Advantages of cast iron sewer pipes

When compared with analogues made of plastic, this type of pipe is distinguished due to the many advantageous offers for:

- wear resistance;

- strength;

- excellent sound insulation characteristics;

- optimal stretch performance.

Consider cast iron sewer pipes with a diameter of 200 mm. These products are in great demand when installing drainage systems in multi-storey buildings with a load significantly higher than the standard for household needs.

These pipe products are most often installed:

- in large-scale slaughterhouses;

- in meat processing plants;

- at catering and food industry enterprises;

- in beverage factories;

- on farms with animals;

- in medical and educational institutions;

- in medical sanatoriums;

- in non-industrial laboratories, etc.

Connection types

In addition to the fact that there are differences in the type of pipe connection, they also differ in diameter. For use in residential buildings, 3 standard sizes are usually used:

When selecting pipes, it is extremely important to take into account both the standard size and the method of connection. Check the quality of the product. Be sure to pay attention to the following points:

Popularity of cast iron pipes

This component of drainage is in demand:

- when arranging sewerage, water and heat supply;

- when moving petroleum products;

- during the period of water supply to fire safety systems;

- at enterprises of the chemical industry, oil refining and coal mining.

Cast iron sewer pipes are equipped with shaped elements that are produced in one piece. The material, gray cast iron, can be easily machined using a variety of cutting tools.

As for the service life of cast iron pipe products for sewerage, it can be increased by using a coating - petroleum bitumen or whitened cast iron, which has high strength and excellent anti-corrosion properties. The service life of the products will be even longer if the coating is free of slag inclusions, fistulas and seams (pro

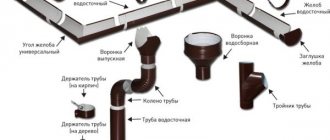

Drainage system

During the installation of cast iron sewer pipes, in order to extend their service life and prevent mechanical defects, a very careful attitude is necessary.

Thanks to the layer of petroleum bitumen, which is applied to pipe products, reliable protection against corrosive destruction is provided, and the internal surface is made smoother. In this case, the friction of the liquid on the surface of the pipe is significantly reduced.

The joining of cast iron products is carried out thanks to shaped parts made of the same material. When installing a drainage system under sinks, sinks, washbasins, it is better to use cast iron pipes with a cross-section of 50 mm, and when installing a toilet - 100 mm under the outlet pipe. All pipe products in the toilet and risers have the same diameter.

How to dismantle old pipes?

But no matter what material is chosen for the new pipes, you first need to decide how to dismantle the old cast-iron sewer and how to cut the cast-iron pipe. Before dismantling a cast iron sewer, you should ask your neighbors not to use water, otherwise, after removing the riser, all the neighbors' drains will flow into your apartment.

Dismantling a cast iron sewer system is not an easy task. The fact is that previously standards were adopted, according to which the plumber who installed the cast iron sewer sealed the pipe connections using a composition containing cement. Such connections do not become loose over the years, but, on the contrary, become stronger. Therefore, hammering cast iron pipes with your own hands will require effort.

Especially great difficulties arise when it is necessary to dismantle the sewer riser, which runs from apartment to apartment. To install this element in Soviet times, they used sulfur filling. This installation option gives an unusually strong connection, so disassembling such a riser is very difficult. Let's figure out how to dismantle a cast iron sewer.

To remove sulfur filling, you cannot do without heating; a gas torch or blowtorch is used for burning. Moreover, such work should be carried out in a gas mask, since the sulfur vapor released is very poisonous.

The second difficulty is that when dismantling the sewer with your own hands, you need to be as careful as possible in order to prevent destruction of the sewer tee and parts located in the ceilings and neighboring apartments.

Otherwise, you will have to change the cast-iron sewer riser in the neighboring apartment, and this is an additional and significant expense. So, how to remove the riser and dismantle the cast iron sewer? Here are some useful tips:

- First, you need to disconnect the pipes adjacent to the bathtub, washbasin and toilet, so as not to damage the plumbing items and water supply laid nearby in the process.

- If the toilet was installed on a cement joint, then the likelihood that it will be possible to maintain the previous model is incredibly low. Even if the work is done carefully, the neck will most likely break off, and the cracked product will not be usable. Therefore, you should not waste time; it is better to immediately break the toilet with a hammer and then remove it in parts.

Advice! You need to break the toilet as carefully as possible, otherwise fragments of sanitaryware flying in different directions can cause injury.

- You can begin the process of disassembling the pipeline. First, you should disassemble the short elbows, the master saws them and removes parts of the putty in the joint using a screwdriver. How to cut cast iron pipes? The wiring elements are cut using a grinder; sawing a cast iron pipe with a hacksaw will take a very long time.

Installation and joining of sewer pipes

What characterizes the joining of cast iron pipes in a drainage system?

Let's look at the most basic ones:

- When installing cast iron sewer pipes, attention is paid to error-free joining of pipe products. For everything to work out perfectly, you need to prepare tow in a timely manner that does not contain impurities and wood waste.

- Before you start filling the socket with an asbestos-cement mixture, you need to fill it with tarred hemp strands, which you then roll into a rope and caulk into the cracks of the socket of the cast-iron pipe. The thickness of the strand should be slightly larger than the width of the socket slit, and the length should be such that the strand enters the socket no more than 30 mm from the edge.

- To obtain a mixture of asbestos and cement, it is necessary to mix Portland cement grade 400 or more (70% by weight) and asbestos fiber, grade at least 4 (30% by weight). Before use, almost 30 minutes before use, the mixture must be moistened by adding water (10-12% of the total mass).

- Fittings are joined to cast iron pipes by sealing the gap that has arisen between the inner surface of the socket and the outer side of the shaped part or the end of the pipe inserted into the socket.

- When installing cast iron pipes, the direction of the sockets is ensured in the opposite direction of fluid movement.

- To make the pipe shorter, you need to place it on wooden blocks, use a chisel to punch a groove, the depth of which is a third of the wall thickness, and divide the pipe into parts with a hammer.

- The tail component of the tubular product is placed into the socket of another so that a gap of 5-6 mm is obtained, which can be controlled with a special hook. Further actions include: centering the pipes, sealing the annular gap with tarred strands of flax or hemp rope, previously greased.

- The initial sealing layer is placed in a ring so that the edges of the strands or rope do not end up in the pipe. Continue the compaction procedure until the socket is two-thirds full. Moreover, the outer sealing layer is covered with a strand/rope without fat/resin to ensure excellent adhesion to the cement mixture.

- After the sealing layer has settled, it will be necessary to center the pipe in the socket using wedges. The third part of the depth of the socket, which is still empty, now needs to be filled with cement (grade 300-400), maintaining a ratio of 9:1 (cement and water).

- Then they begin to tamp the cement, which is best covered with a wet rag to ensure reliable hardening. By the way, instead of it you can take bitumen mastic, a mixture of asbestos and cement, clay or other materials coated with oil paint.

Types of cast iron sewers

There are two types of sewer pipelines:

- Bell-shaped - to ensure the tightness of the joints, in this case, padding is used (a cord impregnated with a water-repellent agent). To ensure maximum tightness, the cord is minted. Such a pipeline looks more aesthetically pleasing than a socketless one.

- Socketless - in this case, metal clamps with rubber cuffs are used to ensure the tightness of the joints. The repairability of such mains is higher than that of bell-type ones. As a rule, socketless pipelines in buildings are masked with panels or placed in grooves.

Note! Mechanical cleaning of clogged areas of the system is ineffective. Therefore, high-pressure flushing is used to completely restore throughput.

In the photo - socketless sewerage

Restoration and repair of pipes

If there is a need for repairs, then the sequence of actions is as follows:

- Cover the damaged area on the pipe with a pair of rubber gaskets.

- Press them onto the product using steel plates.

- Crimp the bandage tape with hoops using bolts or steel wire, which must be twisted with pliers.

- When the crimping process is completed, use a lever to carefully tighten the bandage tape.

As you can see, a competent choice and further installation of cast iron sewer pipes will ensure the efficient and reliable functioning of the drainage system for several decades.

The nuances of connecting smooth pipes

As we noted earlier, they are connected using special couplings, crosses, and bends. Such cast iron fittings can be found on sale. The connection method depends on many parameters, including the diameter. But still the most popular option is the coupling, which comes in several types:

- Cylindrical. This is used if the pipes are of the same diameter. There is a thread inside the coupling.

- The futorka is used for heating systems; in fact, it is the same cylinder, but it also has an external thread.

- Two cylinders - this type of connection is used if it is necessary to join pipes of different diameters. The cylinders also have internal threads.

If necessary, a cast iron tee for sewerage is installed. It allows you to connect several sources of wastewater to the riser.

The joining process is not very complicated; first you will have to outline how far the pipes will enter the coupling. Please note that the joint must be clearly in the middle of the coupling. After this, you can install the pipes. To improve the tightness, you can use silicone or bitumen compounds. There are also other connection devices - these are saddles, tees, crosses, and various cast iron fittings. So, it is not difficult to choose the right option.