In construction and installation work there is often a need to secure any parts or structures on a concrete base. If we are talking about heavy loads on the fastening, then the dowel-screw system is indispensable. Here you need a more powerful fastener - a metal anchor. It, like a dowel, is held in place by the friction that occurs between the base material and its spacer zone, but unlike a dowel, its adhesion force to the walls of the hole is higher, and therefore the tearing load is higher.

To ensure a long service life of anchors, it is necessary to take into account such an important characteristic of the anchor as corrosion resistance in certain operating conditions, which depends on its material or type of protective coating.

Any anchor fastening, to one degree or another, resists corrosion damage, since all types of anchors are made either from corrosion-resistant alloys or have a special protective coating. If a steel anchor is not able to withstand the aggressive influence of the environment, then sooner or later this will lead to a decrease in its strength, weakening of the fastening and catastrophic consequences.

Let's consider the main types of steels and types of protective coatings that are most often used in the manufacture of anchor fasteners.

Anchors made of corrosion-resistant steels

A2 (Cr-Ni) that are similar in composition are used.

and

A4 (Cr-Ni-Mo)

. Their excellent corrosion resistance in wet conditions and industrial environments is due to their high chromium content (16 - 19%), which forms a protective passive film on the surface of the parts. After hardening, steels have a homogeneous austenite structure, which resists corrosion well in these environments.

Anchors made of corrosion-resistant A4 steel are resistant to operation in environments of medium and severe aggressiveness. Molybdenum, which is part of the steel composition, increases the stability of the passive state and ensures high resistance of austenitic steels in acidic, chloride-containing environments and atmospheric conditions with a high content of sulfur dioxide - in road tunnels, at hydroelectric power stations, in water basins, at hydroelectric power stations and in close proximity to the sea .

Examples of popular stainless steel anchors made of A2 and A4 steel

, which can be purchased at the Krepcom store:

- driven LAH (Sormat), m2r (Mungo), HST-R (HILTI);

- wedge S-KAH (Sormat);

- self-anchoring spacer bolt BSR (GOST 28778-90);

- anchor nail (Sormat)

- concrete nail Confix (Sormat);

- anchor rod FHB (Fischer) for chemical anchoring.

Alloy 625

Nickel alloys

The purpose of Alloy 625 (Inconel® 625), which is composed of nickel, chromium and molybdenum with a small addition of niobium, is to reduce the risk of intergranular corrosion in a wide range of highly aggressive environments.

- Resistance to hydrochloric and nitric acids.

- Strength and ductility.

- Resistant to crevice and pitting corrosion at high temperatures.

- Suitable for use in sour gas environments (NACE MR0175/ISO 15156)

Material matters

For more information, see Alloy 625 Tube Compression Fittings, Medium Pressure Fittings, Tube Fittings, and Weld Weld Fittings Conforming to NACE Standard MR0175, Table A.13, MS-06-0119-E.

To combat:

continuous corrosion; local corrosion; stress corrosion cracking; Corrosion due to high sulfur environments

Types of coatings for carbon steel anchors

Steel anchors made from carbon and low carbon steel are produced by cold forming. Corrosion resistance is ensured by metal coatings, in most cases zinc. There are various methods of applying this coating - galvanic, hot-dip galvanized, thermal diffusion. The degree of corrosion resistance of the fastener depends on the galvanizing technology and the thickness of the zinc layer.

Galvanic zinc coating (electrolytic)

provides a low degree of corrosion resistance in external building structures, especially in an industrial atmosphere, since its thickness is only 7-18 microns. Corrosion of zinc under atmospheric influence manifests itself in the form of white spots (“white rust”) at a rate approximately ten times slower than the appearance of ordinary “red” rust on uncoated steel hardware.

Domestic consumers are well acquainted with galvanized wedge concrete anchors S-KA Sormat, which are widely used by craftsmen for preliminary, through and remote installation of heavy structures inside dry rooms.

To increase the protective properties of galvanized zinc anchors, they are additionally subjected to rainbow passivation, resulting in a composite film on their surface that protects the galvanic zinc from destruction in most polluted atmospheres. This method is usually used to protect expansion sleeve anchors or, as they are also called, anchor bolts. In the catalog, such fasteners are presented in various modifications: with a hex head (LSB), with a nut (LSI), a hook (KLHS) or a ring (LHO).

Hot zinc coating

recognized as one of the best ways to protect anchor bolts and studs from corrosion, the effectiveness of which is several times higher than that of electrolytic zinc. The technology of applying hot zinc coatings makes it possible to obtain a protective layer of zinc on the anchors with a thickness of 45-50 microns. It is its thickness that determines the durability of all elements of the fastener.

For example, the Sormat S-KAK wedge anchor (hot zinc) is approved for use in damp rooms and outdoors in rural areas, subject to regular monitoring of the integrity of the protective layer. The end of the service life of protective metal coatings is considered to be the appearance of red rust.

Anchors can also be supplied with alternative types of protective coatings such as DELTA

.

This is a complex zinc-lamella coating, consisting of a base zinc layer applied by galvanic method, 20 microns thick

and protective protection from additional insulating words Delta Protekt RL100 + Delta Seal GZ Silver of at least 15 microns. Thus, the total thickness is 35 microns (this is less than hot-dip galvanized, but the degree of protection is higher). A worthy example of a fastener with such a coating is the Sormat S-KAD wedge anchor.

What makes up the price of stainless steel?

Like any metallurgical product, the price of stainless steel depends on the amount of alloying elements and the production method. Recently, powder and CPM technologies have begun to be used for sheet production. Despite their progressiveness, you can get stainless steel sheets at a good price https://www.alfa-sous.ru/katalog/nerzhaveyushhij-metalloprokat/list/list-nerzhaveyushhij-gost-19904-74,-7350-77.html using long-established rolling technology, the main advantages of which are large production volumes and low costs.

Assessment of the degree of corrosion resistance of anchors

- Atmospheric corrosion of galvanically galvanized anchors with a zinc thickness of 10-12 microns in non-aggressive and slightly aggressive environments (under a canopy) will proceed at a rate of no more than 1 micron/year. Taking into account the possibility of droplet condensation of moisture and, consequently, ulcerative damage to zinc, it is possible to predict the preservation of the protective ability of the coating for about 20 years.

- Hot-dip galvanized anchors with a protective layer thickness of at least 45 microns have good corrosion resistance, which is due to the large thickness of the zinc. The rate of destruction of hot zinc coating in mildly aggressive environments (under a canopy) is 2-3 microns/year. It should be taken into account that during operation, a coating of zinc corrosion products forms on the coating, which plays the role of a protector, inhibiting the development of the corrosion process and preventing the destruction of the lower protective layer. The film formed on the surface of zinc determines the final speed of the corrosion process, which slows down over time. The service life of anchors with hot zinc in a slightly aggressive atmosphere will be about 50 years.

- A4 stainless steel anchors have the highest degree of corrosion resistance and are recommended for use in mildly and moderately aggressive industrial (with high humidity and sulfur dioxide content) and coastal (with high humidity and chloride content) environments for up to 50 years when used outdoors.

Table 1. Recommendations for the use of galvanized and stainless steel anchors in various environmental conditions.

| Anchor material | Coating type and thickness, microns | Environment characteristics | |||

| external | internal | ||||

| humidity zone | degree of aggressiveness | humidity conditions | degree of aggressiveness | ||

| Carbon steel | galvanic zinc>10, hot-dip galvanizing>25 | — | — | dry, normal | non-aggressive |

| hot galvanizing >45 | dry, normal | slightly aggressive | dry, normal | non-aggressive, slightly aggressive | |

| Carbon steel | zinc lamel>35 | dry, normal, wet | mildly aggressive, moderately aggressive | dry, normal, wet | non-aggressive, slightly aggressive, moderately aggressive |

| Corrosion-resistant steel A2 | — | dry, normal, wet | slightly aggressive | dry, normal, wet | non-aggressive, slightly aggressive |

| Corrosion-resistant steel A4 | — | dry, normal, wet | mildly aggressive, moderately aggressive | dry, normal, wet | mildly aggressive, moderately aggressive |

Note.

The humidity zone and the degree of aggressiveness of the environmental influence are determined taking into account SP 28.13330 and SP 50.13330. The assessment of the corrosion resistance of anchors is given without taking into account the impact of other elements of building structures on them.

Since fasteners are used in structures in direct contact with other materials and metals, the durability of the anchor fastening depends not only on the degree of aggressiveness of the external environment, the characteristics of the steel and coating, but also on the metals and non-metals in contact with it.

Fasteners must be made of the same metal as the part being fastened, or a metal with a higher corrosion potential. Direct contact of dissimilar metals is not allowed to prevent contact corrosion.

Conclusion:

- Conventional zinc coated (galvanized) anchors should only be used in dry, humidity-controlled indoor environments or for temporary anchorages in damp conditions.

- Hot-dip galvanized fasteners can be used for interior work in dry and normal humidity conditions, outdoors under a canopy, in curtain wall systems with a low degree of environmental pollution.

- A2 stainless steel anchor bolts are suitable for most atmospheric conditions, for long-term use in rural and urban areas with high humidity and sulfur dioxide concentrations, without chlorides.

- Stainless steel anchors made of corrosion-resistant A4 steel are approved for use on the sea coast, swimming pools, tunnels, in urban and industrial areas with high concentrations of chlorides and acidic condensates.

All about fasteners Updated: 07/13/2021 14:13:02

Victor

Interesting article. Thank you. Are ordinary galvanized (galvanized) anchor bolts suitable for the kitchen? And in the bathroom (without the condition of contact with water, for example, for shelves)?

14.12.2020 01:30:18

Selection of material for the flow part

Home / Documentation / Knowledge base / Selection of material for the flow part

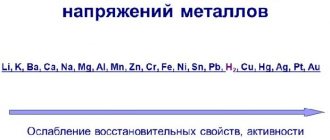

Surface destruction of metal under the influence of the external environment is called corrosion.

Pure iron and low-alloy steels are unstable against corrosion in the atmosphere, in water and many other environments, since the resulting film of oxides is not dense enough and does not isolate the metal from the chemical influence of the environment. Some elements increase the resistance of steel against corrosion, and thus it is possible to select steel that is practically not subject to destruction in a given environment.

With the introduction of such alloying elements, a sudden increase in corrosion resistance occurs. For example, adding more than 12% chromium (Cr) to steel makes it resistant to corrosion in the atmosphere and many other industrial environments. Steels containing less than 12% Cr are almost as susceptible to corrosion as iron. Steels containing 12-14% Cr behave like noble metals: having a positive electrochemical potential, they do not rust or oxidize in air, in water, in a number of acids, salts and alkalis.

Chromium stainless steels

Chromium stainless steels are used in three types: 13, 17 and 27% Cr, depending on the requirements, they have different carbon contents.

Steels with more than 17% Cr sometimes have small additions of titanium and nickel, which are introduced to improve mechanical properties. In addition, steels with this chromium content have high corrosion resistance up to temperatures of 900 ºC.

Steels with a chromium content of 13% are more common and less expensive; they are used for household purposes and in technology. These steels are easy to weld. Alloys with a low carbon content are ductile, while alloys with a high carbon content have high hardness and increased strength; they are used to make parts with increased strength and wear resistance (surgical instruments, bearings, springs and other parts operating in an active corrosive environment).

Austenitic steels

Adding sufficient nickel (Ni) to chromium steel provides better mechanical strength and makes the steel more corrosion resistant and less cold brittle. Stainless steels with 18% Cr and 10% Ni are most widely used in mechanical engineering.

In order to increase the resistance to corrosion in acids, molybdenum and copper are introduced into steel, especially molybdenum with copper, while simultaneously increasing the nickel content. If necessary, in order to also have high mechanical properties, titanium and aluminum are introduced.

Nickel alloys such as Hastelloy 80% Ni and 20% Mo (NIMO alloys) with additional alloying have higher corrosion resistance.

Titanium

Titanium (Ti) has a high specific strength, due to which alloys based on it are widely used in technology, especially in those areas where mass is important (aviation, rocketry, etc.). Titanium has high corrosion resistance in a wide range of aggressive environments, often surpassing stainless steel in this regard. Therefore, it is easier to list the media in which titanium dissolves: for example, hydrofluoric, hydrochloric, sulfuric, orthophosphoric, oxalic and acetic acids.

The high corrosion resistance of titanium is due to the formation of a dense protective oxide film on the surface. If this film does not dissolve in the environment, then we can assume that the titanium in it is absolutely resistant. For example, sea water will dissolve a layer of titanium 30-40 microns thick in 4000 years (1 micron is equal to 10-4 cm). If the oxide film is soluble in a given environment, then the use of titanium in it is unacceptable.

Refractory metals

Refractory metals include: vanadium, tungsten, hafnium, molybdenum, niobium, tantalum, technetium, titanium, chromium, zirconium, whose melting point is higher than the melting point of iron (1539 ºС), except for metals of the platinum and uranium groups and some rare earths.

It should be noted that at high temperatures all refractory metals are acid-resistant. In this case, tantalum stands out most strongly. Niobium and molybdenum are superior in corrosion resistance to alloys based on iron or nickel, but are inferior to tantalum.

The use of such materials is advisable in environments where other materials do not have corrosion resistance. Such environments include inorganic strong acids at elevated temperatures, as well as some industrial environments.

Despite the high cost of metals compared to such corrosion-resistant materials as high-alloy stainless steel or Hastelloy, the use of alloys of refractory metals is justified, since due to their high resistance it is possible to operate chemical plants for almost the entire period without replacing devices. Corrosion resistance of stainless steels in some acids. At room temperature All products are highly resistant to temperature in this acid.

Corrosion resistance of stainless steels in certain acids

Sulfuric acid

At 70ºC, chromium-nickel steels are unstable even in low concentration acids, but steels with the addition of molybdenum and copper can work up to approximately 5% H2SO4.

However, the latter are destroyed in boiling sulfuric acid to a concentration of 30%. In these cases, Hastelloy type alloys should be used, and at a concentration above 30%, only refractory metals can work in boiling sulfuric acid.

Phosphoric acid

At room temperature of any concentration, austenitic steels are stable, chromium steels are not. Steels with additions of molybdenum and copper up to a concentration of 25% are stable in hot acid, Hastelloy up to 50% in boiling acid, and only refractory metals are stable at higher levels.

to hydrochloric acid at room temperature and up to a concentration of 5%.

Corrosion Resistance of Metals and Alloys under Normal Conditions This corrosion resistance table is intended to provide a general idea of how various metals and alloys react with certain environments. Recommendations are not absolute, since the concentration of the medium, its temperature, pressure and other parameters may affect the applicability of a particular metal and alloy. Economic considerations may also influence the choice of metal or alloy.

| Legend: A - usually non-corrosive, B - minimal to negligible corrosion, C - not suitable |

| Wednesday | Cast iron and carbon steel | Stainless steel | Titanium | ||||

| 416 and 440С | 17-4 | 304, resp. 08Х18Н10 | 316, resp. 03Х17Н142 | Duplex | |||

| Acetaldehyde | C | A | A | A | A | A | A |

| Acetic acid, without air | C | C | C | C | A | A | A |

| Acetic acid, air-saturated | C | C | B | B | A | A | A |

| Acetone | A | A | A | A | A | A | A |

| Acetylene | A | A | A | A | A | A | A |

| Alcohols | A | A | A | A | A | A | A |

| Aluminum sulfate | C | C | B | A | A | A | A |

| Ammonia | A | A | A | A | A | A | A |

| Ammonia | C | C | C | C | B | A | A |

| Ammonia is caustic | A | A | A | A | A | A | A |

| Ammonium nitrate | B | B | A | A | A | A | C |

| Ammonium phosphate | C | B | B | A | A | A | A |

| Ammonium sulfate | C | C | B | B | A | A | A |

| Ammonium sulfite | C | C | A | A | A | A | A |

| Aniline | C | C | A | A | A | A | A |

| Asphalt, bitumen | A | A | A | A | A | A | A |

| Beer | B | B | A | A | A | A | A |

| Benzene | A | A | A | A | A | A | A |

| Benzoic acid | C | C | A | A | A | A | A |

| Boric acid | C | C | A | A | A | A | A |

| Bromine dry | C | C | B | B | B | A | C |

| Bromine wet | C | C | C | C | C | C | C |

| Butane | A | A | A | A | A | A | A |

| Calcium chloride | B | C | C | B | B | A | A |

| Calcium hypochlorite | C | C | C | C | C | A | A |

| Carbon dioxide dry | A | A | A | A | A | A | A |

| Carbon dioxide wet | C | C | A | A | A | A | A |

| Carbon disulfide | A | B | B | A | A | A | A |

| Carbonic acid | C | C | A | A | A | A | A |

| Carbon tetrachloride | B | B | A | A | A | A | A |

| Chlorine dry | A | C | B | B | B | A | C |

| Chlorine wet | C | C | C | C | C | C | A |

| Chromic acid | C | C | C | C | C | B | A |

| Lemon acid | C | C | B | B | A | A | A |

| Coke acid | A | A | A | A | A | A | A |

| Copper sulfate | C | C | C | C | B | A | A |

| Cottonseed oil | A | A | A | A | A | A | A |

| Creosote | A | A | A | A | A | A | A |

| Dauterm | A | A | A | A | A | A | A |

| Ethane | A | A | A | A | A | A | A |

| Ether | B | A | A | A | A | A | A |

| Ethyl chloride | C | C | B | B | B | A | A |

| Ethylene | A | A | A | A | A | A | A |

| Ethylene glycol | A | A | A | A | A | A | A |

| Ferric chloride | C | C | C | C | C | C | A |

| Fluoride dry | A | C | B | B | B | A | C |

| Fluorine wet | C | C | C | C | C | C | C |

| Formaldehyde | B | A | A | A | A | A | A |

| Formic acid | C | C | C | C | B | A | C |

| Freon wet | B | C | B | B | A | A | A |

| Freon dry | B | A | A | A | A | A | A |

| Furfural | A | B | A | A | A | A | A |

| Gasoline is stable | A | A | A | A | A | A | A |

| Glucose | A | A | A | A | A | C | A |

| Hydrochloric acid saturated with air | C | C | C | C | C | C | WITH |

| Hydrochloric acid, without air | C | C | C | C | C | C | WITH |

| Hydrofluoric acid, saturated with air | C | C | C | C | C | C | WITH |

| Hydrofluoric acid, without air | C | C | C | C | C | C | WITH |

| Hydrogen | A | C | B | A | A | A | WITH |

| Hydrogen peroxide | C | C | B | A | A | A | A |

| Hydrogen sulfide | C | C | C | A | A | A | A |

| Iodine | C | C | C | A | A | A | WITH |

| Magnesium hydroxide | A | A | A | A | A | A | A |

| Mercury | A | A | A | A | A | A | WITH |

| Methanol | A | A | A | A | A | A | A |

| Methylethylglycol | A | A | A | A | A | A | A |

| Milk | C | A | A | A | A | A | A |

| Natural gas | A | A | A | A | A | A | A |

| Nitric acid | C | C | A | A | A | A | A |

| Oleic acid | C | B | B | B | A | A | A |

| Oxalic acid | C | C | B | B | B | A | WITH |

| Oxygen | C | C | B | B | B | B | WITH |

| Mineral oil | A | A | A | A | A | A | |

| Phosphoric acid, saturated with air | C | C | B | A | A | A | WITH |

| Phosphoric acid, without air | C | C | B | B | B | A | WITH |

| Picric acid | C | C | B | B | A | A | A |

| Potassium carbonate/potassium carbonate | B | B | A | A | A | A | A |

| Potassium chloride | B | C | C | B | B | A | A |

| Potassium hydroxide | B | B | A | A | A | A | A |

| Propane | A | A | A | A | A | A | A |

| Rosin, resin | B | A | A | A | A | A | A |

| Silver nitrate | C | C | B | A | A | A | A |

| Sodium acetate | A | A | A | A | A | A | A |

| Sodium carbonate | A | B | A | A | A | A | A |

| Sodium chloride | C | C | B | B | B | A | A |

| Sodium chromate decahydrate | A | A | A | A | A | A | A |

| Sodium hydroxide | A | B | B | B | A | A | A |

| Sodium hypochlorite | C | C | C | C | C | C | A |

| Sodium thiosulfate | C | C | B | B | A | A | A |

| Tin chloride | C | C | C | C | B | A | A |

| water vapor | A | A | A | A | A | A | A |

| Stearic (octadecanoic) acid | B | B | B | A | A | A | A |

| Sulfur | A | A | A | A | A | A | A |

| Sulfur dioxide dry | C | C | C | C | B | A | A |

| Sulfur trioxide dry | C | C | C | C | B | A | A |

| Sulfuric acid, saturated with air | C | C | C | C | C | A | WITH |

| Sulfuric acid, without air | C | C | C | C | C | A | WITH |

| Sulfurous acid | C | C | C | B | B | A | A |

| Tar | A | A | A | A | A | A | A |

| Trichlorethylene | B | B | B | B | A | A | A |

| Turpentine | B | A | A | A | A | A | A |

| Vinegar | C | C | A | A | A | A | A |

| Chemically purified water | A | A | A | A | A | A | A |

| Distilled water | C | C | A | A | A | A | A |

| Sea water | C | C | C | C | B | A | A |

| Whiskey, vodka, wine | C | C | A | A | A | A | A |

| Zinc chloride | C | C | C | C | C | B | A |

| Zinc sulfate | WITH | WITH | A | A | A | A | A |

Disclaimer: the information posted on this page is for reference purposes only and under no circumstances can be considered as a recommendation for use!