Not all users know how to caulk a cast iron sewer pipe. Moreover, not everyone understands what we are talking about. However, during the assembly or reconstruction of a sewer system, the ability to correctly caulk pipe joints will be very useful.

Many houses still have old cast iron pipelines, which are not practical to completely replace with modern plastic. The pipes are still strong, capable of working for decades. As a rule, they are left intact, replacing only the apartment horizontal sections of wiring. Let's look at how cast iron pipes are connected when installing drainage systems.

Features of cast iron pipes

Cast iron pipes were used everywhere in Soviet times. Alternative fabrication materials have been used on a limited scale for the assembly of specialty sewer lines. The properties of cast iron pipelines allow the old system to still work. The advantages of these pipelines:

- strength;

- long service life;

- resistance to temperature changes;

- ability to work with aggressive liquids.

The disadvantages are:

- susceptibility to corrosion;

- heavy weight;

- fragility, inability to withstand sharp blows;

- difficulty of assembly.

The most significant drawback is the complex connection procedure, or chasing, of cast iron sewer pipes. Combined with the large weight of the parts, which create a significant load on the supporting structures, such drainage lines were difficult to install and maintain. However, the durability and reliability of cast iron systems are appreciated by experts. All networks, the condition of which does not cause concern, are still effectively used for wastewater disposal.

Preparatory work

Products are checked for defects. External characteristics are assessed: the pipes should not have dents, cracks, bumps or stains. It is recommended to use communications characterized by a smooth wall surface. You can lightly tap the products. The sound should be the same in different places. The condition of the cut is also assessed. Its structure should be uniform, fine-grained.

If you plan to replace cast iron pipes, you must first dismantle the old communications. For this purpose, prepare a hammer (for horizontally oriented products) and a grinder. The riser is cut only using a grinding machine. It is not recommended to use a hammer in this case, since individual parts may fall into the lumen of the pipe, which will lead to a blockage that is difficult to remove. Before installing communications, it is necessary to shut off the water riser. If the toilet connection is changed, you should not use the flush for some time.

Connection methods

The assembly of cast iron pipelines is a complex and responsible task. There are several types of connections:

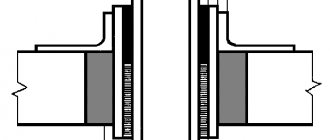

- into the bell This is the most popular type, which is called “caulking of sewer pipes.” The process requires accuracy and experience, strict adherence to technology requirements. Proper caulking can withstand several decades of leakage use;

- coupling connection. This option is used for socketless pipes. Special couplings are used that tightly grip the edges of the elements being connected. The build quality is high; no special experience or skills are required to complete the work. However, the necessary conditions for installing the coupling are not always available.

There are couplings that are not equipped with threaded clamps. They consist of two sockets into which the ends of the elements to be connected are inserted. Assembly of such lines also requires stamping of sewer pipes, performed using standard technology.

The procedure consists of filling the socket gap with a sealant and sealing it using hardening compounds. The sealant most often used is tarred hemp strand, which is stuffed into 2/3 of the socket and thoroughly compacted. The remaining third is then filled with a durable protective compound. For this purpose, cement and plumbing sulfur are used. Lead caulking is sometimes used in pressure lines, a complex but very effective procedure.

Work algorithm

Depressurization of cast iron elements is one of the most difficult tasks when repairing sewer systems yourself. To get the job done as quickly and efficiently as possible, it is recommended to prepare all the necessary tools in advance.

To carry out the work you need:

- grinder (you can use it to cut off part of the pipe);

- grinding discs;

- safety glasses, gloves and mask;

- soldering iron (useful for heating connections);

- hammer;

- screwdrivers of different sizes and configurations;

- pipe wrench;

- chisel.

Sequence of work performed:

The first step before hammering out a sewer cast iron pipe is to tap the joint with a hammer

However, this should be done carefully. Otherwise, the structure can be damaged, which will lead to a complete replacement of the riser. It is also possible to carry out such manipulations, often using a wooden tool. As soon as you finish tapping, you should pay attention to the condition of the fasteners

If the pipe moves from side to side, and it is possible to disconnect it, you need to do the following: You need to rock the product by prying it with a screwdriver. The rope should be hooked with pliers and carefully pulled out.

- If, even after frequent and prolonged hammering, the pipe does not change its position, we can conclude that the fastening was carried out using a sulfur solution. To remove the fasteners, you must first burn out the dried mixture. This can be achieved in several stages. The first step is to heat the joint using a soldering iron. This needs to be done in a circle. Next, you need to continue hammering, trying not to damage the integrity of the product. If the structure of the elements begins to wobble, you can try to dismantle the element using a key.

- Having successfully dismantled the product, you should thoroughly clean the joints using a chisel. The emphasis should be on cleaning the edges, since this is where the rubber seal will be installed.

- Before installation, the sealing material must be lubricated with a special substance.

- The last step is to install the new product in the prepared area.

When burning sulfur, you must wear a protective mask and goggles. They will not allow harmful vapors to enter the body.

How to hammer a bell

During repair work, reconstruction or expansion of the drainage system, it often becomes necessary to connect different lines. Before caulking a sewer pipe, it is often necessary to disassemble an old, defective connection. It is extremely difficult to hammer out a bell that has become overgrown with monolithic layers over many years. The main problem is the danger of destroying the socket of an entire pipe or tee. If this happens, you will have to disassemble and replace the entire riser or horizontal pipeline.

Before caulking out an old cast-iron sewer, it is necessary to clean the connecting element and remove all foreign objects and deposits. As a rule, various temporary patches of paint, additional layers of mortar, and other materials are applied over the standard connection. All such areas must be completely removed.

After this, it is necessary to determine what material the insulating seal is made of, since it is much easier to caulk a cast iron sewer with cement than with sulfur. If cement mortar is used, the process of disassembling the joint will be easier. However, if pouring with plumbing sulfur was used, the procedure will be complicated. The material will have to be heated with a gas torch or blowtorch, since it will not be possible to simply break and remove particles from the gap - sulfur has high strength and viscosity. You will have to work in a gas mask, since toxic gases will be released when heated.

Procedure

In order to caulk a cast iron drain, you must first remove the cement or sulfur filling (1/3 of the depth of the socket), and then remove the hemp strand (2/3 of the depth). The first stage requires caution and accuracy. There is a high risk of breaking the socket of a tee or other receiving element. First they use a chisel, then a screwdriver with a long thin blade. With gentle blows of a hammer, the screwdriver is immersed in the gap, breaking off small pieces of the seal.

Many sources recommend first tapping the socket around the circumference with a hammer, and then checking to see if the pipeline has become loose. This is useless advice, since it is impossible to caulk cast iron sewers in this way. Until the top layer of cement or sulfur is removed, the pipe will not be able to swing. In addition, hammer blows can break the socket, which will significantly increase the amount of work.

When the hard plug is removed, the joint will gain mobility. They move it a little to the side, pick up the rope and pull it out, swinging the pipe to the sides to facilitate the process. After this, the bell will be completely freed, the connecting element can be easily removed.

Also read: What is the danger of sewer smell to health: the composition of the gas, where it comes from

Beginning and sequence of repairs

Chasing cast iron pipes

You have to think about how to caulk a cast iron pipe if it is necessary to replace an element and it is impossible to correct the damage directly at the scene of the accident.

The first step is to carry out preparatory work, that is, carefully inspect the pipes and figure out exactly how they are welded to each other.

Quite often you have to deal with pipes filled with a special solution used to glue their parts together.

In this case, while underground, the elements can grow together so tightly that they cannot be disconnected without applying force. In this case, experts recommend using a gas cutter, which allows you to quickly remove the fastening compound and disconnect the pipes.

Speaking about caulking a cast iron pipe, it should be borne in mind that the work ahead is not easy and requires turning off the water in the whole house or even in the area if an important area is being repaired.

The pipe is prepared for repair using special tools:

- Use a grinder to cut down the damaged or burst area;

- Install a new part of the pipe in place of the damage;

- The seam is closed with a construction bandage and cement.

Preventing the Problem

Embossing example

It should be borne in mind that for all its excellent physical qualities, cast iron is a rather fragile material. It is deformed under the influence of water and the chemical reactions that occur in it, so the pipes are affected by all changes, including changes in temperature, which makes them fragile and unable to withstand high pressure.

Chasing cast iron pipes is a rather complex process, the high-quality implementation of which includes replacing the pipe element, also leaving a certain margin for its expansion.

The new part of the pipe is inserted into the socket, after which the seam must be securely secured using a resin strand. To tightly lay and secure the threads, a tool such as a caulk is used.

Practical experience shows that the formation of a crack in a cast iron water pipe is only part of the problem, which grows if decisive measures are not taken. Patching holes with special compounds helps temporarily, but sooner or later replacement will still be required, so it’s easier to deal with the damage right away.

How to mint

Caulking is a procedure for compacting and sealing a connecting element. It is necessary to prepare materials and tools:

- oiled rope (hemp strand);

- cement (or asbestos cement) mortar;

- a wooden spatula that fits freely into the gap of the socket;

- long screwdriver;

- hammer.

Caulking of sewer pipe sockets takes place in 2 stages:

- filling the gap with tow or rope (bonding). Using a cord is considered a more effective option. The sealant is inserted into the gap and begins to be wound onto the pipe, constantly tamping it with a spatula. The material must be compacted and pushed into the gap until it stops. The process is stopped when the gap is filled to 2/3 of the depth;

- Cement mortar is poured into the gap over the seal. It is pushed with a wooden spatula or screwdriver, evenly distributing the material throughout the entire volume of the cavity. The quantity should be such that the entire gap is completely filled to the very top of the socket.

Caulking the bell with sulfur is not practiced at home. It is necessary to melt lump sulfur with 10-15% kaolin, which requires special equipment and enhanced ventilation. This method is only possible in factory conditions.