Sequence of installation of external sewerage

Installation work is carried out in the following sequence:

- A trench is dug with a slope towards the cesspool;

- A waste pipeline is laid over a sand bed until it connects with the storage tank;

- The junction of the septic tank with the pipeline is sealed.

When installing sewerage, the following recommendations should be strictly followed:

- When laying PVC pipes, it is recommended to lay them in a specialized box made of protective material;

- The depth must be clearly calculated and be above the soil freezing level;

- If necessary, additional insulation of pipes can be made from any insulating material.

Installation Features Factors

- Bends;

- Ground water level;

- Turns.

Sewage of any type is equipped with treatment facilities.

Any sewerage system is located on a slope. If you need to change the slope level, then you need to build on the indicators of the pipe cross-section. In individual cases, inspection wells or pumps are installed.

Compound

A pipeline is a route of pipes of different diameters and lengths that are laid at an angle.

Wells are structures that are divided according to their purpose. And they are: drainage, differential, rotary, viewing. Wells are usually equipped with brackets so that specialists can go down for repairs, as well as hatches with covers.

Outlets into water intakes are structures that provide free drainage of sewage from pipelines into a container.

Collectors are underground tunnels, which are made in the form of large-diameter pipes through which wastewater moves to its final destination.

Local treatment facilities are installations that are used for the discharge and treatment of wastewater. Such structures include biological treatment stations. The number of houses served depends on the productivity and size of the structure.

Pumping stations are units that are installed at individual facilities that require a dosed supply of wastewater.

What you need to know before installing an external sewer system

When building a household or cottage, it is necessary to remember that the laying of engineering systems is carried out at the design stage. It is especially necessary to take into account the location, since the optimality and rationality of their performance will completely depend on this. In addition, you should carefully select equipment and components. They must match the operating loads on the systems. Recently, pipes for the installation of external sewage systems made of polypropylene or polyvinyl chloride have become extremely popular. They are distinguished not only by their excellent quality, but also by their low price, as well as the possibility of installation without the use of a welding machine. As for the diameter of the pipes, when choosing, it is worth taking into account the number of plumbing fixtures and the expected volume of water.

Also, before you start laying a sewer system, you should decide on the following points:

- Select the type of sewer system;

- At the initial stage, it is necessary to make a calculation on the number of people who will live in the household;

- Decide on the type of sewer system.

Preparatory work

Before proceeding directly to the installation of external sewerage, it is necessary to carry out preparatory work. First of all, you need to decide on the autonomy of the system, the material and draw up the necessary diagrams. After this, it will be possible to more accurately calculate the cost of the work. At the same time, analyze possible difficulties and find ways to solve them.

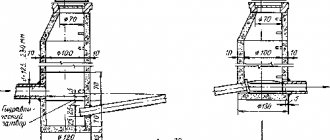

Prefabricated well

Last in the order of wastewater, but not in terms of its role in the operation of the sewerage system, is the collector or septic tank - a well into which sewage flows from the pipeline. The well is located so that it is at the lowest point of the drainage system.

Distance between the well and other objects located on the site and nearby:

| An object | Distance not less, m |

| non-residential outbuildings | 1 |

| residential buildings | 5-7 |

| water well | 50 |

| fence between plots | 2 |

| open waters | 15 |

Types of wells

For a private home, you can equip a well of one of three types:

- storage well or collector - a sealed container into which wastewater flows; when the collector is filled, the sewage is pumped out;

- a well with post-treatment, a septic tank - a container of several series-connected chambers in which wastewater gradually settles, the sediment is processed by bacteria, and partially purified water enters the last of the chambers and from there goes into the soil;

- deep treatment station - a well with filters and a bioreactor (a set of substances and bacteria), in which wastewater is purified from dangerous microorganisms and safe organic matter is separated, the purified water goes into the soil, and the separated organic matter can be used as fertilizer.

The first two types of wells can be equipped with your own hands. Ready-made plastic containers or reinforced concrete rings are used for these purposes. Septic tanks are also built from brick and concrete.

It is difficult to equip a deep cleaning station with your own hands, as it requires special knowledge. It is easier to buy a well of this type and install it ready-made in a prepared pit.

How to calculate the volume for a septic tank and collector?

The dimensions of the well are calculated based on the number of residents of the house, the presence of various household and plumbing appliances connected to the sewer system, the activity of water consumption and the planned frequency of pumping out wastewater from the septic tank, if it is a storage tank.

The volume of the septic tank is calculated based on the maximum daily water consumption by a person. If plumbing and household equipment are available, one person per day consumes no more than 0.25 cubic meters. m. In the septic tank, wastewater settles for about 3 days. Therefore, to obtain the volume of the collector, you need to multiply the number of family members by 0.25x3, that is, by 0.75 cubic meters. m.

You can use an online calculator to calculate the minimum volume of a septic tank. This calculator takes into account the number of residents, the availability of plumbing and household appliances and the frequency of their use.

The volume of a sealed collector can be calculated by knowing the average monthly water consumption in the house. If cleaning is planned to be carried out 2 times a month, then the well should have a volume of about half the average monthly water consumption.

When calculating the volume of the collector, it is worth taking into account the capabilities of the vacuum cleaners, which will need to be used periodically to clean the tank. Typically, the volume of a sewage disposal truck tank is 3 cubic meters, so it is better to make a well of multiple volumes. This will allow you to spend money more efficiently: you won’t have to overpay for calling an extra truck that will leave incomplete, and you won’t leave unpumped sewage in the sewer because there isn’t enough space in the sewer tank.

Note! If there are pets or livestock in the yard, water consumption increases, but this does not affect the volume of wastewater. Animal waste products are usually not discharged into sewers; for this purpose, places are provided for processing waste into humus.

Source

Materials and equipment

The choice of materials for the manufacture of external sewerage is considered one of the most important stages. After all, the practicality and durability of the sewer system will completely depend on them. For quite a long time, cast iron pipes were used during installation, but now they have been replaced by plastic products. There is still no consensus on which ones are better. In order to finally decide on the material, it is necessary to compare their distinctive qualities.

Cast iron pipes have the following advantages:

- Reliability;

- Durability;

- Excellent thermal and noise insulation;

- High throughput;

- Mechanical strength.

Plastic products are not inferior to cast iron pipes in their advantages. Their advantages include the following:

- Low cost;

- Resistance to chemicals;

- Corrosion resistance;

- Easy installation and transportation;

- Possibility of installation without welding.

Which of the listed materials is preferred will depend entirely on each specific case. Since operational characteristics, flow intensity, as well as the load on the highway are always taken into account. Nowadays plastic pipes are mainly used, which are:

- Polyethylene corrugated. They differ from others by their increased strength.

- Polypropylene. They are able to withstand high temperatures and are mainly used for internal sewers. The disadvantage of such pipes is their lack of strength.

- Polyvinyl chloride. Withstands sub-zero temperatures and has excellent strength.

When installing sewerage outside, in most cases, polyvinyl chloride pipes are used, which in turn are divided into three classes:

- Light class - not used under the roadway;

- Middle class - used under the roadway with minimal traffic;

- Heavy class – used in any conditions, including industrial networks.

For private households and country houses, the first or second class is best suited.

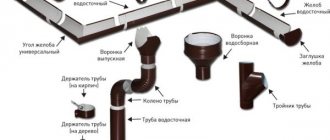

Among other things, you need to take care of purchasing various kinds of turns, adapters, as well as mechanisms for fastening. In the event that the installation is carried out on an autonomous external sewer system, then it is necessary to select drainage and filtering mechanisms. They should only be of good quality and from trusted companies, since the likelihood of clogging groundwater directly depends on them. You will also need a septic tank or various kinds of materials that are produced for arranging a cesspool. In some cases, a fecal pump is purchased. But this happens quite rarely and when absolutely necessary.

Check valve device

A check valve is a special device that allows liquid flow only in a given direction and does not allow reverse movement. A check valve is indispensable in a private house, where during the rainy season the level of liquid in the septic tank may increase, as a result of which the liquid will begin to move in the opposite direction - towards the house. And only the installed check valve prevents excess liquid from flooding the basement of the building.

The check valve is installed on the section of the pipeline between the building and the septic tank. It is imperative to provide an inspection well to monitor and control the operation of the check valve.

The Capricorn check valve is of high quality, reliability, anti-corrosion properties, light weight, resistance to aggressive chemicals, and can be easily installed by yourself.

The Capricorn check valve is equipped with a special protective cover, with the help of which the operation of the device is audited. The design, thought out to the smallest detail, protects against the accumulation of solid impurities in the internal elements of the device.

Insulation of external sewerage pipes

External sewerage pipes are insulated only if they are laid above the freezing level of the soil; in other cases, insulation is not required. Thermal insulators meeting the following requirements are used as insulation:

- Easy installation;

- Tightness;

- Low cost;

- Large resource of use;

- Low thermal conductivity coefficient;

- Moisture resistance;

- Biological activity;

- Resistant to chemical and mechanical influences.

Basically, such materials include various types of insulation, such as mineral or basalt wool, glass wool, polystyrene foam, polystyrene foam and penoplex, as well as polyurethane foam shells. The cheapest option is polystyrene foam, and the most expensive is polyurethane foam shell.

Regardless of what material the sewer system will be insulated with, all steps must be performed in strict sequence. First of all, you need to dig a trench with a depth reserve of approximately ten centimeters. This is necessary for laying the shock-absorbing cushion. After this, lay out the pipeline along its entire length and make sure the connections are secure. Place a seal on the pipe and secure it tightly. Basically, adhesive tape is used for this, which is used to wrap the treated pipe. One of the final stages is filling it with sand and compacting it. At this stage, you need to do everything very carefully, as there is a risk of damaging the insulation. Finally, the trench is covered with earth in the form of a mound.

Planning and preparation for installation: organizing the process ↑

The question of how to make an external sewer system in a private house with minimal investment so as not to damage a large area of the site is decided depending on the type of drainage arrangement chosen. Relief features may limit the possibilities of planning the trajectory of sewerage installation.

Marking the trajectory and choosing a location for an autonomous sewer ↑

Before developing a pipeline laying scheme on the site, it is necessary to select a place to deepen the tank. The installation point of the septic tank is determined according to the rules: the containers must be removed from the house, water source, road and neighboring areas.

Autonomous station with discharge of treated wastewater to a drainage field

It is difficult to determine the correct installation depth - if you have to regularly pump out sediment, then digging the tank deeper than 3 m is impractical. Due to the technical features of servicing autonomous treatment plants, it is necessary to install the external sewerage pipe to a depth above the freezing level of the soil.

The footage and diameter of the pipeline are calculated based on the planned daily volume of wastewater. For a private sewer system in a residential building, which you can install yourself, pipes with a diameter of up to 150 mm are sufficient.

Be sure to calculate the overall slope of the pipe laying: from the point where the drain exits the house to the entrance to the tank, and plan the trajectory so as to avoid turns and sudden changes in height.

Pipeline supply to the central sewerage system: preparatory stage ↑

It is easier to correctly supply pipes to the central main than to an autonomous septic tank: the city sewer pipe is located at a depth below the freezing point. It will be possible to save money on pipe insulation - only the part adjacent to the exit point from the house needs to be insulated.

Scheme of supplying a local pipeline to the central main line

If the house is far away from the point of insertion, difficulties may arise that will have to be resolved before work begins:

- If there are objects on the planned trajectory where work is prohibited, you will have to make a detour, which will increase the total cost of sewerage installation.

- You must obtain permission if the pipe passes through a private plot or social infrastructure facility.

The final calculation of the number of pipes and the selection of materials is carried out only after the technical conditions have been agreed upon.

Slope and depth: rules for pipeline installation ↑

The main technical parameters that need to be taken into account are the installation depth and the minimum angle of inclination of the external sewer system. It is important to avoid deviations from the minimum and maximum indicators.

Typical errors in installing an external sewerage pipeline

If the slope is too low, the liquid in the pipeline will stagnate due to the low flow rate. In winter, stagnation is fraught with freezing in shallow areas. Lack of inclination leads to clogging of the line, especially at turning points.

Consequences of installing a sewer system at too great an angle:

- A high drain rate provokes the failure of the seals in the siphons - a persistent unpleasant odor appears inside the room.

- There is a risk of backflow when large volumes of liquid enter the drain.

- Dense waste remains in the pipe at high drain rates, which leads to blockages.

Key points: slope and correct depth

You can determine on your own what slope the external sewer system should have in 2 ways: use ready-made level deviation values for pipes of different diameters or apply a formula for an accurate calculation.

Relationship between filling degree and inclination angle

The formula calculates the fill level of the pipe. If we take a gap completely filled with water as a unit, then the value that is considered acceptable for external sewerage should be from 0.5 to 0.8. That is, the pipe should be filled to 50 - 70% of the internal diameter. If the indicator calculated by dividing the level height inside the pipe by its diameter is within the acceptable range, then the angle of inclination is determined correctly.

Minimum slope values

In order not to complicate planning with complex calculations, it is better to use data on the slope of the pipeline in the ground, calculated for standard pipeline diameters. By multiplying the difference, indicated in centimeters per linear meter, by the distance from the point of exit from the house to the insertion, the total slope height is obtained. It is necessary to take into account that the maximum permissible slope of the external sewerage system should not exceed 15o.

Ventilation sewer system

When installing external sewerage, it is also worth taking care of ventilation, which will help ensure the following:

- Equalize the pressure;

- Increase the flow of fresh air;

- Ensure quiet operation of the sewer system;

- Eliminate unpleasant odors.

Many homeowners ignore this stage, which over time leads to unpleasant consequences, such as a decrease in the efficiency of the sewer system and the appearance of unpleasant odors. The only solution in such a situation is ventilation. Depending on the location, the ventilation system is of two types: internal and external.

To arrange ventilation for external sewerage, in most cases, a drain pipe is used, which serves as a continuation of the internal riser. It refers to the internal sewer system. For such a pipe to work effectively, it must be installed above the roof. It is worth considering the fact that it is necessary to place the fan pipe away from doorways and windows. In addition to the fan pipe, an air valve is also used, located on top of the riser. Its installation is much simpler than a vent pipe and can be done in an already built and functioning house. You can also make an air valve yourself using available materials. This rather simple design can not only block the movement of warm air, but also protect water pipes from frost during the cold season.

Preventing wastewater overflows on site

A sewer overflow gully is a small grated drain located outside the home, usually connected to the end of the sewer. It is designed to release any odors or sewage overflows away from the site in the event of a sewer blockage and is an important part of the system. It is the owner's responsibility to ensure that their home is equipped with a properly designed and functioning drain. The grate at the top of the drain must be free to pop out and release any leaking sewage in an emergency. If the drain grate is covered or backfilled, it will not function properly and waste water will flow into the home. Property owners are advised to install sewer manholes and regularly check that they are not blocked. Outdoor sewerage carries out a process in which wastewater is transported throughout cities and towns to treatment plants, where it is then treated to remove pollutants to produce environmentally friendly waste. Wastewater disposal protects public health and prevents disease and water pollution from wastewater. Many modern cities have wastewater disposal systems, and advancing technology has created more environmentally friendly and healthier solutions for wastewater disposal and treatment. Sewage is part of modern infrastructure and utilities, which also include the installation of gas and electrical equipment.

Preventing unpleasant odors in the room

Basically, the problem of unpleasant smell from the sewerage arises due to failure to comply with basic rules and the formation of various types of blockages. In addition, sometimes the cause of the smell may be an incorrect construction scheme or poor-quality installation work. Small cracks can also be a source of unpleasant odors. This is mainly observed on siphons. To prevent such a problem, it is necessary to pay special attention to the condition of the water seal. Sometimes it is enough to simply change the gasket or repair the crack in one of several ways.

One possible reason for the unpleasant odor may be the lack of liquid in the siphon. To solve this problem, you need to open the tap and fill it with water. After a fairly short period of time, not a trace of the smell will remain.