When landscaping a dacha or other country property, many people used to build a cesspool. This is an extremely inconvenient and environmentally unsafe method. In addition, the cesspool spreads an unpleasant odor. That's why most homeowners today choose more efficient solutions. An example of such a solution is the Astra septic tank.

When doing home improvement, most homeowners want to purchase a reliable wastewater treatment facility that processes wastewater without releasing an unpleasant odor.

Deep biological treatment stations meet these requirements. One of the most popular options for such an installation is the Astra septic tank. Let's figure out what kind of installation this is, what malfunctions it has and how to repair it.

Design and principle of operation of septic tanks Unilos Astra

The design of the station provides for the gradual removal of contaminants in four series-connected tanks enclosed in one housing:

- Receiver

This is the primary sedimentation basin for heavy sediments, connected to the sewer line. This is where small and large solid particles from kitchen sinks or plumbing fixtures settle to the bottom. The liquid moves through the mamut pump for the next stage of cleaning.

- Second camera

Aerobic biological purification reactor that converts pollutants into sludge. In it, under the influence of bacteria, fat, chemical compounds and microparticles that do not settle in the receiving area are broken down.

The liquid flows further through a grease filter that retains the film on the surface of the drain.

In an aerobic reactor, microorganisms are generated within a month from the start of Astra’s operation. The number of users is regulated by the manufacturer for each model.

If operating conditions are violated, bacteria are introduced artificially - a special mixture is purchased and poured into the home sewer.

- Third compartment

Separates sludge deposits. The old ones fall to the bottom, and the new ones return to the second tank for further processing.

- Fourth tank

Pure water flows into it with a purification degree of up to 98%. The autonomous station produces process water with hygienic characteristics, suitable for watering plants or washing buildings and cars.

Compliance of the degree of purification with SanPiN standards and the environmental safety of the process are confirmed by sanitary and epidemiological conclusions.

Organization of purified water drainage

One of the most popular questions that our septic tank engineers are asked is “How to organize the removal of treated wastewater from an autonomous sewer system?” And there is no definite answer here, since you just need to look at the site and find the ideal option. The most suitable in 90% of cases will be a drainage well made of ordinary concrete rings. It is installed near an autonomous sewer system and receives all wastewater into itself. Then they simply fall into the ground. Many summer residents organize a drip irrigation system. That is, they use treated wastewater to water their garden. Others are simply dumped on the ground when the terrain of the area allows it. Basically, these are the outermost houses on the street, when there are no neighbors on any side. As you can see, there are many options for organizing the removal of purified water from an autonomous sewer system. But it is better to consult a professional. After all, there are a lot of points that need to be taken into account, up to the water absorption of the soil, where the ability of the soil to absorb water is taken into account. An important point is also the groundwater level. If it is high, there is a risk of creating a small swamp on the site. Therefore, installing Unilos Astra with your own hands often leads to the need for dismantling, followed by installation by an experienced team and correction of all the jambs. If you are not sure that you can install the Astra septic tank on your own, then do not take risks.

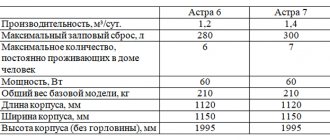

Technical characteristics of Unilos Astra 3, 5, 8

VOC Astra engineering systems are classified according to the volume of liquid waste received. The numbers in the labeling are the maximum number of people for which a particular model is designed.

| Conditional users | Productivity per day, m3 | Salvo discharge, l | |

| Astra 3 | 3 | 0,6 | 150 |

| Astra 4 | 4 | 0,8 | 180 |

| Astra 5 | 5 | 1,0 | 250 |

| Astra 6 | 6 | 1,2 | 280 |

| Astra 7 | 7 | 1,4 | 300 |

| Astra 8 | 8 | 1,6 | 350 |

What capacity should a treatment plant have?

The manufacturer must indicate the performance of its models. To find out this indicator, you need to look at the number that follows the name of the technology. It indicates how many users the station is designed for.

The daily volume of water consumption per person is considered to be 200 liters. To find out the productivity of the installation, you should multiply the water consumption of one person per day by the number of people. For example, the ASTRA-8 system can clean 1600 liters. per day.

↑ return to content

Rules for choosing septic tanks Unilos Astra

The correct operation and performance of the station depend on the number of users (including regularly visiting guests), the type and quantity of plumbing fixtures, the distance to the treatment structure, and the purified liquid discharge system.

The approximate number of plumbing fixtures for some Unilos models is given in the table.

| Name of plumbing fixtures\version of septic tanks Astra (number of residents including regular guests) | 3 | 4 | 5 | 6 | 7 | 8 |

| Toilet | 1 | 1 | 1 | 2 | 2 | 2 |

| Sink | 2 | 1 | 2 | 2 | 3 | 3 |

| Shower stall | 1 | 1 | 1 | 1 | 1 | |

| Standard bath | 1 | 1 | 1 | |||

| Washing machine | 1 | 1 | 1 | 1 | 1 | 1 |

| Dishwasher | 1 | 1 | 1 | 1 | 1 |

Take extra equipment if there are more points installed in the bathrooms and kitchen, or if you use bulky plumbing fixtures. If you are in doubt about choosing a specific model, seek help from a specialist.

The outlet of the waste line from the building affects the installation location and the height of the Astra station building. It is better to calculate these parameters simultaneously. According to SNiPs, the conductive line is lowered by 2 cm every 1 m of the line.

If the location of the VOC on the site has already been determined, then its modification must be selected depending on the depth of the supply pipe.

The type of soil influences the choice of the Unilos septic tank drainage system. The gravity flow scheme is suitable for sandy soils. For clay and loam with a high groundwater level, forced pumping is necessary.

Installation of autonomous sewerage

If you have chosen the Unilos Astra sewage treatment system, then you have made the right choice. The next step will be the installation of an autonomous sewer system. For many reasons, it is better for the installation to be carried out by a professional installation team, but you can also do this process yourself.

The first stage of installing an autonomous sewer system is to select a suitable location. Mostly they choose a place somewhere near the fence or in the corner of the site. It is desirable that the sewer pipe leading to the septic tank does not have bends. The maximum permissible pipe bend is 90 degrees.

But in this case there are some points that you need to familiarize yourself with in advance and subsequently install according to technology. Another point in choosing a location is the distance from home. The Unilos autonomous sewer should preferably be located no further than 15 meters from the house. And if this cannot be achieved, then it is necessary to organize audits or cleaning.

After choosing a location, you can proceed to installing the Unilos Astra autonomous sewage system yourself, only for this you need to follow one by one.

First of all, we start digging a pit. The size of the pit should be 15-20 centimeters wider on each side than the overall dimensions of the autonomous sewer system. The depth of the pit should be calculated so that the septic tank rises 15-20 centimeters above ground level. At the same time, do not forget that a sand cushion 15 centimeters thick should be formed at the bottom of the pit.

After the pit has been dug and the sand cushion has been filled evenly, it is necessary to immerse the autonomous sewerage station itself into the pit. It will be very difficult to manage on your own, since the weight of the station exceeds 200 kilograms. It is best to call several people for help. Loading occurs as follows. The station is installed near the pit. Afterwards, a strong rope is securely attached to the upper stiffening ribs of the station. And after that, at least three people load the septic tank into the pit. Do not forget that the receiving chamber must be turned towards the house and the supply sewer pipe.

Using a building level, the septic tank must be accurately leveled in the pit. All sides must be strictly horizontal.

At the next stage, clean water is poured into the Unilos Astra autonomous sewerage station to the levels specified by the manufacturer. You can see them on the walls from inside the station. While adding water, it is also necessary to sprinkle the septic tank with sand with periodic abundant watering for maximum compaction.

Then we move on to installing the sewer pipe. To save time, it is best to carry out this step in parallel with digging a pit for the septic tank and loading it, but this is the case when you have assistants. If the installation of Unilos Astra is done by yourself and you are alone, then digging trenches and laying a sewer pipe will be done after loading the septic tank into the pit.

Once the trench, about 50 centimeters wide, is ready, its bottom must be filled with sand 10 centimeters thick. The sewer pipe must be orange for external installation in the ground.

We return to the septic tank in the pit. After all, you need to drill access to the receiving chamber. To do this, you will receive a polypropylene pipe along with the station. Using polypropylene solder, it is hermetically sealed in the place where the sewer pipe will be connected. The pipe is connected accordingly.

Depending on the depth of the trench, you decide whether to insulate the sewer pipe or not. Insulation of a sewer pipe can be done using different methods. The most reliable is the installation of a heating cable. But you can use foamed polyethylene and other insulation methods. It's up to you to decide, since the installation of Unilos Astra is done by yourself. This means that you take all the risks on your shoulders. Therefore, it is better to play it safe and do everything reliably the first time.

Unilos autonomous sewerage stations are energy-dependent. That is, they need electricity. For this reason, an electrical cable is also laid in the trench along with the sewer pipe, which leads to the compressor compartment. The quality of the cable must be suitable for laying in the ground. Afterwards the trench is backfilled and the station is finally covered.

At the last stage, you will need to connect all elements of the Unilos Astra autonomous sewage system in accordance with the diagram that comes with the septic tank.

Installation of a Unilos Astra septic tank and its maintenance

You can install an autonomous sewer system yourself in the manner prescribed by the manufacturer. But the warranty on parts and proper operation of the equipment is valid only when the system is connected by certified specialists.

Expert opinion

Ilya Kozhevnikov

Design engineer. 10 years of experience

Ask a Question

In the first month, it is necessary to limit the use of dishwasher and washing machine products. This will promote faster development of microflora inside the septic tank.

Maintenance of the station involves removing contaminants from inside the system:

- pumping out excess from the third chamber;

- removing contaminants from the walls of the tank;

- washing the filtration element in the aeration tank - removing stuck hair, wool and other fluff;

- cleaning the compressor air filter.

This work is carried out once a quarter, according to the operating instructions for the Unilos Astra septic tank. Every 5 years, the first settling tank is cleaned of accumulated solid heavy particles. Electrical components and the control unit should preferably be inspected and maintained by electricians-installers.

Note!

In case of self-service, the manufacturer has the right to disclaim warranty obligations.

For self-service, you will need to use a minimal set of tools and these step-by-step instructions:

1. Preparation

Visual inspection of the station: internal parts, electrical components, presence of dirt in all chambers and on parts; as well as preparing rubber gloves, a pumping container and a Phillips screwdriver.

Next, turn off the power supply to the compressor on the main panel (button - Network) and after 20-30 minutes you can begin servicing.

To do this, move the switches to the position:

- "Compr." — “0”

- "Manual" - "1"

- "Return." — “0”

It is recommended to remove sediment from activated sludge inside the settling tank, wash the walls of the secondary settling tank, nozzles, clean the filter and pump from untreated fractions, as well as the air filter and hair trap.

2. Pumping out waste sludge

- Remove the pipe from the mount leading to the standard pump and unscrew the clamp using a screwdriver or socket wrench to remove the plug;

- Lead the edge of the pipe into the container, turn on the network on the control panel (“Comp.” - position “1”). The removal of excess activated sludge will begin;

- Pump out approximately 50% of the sludge mixture from the stabilizer volume;

- Turn off the power and manual mode (“Compr.” - “0”, “Manual” - “0”);

- Return the pipe plug and clamp to their original place, and turn on the compressor.

After completing all maintenance items, fill the station with water in a volume equal to that pumped out.

Note

: A standard mamut pump is not capable of pumping out the entire mass to the bottom, so excess activated sludge should be removed in this way once every 3 months during active operation of the station.

3. Cleaning the coarse filter and the main pump

With the compressor turned off, you need to release the main pump hose from the holding clips and the filter itself (you will need a screwdriver again), then disconnect the hoses and remove the devices from the septic tank. Turn the filter over and pour out the impurities. Place the pump back into the coarse filter and install it in the receiving chamber.

4. Cleaning the secondary settling tank

To do this, the walls of the tank are washed with powerful water pressure, after which the dirty film is caught with a juicer or a scoop. Everything is done with the station de-energized!

5. Cleaning the compressor filter

Unscrew the compressor cover, remove the filter and clean it (it is not necessary to wash or wash it).

6. Removal of secondary contaminants

We are talking about a hair collector, which should also be removed from the aeration tank and thoroughly rinsed under powerful water pressure.

7. Pumping out stabilized sludge

The procedure is performed every 3-5 years. And for this you will need to connect a separate fecal or drainage pump, or call a sewer truck if the station is designed for a large number of people.

Pumping is performed chamber by chamber with the compressor power turned off. For example, we pumped out the sludge settling chamber, filled it 50% with water, then proceed to the aeration tank, receiving chamber, etc.

Expert opinion

Ilya Kozhevnikov

Design engineer. 10 years of experience

Ask a Question

During pumping, it is better to dilute the sludge with water by pouring it into the chamber from a hose to collect all the sludge from the bottom.

Time intervals for replacing components

Manufacturer Unilos Astra recommends:

- every 6 months, clean the filter to catch hair in the aeration tank;

- Change all filters once a year;

- Change all membranes in the compressor once every 2 years;

- Complete replacement of components once every 5 years.

Advantages of autonomous sewage system Unilos

The Unilos Astra domestic wastewater treatment station stands out from other equipment with many advantages. The main ones among them are the following:

- Low price compared to foreign analogues.

- Fast installation within one working day.

- Wastewater treatment occurs fully automatically.

- The degree of purification reaches an unsurpassed rate of 98%.

- The amount of electricity consumption is low and will not affect the family budget.

- The tightness of the structure and the activity of bacteria prevent the appearance of odors.

- Each element of an autonomous sewerage station is designed for long-term operation.

For private houses, dachas and cottages, the most optimal solution will be the Unilos Astra septic tank. This is a separate series for use in private households. Among the model variety there are both small autonomous sewers for 3 people to purify 0.6 cubic meters per day, and huge systems that can serve 150 people and purify 30 cubic meters of wastewater per day.

Preservation of the Unilos Astra septic tank

If the station does not receive wastewater for 3 or more months, its conservation is required.

To do this, when preserving “Standard” and “Midi” stations with a capacity of 0.8 m3/day or more, according to the manufacturer’s instructions, you must:

- Carry out maintenance;

- Disconnect the septic tank;

- Remove the compressor from the station and store it in a warm, dry place;

- Completely pump out the sludge stabilizer chamber, then fill it no higher than the level of the supply pipeline (about 1.8 m from the bottom);

- Remove excess activated sludge from the aeration tank to a level of 1.7 m from the bottom;

- Add clean water to the receiving chamber no higher than the point of the supply pipeline (about 1.5 m from the bottom);

- Prepare 2 liters or 5 liters of plastic bottles filled 50% with sand, and place 1-2 in each chamber;

- Insulate the septic tank lid with material that does not absorb moisture and is at least 5 cm thick;

- Cover the perimeter of the station with film and secure it.

For the Long and Astra-3 stations, after pumping sludge from the chambers, the aeration tank, secondary settling tank and sludge stabilizer must be completely filled with clean water to the overflow level, and the equalization tank must be filled to a height of about 1 m.

Important ! After conservation, the septic tank should be completely de-energized, and no more waste should flow into it.

To resume operation of the station after mothballing you will need:

- Remove bottles with sand from all chambers;

- Fill the aeration tank and sludge stabilizer chambers with water to the top level;

- Install the compressor and connect it to the station;

- Connect the septic tank itself to the network.

How does the Unilos autonomous sewage system work?

Let's study in detail the operating principle of a wastewater treatment plant. The cleaning process occurs continuously according to the following algorithm.

- Domestic wastewater enters the receiving chamber, where it is actively mixed with activated sludge. Activated sludge contains a very large number of living bacteria. Several processes occur at once in the receiving chamber. So, in addition to the fact that the wastewater is mixed with activated sludge, the wastewater is also subjected to preliminary oxidation and anoxic-anaerobic treatment. In addition, in this chamber the volume of wastewater is equalized and large inorganic debris settles to the bottom.

- Then the water mixed with sludge is sent to the aeration tank. This is helped by airlift or simply airlift. They never came to a common name. In the aeration tank with wastewater, their further oxidation and aeration is carried out. This leads to the breakdown of organic elements into nitrites and oxidized carbon.

- At the third stage of treatment, the wastewater is sent independently and without coercion to a secondary settling tank. There is no oxygen in this part of the autonomous sewerage station. This is necessary for the activated sludge to settle to the bottom and for the reduction of nitrate and nitrite nitrogen to molecular nitrogen.

- Activated sludge settles to the bottom on its own. And at the same time, clarified and purified wastewater to the required level is sent outside from the autonomous sewerage station by gravity or by force if the model is equipped with forced drainage.

- When the water level in the secondary settling tank decreases, the recirculation phase will begin.

- Part of the activated sludge settles in the aeration tank. The remaining activated sludge is pumped by airlifts into the activated sludge stabilizer provided for it. Here the sludge is stabilized and made ready for disposal. It is removed during service. During recirculation, the wastewater with part of the activated sludge is sent to the receiving chamber. The aeration and mixing process begins again.

- As soon as new wastewater arrives, which leads to an increase in the level in the equalization chamber, the whole process occurs in the same order.

Conditions and warranty period for the Unilos Astra station

Require filling out the warranty service book, because... Only if it is available will the warranty be valid.

The warranty service life for the body of the treatment station is 5 years starting from the date of sale, for electrical equipment and the compressor - 3 years in the presence of a voltage stabilizer and subject to installation by specialists from SBM-Group or holding members. In other cases, the warranty depends on that stated by the manufacturer and begins from the date of sale.

The warranty does not apply in the following cases:

- when the installation and launch of the station was carried out by an unauthorized organization without documents giving the right to perform such work;

- in case of mechanical damage, incorrect connection, non-compliance with the rules for using the station and its maintenance, violation of the seals, attempts to independently repair or make changes to the design without agreement with the manufacturer;

- in case of damage during transportation, if this service was not performed by the manufacturer.

Why is it better to order Astra from us with installation (turnkey Astra):

DISCOUNT 15%

When ordering a turnkey Astra septic tank, you will receive a 15% discount on the station, and a discount on installation will also be a nice bonus. You only have to pay for water and sand (at the customer’s request, we can take care of organizing the delivery of sand and water)

Professional measurement!

The measurement costs 1,000 rubles, but when concluding a contract, this amount is COUNTERED into the contract! After the measurement, you will receive: a layout diagram of the treatment plant on the site + a description of the proposed solution with justification (explanations).

Present

By ordering a turnkey septic tank, you receive a drainage pump as a gift.

Installation 1 day

Standard installation will take 1 day, or we will pay for you to go to the cinema! We will deliver and install a septic tank within 24 hours after your application!

Warranty 36 months

Guaranteed service life of 50 years. The basic warranty for the station is 36 months! We also provide a 36 month guarantee on installation! (other companies give only 12 months!!!)

Those. support 7/7

We don't abandon our clients! If you encounter any difficulties, you can always get specialist advice in any convenient way: by phone, mail, whatsapp, etc.

Please note that you can order an Astra septic tank from us with turnkey installation in installments of up to 6 months. with an initial payment of 10%, and on credit up to 36 months with an initial payment of 0 rubles.

Wastewater treatment on sea and river vessels

UNILOS stations located on the ship

In past years, drainage from sea and river vessels, as well as landing stages, was taken by sanitary vessels. They transported them to special treatment plants. Calling such a vessel requires financial expenses. Trying to save money, many ships solved waste problems in a simple way - they dumped it overboard. Many believed that such discharges do not affect the state of natural water. Thus, most sea and river vessels are still not equipped with treatment facilities. The optimal solution here is the use of treatment plants. They help prevent pollution of the aquatic environment by wastewater from ships.

For the manufacturer of UNILOS stations, the tasks of environmental improvement of rivers are of priority importance. The company has extensive experience in the production and installation of treatment facilities. Stations can be assembled directly in the holds of ships. Our specialists quickly install the installation. Such treatment plants are recommended for restaurants and cafes located on the water.

The stations optimally solve economic and environmental problems. They make it possible to eliminate waste without polluting water resources. The installations do not cause any trouble to their owners and allow them to save energy.

◄

Request a callPrices for UNILOS ASTRA modelsDeliveryRequest

Selecting the optimal station height

The level of insertion of the supply sewer pipe in wastewater treatment plants is different. It all depends on how deep the outlet pipe is. The distance from the station to the house also matters.

Today the manufacturer produces the following systems:

Long (height 3 m) Midi (height 2.5 m) Standard (height 2.36 m)

The pipe entrance (insert) can reach 0.6 m, 09 m or 1.2 m.

There are also non-standard options that provide a station with a height of more than 3 m.

The station kit may include an integrated sewage pumping station (SPS). It is used when deepening a sewer supply pipe if the distance from the bottom edge of the pipe to the ground level is less than 1.2 m. SPS can be used when inserting supply lines into the cleaning system that are at different heights. If a one-time salvo discharge is uneven or exceeds the permissible norm, then CNS is also used. The pumping station is equipped with an alarm system and a sewage pump.

If the facility is located in an environmental protection area or within the city, then the characteristics of the purified liquid can be improved. For this purpose, a special post-treatment unit is used. The kit includes a frame-fill filter, a drainage pump and an ultraviolet disinfection unit.

↑ return to content

Features of the use and organization of biological treatment systems

Wastewater treatment processes are based on the activity of bacteria. Activated sludge plays the main role here. Its components provide effective biological treatment. If the conditions for the growth, development and nutrition of living organisms are unfavorable, then the quality of purification deteriorates. To prevent such a situation, you must adhere to the rules for using sewer networks and plumbing units.

The following must not be disposed of in the sewer:

- construction waste, lime, sand, cement and other waste;

- petroleum products, paints, fuels and lubricants, antifreeze, alkalis, acids, alcohol and other similar substances;

- materials made of polymers and other substances that do not biodegrade (films from packaging, cigarette filters, contraceptives, hygiene bags, etc.;

- garden and household waste, fertilizers and other waste;

- garbage in the form of rotten vegetables, wild mushrooms, washing liquids with disinfectants (active chlorine, ozone, etc.);

- regeneration (wash) waters from water purification systems, if they contain external oxidizing agents (potassium permanganate);

The release of the above substances causes osmotic shock in the cleansing bacteria. As a result, the quality of cleaning deteriorates sharply. In some cases, the activated sludge dies completely.

What other substances are not advisable to pour into the sewer:

- A large amount of waste after bleaching clothes (if the substances contain chlorine). These include “Whiteness”, “Persole”, etc.

- Cleaning preparations with chlorine and antiseptics. This can lead to the death of sludge and loss of system functionality.

- Medicinal substances.

- Pet hair in large quantities.

Experts say that using special nozzles with toilet dispensers can also cause system failure. After all, such attachments contain antiseptics.

If the operating rules of the treatment station are fully followed, the purified water has no odor. It is completely transparent.

What can be disposed of in the sewer:

- soft toilet paper that disintegrates easily;

- chlorine-free wastewater from washing machines;

- kitchen drains if non-chlorine detergents are used;

- bath and shower drains;

- · a minimum amount of preparations for cleaning plumbing fixtures and household kitchen equipment (no more than once a week).

In order for a treatment plant to function effectively, exposure to chemicals must be avoided. All of them have a negative effect on bacteria. Experts recommend activating biological processes. Users can use detergents, disinfectants and cleaning ingredients that contain biodegradable substances. Washing, cleaning and cleaning should be done at different times. This will prevent the massive release of harmful substances into the purification system.

UNILOS treatment stations are reliable and convenient devices that function properly for many years. Cleaning is controlled automatically. This avoids constant maintenance. The user has minimal responsibilities for system maintenance.

Water purified by UNILOS biological treatment stations of the Astra and “SKOROBEY” series is transparent and odorless. Ice block removed from the aeration tank. Purified water in the upper part, and activated sludge in the lower part

↑ return to content