The cottage has been built or renovated, all that remains is to build a wastewater drainage system and a water supply system. Call a plumbing expert; not everyone can be trusted. Do the installation of sewerage from plastic pipes and water supply yourself, enjoy the work done, and save money.

Carrying out plumbing work on your own without experience is scary. You need to know the rules and tricks to build a working structure. It will be useful for home craftsmen to learn about the stages of work and where to pay attention.

Technical characteristics of PVC products

Polyvinyl chloride products are made from thermoplastic, which even after heat treatment retains its properties and shape. The main components used in production are ethylene and stabilized chlorine. In addition to them, stabilizers are used, as well as additives to improve the quality of technical characteristics.

Main technical indicators:

- Density – 1.4 kg/m3.

- The fluid yield strength is 50-56 MPa.

- Thermal conductivity – 0.15-0.25 W/m.

- Tensile strength – 30-50 MPa.

- Installation at extreme temperatures of plastic sewer pipes – from -5°C to +90°C.

- Plasticity and maximum bending radius – at 20°C – 300mm.

Varieties of prefabricated PVC sewer elements

Due to their excellent characteristics, PVC products have gained particular popularity among builders. Plastic products have a number of distinctive advantages:

- Light weight.

- Resistant to blockages and dirt buildup on walls.

- Not subject to corrosive processes.

- Easy to assemble. Therefore, you can do the installation of sewerage from plastic pipes yourself.

- Strong and durable. The service life of the pipeline, if installed correctly, is 80 years.

- Resistant to acids and alkaline substances.

- Low price.

- High range of internal pressure, depending on wall thickness and pipe diameter.

- A wide selection of elements, as well as fasteners, allowing you to create a structure of any complexity.

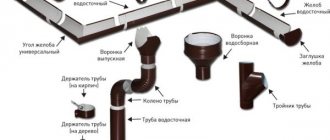

Plastic elements, adapters

There is a small drawback - plastic does not tolerate high temperatures, so this material is not suitable for creating heating systems. But it works great when creating sewers:

- internal;

- external;

- pressure;

- gravity flow.

The names quite accurately reflect the essence of the design. You can lay sewer pipes of these systems in a private house and apartment. To create a reliable drainage pipeline, you need to know the installation rules and the nuances of its construction.

Use of PP and PE pipes

Despite the fact that sewerage systems, in most cases, are equipped with PVC products, when describing the advantages of the corresponding plastic structures, they usually refer to the advantages of using polypropylene.

For external sewer systems with heavy loads, double-walled polyethylene pipes are used

Indeed, at a higher cost, polypropylene products are characterized by:

- duration of operation with a minimum period of 50 years. Under relatively favorable conditions, centuries-long use of PP products is possible;

- low thermal conductivity, due to which there is practically no need for thermal insulation;

- inertness to various types of corrosion phenomena;

- low roughness, eliminating the possibility of clogging and contamination within the system;

- resistance to temperature changes, at which the linear dimensions and strength remain unchanged.

Note! PE pipes for sewerage are rarely used, although they are excellent for installing a system in a country house.

Many properties of PE pipes, especially those made of cross-linked polyethylene, can be very useful when installing sewers:

- inertness to the effects of chemically active substances, including acids and alkaline solutions;

- constancy of physical properties during freezing. PE pipes will stretch when the working medium freezes, and after thawing, thanks to the memory effect of the material, they will return to their original shape;

- flexibility;

- less noise compared to other plastic analogues;

- The melting point is slightly higher than that of PVC, and that of heavy-duty cross-linked polyethylene with a modified molecular structure is above 200 degrees.

Sewerage in country conditions can also be built from ordinary PE pipes

Laying sewerage in a private house

The fundamental difference between sewerage and water supply is the thickness of the walls. There is no high pressure or pressure surges in the waste system, so the walls are chosen thinner. For owners of cottages or private houses, sewerage installation is divided into two parts: internal and external.

Indoor sewerage installation

Features of the internal design

For interior work, products with small diameters of 50, 100 and 110 mm are used. The widest one is used when laying a drain from the toilet to the collector. To connect other plumbing fixtures, a diameter of 50 mm is sufficient. When arranging the internal system, you must follow the following rules:

- The width of the fan pipe should not be less than the main main branch.

- Connection of branches adjacent horizontally is carried out only using beveled tees.

- A design plan should be drawn up and work should be carried out where it will be more convenient. The location should take into account accessibility for repairs in emergency situations. Most often this is the basement.

- The main part of the structure is assembled in the warm part, the final part is taken out into the street.

- A mandatory requirement is the presence of a safety release valve.

- Turns must be equipped with revisions - this is access to the interior of the structure. It is necessary, since it is in these places that the most problematic situations happen.

- Particular attention should be paid to the installation of the drain pipe.

- The sewer system is installed at an angle of 45 degrees.

- The exit point to the street must be securely sealed.

Installation of a drain with an outlet under the toilet

After clarifying all the details, you can begin assembling the internal sewage system. To do this you will need to prepare the following tools:

- hammer, chisel;

- silicone sealant;

- soldering iron for plastic pipes;

- level, marker.

Preparation begins with marking the diagram from the entrance of the tee to the riser to all plumbing fixtures. Marks are placed taking into account the required slope. Clamps for attaching sewer pipes to walls and ceilings are installed according to the diameter.

A special feature of internal sewerage wiring is the force of gravity. Wastewater is drained by gravity downwards according to the laws of physics. Therefore, assembly is carried out at a slope of 1-1.5 degrees. Another important point is the selection of the diameter of the prefabricated elements:

- For the riser and corrugation under the toilet, choose a diameter of 100 mm.

- For laying the line to the bathroom and sink - 50mm.

- Drain from household appliances (washing machine) – 32 mm.

Plastic pipes of different diameters

After adjusting all structural elements, proceed directly to installation. The algorithm of actions will be as follows:

- The inner surface is sanded to a slight roughness. This will ensure better adhesion of the material.

- Degrease the edges of parts with methylene chloride.

- Gluing of elements is carried out. To do this, use a swab or brush, with which a small layer of glue is applied to the inside of the socket, and a thick layer is applied to the outer connecting surface.

- The fitting is put on so that the marks correspond to the dimensions of the markings. Next, the parts unfold according to the marks. They must match each other. Hold in this position for about 30 seconds.

- The joint is coated with sealant or glue.

Connecting plastic elements with glue

According to this scheme, the entire structure is assembled.

If you have a soldering iron, you can use it to connect plastic pipes, but the joints must be treated with sealant. Assembling the entire sewer system will take no more than 3 hours if all rules are followed. This scheme also applies to installing drainage systems in an apartment with your own hands.

Prefabricated well

Last in the order of wastewater, but not in terms of its role in the operation of the sewerage system, is the collector or septic tank - a well into which sewage flows from the pipeline. The well is located so that it is at the lowest point of the drainage system.

Distance between the well and other objects located on the site and nearby:

| An object | Distance not less, m |

| non-residential outbuildings | 1 |

| residential buildings | 5-7 |

| water well | 50 |

| fence between plots | 2 |

| open waters | 15 |

Types of wells

For a private home, you can equip a well of one of three types:

- storage well or collector - a sealed container into which wastewater flows; when the collector is filled, the sewage is pumped out;

- a well with post-treatment, a septic tank - a container of several series-connected chambers in which wastewater gradually settles, the sediment is processed by bacteria, and partially purified water enters the last of the chambers and from there goes into the soil;

- deep treatment station - a well with filters and a bioreactor (a set of substances and bacteria), in which wastewater is purified from dangerous microorganisms and safe organic matter is separated, the purified water goes into the soil, and the separated organic matter can be used as fertilizer.

We recommend that you read: How to determine why a water tap is humming and eliminate the cause?

The first two types of wells can be equipped with your own hands. Ready-made plastic containers or reinforced concrete rings are used for these purposes. Septic tanks are also built from brick and concrete.

It is difficult to equip a deep cleaning station with your own hands, as it requires special knowledge. It is easier to buy a well of this type and install it ready-made in a prepared pit.

External system assembly

To install the external drainage system, orange pipes are used. The coloring in this case indicates the use of this product exclusively outside the premises.

To arrange a place for laying a drain, create a cushion of sand and crushed stone. The height of such a blanket is no more than 200 mm. The creation of such a gasket is carried out under the pipes and on top of them. Sand is poured first, then crushed stone. The installation order should not be violated.

External sewerage installation in a private house

Sewerage is laid in specially prepared trenches. If the trench is not high enough, the system may freeze. Therefore, it is necessary to know at what depth to bury a plastic sewer pipe. To determine this parameter, there are mandatory requirements:

- The path of the system must lie below the soil freezing level. This figure will vary depending on the region. In the European part this figure is 80 cm.

- At the entrance to the septic tank or sewage pit, the level drops to 100 cm.

- The depth of the trench at the outlet under the foundation is 50 cm, provided the wastewater temperature is above 15 degrees.

If it is not possible to lay the system at a given depth, the pipes are insulated using insulators or a heating cable. They will help retain heat inside the system and will not protect against freezing of the liquid and the creation of ice plugs.

Trench laying of drainage from the house

The installation of sewer pipes is carried out as follows:

- The pipe is inserted into a special sleeve in the foundation.

- The treated edges with lubricant, with a rubber seal installed, are joined together until they stop. The entrance of the end of the bell is 40-45 mm. It is not advisable to use silicone lubricant in this case to prevent delamination of the rubber.

- The drainage system is laid on a flat surface without displacement. If a change in direction is required, bends are used. A revision is installed at each branch.

- If the area is flat, but its length is over 20 meters, installation of a well will also be required.

- The sewer system is led to a cesspool, septic tank or well. At this location, treatment stations are connected to obtain process water. It is convenient to use for hydroponic setup or cleaning the area.

- Next, the entire system is checked for leaks and tightness of joints.

- Thermal insulation is laid on the assembled structure and covered with sand.

Drain outlet through the foundation

The socket method is used to connect pipes. It is unacceptable to assemble a structure from elements made of different materials. Since they have different thermal conductivity coefficients. Temperature changes can deform the system and create leaks in the main line.

Replacing cast iron sewer pipes with plastic ones

In older houses, cast iron pipes were used in the bathroom and toilet. I would like to replace them with a modern analogue. It’s easy to handle, the main thing is to come to an agreement with the neighbors on the riser so that there are no incidents. Let's get started:

- They cut out the old riser: leave 10 cm at the top, 40 cm at the bottom. To make it easier, make several cuts with a small jumper, then knock them out with a sledgehammer. The main thing is not to damage the rest.

- The joints with the plastic are cleaned.

- Fastenings for the new riser are being prepared.

- The plastic is installed with the sockets facing up; work must begin from the bottom.

- After preliminary fitting, the plastic is installed and secured with clamps with rubber gaskets.

Now you know how to do wiring, installation of sewerage, heating, and water supply systems using modern materials. And also that a home handyman can do anything.

How to check the system for leaks

Any assembled structure requires testing and verification of its functionality. The installed sewer system is tested according to the following algorithm:

- For the internal system, use a 10 liter bucket. It is filled full and sharply tipped into the sink to create the maximum volume of liquid in the sewer and pressure on the walls of the pipes. For reliability of tests, water transfusion is used several times in a row.

- Throughout the entire structure, all available plumbing fixtures are included to create maximum load along the entire length of the system. To do this, open all the taps and turn on the flush of the toilet and washing machine. Such a check will allow you to identify leaks, find out the throughput, and evaluate the tightness of the joints.

- If a problem is identified, it is fixed immediately. To do this, the leak site is dismantled and reassembled, paying special attention to the quality of assembly and the tightness of the joints.

- If the problem occurs again, the joint is additionally treated with silicone sealant. After drying, testing must be repeated.

A special device for determining the presence of leaks.

If no new leaks are detected, the structure is ready for operation.