hands is a very difficult and costly task, both in time and money. That is why it is extremely important to determine the feasibility of a future event.

First of all, you need to answer a few questions:

- A decrease in the amount of water in the well cannot be associated with the weather: prolonged frosts or prolonged drought.

- The water remaining in the well retained its quality. It has no foreign odors, is tasty and clean. If this is not the case, the bottom filter may become silted. The problem can be solved by proper cleaning.

- The water level in nearby wells has not changed.

If the answer to all questions is positive, it is quite possible that the problem is in your well, and it needs to be deepened. But there is still no need to rush to start work.

To begin with, it makes sense to carry out the following activities:

- conduct geological exploration by interviewing neighbors - owners of wells or wells;

- accurately determine the daily water flow;

- find out from the meteorological service or from the owners of exploited water sources at what depth their aquifer is opened;

- determine the ability of the soil to “hold” the walls of the mine without settlement.

Such labor-intensive preparatory work is due to the fact that all types of soil have their own characteristics and are characterized by certain nuances during work. Violation of technology and incompetence of the employee can lead to the blocking of the aquifer, or even destruction of the trunk when it gets into quicksand.

Deepening a well is an extremely labor-intensive and costly undertaking. Before starting work, you need to ensure its feasibility. It is quite possible that digging a new well will be the best solution

Quicksand is soil consisting of a water-saturated mixture of sand, organic matter and silt, which under certain conditions begins to move, which is dangerous not only for the well, but also for nearby buildings.

Mistakes in deepening a well shaft can be costly, both in terms of labor and money. The procedure can be carried out only once and if it fails, the only thing left to do is fill up the well.

At the same time, the cost of a new well dug nearby in some cases may turn out to be less than deepening the old one, and no one can guarantee success.

Experts recommend deepening the mine if several conditions exist:

- There is no quicksand at the bottom of the trunk.

- The well shaft is very deep, at least 10 rings. Otherwise, building a new structure will cost less.

- Good quality of water at the source.

- No deformation of concrete rings inside the trunk. If there are displacements, their value does not exceed 40 mm.

- The daily water flow is less than one ring.

The well will have to be deepened to the second aquifer. This is at least 5 meters, and there are no guarantees that the water in it is suitable for drinking.

The presence of quicksand at the bottom of the well, a moving layer of a mixture of sand, organic matter and silt, often becomes an insurmountable obstacle to further deepening

Weigh everything carefully!

As can be seen from the above, the work of deepening wells in a dacha with your own hands is very complex and difficult. If you do not have experience, then it is better not to take on the job in a hurry. It may be more cost-effective to turn to specialists. If you still decide to do this work yourself, then you should carefully consider each stage of the work. As for the choice of material that will act as a filter, you can use fine-grained crushed stone, sand concrete and coarse sand.

Koepka

So, if you already have experience in deepening a well in your country house, leave your comments at the end of the article. Successful work to you!

Final stage

After the well has been deepened with a plastic pipe or reinforced concrete rings, dirty water will flow into the mine. It must be pumped out with a deep-well pump. The walls of the plastic pipe and concrete shaft are treated with a solution of potassium permanganate or bleach (10%). After disinfection, the walls are washed well, and the water from their source is pumped out. The final stage of work is the arrangement of protective structures and a lifting mechanism (gate).

Self-deepening of the source will reanimate the water supply and will save on the cost of the services of a specialized team. The repaired well will provide moisture for up to 50 years, until the water horizon dries up.