A sewer sololift is an electromechanical equipment that pumps human waste products from low-lying plumbing fixtures to the level of the main outlet line. The use of a sewer pump allows the installation of sanitary equipment in the basement floors of a building where, for some reason, there is no sanitary pipeline.

Sololift for washing machine.

A few words about Sololift markings

When choosing a pumping unit, you need to pay attention to the product labeling. This nuance determines the installation location, functionality and everyday tasks that can be solved using the equipment.

The manufacturer uses capital letters of the Latin alphabet to label products. It looks like this:

- WC – these models have a built-in grinding mechanism. The station is designed for the removal of black (fecal) waste and can be connected to floor-mounted toilets.

- CWC - this category of equipment is also equipped with a grinder and is designed for the removal of fecal waste. However, such models are designed for wall-hung toilets.

- C and D – pumps for removing gray (fecal-free) wastewater, suitable for any plumbing fixtures except toilets.

In addition, the marking of each product includes a numerical designation: 1-3 .

This indicates the number of additional outlets in addition to the main drain. Essentially, the numbers indicate the number of plumbing fixtures connected to the pump.

Features of sololift installation

Vertical sections of the pipeline should be located after the pumping station. When connecting, it is worth monitoring the angle of inclination of the sewer pipe (pressure system - 1°, non-pressure system - 3°).

If the device is installed in the bathroom of an apartment or house, it is recommended to place it close to the toilet. The minimum distance will ensure effective drainage and good performance. Do not forget about the gaps to the walls (from 10 mm and above).

When connecting the pump to a bathtub or shower, place a filter in front of the device to collect hair. If they enter the forced drainage housing, they can cause blockage and affect engine wear.

Access to the sololift cover must always remain free for convenient maintenance.

How does the drainage system work?

Sololift2 Grundfos sewage pumping stations are equipped with an electric motor and a liquid level sensor. In addition, the structure is made of composite tanks, the storage tank has spherical walls, and the bottom is inclined in the direction of the pump.

This design and layout option minimizes the likelihood of sediment forming on the bottom and walls of the tank. The sensor ensures that the engine turns on only when necessary, which saves energy.

The principle of operation of pumping stations is as follows: wastewater flows into the tank and reaches the control level. The sensor gives the engine a start command, and the liquid is pumped into the public sewer system. When the level drops to the set values, the motor turns off and the pump stops working.

What is Sololift and why is it needed?

Properly organized operation of the sewer system involves the placement of pipes in it with a slope towards the drain. But sometimes there is a need to reconstruct the network, in which the drain sources are below the level of the drain hole.

To remove wastewater from this level, fecal pumps are used, as well as more advanced, relatively new equipment - Sololifts.

What is Sololift for sewerage (Sololift2 from the manufacturer Grundfos)? This is a pumping unit in a durable plastic casing, designed to process the drain and transfer it to a higher level corresponding to the level of the collector.

This happens in the following order:

- Liquid from the plumbing fixture enters the chamber with the pump. There can be up to three such inputs on the case, which makes it possible to connect a corresponding number of devices. The second method is to combine several sources, then it is possible to connect them all to one pipe. This is possible if all sources of drainage are in close proximity. It should be noted that horizontal sections of pressure sewerage also need to be placed with a slope of at least 1 millimeter per meter of length. This is necessary to prevent plugs from forming in the pipeline when the device is turned off.

- In front of the pump, on the same shaft with it, there is a grinder of inclusions. Its purpose is to destroy the solid fractions present in the drained substance. This could be leftover food or product from the kitchen sink, or hair or pet hair from the sink or bathtub. In combination with fat residues, such contaminants can form quite dense plugs in sewer pipes. In the shredder, all these materials are processed almost to an emulsion state. The working body of this device is made of high-strength stainless anti-corrosion steel.

- The most important role in the system is played by the pump, which ensures the movement of the drain through the pipe. Its performance provides a pressure of at least 5 meters in the vertical direction and freely pumps a horizontal section up to 100 meters long. The peculiarity of the pump is that it operates submerged in water. This, with fairly high performance, makes the operation silent. The pump and grinder axles are also made of stainless steel, taking into account the characteristics of the pumped substances.

- Since the pumps are designed for use in residential areas, they are equipped with a special carbon filter to eliminate odors. Air from the sewer, even if it has entered the system, is purified by this device. The filter element must be periodically cleaned with a stream of water under pressure. After this, it is quite suitable for further use.

- The Sololift drain pipe for sewerage has a diameter of 100 millimeters, which allows you to connect a 110 mm pipe to it.

Application area

Depending on the marking and purpose, Sololift2 Grundfos pumping units are used for pumping out black and gray wastewater in rooms where it is impossible to use gravity sewerage. In addition, the equipment is ideal for draining water in bathrooms located below the sewer level.

If we talk about connected elements, the pumps are suitable for the following types of plumbing equipment:

- Baths.

- Wall-hung and floor-mounted toilets.

- Bidet.

- Showers.

- Sinks and washbasins.

- Washing machines.

Thanks to their compact dimensions, pumping stations are built into wall and floor structures, and therefore do not spoil the interior.

About pumping stations intended for water supply, read the article about the series of equipment from Grundfos >>>

Choosing a sololift for sewerage

Before you start choosing a sololift model, you should decide on the number of all connected plumbing fixtures and the total amount of waste water discharged. If there is a need to connect several plumbing fixtures at once, then it is advisable to give preference to models with an additional pipe. Particular attention is paid to the installation location of the system and the power indicators of the sololift.

The choice of sololift depends on the type and number of connected devices

- Sololift + WC - connection of one toilet;

- Sololift + WC-1 - connection of a toilet and sink;

- Sololift + WC-3 - connection of a toilet, sink, shower and bidet;

- Sololift + CWC-3 - connection of a wall-mounted toilet, sink and shower;

- Sololift + C-3 - connection of a washing machine and kitchen sink;

- Sololift + D-3 - connecting a shower stall and sink.

Sololift+ is used to equip an additional bathroom, toilet and any utility room on the ground floor of the house, a bathroom in a summer cottage and an additional bathroom in guest houses. The model is ideal for installation in a bathroom used by elderly or disabled people.

The most significant selection parameters:

- number of connection points;

- maximum height for vertical pumping;

- maximum horizontal pumping distance;

- performance;

- power consumption;

- permissible temperature of the pumped liquid;

- dimensions;

- weight;

- price;

- possibility of self-installation.

When choosing sewage pumping equipment, it is recommended to give preference to reliable and durable devices produced only by trusted European manufacturers, which include Grundfos, Lowara, SFA, DAB and WILO.

Expensive products from SFA and Grundfos are industry leaders with a developed service network, producing models with a long warranty period.

The internal part should be made only of durable and corrosion-resistant materials, including high-strength plastic.

Other models fall into the category of technically simpler devices, but they also cope quite well with their basic functions. It is important to remember that the presence of additional chopping knives in the pump design and increased power directly affect the noise level of the device during operation.

Types of compact sewage pumping units

Currently, Sololift Grundfos products are represented by 5 models . Pumping stations with the following markings are suitable for installation in bathrooms:

Pumping unit Sololift2 WC-1 for pumping wastewater from washbasins and toilets

Pumping unit with a power of 620 W, a liquid reservoir of 9 liters. The model is standardly equipped with a chopper and has a throughput capacity of 149 l/min. In addition to the main plumbing fixture (floor-standing toilet), it can be connected to a sink or urinal at the user’s choice.

| Net weight | 7.3 kg |

| Tank capacity | 9.0 l |

| Flexible pressure pipe | ∅22/25/28/32/36/40 |

| Connection to toilet | Toilet with horizontal outlet according to EN 33 or EN 37. The toilet flush must be at least 4 liters. |

| Possible entrance dimensions | 1 x ∅ 32/36/40 |

| Start and stop levels | Launch: 72 mm above floor level Stop: 52 mm above floor level |

| pH value of the pumped liquid | from 4 to 10 |

| Maximum fluid temperature | 50°C |

| Ambient temperature | from +5 °C to +35 °C |

| Operating mode | S3-50% - 1 min. (30 sec. on; 30 sec. off) |

| Supply voltage | 1 x 220-240V - 10%/+ 6%, 50 Hz |

| Power consumption | Max. 620 W |

| Rated current | 3.0 A |

| Power factor | 0,87/0,92 |

| Rotation frequency | 2800 min-1 |

| Protection class | IP44 |

| Insulation class | F |

Automatic sewage pumping installation Sololift2 WC-3 for private homes

An exact analogue of the previous model, but here, in addition to the floor-standing toilet, you can connect a choice of three additional elements: sink, bidet, shower cabin, urinal.

| Net weight | 7.3 kg |

| Tank capacity | 9.0 l |

| Flexible pressure pipe | ∅22/25/28/32/36/40 |

| Connection to toilet | Toilet with horizontal outlet according to EN 33 or EN 37. The toilet flush must be at least 4 liters. |

| Possible entrance dimensions | 1 x ∅ 32/36/40, top connection 2 x ∅ 36/40/50, side |

| Start and stop levels | Launch: 72 mm above floor level Stop: 52 mm above floor level |

| pH value of the pumped liquid | from 4 to 10 |

| Maximum fluid temperature | 50°C |

| Ambient temperature | from +5 °C to +35 °C |

| Operating mode | S3-50% - 1 min. (30 sec. on; 30 sec. off) |

| Supply voltage | 1 x 220-240V - 10%/+ 6%, 50 Hz |

| Power consumption | Max. 620 W |

| Rated current | 3.0 A |

| Power factor | 0,87/0,92 |

| Rotation frequency | 2800 min-1 |

| Protection class | IP44 |

| Insulation class | F |

Sewage pumping unit with built-in professional cutting mechanism Sololift2 CWC-3

Pumping station, power 620 W and capacity 137 l/min. The model is designed to be connected to a wall-mounted toilet, making it possible to connect 3 additional elements: a washbasin, a shower stall, and a bidet or urinal.

| Net weight | 7.1 kg |

| Tank capacity | 9.0 l |

| Flexible pressure pipe | ∅22/25/28/32/36/40 |

| Connection to toilet | Toilet with horizontal outlet according to EN 33 or EN 37. The toilet flush must be at least 4 liters. |

| Possible entrance dimensions | 1 x ∅ 32/36/40, top connection 2 x ∅ 36/40/50, side |

| Start and stop levels | Launch: 72 mm above floor level Stop: 52 mm above floor level |

| pH value of the pumped liquid | from 4 to 10 |

| Maximum fluid temperature | 50°C |

| Ambient temperature | from +5 °C to +35 °C |

| Operating mode | S3-50% - 1 min. (30 sec. on; 30 sec. off) |

| Supply voltage | 1 x 220-240V - 10%/+ 6%, 50 Hz |

| Power consumption | Max. 620 W |

| Rated current | 3.0 A |

| Power factor | 0,87/0,92 |

| Rotation frequency | 2800 min-1 |

| Protection class | IP44 |

| Insulation class | F |

The following models are suitable for draining gray waste:

Compact and ready-to-install sewage pumping unit Sololift2 C-3.

Installation with a power of 640 W, capacity of 204 l/min . There is no chopper here, but the following devices can be connected: sink, bath, shower, bidet, dishwasher and washing machine.

It should be noted that, unlike other models, this station is suitable for draining water whose temperature varies between 75-90 degrees.

| Net weight | 6.6 kg |

| Tank capacity | 5.7 l |

| Flexible pressure pipe | ∅22/25/28/32/36/40 |

| Possible entrance dimensions | 1 x ∅ 32/36/40, top connection 2 x ∅ 36/40/50, side |

| Start and stop levels | Launch level 1: 65 mm above floor level Launch level 2: 115 mm above floor level Stop level: 35mm above floor level |

| pH value of the pumped liquid | from 4 to 10 |

| Maximum fluid temperature | 75 °C constant 90°C for 30 minutes |

| Ambient temperature | from +5 °C to +35 °C |

| Operating mode | S3-50% - 1 min. (30 sec. on; 30 sec. off) |

| Supply voltage | 1 x 220-240V - 10%/+ 6%, 50 Hz |

| Power consumption | Max. 640 W |

| Rated current | 3.1 A |

| Power factor | 0,66/0,90 |

| Rotation frequency | 2800 min-1 |

| Protection class | IP44 |

| Insulation class | F |

Automatic sewage pumping unit Sololift2 D-2

The lightest model in the series, designed for washbasins, showers and bidets. Here the output power is 280 W , the throughput is 119 l/min.

It should be noted that pumping units for toilets have a storage tank size of 9 liters . Equipment weight: 7.3-7.1 kg . Equipment for gray waste has more modest parameters: tank – 5.7/2 l, weight – 6.6/4.3 kg. The data is given in order of listing.

| Net weight | 4.3 kg |

| Tank capacity | 2.0 l |

| Flexible pressure pipe | ∅22/32 |

| Possible entrance dimensions | 2 x ∅32/36/40 side |

| Start and stop levels | Launch level: 58 mm above floor level Stop level: 35mm above floor level |

| pH value of the pumped liquid | from 4 to 10 |

| Maximum fluid temperature | 50°C |

| Ambient temperature | from +5 °C to +35 °C |

| Operating mode | S3-50% - 1 min. (30 sec. on; 30 sec. off) |

| Supply voltage | 1 x 220-240V - 10%/+ 6%, 50 Hz |

| Power consumption | Max. 280 W |

| Rated current | 1.3 A |

| Power factor | 0,90/0,95 |

| Rotation frequency | 2800 min-1 |

| Protection class | IP44 |

| Insulation class | F |

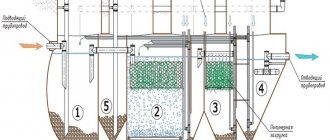

Design and principle of operation

The pumping unit, designed for forced pumping of wastewater when plumbing equipment is located lower than the level of the general house sewer system, has a fairly simple diagram:

- storage tank body;

- submersible pump;

- check valve device;

- receiving filter system;

- cutting and grinding mechanism;

- carbon filter.

The sololift consists of 6 main elements, including a cutting and grinding mechanism

The principle of operation is not too complicated and consists in drawing liquid through a filter receiving system into the storage tank of the pumping device. An impeller-shaped cutting mechanism located on the inlet part of the device quickly crushes all inclusions entering the sololift, represented by feces, paper and personal hygiene products. At the next stage, all wastewater moves inside the outlet pipe, and a special shut-off valve in the form of a valve prevents the backflow of all the discharged liquid.

Thanks to the presence of a carbon filter installed on the top of the device, unpleasant sewer odors do not leak into the room. A hydrodynamic thermal relay controls the degree of filling, and a plastic check valve system with adapters moves through pressure pipes during the filling process. An automatic start float sensor detects the filling level of the sewerage installation, and the pump is driven by a relay signal.

Advantages and disadvantages

Sololift2 sewage pumping units have a number of undeniable technical advantages. For example:

- High technical characteristics and long-term operation.

- Easy to install.

- Minimum maintenance requirements: the system is self-cleaning.

- Minimum noise level during operation.

- Compact dimensions: ideal solution for small bathrooms.

- Sloped bottom of the storage tank, which minimizes the likelihood of sediment accumulation.

- Withstands high temperatures and pressure.

There are only two significant disadvantages:

- Dependence on uninterrupted power supply.

- Inability to pump large volumes of water.

Sololift2 is a modern solution for arranging sewer systems in country houses. It should be noted that the equipment is practically free of disadvantages, while being sold in an affordable price segment of the market.

Operation and Maintenance

The Sololift system can be fully used only after proper installation without any defects. A correctly installed station will serve its full life without failures or breakdowns. But even if some checks and adjustments are required, they can be done quite easily.

In the second generation SOLOLIFT line, the key components are located in the tank above the wastewater level, and the relay, which is activated when the liquid pressure increases, is located outside. Grundfos calls this hand cleanliness.

With proper preparation, connecting the Sololift system to the sewer system will be simple and without “surprises”.

Equipment Maintenance

The design features of Sololift2 units allow for minimal maintenance requirements. In order for the equipment to operate correctly over a long period of time, it is necessary to carry out regular preventative cleaning of the tank. For this purpose, a chemically active component is used - a detergent.

For this procedure, you must complete the following steps:

- Disconnect the device from the power source and remove the top cover.

- Pour in the cleaning agent and wait a while.

- Connect the device and drain the water.

- Run the pump with water several times.

- Install the cover.

The maintenance scheme is quite simple, so it does not require the involvement of specialists.

Basic pump models, their cost and installation method

1. WC-1 . The small size of this device allows it to be included in sewer systems inside small rooms. The device is equipped with a powerful pump and shredder that allows you to successfully destroy even items such as sanitary pads. The unit has its own alarm system that responds to malfunctions. The design of the device allows for maintenance and repair without disconnecting from the sewer water supply.

Main parameters: 1. weight 7.3 kg; 2. Overall dimensions – 347 x 426 x 176 millimeters; 3. Capacity – 9 liters.

Depending on the complete set, the device can cost from 13 to 18 thousand rubles.

The Sololift is installed by fastening it to the floor with dowels or screws. The most common installation location is the space behind the toilet, and the distance from the device to it should be about 15 centimeters.

For fastening, it is necessary to drill several holes in the floor for plastic inserts (dowels). Fastening is done with self-tapping screws. When purchasing a Sololift, there is no need to purchase fastening elements - they are usually included in the sales kit. 2. WC-3 . This model has the same characteristics as the previous one. The difference is that three pipes are installed on it, which allows you to connect wastewater from several sources simultaneously - toilet, sink, shower and others. When choosing this model, you should take into account the temperature of the wastewater.

Parameters of Sololift WC-3:

- weight characteristics – 7.3 kg;

- overall dimensions – 426 x 442 x 176 millimeters;

- Tank capacity – 9 liters.

You can purchase a Sololift of this modification for the drainage system for 22 thousand rubles.

3. СWC-3 . An installation of this type can be combined with any type of plumbing equipment, since it has a high-power pump and a grinding mechanism. Almost any contaminant, except stones, is accessible to it. The device has an audible alarm, is protected from overheating, and has a self-restart device.

Basic technical data:

- weight – 7.1 kilograms;

- Dimensions: 539 x 496 x 165 mm;

- capacity

- You can buy it for 22 thousand rubles.

The rounded bottom of the housing prevents the accumulation of solid components inside the housing, therefore the frequency of preventive cleaning is significantly increased. This indicator must be clarified in accordance with the recommendations of the technical documentation.

4. Model D-3 device . This is a small-sized unit designed for pumping clean media, since it is not equipped with a grinder. Therefore, it cannot be connected to the toilet. The device is installed by fastening it to the floor with dowels. When installing in a shower room, you need to pay attention to the frequency of the drain mesh - it should trap hair and small debris. The level of the device must be below the drain level; it is usually installed in a pit.

The rounded bottom of the case does not allow dirt to accumulate. It has the following parameters:

- weight 4.3 kilograms;

- overall dimensions – 165 x 380 x 217 millimeters;

- tank with a capacity of 2 liters.

Cost from 15,000 rubles.

5. Model C-3 differs from others in its ability to pump hot water. The device stably pumps substances with a temperature of 75 degrees, and for a limited time of 30 minutes it can withstand temperatures up to 90 degrees. It is purposefully used for recycling waste from washing machines and dishwashers.

There is no chopper in the design. No more than three drain sources can be connected to such a unit. This type of sololift is equipped with a magnetic float switch and a malfunction indicator.

Main characteristics of the device:

- weight 6.6 kilograms;

- dimensions 158 x 493 x 341 mm;

- The housing capacity is about 5.7 liters.

The cost of Sololift model C-3 is from 20,000 rubles.

Which Sololift for sewerage should I choose?

Let's imagine how Sololift works in a sewage system. Wastewater from the plumbing fixture enters the plumbing fixture through the sewer drain.

Watch the video

The drain is most likely contaminated with solid or fibrous particles. Drawn by the flow of water to the pump, they enter the grinder, which turns them into a fine mass. In this state, it no longer creates the prerequisites for the formation of a blockage in the sewer.

Next, the water rises through the outlet in the Sololift to the required height and pours into the sewer riser or collector pipe. It is necessary to pay attention to compliance with the requirement that the pressure section slope towards the drain of at least one millimeter per meter of length. Otherwise, the drained mass may backflow to the pump.

When choosing a model you need to consider:

- The temperature of the drain water, which can reach from 40 to 75 degrees, in some cases reaching 95. Naturally, taking into account your own operating conditions, you need to check the compliance of the unit with this parameter.

- The performance of the unit must be selected so that it is 10-15% higher than the maximum possible flow volume. It is difficult to imagine a situation where the total volume is formed simultaneously, but theoretically such a situation is possible and must be taken into account.

- The pump pressure must ensure that the water column rises to a certain height, therefore, when selecting a Sololift for sewerage, the power must also be controlled according to the attached documents.

When choosing a device for a sewerage pressure station, you can consider other configuration options. Of course, Grundfos is the most reputable manufacturer of pumping equipment, but a person should always have a choice.

First of all, this concerns the cost of products from this manufacturer. We must pay tribute - their equipment is invariably of high quality and durability, but I would like a more reasonable price.

The market also offers products from other manufacturers of pumping equipment for pressure sewerage:

- Onyx;

- Alta;

- Helix;

- Flotenk.

The listed pumping stations can be equipped with pumps of both imported and domestic production:

- Grundfos (Denmark);

- KSB (Germany);

- DAB (Italy);

- Willo (Germany);

- Takeoff (Russia);

- KIT (Russia).

It should be noted that with similar technical characteristics, domestically produced equipment has a certain advantage, as it is the most repairable.

Installation of Sololift for sewerage

Despite the ease of installation of fecal pumping units, you need to know and clearly follow certain rules for their installation:

- The drain hose should not have kinks, this will negatively affect the filling of the container.

- If the pumping unit is mounted on a shower stall or bathroom, the connection must be made at the lowest point. For this purpose, the manufacture of a special pit for the installation of Sololift is often used. The drain grate must be selected with openings such that hair and animal fur are retained.

- Before installing the Sololift, you need to check the equipment of the device to make sure that there are check valves to prevent the reverse flow of liquid from the sewer into the room.

- When installing a pumping station, it is advisable to place a shock-absorbing plate under its body; in this state, the installation will operate more quietly and increase its service life. To do this, you can use a sponge rubber plate of the appropriate size with a thickness of 3-5 millimeters.

- When joining pipes, sealants must be used to prevent liquid leakage.

Manufacturers, as a rule, include in the delivery set all the materials necessary for installing the Sololift, so when purchasing equipment you do not have to purchase fasteners.

When laying the pressure part of the pipeline, we must not forget about observing the slopes that were indicated above.

Upon completion of installation, you need to conduct a test run of the product. If leaks are detected, they must be repaired.

Rules of operation and maintenance

The main task of maintaining a pumping station for forced sewerage is periodic cleaning of equipment and washing of filters.

The position of the bottom or its spherical shape does not fully guarantee the self-cleaning of the pump. The frequency of washing the device is indicated in the technical documentation.

To do this you need:

- De-energize the device by unplugging the electrical cord.

- Remove the top cover of the unit.

- Pour cleaning liquid into the device. Which one to use - you need to look at the operating instructions. Many manufacturers produce detergents on purpose.

- Wait a certain time to give the liquid the opportunity to “work off” the contamination as much as possible.

- Connect the device to the network and turn on the pump to pump out the flushing solution.

- Fill the container several times and pump out water to flush the housing.

- When you have finished cleaning the device, close the lid.

- Remove the filter and rinse it thoroughly with running water several times. If you cannot wash the filter, you need to replace it with a new one.

Sololift and forced sewerage, with proper installation and operation, will significantly improve the living conditions in your home.

How to choose a Sololift sewer pump for a toilet and sink - recommendations from our editors

Before buying a Sololift for sewerage, you should first study the technical parameters of the device, as well as decide on the intended use. If renovation work is to be done in the house with subsequent redevelopment and relocation of equipment, preference should be given to pumping stations with several inlets.

Types of devices compatible with Grundfos pumping stations

It is extremely important to take into account the maximum water temperature at which normal operation of the equipment is allowed. Also, when choosing a pumping station, you need to take into account the method of its installation, since the higher it is located, the greater the power consumption will be. If you choose the wrong installation (in terms of power and performance), there is a high probability that the pump will not withstand the load and will burn out. For this reason, you should select a system with a small margin of basic technical parameters. We offer you to watch a video that will allow you to quickly understand the criteria for choosing Sololift pumping systems.

Video “Criteria for selecting Sololift pumping stations”: