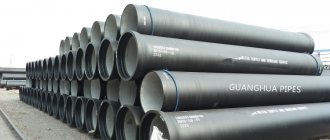

Today, heavy cast iron pipes have been replaced by new products made from composites and the latest polymer materials.

They are installed in sewer systems, as well as in melt water drainage devices. But no one has forgotten about cast iron pipes; their popularity has remained at the same level. In some places, only cast iron products can be installed; plastic is simply unacceptable. The service life of cast iron sewer pipes is approximately equal to their polymer counterparts.

Life time

The operating time depends on several parameters. In addition to high strength, the duration of operation of the entire system without repair and replacement of failed parts in different areas is considered very important.

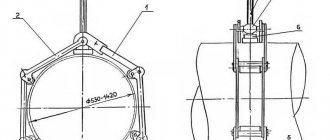

The type of connection present is also taken into account. Bell-shaped sewer systems are considered the most profitable. They make it possible, if a leak occurs, to restore the tightness by additionally sealing the connection.

If a socketless pipeline is installed, such repairs cannot be made; the failed section of the pipe will have to be completely replaced. A main line laid from a gray cast iron pipe, if properly maintained and regularly cleaned, will last approximately 80 years.

You can, of course, not monitor the sewer system and not do any cleaning work. The service life of cast iron sewer pipes is reduced by almost half.

Ductile iron pipes are designed to operate for 100 years or more.

Material of manufacture and technical characteristics

Before purchasing plastic pipes for sewer or water supply installations, you need to pay attention to the technical characteristics of the material and weigh the pros and cons.

Polypropylene pipes

Socketed polypropylene pipes

Polypropylene is produced in the form of granules, from which pipes of different diameters are cast during heat treatment. PP does not chemically interact with acids and alkalis, does not emit harmful substances, therefore it can be used in cold and hot water supply systems. The material becomes soft at 145 degrees, so it can withstand hot drains up to 95 degrees without deformation.

Physical and mechanical parameters:

- resistant to mechanical shocks;

- low temperatures have no effect if ethylene is added to the molecules;

- wear resistant;

- Aluminum-reinforced polypropylene deforms less when heated;

- sensitive to oxygen and ultraviolet radiation - to reduce the performance, stabilizers are added to the composition.

Depending on the filling, you can create a material with new properties:

- Glass filled. Fiberglass increases bending elasticity and increases the strength of finished products.

- Mineral-filled. The introduction of calcium carbonate increases the thermal insulation properties of PP.

- Elasticated. By adding elastomers, the frost resistance of pipes and their elasticity when bending increases.

- Low-flammability. Produced by mixing granules with antiprene. If a fire occurs, the material extinguishes on its own.

Plastic pipes made of polypropylene are much cheaper and more practical than metal ones. They have a smooth inner surface, which prevents dirt from sticking and clogging the drain. Mineral sediments - calcium, iron - are not able to clog the lumen and change the diameter of the pipes, because the material is not electrified and does not attract salt molecules. It is recommended to install filters for drinking water if it contains dissolved minerals, as they can damage household appliances - dishwashers and washing machines, boilers, boilers or radiators.

Polypropylene is the second material after PVC in the ranking of production volumes.

PVC pipes for sewerage

PVC pipes

Unplasticized polyvinyl chloride is a material that successfully replaces steel structures, which are much more complex and expensive to maintain. It is used in the food and chemical industries, since PVC can withstand aggressive loads from acids - nitric, hydrochloric, sulfuric, and does not release harmful substances into the transported liquid.

Characteristics:

- low expansion coefficient when heated;

- the material begins to soften at 80 degrees;

- melts at 180 degrees;

- In warm weather, it is shock resistant.

The disadvantage of PVC is that fragility increases with decreasing temperature.

PVC pipes are smooth inside, which eliminates sewer blockages at the correct angle of inclination. Mineral deposits do not stick to the material, therefore, the diameter remains the same throughout the entire service life.

Polyethylene pipes

Polyethylene sewer pipes

High-density polyethylene is used to make pipes. The service life of the material is about 50 years. This is much longer than pipes made of concrete, metal or cast iron last.

Advantages of polyethylene pipes for sewerage:

- do not deteriorate upon contact with water or aggressive liquids;

- environmentally friendly;

- welding does not require additional consumables, as for steel;

- the installation process takes less time due to the relatively light weight of the products;

- elastic – withstands pressure and temperature without cracking or deforming;

- the ice that forms inside the pipe does not damage it;

- Suitable for installation in areas where there is a high load on the ground and where earthquakes occur frequently.

Used polyethylene pipes can be recycled and reused.

Cross-linked polyethylene

Cross-linked polyethylene

Not inferior in strength to solid substances. It is obtained by adding peroxides, silane, and nitrogen.

Advantages of cross-linked polyethylene over regular polyethylene:

- thermal insulation properties are 30% higher;

- resistant to ultraviolet radiation and atmospheric conditions, therefore can be used for arranging open water pipes;

- high mechanical tensile strength, as well as flexibility of the material;

- shockproof in frosts below 50 degrees.

The material burns at a temperature of 400 degrees, while decomposing into water and carbon dioxide. Melts at 200 degrees. Used in seismically hazardous areas because pipe connections are not damaged by soil movements.

What parameters determine the operating time of the sewer system?

To ensure long-term operation of the drain, it is very important that the water supply is made from the highest quality connecting materials.

The surface of cast iron pipes must be flat and smooth. No depressions or growths are allowed.

All dimensions of the pipe (its length and diameters) must fully comply with the current standard.

To increase the service life and protect cast iron from corrosion, the internal and external surfaces of the pipes are treated with petroleum bitumen. To create a special protective coating, special whitened cast iron is sometimes used.

When creating an anti-corrosion coating, the presence of fistulas or any foreign inclusions is not allowed. The surface should be smooth and continuous.

Even the slightest drop of metal that breaks the anti-corrosion coating can cause corrosion. Moreover, this will happen at the very beginning of the operation of the sewer system.

External pipe defects can be easily determined visually by carefully examining the condition of the surface of the product. Internal defects can only be determined by hearing.

When there is a crack or a sinkhole in the pipe, the pipe will make a characteristic sound when tapped. Its duration, as well as the pitch of the tone, is very different from the sound of quality material.

This technology even helps to detect where the damage is located.

In addition to the correct choice of a high-quality connection, the service life of the sewer system also depends on proper installation. Bell pipes must be installed in a specific order. The connection direction must be opposite to the fluid flow. Joints must be sealed and caulked only with high quality materials.

For sewer installation, a large number of additional parts are used:

- Fitting;

- Plugs;

- Tees;

- Adapters;

- Cross-shaped splitters.

When choosing shaped parts, it is necessary to take into account the grade of material. It must correspond to the parameters of cast iron.

If the grades of material are incompatible, the shape of the product connections is disrupted. This happens especially often with large temperature changes.

The socketless bathroom sewer system suffers greatly from these defects. When installing socket connections, when combining them with other parts, such defects do not arise.

Main defects in the installation of sewerage systems: causes, methods of elimination

Defects in installation work of sewer systems include:

- periodic blockages of pipes in one place of intra-block (yard) sewer networks;

- freezing of drains; clogging of internal pipelines and sanitary fixtures;

- leakage of pipelines and malfunction of sanitary fixtures.

Periodic blockages in one place occur for the following reasons:

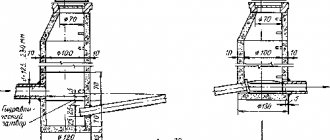

- pipe breakage mainly due to poor installation (for example, brick linings were left under the sockets). To find broken pipes, look at areas “in the light” with the yard network turned off. To do this, install a lantern in one of the wells in the center of the pipe, and a mirror in the other. If the pipes in the area are intact and have not settled, then the rays of the lantern will be reflected in the mirror in the form of a circle; otherwise, the light in the mirror will either not be reflected at all, or will be partially visible in the area where the damage is detected; then it is necessary to repair the pipeline and make a base 15-20 cm thick for it from slag or sand compacted into the ground;

- subsidence of the line that occurs due to weak soil, as well as if the pipes were laid on bulk soil without careful compaction and tamping under the pipes. The methods for detecting and eliminating this malfunction are the same as for pipe breakage;

- faults in the well tray, for example the tray is broken or has significant roughness on the surface or sharp turns. To prevent this malfunction, check the condition of all trays in the wells monthly and seal any roughness that appears on their surface with a greasy cement mortar. In conditions of continuous operation of the yard network, quick-setting cement is more convenient;

- When the pipeline slope is low, the wastewater moves at a reduced speed and solids fall out, forming a blockage. The slope is checked with a level; if the insufficient slope is confirmed, the network is re-routed (according to the project).

Before carrying out repair work, the resulting blockage is eliminated using a steel wire 25-35 m long and 5-6 mm in diameter, bent into a ring. To facilitate the work, the wire is first passed through a piece of pipe 40-50 mm in diameter with a bent end, which is inserted into the section of the pipeline in the direction of the blockage. If the well is deep, pipes with couplings at the end are screwed onto the pipe. Having lowered the pipe into the well, it is secured with a holder that the mechanic presses to the ground while cleaning the line. The wire is pushed into the pipe to the point of blockage, then it is clamped in the handle and moved sequentially back and forth until the blockage is cleared. The cleaned area is washed with water, which is supplied through a hose connected to the water supply. Light clogging can be removed by washing with water from a hose. For dense blockages, use a flexible steel cable with a diameter of 5 mm and a length of 15-20 m with a metal tip. The same cable is used for cleaning internal sewer pipes.

Freezing of drains usually occurs in severe winters, if the sewer line is laid shallow, there is no second cover in the manholes and inspection wells are not insulated. The resulting ice plug is removed with water from the city water supply, hot water or steam using a rubber hose, which is lowered into a well located below the plug. The hose is gradually moved inside the pipeline, close to the ice plug. After the plug has been washed away, the area is temporarily insulated by pouring slag 0.6 m high and 1.2-1.5 m wide onto the ground along its entire length. The slag can be replaced with a higher embankment of soft earth. In the summer, the area should be permanently insulated. To do this, you need to dig up the soil and fill the trench with slag or other insulating materials. In the autumn, second wooden covers are installed in the hatches of inspection wells, on which slag or sawdust is also poured.

Clogging of pipelines and sanitary fixtures usually occurs in long horizontal lines and in places where they turn. Therefore, it is undesirable to use elbows (at an angle of 90°) on outlet pipes from devices. Instead, two 135° bends are installed in series. Blockages occur if preventive cleaning of sewer pipelines is not carried out or if residents violate the rules for using the sewerage system. The blockage can be removed using a flexible shaft or flexible steel wire, which is pushed into the pipe through an inspection located above the blockage.

If the blockage occurs in a place where there is no inspection nearby or it is impossible to remove any sanitary fixture for cleaning, then they resort to an extreme measure - a hole with a diameter of 20-25 mm is punched in the pipe above the blockage using a cross-section and a wire is passed through it. After cleaning, the punched hole must be covered with a rubber gasket, lubricated with red lead, and tightened from above with a clamp. In the future, when repairing the sewer system, an inspection should be installed in this place.

Pipeline leaks most often occur in places where they are connected to sanitary fixtures - audits, socket connections, holes punched in pipes to remove blockages, and in valves. An elastic gasket coated on both sides with red lead paste is placed between the inspection cover and its flange; Instead of rubber, you can install a gasket made of woven flax strands soaked in red lead paste. A loose socket joint is repaired by removing the old seal with a cross-section or caulk, then several turns of resin strand are caulked into the socket and one and a half turns of white rope are placed on top. After this, the socket is filled with cement moistened with water and caulked.

The operation and repair of polyethylene and cast iron sewer pipelines differ. The surface of polyethylene pipelines is protected from mechanical damage and exposure to high temperatures; They should not be cleaned with wire brushes, hit with a hammer, ropes tied to them, or ladders leaned against them. If there is a leak in a socket joint with a rubber ring, the gap between the socket and the smooth end is sealed with flax strands impregnated with polyisobutylene. Punctures and minor holes in the pipe can be eliminated by installing steel clamps with plastic sheet rubber underneath them in the damaged areas. A section of pipe with large holes and cracks is cut out with a hacksaw and replaced with a piece of new polyethylene pipe, which is connected to the pipeline using two couplings with rubber rings. Damaged polyethylene fittings are replaced with new ones of the same size. The new fitting is connected to the pipeline using a coupling and rubber rings. Clogging in polyethylene sewer pipelines is eliminated with a polyethylene pipe with a diameter of up to 25 mm or a rigid rubber hose. Steel wire must not be used.

How can you increase the service life of cast iron products?

To extend the operating time of a cast iron sewer, the installation of the main should be done using only high quality fittings. The following must not be present on the surface of the pipe:

- influx;

- growths;

- slag;

- metal drops.

If you strictly comply with all GOST requirements and properly care for the system, the service life of the system will reach 100 years.

How well cast iron pipes are made is easy to determine, taking into account the external characteristics:

- A fine-grained structure is visible at the fracture.

- Hidden defects are detected by hearing. By tapping the part and listening to the pitch, you can determine the presence of cracks. With high-quality parts, the sound is very different from a defective product.

- Proper installation of the pipeline increases its service life.

Products equipped with a socket must be positioned strictly according to technological rules. The bell line is made in the direction opposite to the direction of flow of the discharged liquid. Sealing of joints and caulking is done only from high-quality materials.

Reliable connection of individual parts is ensured by installing special fittings.

The fitting material must be compatible with cast iron. If you ignore this rule, then when the temperature changes, the shape of the fitting will change. Its geometric parameters will change greatly. As a result, a leak will appear at the junction of the cast iron pipe and fitting. You will have to restore the system and replace failed parts.

Cleaning pipes to increase service life

Over time, sewage deposits appear on the inner surface of the pipes in the system. This is a completely natural process that occurs for a number of reasons. On the one hand, deposits that are present in sewage are deposited on the walls, and on the other, layers of rust grow on the inner surface of pipes that have been corroded. Because of this, the cross-section of the pipe may decrease. In order to avoid this, a cement-sand coating can be applied to the inner surface. This coating also protects against corrosion, since the water passing through it is enriched with alkaline elements. However, this may not always prevent clogging completely, and the pipes will still need to be cleaned.

Sewer flushing can be of several types:

- Chemical cleaning, using liquid or powdered products that, when mixed with water, break down dirt and deposits in the pipe;

- Mechanical cleaning is carried out only by specialist craftsmen when using flexible or spiral torsos. The master inserts the torso into the pipe and, as soon as it reaches the seal, it is necessary to begin to rotate it in order to destroy it completely. Cast iron pipes are not afraid of such cleanings - due to the durability of the material, when using a torso, cracks and damage do not occur on the inner surface of the pipe;

- Cleaning sewer pipes using special machines. This method is the most expensive because it requires calling out special equipment, but it guarantees complete cleaning of the pipe from blockages and deposits. The most commonly used hydrodynamic cleaning method is based on the use of water energy released under pressure to the site of deposits.

How to repair cast iron systems

If a crack or other damage appears, you do not need to replace the entire pipe at once. It can be restored by installing a sealing strip.

Take a rubber gasket and forcefully press it with a metal plate to the site of damage. A clamp is installed on top of the plate. It can be made of copper wire or steel strip held together with bolts.

Today, when laying sewer systems, builders always install cast iron pipes. Their quality and properties fully comply with operating requirements.

We can safely say that cast iron pipes, designed for many years of operation, will never be forgotten. Their characteristics are in many ways superior to the most modern new materials.

Why cast iron components continue to be used

Almost all Soviet-built apartment buildings have a cast-iron sewer riser, the service life of which exceeded the initial service life of the building itself. Despite the long-standing commissioning, the system is in no hurry to change. Usually the internal (apartment) part of the sewer system is replaced with plastic elements, but the riser and external section are retained. This is explained by the serious advantages of cast iron parts:

- high strength, rigidity;

- ability to withstand high loads;

- Cast iron wears out significantly less than other materials under the same load.

An important quality of metal is its ability to withstand significant loads. Cast iron does not withstand sharp impacts, but it can easily withstand uniform and stable pressure. This has become the main reason for the use of metal elements in external and underground lines. Considering the long service life of cast iron sewer pipes, replacing old mains is not yet relevant. In addition, possible costs must be taken into account. Work to update the network will cost an amount comparable to the construction of a new system.

It is necessary to take into account that in conditions of industrial or storm drainage networks, metal pipelines are far superior to alternative options. They are able to carry loads that plastic nets cannot. In addition, the material can work with chemical components and has a relatively low coefficient of thermal expansion. If connections are made without any disruption to technology, the network can operate for 100 years or more. There are many examples of such durability. For assembling external sections of the network, metal pipelines are much better suited than plastic elements.

The relevance of the use of cast iron pipes

Today, when a large number of different polymers and the latest composite materials have appeared, cast iron products are considered something ancient.

But despite everything, these “prehistoric products” remain in demand in a variety of industries:

- water supply;

- fire fighting;

- oil pipelines;

- sewerage.

This popularity is due to the ability to operate these pipes for many years. Moreover, the properties of such products fully meet all the requirements necessary when laying a sewer system:

- Not afraid of corrosion. Cast iron resists corrosion more than any steel;

- Thermal expansion always has a minimum value;

- Excellent sound insulator. During operation, the noise of flowing liquid is never heard;

- High strength. Cast iron is not afraid of any mechanical impact. He is not afraid of large pressure drops.

- Emergency situations happen very rarely.

- Cast iron pipes can operate freely at very low or high temperatures. Long-term exposure to a variety of temperature conditions does not affect their properties at all; they remain unchanged.

- Cast iron meets all modern environmental requirements. It does not emit toxic or poisonous substances.

- Does not burn.

- Fire resistant.

- Easy installation due to a large number of various components.

- The labor intensity of the work on laying a sewer line is characterized by low cost.

- Long service life - 100 years.

- Low cost pipe.

Plastic

When purchasing plastic pipes, the first question that arises from the buyer may be: “What is the service life of such products, what advantages do they have?” In addition, the potential client is interested in the scope of application, the main operating and linear parameters of the pipes.

Plastic pipes differ:

increased resistance to corrosion processes

Therefore, they are not afraid of moisture, they do not rust or rot, which is very important when using products in heating systems and water supply systems; environmentally friendly, since they do not contain chemically hazardous and harmful substances; low thermal conductivity coefficient, which contributes to long-term heat retention, which cannot be said about metal products; high resistance to sudden changes in temperature and pressure; complete absence of noise during water flow inside. Thanks to the internal smooth surface, the possibility of limescale and other mineral deposits is eliminated; lightness, which is very convenient for loading, transportation, installation; ease of installation, connections in which are made by soldering; external neatness and aesthetics; low cost, which is important for many consumers.

They are used for installation of water supply systems, sewerage systems, and horizontal wiring of heating systems.