What is included

The first thing you should pay attention to when choosing equipment is the basic configuration. Some enterprising sellers remove some items, which they then offer to purchase additionally. This clever marketing move leads to additional financial costs.

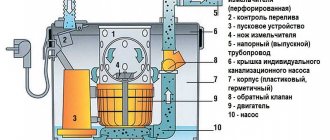

The standard configuration of the pumping station looks like this:

- The pump is usually self-priming, designed for forced transportation of liquid.

- A hydraulic accumulator is a storage tank whose capacity varies between 10-100 liters.

- Relay – ensures automatic activation of the pump when the water level drops.

- Pressure gauge – controls the pressure in the system.

- Pipeline is a highway for supplying water to intake points.

- Filters - fine and coarse filters that remove debris that enters the well.

Please note that depending on the manufacturer, the equipment may vary, however, the listed elements must be included in the basic set.

Construction of a water supply network

Technically, connecting the pumping station to the well can be divided into two sections. Before and after the station. There is an important difference between them. Figuratively speaking: up to the station is the sphere of influence of the pump itself.

After the station, the accumulator tank is the area of concern, since it is responsible for water flow and creating pressure in the water supply system. Therefore, it is easier to consider them separately. Moreover, they can use a wide variety of pipes.

The pumping station is very simply designed - for successful operation you just need to connect it correctly

Intake part of the water supply system

This part of the overall scheme is located between the pumping station and the well. It is through this that water is drawn in and the system is powered. Its device is simple, but there are several important points.

Most often, a HDPE pipe with a diameter of 32 mm is used for the fence. A supply pipe of this cross-section will not create unnecessary loads on the pump. A plastic pipe is more resistant to freezing and water hammer. Not afraid of corrosion. That’s why she’s preferred in this role. One end of it is lowered into the water, the other is connected to the station.

On the water side, a casing coupling is attached to the pipe. A check valve is screwed onto it, preventing the flow of water from moving back into the well. Thus, the valve prevents the system from emptying - it always remains full.

A special mesh tip should be screwed onto the valve. The mesh plays the role of a coarse filter that retains suspended sand and large fractions that may be found in the water.

Most often, the return filter has an inch fitting thread. So this unit will require couplings with a transition of 32 - 1РН.

It is better to remove the pipe from the well at a level below the depth of soil freezing. You can insulate the pipe and pass it through the top, but it is still better to run it to the house at a depth. If this is not possible, then it is good to supplement the heat-insulating shell with a special electric heater for pipes - it will prevent the water from freezing.

HDPE pipe can be considered the best material for the intake line - thanks to convenient fittings, assembling the chain will be similar to a simple construction set

The pipe is led underground, at a depth below the calculated freezing point. Most often this value is 1.4 - 1.8 meters. Depends on the region. It is better to enter the house at the same depth. If this does not work, then the input must be insulated, and very, very carefully. The insulation should start below the freezing depth.

When running a pipe through a trench, it would be a good idea to cover it with sand before filling it with soil. A layer of sand will not provide any major advantages for drainage or similar things, but later it can serve as a good indicator - the sand will serve as a signal when digging when the pipe is close.

The supply pipe ends with a crimp coupling with a transition to an inch thread for connection to the station. In this area it would be nice to install another additional mesh filter (optional) and a collapsible American fitting. Already a must - it is needed in case of preventative maintenance or repair of the station. There is no need for shut-off valves or additional water purification systems in this area.

When organizing water supply from a well in a country house, it is necessary to provide for the possibility of preserving the system. Before entering the pumping station, you need a drain valve or an American valve to disassemble the pipeline

Water supply after the pumping station

The outlet of the pumping station usually has a 1-inch thread. But this diameter is no longer so important when installing the system - it can be easily reduced to half an inch. It is no longer the pump that operates on the flow line, but the hydraulic accumulator. Therefore, a possible increase in load due to the smaller cross-section of the pipeline does not play a role.

So during installation, many people install a transition fitting from an inch to a half - this way they save money on further assembly of the system, since pipes and fittings of a smaller diameter are cheaper.

A shut-off ball valve is screwed into the fitting in case of carrying out preventive and repair work on the system. From the ball valve, through a collapsible “American”, an outlet is already made into the water supply system of the house. Its features already depend on what kind of pipes are used in the house - polypropylene, metal-plastic or traditional metal pipes.

The check valve must be equipped with a mesh filter - without it the valve will quickly fail

Immediately behind the shut-off ball valve, a flask with a water purification filter is also installed. It is not advisable to place it before the station. It works better with a uniform flow of water, which is only possible after the pumping station - on the supply line to the station, the water moves too impulsively, with a higher peak power. After the hydraulic accumulator, its movement is more predictable and stable.

The filter should also be cut off from the system by taps in case it is replaced. And then it’s a good idea to provide a bypass line - in case this replacement is delayed for one reason or another. Naturally, this bypass must also be closed. Otherwise, the water current will always flow through it - according to the rule of least resistance.

After the filter, it is already possible to branch the main line - to cold and hot water supply, to the supply branch for the heating system, and so on. Before the filter, you can make a diversion for the needs of watering the site - plants are not as demanding of water quality as humans. For other purposes, it is better to use prepared water.

The characteristics of the filter depend on the characteristics of the water in the well. They can be determined after making a conclusion about the composition of the water. Sometimes even several filters may be required - for example, against limescale inclusions and ferrous compounds. Universal types do not exist in nature.

If you plan only seasonal operation of the water supply system (for example, in a country house), then fittings for draining the system should be installed. Usually this is a simple tap at its lowest point.

The check valve is one of the most important elements of the entire system and cannot be neglected.

Operating principle

Pumping stations operate according to a simple scheme. The work cycle consists of the following stages:

- After being connected to the network, the pump begins to pump water into the system, filling the accumulator to a certain level.

- When the pressure gauge shows maximum pressure, the pumping station automatically turns off.

- The withdrawal of water lowers the level in the hydraulic accumulator, and accordingly the relay gives a command to start the pump.

- If the tap is constantly open, water is pumped in uninterruptedly; when closed, it flows until the set level is reached.

In principle, it is an autonomous water supply system that requires only periodic maintenance.

Pump classes

All pumping stations on the market can be divided into three groups. The classification of each category is determined not only by technical features, but also by the height of the water rise. It looks like this:

- With a built-in ejector

The heart of such a system is a jet-centrifugal pump, which is of the self-priming type. The maximum depth of water intake is 8 meters, the outlet stream can rise up to 40 meters. According to experts, the system is very reliable; the main disadvantage is the high noise level during operation. - With remote ejector

Such systems make virtually no noise and can lift water from a depth of up to 50 meters, while the output stream can rise to 40 m. The kit includes two pipes, one of which is immersed to a given depth, the second is connected to the water supply main. The disadvantages include the following: when air enters the system, the pump begins to overheat and the shutdown relay is triggered.

- Without ejector

This is a multi-level system of tanks, each of which is equipped with a separate pump. The main tank is installed at a certain level, which ensures natural circulation of water in the system. The liquid is taken from a depth of 9 meters, the jet height is 45-50 m. Such systems are reliable and are designed for a large number of consumers. Disadvantages include the complexity of installation and the high cost of spare parts.

Knowing these features, you can select a pumping station in accordance with individual requirements.

Installation Features

To draw water from a well using a pumping station, it must be close to the source - removing it to any distance reduces the suction depth. Typically, a water intake station is installed in the following ways:

Inside the well

Most often, the well consists of concrete rings, so a strong platform made of thick boards is placed on them, a pump is placed on top, the pressure pipe from which is lowered into the water.

External installation in a well requires insulation in the winter; for these purposes, thermal insulation materials are used to cover the external well house. Since in severe frosts such thermal insulation can protect against freezing for a short time, you can additionally use a self-heating electrical cable placed in the pressure pipeline. Also, the internal laying of the electrical cable in the water supply will allow you not to bury it deep underground and in many cases it can be run along the surface, covered with a heat insulator.

Inside the house

If the well is located not too far from the house, the pumping station can be installed inside on the ground floor or in the basement; it is often placed next to the water heating boiler. When arranging, you should take care of good sound insulation of the room - during operation the pump is not silent and makes loud sounds.

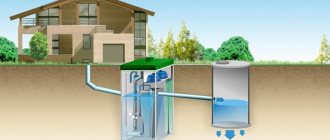

In a caisson well

Although caisson chambers recessed into the ground are constructed mainly for the installation and operation of borehole submersible electric pumps, a similar structure can also be installed for a pumping station. To do this, a hole about 2 meters deep is dug next to the well and a purchased polymer caisson is installed in it (you can make it yourself from concrete rings), then a pumping unit is placed inside. The pressure pipe is connected to the pump and lowered into the well through a hole made in its concrete wall underground. Although the method is expensive and labor-intensive, it allows you to reliably and effectively protect the pipeline and station from freezing in winter.

In a separate building

To protect the electric pump from freezing and precipitation, the installation can be placed in a small separate building or shed, if they are located near the well. The system is insulated using thermal insulation materials in combination with a self-heating electrical cable.

Options for installing stations in wells

Installing a pumping station in a well is one of the main methods of drawing water from this type of source and is used if the static and dynamic water level does not fall below 8 - 9 m from the ground surface. A typical pumping station is capable of providing water to a family of 3 people, and during operation it does not require the installation of special additional equipment. Usually, coarse filters, plumbing fittings, and, if necessary, a check valve at the inlet of the pressure pipeline are added to the water main.

Equipment types

According to the principle of operation, pumping stations are divided into 4 groups. Let's look at the key features of each category.

- Vibrating

Practical and inexpensive devices with vertical installation. The design excludes complex elements, which determines the final cost. The main disadvantage is the technical impossibility of installing water level control sensors, which is why such pumping stations are used in summer cottages to fill containers. - Screw

The equipment is based on an “Archimedes screw”, which uniformly supplies water through the outlet pipe. Such pumps provide stable water pressure, but show relatively low efficiency during operation, so they are used very rarely.

- Centrifugal

A wheel with intake blades, which is driven by an electric drive, is responsible for supplying water. This type of design is the most common and is installed on most pumping stations.

- Vortex

The operating principle of such products is reminiscent of centrifugal analogues, however, the design is simple. The shape of the intake elements gives the fluid turbulent acceleration, which has a positive effect on performance.

The pumps easily absorb air into the system and do not emit noise or vibration during operation. However, the equipment is demanding on the purity of water, so even a slight presence of suspended solids can cause device failure.

These pumping stations differ not only in cost, but also in service life. In terms of durability, vortex pumps are noticeably inferior to other models.

Water supply installation

We suggest you study the installation features. There are several important criteria:

- Electricity. The selected location must be accessible to connect the device to electricity. Often, a caisson is installed near the source, and electricity is supplied to it.

- Location. The hydraulic system is installed at a distance that will allow the pump to operate without load. That is, those must be taken into account. characteristics of the unit. It is important to take into account the depth of the water surface and the length from the pump to the tap.

- Immersion depth. It’s good if you can install it in a warm place. Otherwise, a caisson is installed. It is made at a depth that is inaccessible to frost in your area. A natural change of air must be ensured to prevent the formation of condensation.

- Soundproofing. If the system is installed inside the house, the room should be properly soundproofed. Otherwise, the operation of the device will interfere with a calm and quiet life.

Please note! The unit must not be leaned against a wall, as vibration will be transmitted to the room above. Therefore, installation is only on the floor.

Installation errors

Incorrect installation leads to malfunctions. Common mistakes:

- Wrong choice of equipment. A heavy-duty pump is installed that has greater productivity than the well's flow rate.

- No filter. Because of this, sand gets into the system, which can destroy important structural elements.

- Significant waste of water. You need to understand which system to choose. If the consumption is expected to be 3 cubic meters per hour, then you should not take more, otherwise the unit will wear out. This option provides a different connection scheme for a submersible pump with a hydraulic accumulator, which reduces the frequency of pump activation.

- Anticipate power surges. If the power goes out frequently, this can damage the installation.

- The well system is selected based on capacity.

- Selecting a smaller pipe diameter than the thread on the device.

- Buying a small cross-section cable. An incorrect choice will result in engine overheating.

- Lack of RCD. The station for supplying water from a well must be equipped with an individual automatic power shut-off system.

- Lack of measuring instruments: sensors, etc.

Selection by power indicators

The main criterion when choosing a pumping station is the power and performance of the equipment. The average power of household models varies between 600-1,500 W. If we are talking about a small country house, where the water intake will be carried out for one mixer, an internal pressure of 1.5 atmospheres is sufficient, which will ensure a jet height of approximately 15 meters.

For large buildings, it is necessary to select such models so that water is consistently supplied to the most remote point of intake. In this case, the optimal performance of the pumping station will vary between 3,000-6,000 l/hour.

This information is indicated by the manufacturer in the technical specifications of the product.

What else to pay attention to

In addition to performance and power, we recommend paying attention to the following parameters of the pumping station:

- Hydraulic accumulator volume. It is important to take this into account in case of a power outage, so that the water supply is sufficient for the needs of the household.

- Suction depth. This parameter determines the depth of the well from which water will be drawn.

- Lifting height. Necessary to determine the number of consumers.

- Protection. Helps prevent equipment failure in cases of overheating or air intake.

In addition, you can select the type of equipment control: manual, automatic or remote. These nuances determine ease of use.

How to assemble and connect a household system to a well?

It is necessary to prepare all the components: pump, accumulator, automation, pipe, cable, filter, check valve and adapters.

Knowing the connection diagram, you will understand the sequence in which the installation should be assembled:

- A HA is attached to the pumping apparatus for the well.

- The pump is connected through a special adapter.

- An automation system is mounted on the same adapter: dry running relay, sensors, etc. It is important to know how to properly configure the automation for its correct operation.

- A check valve and a coarse strainer are attached to the end of the pipeline, and all this is lowered into the source.

- Additionally, you can mount a check valve in front of the hydraulic accumulator in case the first one fails.

- A hydraulic station with an electric drive necessarily requires the installation of an individual RCD.

- Before connecting the unit to the well and starting it up, it is important to make wiring around the house and install shut-off valves.

The water supply device itself from the well is installed in a clean and dry basement, on a rubber gasket to level out possible vibration. This option is suitable for a summer residence.

Advice! In addition to the coarse filter, the well station can be equipped with a system for retaining fine fractions. The quality of the water influences the decision. The fine filter is mounted on the surface.

The best pumping stations

Here are a few units that attract attention with their affordable price and good performance.

LEO XSHM 1500

Centrifugal pumping station from Chinese manufacturers. The immersion depth of the equipment is 9 meters, the height of water rise is 16 m. The average productivity is 1.44 m3/hour. The model is equipped with built-in overheating protection and can pump water with a low content of suspended solids.

| Performance | 16200 l/h / maximum / |

| Pressure | 16 m / maximum / |

| Maximum working pressure | 10 bar |

| Operating principle | centrifugal |

| Suction lift | 9 m |

| Content of mechanical impurities | 10 g/m3 |

| Max. t liquid | 40 °C |

| pH value | 6.5 – 8.5 |

| Suction system | multi-stage |

| Exit connection hole/pipe | 2″ |

| Entrance. connection hole/pipe | 2″ |

| Power | 1100 W |

| Nutrition | electric |

| Mains voltage | 220 V |

| engine's type | asynchronous |

| Power cable length | 1m |

| Protection class (IP) | X4 |

| Housing material | cast iron |

| Impeller/Auger Material | plastic |

WILO PW-175EA

A German pump that takes water from a depth of 8 meters and raises the jet to a height of 35 m. Average productivity: 2.1 m3/h. The equipment is installed horizontally and has built-in overheating protection. The pump has a low noise level; users note the unreliability of the on/off relay.

| Performance | 2100 l/h / maximum / |

| Pressure | 35 m / maximum / |

| Operating principle | centrifugal |

| Device | self-priming |

| Suction lift | 8 m |

| Max. t liquid | 40 °C |

| Accumulator volume | 2 l |

| Suction system | single stage |

| Exit connection hole/pipe | 1″ |

| Entrance. connection hole/pipe | 1″ |

| Power | 125 W |

| Nutrition | electric |

| Mains voltage | 220 V |

| Protection class (IP) | 54 |

| Manufacturer country | Germany |

| Housing material | cast iron |

| Impeller/Auger Material | brass |

GRUNDFOS MQ3-45

The equipment is manufactured in Denmark, has compact dimensions and a long service life. The productivity of the equipment is 4.1 m3/h, water is taken from a depth of 8 m, the height of the liquid rise is 45 m. The disadvantages include the high cost and complexity of installation.

| Performance | 4200 l/h / maximum / |

| Pressure | 43 m / maximum / |

| Maximum working pressure | 7.5 bar |

| Operating principle | centrifugal |

| Device | self-priming |

| Suction lift | 8 m |

| Max. t liquid | 35 °C |

| Accumulator volume | 1 l |

| Suction system | single stage |

| Exit connection hole/pipe | 1″ |

| Entrance. connection hole/pipe | 1″ |

| Power | 1000 W |

| Nutrition | electric |

| Mains voltage | 220 V |

| Protection class (IP) | 54 |

| Manufacturer country | Denmark |

| Housing material | stainless steel |

| Impeller/Auger Material | stainless steel |

| Accumulator material | steel |

| Weight | 13 kg |

In addition, you can pay attention to the GARDENA 3000/4 and Gilex “Water Jet” models, which are standardly equipped with fine and coarse filters.

Kinds

To select a NN, you first need to take into account the capabilities of the well and take a model just below this limit. But if the limit is less than 1.7 cu. m/hour, then you will have to forget about the HC: the motor will not provide constant pressure and interruptions in water supply are inevitable.

Domestic pumps have a capacity of 1.5 to 9 cubic meters. m/h, determined by the number of water points (kitchen, toilet, bathroom, washing machine or dishwasher).

Water consumption at a point: 0.35 cubic meters. m/h. X 5 = 1.75 cu. m/h. In this case, you can limit yourself to a NS with a capacity of 2 cubic meters. m/h (reserve will not hurt).

The tank capacity also depends on the points of consumption.

The average tap capacity is 12 liters, therefore, in our case, a 60 liter tank is suitable. The instructions usually indicate the maximum that a given model can provide.

Well data is obtained using any motor to measure the volume of liquid pumped out. The level of the mirror will be indicated by a nut on a thread lowered into the well.

There are three types of pumps on the domestic market:

- The station with a centrifugal self-priming pump and a built-in ejector with a water pressure of up to 40 m and a suction depth of up to 9 m is the most popular. But its main advantage is its low susceptibility to air. To start the NS, open the lid and fill it with water to the brim. After pumping the air, the motor will release water. Excess air escapes through a tap or valve.

- Centrifugal self-priming pumps with an external ejector are suitable for wells with a depth of up to 45 m. The pump is installed in a boiler room or other utility room.

An ejector with two pipes is placed in a well. One supplies water to the ejector for suction, the second for lifting. This type of NS is very sensitive to air and pollution, but allows it to be used in the home by lowering the ejector into a well at a distance of up to 40 m. - Submersible pumps operate in areas with groundwater levels up to 10 m. They are lowered to the water level, pumped up and raised up. The suction height is 8m, and they can push out to greater heights.

So, we determined the amount of water for a comfortable stay. We calculated the power of the pumping station and chose the type and location. Left to buy:

- Pump;

- Hydraulic accumulator;

- Pipes for external water supply (preferably polymer);

- Automatic protection system;

- Faucets;

- Valves;

- Valves;

- Cranes;

- Flexible hoses;

- Crimp and press fittings

If there is no well on the site yet, one can be made by installing reinforcement around the rings and scalding it. This will save you from floaters and shifting rings.

The sooner you plan your home’s water supply, the better the results will be. Ideally, the station operates autonomously. Every year we check the air pressure in the hydraulic accumulator using a pressure gauge - that’s all prevention. I really wanted it to be like this for you.