You are here: How to install fasteners for sewer pipes?

Previously, sewerage and pipelines were not so often found in private country houses, but today, on the contrary, these communications are necessary for a comfortable stay and recreation even outside the metropolis. Therefore, for modern owners planning to build a private house, the question of proper sewerage installation is a question. In order to install fasteners for sewer pipes, you must strictly follow certain simple rules, which depend on the types of fasteners used in arranging the drainage system.

Fasteners for sewer pipes and its types

In order to install fasteners for sewer pipes, certain fastening devices are used, which are called clamps. Based on the name, it is obvious that the fixation of sewerage elements occurs by grasping it. The wrapping part is sold complete with an anchor, dowel or screw fastening necessary to connect the clamp and the wall or other load-bearing surface. Therefore, for sewer installation work, you may need a hammer drill or drill, a set of screwdrivers and wrenches, which are necessary for tightening screws, nuts, bolts, and so on.

Types of pipe fasteners

Today on the construction market you can find various materials for fastening sewer pipes. When creating a sewerage system, clamps, brackets, clips and hook hangers are used. Each mount has its own purpose. Suspensions are used only for fixing pipes to the ceiling, brackets only to the wall surface, the remaining parts can be used to create both ceiling and wall fixations: vertical and horizontal.

Most often, the choice in favor of one or another fastening is related to the pipe material used: polystyrene clips are used for small plastic pipes, and brackets are used for metal-plastic pipes.

We recommend that you read: How to independently build a chimney in a bathhouse with an exit through the wall?

The most popular fastenings for sewerage are clamps of various types. They can be either metal or plastic. Both types allow you to securely fix the pipes at the desired angle. The choice most often depends on the preferences of the buyer.

Note! Metal products are more durable, but are more often used for installing the system in utility rooms or basements due to their less presentability. Plastic products look more aesthetically pleasing and are not subject to corrosion, which is especially important in conditions of high humidity in sanitary premises.

Hanging hooks

This type of fastener is used to hang pipes from the ceiling. This method of fastening is used when laying, for example, sewer hoses in the basement at a short distance from the ceiling.

Brackets

Suitable for fixing metal-plastic pipes. In its design, the part has a metal fastener. In the working position, they prevent the risk of the pipe moving to the sides.

Attention! When using brackets, there must be a distance of at least 5 mm between the pipe and the wall.

Clips

Clips are designed for fixing plastic pipes of small diameter (up to 50 mm). Made from polystyrene. They are easy to use: the clip is fixed to the wall with a dowel, after which the pipe is inserted into it.

Note! Plastic clips are rarely used for installation of sewer systems. More often they can be seen when installing plumbing or heating. The special design of the clip allows you to securely connect the system elements.

Clamps and their varieties

The main fastening parts of the sewer system are clamps. The mechanism of action of the fastener is that the device covers the pipe and holds it in the desired position. Additional elements fix the clamp, and with it the pipe, to the wall surface. The parts can be equipped with rubber inserts that provide reliable grip of the pipe.

A standard clamp in its design has two brackets fastened together with a bolted connection.

We recommend that you read: Functional and design differences between a valve and a gate valve

When choosing products, it is important to pay attention to the method of fixation. You can achieve perfect tightness of the sewer system using clamps that provide rigid or floating fastening:

- In the first case, the fixation is a strong fastening that prevents even slight displacement of the pipes. In this case, the pipe is tightened completely.

- Floating connection - involves slight mobility along the horizontal plane, which is achieved by slightly loosening the clamp. This method of fastening eliminates the risk of structural failure due to thermal deformation. They are easy to install: just place the pipe in a clamp mounted on the wall, applying a little force. A small click and the pipe is securely fixed.

Note! The most popular clamps are for floating connections, although parts for rigid connections can also be used for the floating method, just loosen the tension on the pipe and do not tighten the clamp completely.

Most often, classification involves division by materials of manufacture. The choice of a product from a certain material is also associated with the method of fixation. If metal clamps can be used in both options, then plastic clamps are used only for floating mounts.

The main advantage of clamps is the ability to use pipes of various diameters for installation.

Metal and plastic clamps

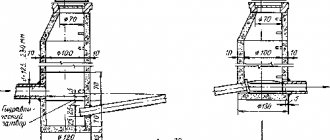

Fastenings for plastic sewer pipes: a - targeted; b - for driving; c - for screw connection

Clamps used to secure sewer pipes today are made of plastic or metal. Fasteners made from one or the other material are quite convenient and simple when it comes to their installation.

Most manufacturers of sewer structures often produce pipes complete with fasteners. Therefore, the question of choosing a specific type of clamp fastener is not considered.

The first thing you should pay attention to when choosing between metal and plastic clamps is the aesthetic component of the room where the sewage system will be installed. Particular attention must be paid to this issue if communications are open and not hidden in walls or interior structures. Here we need to talk about choosing plastic clamps, which are less noticeable and have an attractive appearance. In most cases, sewerage is located in places that are inaccessible to public viewing. Metal clamps are suitable here, they are a universal connection that can be either loose, not tightly tightened, or deaf, motionless.

According to their design features, all clamps are divided into 2 types - solid and double. One-piece ones are usually made of plastic, while double ones can be either plastic or metal. A distinctive feature of double clamps is that the diameter can be adjusted using a screw, so they can be used for pipes with different diameters. Double pipe clamps, in turn, are divided into single-screw and double-screw, depending on the number of screws.

Floating or rigid mount

It is necessary to understand that pipe fasteners installed using a clamp can be rigid, with a strong grip around the pipe, or floating. Floating fastening is performed to maintain the integrity of the pipes during thermal deformation. Both types of fastening can be applied to the same clamp connection. However, there are also clamps that are designed exclusively for floating mounting. They are usually not equipped with tightening and clamping bolts. They simply snap into place; their installation does not require the use of professional equipment.

One of the important components of the design of a plumbing pipe clamp is a special gasket, which is located between the sewer pipe and the female part of the fastener. The main task of the laying is to neutralize noise arising from internal loads on the pipes and vibration. Having examined the popular types of clamp connections and the features of their design, let us turn to the basic rules for their installation.

Basic rules for installing sewer fasteners

Fastening of retaining elements must be carried out in accordance with generally accepted standards, rules and requirements. The sewer pipe system is a complex set of different elements, which in the future will be influenced by various factors: load, corrosion, vibration and possible blockages. Therefore, it is important to adhere to generally established rules and recommendations during sewer installation:

- Location of fasteners. It is necessary to correctly calculate the location of each clamp. It is necessary to make fastenings in every place where the sewerage branches, has bends, pipe connections or fixing fittings. Before starting work, we recommend that you draw up a diagram of the laying of sewer pipes, on which the locations of the clamps will be marked. The scheme can be marked directly on the walls using center lines.

- Pipe slope. The clamps must be fastened so that the minimum slope of the pipe is 20 mm for each linear meter of the sewer pipeline. To avoid frequent sewer blockages in the future, frequent perpendicular turns should be avoided.

- Alternating floating, fixed and rigid fasteners. Important rule! Each pipe must be secured with a non-slip clamp, which, as a rule, is located at its base, where the pipe connects to other parts of the sewer system. In other cases, both rigid and floating mounts can be used alternately.

- Distance between clamps. When installing metal-plastic or plastic pipes, they are fastened based on a two-meter distance between the fasteners. Heavier pipes must be fastened more often, with an interval between clamps of a meter or one and a half.

- Reliability of fastening. During use, sewer system pipes are subject to certain loads, temperature changes and vibration. To ensure that the quality of operation of the system is not affected by any of the listed factors, each pipe must be securely attached to the load-bearing surface. Anchors and dowels of fasteners must adhere tightly to the material from which the surface is made. It should not crack or crumble. Often, in cases where it is not possible to firmly secure the clamp, the sewer laying scheme is completely changed.

As a result, we can say that by adhering to basic rules, you can install a fastening for sewer pipes with your own hands in your own home. In addition, every modern manufacturer of structural elements takes utmost care of simplicity and ease of installation. The installation of a sewer drain does not require professional knowledge, skills or expensive equipment.

Main features of fastening sewer pipes

Wise choice of fasteners

The sewerage network is laid using a hidden or external installation option (in the latter case, the sewer pipes are fixed to the wall) in accordance with the requirements of clause 17.9 of SNiP 2.04.01-85. It is worth considering that the installation of drainage networks is not allowed at every facility and not in every room: a specific list and existing exceptions are given in paragraphs. 10 of section No. 17 of the above regulatory legal act. SP 40-107-2003 Design, installation and operation of internal sewerage systems made of polypropylene pipes (with Amendment)

The most significant advantages of the closed type of fixation are quite rightly considered to be the following:

- Maximum rational use of usable space. Pipes can be hidden in the wall of the house;

- Aesthetics - the appearance of the room is not spoiled by sewer pipes;

- Minimize the risk of damage.

Open laying of the communication network is also not without advantages and has the following benefits:

- Extremely simple assembly that does not require the involvement of professionals - everything can be done independently, following the manuals that are freely available;

- Perfect convenience in terms of repairs;

- Versatility - you can use this type of laying sewer lines almost anywhere. Yes, there are exceptions - but they cannot be compared with the closed type.

The closed type of installation of the system necessarily involves gating the walls, which in some cases is not technically possible. For example, if you need to attach a pipe directly to a sandwich panel or you need to lay a sewer system in buildings with a weak frame foundation. In the above two situations (and in many others, these two were simply considered the most common), a closed type of installation of a sewer system is a priori impossible. It is thanks to this that open-cut installation has become widespread. It makes sense to pay maximum attention to the features of this technology.

Subtleties of outdoor installation

The first step is to select suitable components and fittings. Fastenings of sewer plastic and cast iron pipes must withstand operating and increased pressure in accordance with established requirements.

Correctly performed fixation of sewer pipes guarantees the successful functioning of the system. So, before starting installation work, it makes sense to familiarize yourself with the current SNiP 2.04.01-85 standards. Special attention should be paid to section 17, as well as the published calculations in paragraph 18. It is important to note that, based on the complexity of the project and some of its nuances, numerous types of brackets are used for fixing sewer pipes. In order to ensure reliable fixation when installing an internal sewerage system, fastening clamps are most often used. These parts are responsible for performing several functions at once:

- Preventing deformation of the structure under the applied load;

- Compensation for stretching of a plastic pipeline - as a result of exposure to high and low temperatures;

- Noise absorption;

- Adjusting the distance of the pipe from the wall or, if the sewer pipes are attached directly to the ceiling, the height of their installation.

Before carrying out installation work, you should draw out the communication diagram in detail, as well as carry out precise markings. This will greatly simplify all the work being carried out and will make it possible to establish the main design features.

When laying a drainage system, it is important to establish the pipe fastening distance, which is determined by the diameter and method of drainage. In domestic conditions, it will usually be enough to install the fastener in areas of at least two meters, as well as at a distance of no more than 15 cm on bends or connection areas where sewer pipes are connected to each other. The corresponding standards are in SNiP 2.04.01-85, clause 17.2.

To ensure the normal functioning of the sewer network, it makes sense to place its straight sections only at an angle. The amount of slope is determined by the diameter of the pipes. The minimum slope value should not be less than 0.002, that is, 2 cm per meter (this is stated in the above SNiP). Choosing a smaller coefficient can easily cause flow stagnation, and a larger slope can easily provoke an excessively intense drainage of water, in which the dirt simply will not have time to be washed away.

Stages of sewerage installation

After analyzing the information above, we can conclude that this process is divided into several stages:

- Selection of pipes of suitable material (type), as well as their assembly (installation);

- Determining the required slope;

- Setting the fastening pitch;

- Selection of the most suitable clamps required for fastening;

- Preparation of an appropriate sewer network diagram and marking.

At this point, the preliminary stage can, in principle, be considered completely completed. Next, it makes sense to focus on a detailed study of the rules for selecting fasteners, because it is a key aspect in ensuring the correct functioning of the entire system.