Check valve

Installing a check valve on the drain pipe can improve the efficiency of the system, in particular, prevent the backflow of gases. In addition, check valves reduce the risk of drain pipe clogging.

Sewerage without a drain pipe equipped with a vacuum valve. will perform its functions, however, its ease of use and degree of reliability may be lower, so it is still recommended to use these elements together. In particular, with dry water in the siphon, the valve alone will not get rid of the smell.

Valve on pipe

Installation of the drain pipe is carried out at the stage of construction of the internal part of the sewer; it can be done with your own hands if you have minimal skills

It is only important to strictly follow the recommendations of specialists and the requirements of building codes and regulations. The use of modern materials significantly reduces the labor intensity of work

Dimensions

There is no separate part called a fan pipe, regardless of size.

This design includes:

- regular tee;

- lid or grill;

- one or more pipes;

- safety valve.

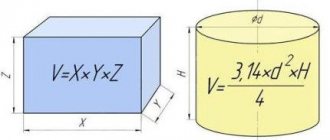

The dimensions of drainage pipes for sewerage, as well as for toilets, depend on the specific conditions of their operation.

The following rules must be followed:

- You can use parts from any materials;

- The size of the pipes for the exhaust riser, including the length, may vary.

Today, the most popular are plastic fan pipes with diameters from 110 to 50 mm, regardless of other linear dimensions (length).

Using a 110x45 ani plast w4220 drain pipe, which can be of different sizes, it is convenient to connect the sewerage system to the toilet outlet. Such a detail will seem to glue the toilet bowl to the sewer riser, which will ensure that there are no leaks in the bathroom. The size of the toilet drain pipe depends on the diameters of the drain, sewer riser, and the distance of these elements to the wall or ceiling.

The diameter of the part must be such that the maximum possible sewer flows do not interfere with its normal functioning. Sometimes ventilation and sewage systems are constructed from risers of different diameters. Then you need to use a special adapter.

There is a catalog where you can select the necessary parameters of parts for arranging an exhaust system.

Important! The ideal location for the exhaust riser is the place where the internal and external sewers are connected.

Functional Features

When a large volume of water is suddenly drained into a pipeline of small cross-section, pipe destruction and water hammer often occur. Therefore, a sewer pipe in a private house is an integral element of internal engineering networks. Due to its use, the sewage system in a private house has an additional air flow, and in addition, the design eliminates pressure drops.

An apartment building without a drain pipe can only function with the installation of a shower stall, where water consumption is low. A standard bathroom refers to peak flow rates; during the discharge of wastewater from a sanitary fixture, the cross-section of the pipes is maximally filled, and the influx of fresh air becomes minimal.

Functional features of vent pipes

A similar situation in houses without a drain pipe provokes flooding of the first floors of the building at the time of massive drainage of water. Installing an additional structure will extend the life cycle of a sewer riser, especially a plastic one, and will also improve the performance of home ventilation in sewer pipes.

Many craftsmen advise narrowing the diameter of the pipeline, citing the lack of costs in the attic of the house. Regulatory documents, as well as experience in operating utility networks in the private sector and apartment buildings, force us to abandon such manipulations.

Sewage pipelines from the sanitary unit where the toilet is installed are dictating. The toilet drain pipe has a cross-section of 110 mm; the domestic sewer riser must match its size or be larger. If there are two toilets and two bathtubs installed on the riser, it is necessary to carry out a hydraulic calculation of the riser's capacity.

Installation

Choosing the ideal device and determining its parameters is only half the battle. Equally important is high-quality installation of equipment. Serious difficulties arise when accessing the roof - installation work inside the house is no more difficult than manipulating other plumbing fixtures. But it is quite possible to get around this problem if you follow the recommendations given by professionals. For example, they warn against using “fungi.”

The rise of warm air through the drain pipe can lead to freezing of condensate on this element and blocking its lumen. In this case, thrust will inevitably decrease. The closer the outlet is to the ridge, the more reliable the system being created and the less likely it is that the snow mass will tear off the roof. In those buildings that have three or more floors with long sewer lines, it is advisable to install two air ventilation risers. But here there is a rule: the risers are made straight, like arrows, since the slightest turn or bend will sharply reduce the efficiency of their work.

The maximum result is achieved if the liner is connected to the outlet using corrugated adapters. When there is one outlet for several risers, the total diameter of the external discharge channel must be equal to the diameter of the riser. The auxiliary ventilation duct must be connected to the sewer option below the outermost plumbing fixture or from above to the upward outlet of the curved tee. But first you should make sure that this outlet is located above the sides of the instruments and inspection hatches, because sometimes, even if there is a vent pipe, foreign odors arise.

The reasons for this circumstance may be related to the following problems:

- wear and depressurization of the cuff that attaches the toilet;

- broken connection of sewer pipes;

- problems in the hydraulic valve.

Only after checking and refuting all these assumptions or eliminating such defects, but not achieving a positive result, is it worth replacing the fan structure. It is advisable not to rely on your own knowledge and skills, but to entrust the matter to trained specialists.

If you still decide to do the work on your own, then you should understand that sometimes you even have to dismantle the toilet tank. It is especially difficult to work with cast iron channels, which cause a lot of inconvenience even for specialists.

It is impossible to turn off the drain pipe in an apartment building. The only option is to negotiate with your neighbors so that they don’t turn on their washing machines or open their water taps for a while. It is also not recommended to use toilets during this time. The dismantling itself is carried out using sledgehammers and angle grinders. Subsequent installation is always carried out from the lowest point, and in private houses it coincides with the base of the foundation.

You can simplify the connection of pipe parts to each other by lubricating the sealing rings with silicone. But even if this reagent is not available, the problem can be easily solved: you need to use simple liquid soap. It is worth considering that the silicone bond is stronger than the soap bond, but it will complicate dismantling. If it is necessary to connect cast iron and plastic pipes to each other, you should use special adapters, which can be purchased at any plumbing store. Fastening to the wall is done with metal clamps, which are much more reliable than their plastic counterparts and more convenient to use.

The old vent pipes, installed several decades ago, were only attached to the floor and ceiling. This solution is currently considered impractical, because connecting all sections of the circuit is considered much more effective. After completing the fastening work, sewer pipes are connected to the risers - bends or tees are used for this purpose. Then comes the turn of connecting the sewer circuit with plumbing equipment.

Recommended diameters according to SNIP

Sanitary standards and rules SNiP 2.04.01-85 regulate the following parameters of the riser exhaust system:

- The diameter of the ventilation part must correspond to the size of the riser in circumference (clause 17.20).

- In the upper part of the riser pipeline there should be an inspection necessary for cleaning the sewer along the entire length of the riser.

- It is permissible to combine several risers at the top with one exhaust pipeline with a slope of at least 0.01 in their direction.

- When combining several risers, the diameter of the prefabricated pipeline from the drain pipe and the ventilation outlet, depending on the number of plumbing fixtures in the building, is taken equal to:

- 100 mm with the number of devices no more than 120 units;

- 125 mm if the number of devices is not more than 300 pieces;

- 150 mm for the number of devices up to 1200 copies;

- 200 mm if the number of plumbing fixtures exceeds 1200 units.

Rice. 6 Permissible volumes of wastewater discharge in unventilated risers depending on their parameters SNiP 2.04.01-85

Pipe materials and diameters

Since the drain pipe in a private house is part of the system, it would be optimal to make it from the same material that was chosen for the rest of the pipelines. In some cases, a combination of materials is allowed, but experts believe that the efficiency of dissimilar systems is significantly lower.

To install the internal part of the sewer system in a private house, cast iron or plastic pipes are used.

- Cast iron pipes have the required durability, but if they have defects during processing or receive mechanical damage, they become susceptible to corrosion. In addition, the large weight of the products significantly complicates installation, not only from the point of view of increasing labor costs, but also from the point of view of fixing vertical sections of the pipeline.

- Plastic pipes are increasingly being used for the installation of internal sewerage systems. which, in addition to light weight, have a number of other advantages, including strength, durability, absolute immunity to corrosion and the presence of a smooth internal surface, which reduces the likelihood of deposits and blockages. Another advantage of plastic is a large selection of not only pipes of different diameters, but also the fittings necessary for the implementation of the developed scheme.

The choice of the diameter of the fan pipe is made taking into account the design features of the system. The main condition: the diameter of the drain pipe should not be less than the largest pipe (including pipes and bends) of the system.

Since in the vast majority of cases the largest sewer pipes are used to connect the toilet and have a diameter of 110 mm, the drain pipes are also installed with the same diameter.

Device

The drain pipe in a private house is formed by individual outlets to drain points and risers. If the home is quite large, and the bathrooms and toilet rooms are far from each other, then a scheme with several vent risers is needed - this will help avoid placing long horizontal sections of the pipeline with their inevitably weakened draft. If several branches are connected into a single circuit, it is recommended to install the pipe with a slight slope. It is worth understanding that placing the initial section in a warm room, and the final section outdoors, is extremely useful for intensive air exchange.

The faster the air flows through such a channel, the better the fresh atmosphere in the home is maintained. Since the key part of the fan pipes is installed vertically, you need to carefully approach the fastening of the structures. The connection is achieved through clamps made of metal materials. Some experts consider it necessary to install sound insulation of fan pipes using rolls of mineral wool and slab structures.

Much attention should be paid to the exit of the fan structure onto the roof of a single-story or multi-story building.

Standard requirements stipulate that sewerage facilities are not allowed into the attic. If you mount the outlet under an overhang, then as a result of falling snow or ice, the expensive structure may be damaged. The height of fan structures above a pitched roof should be at least 50 cm, and if it is flat and not in use, then this figure should be at least 0.3 m. Most often, several pipes lead to the roof at once - among them, the air exhaust pipe will be the highest. The formation of a single circuit of the fan and ventilation system, as well as connection to chimney structures, is strictly prohibited.

It is prohibited to bring the drain pipe closer to the windows than 400 cm. The optimal outlet is considered to be in the area where the largest number of drain structures are concentrated. Transferring it, for aesthetic reasons, is fundamentally unacceptable. It is also prohibited to add any decorations to the drain pipes both inside and outside the house - each such element can provoke the formation of condensation and ice, reducing the effectiveness of odor removal.

Structural layout diagrams

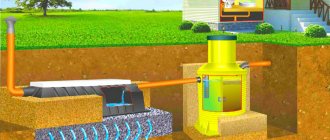

Modern sewer network solutions based on polymer pipes can significantly extend the service life of the system and simplify installation work. Sewage in a private house without a drain pipe remains quite functional, especially in houses with a small number of appliances and people, the standard system copes with the flow of wastewater.

Typical location of vent risers in a private house

An unpleasant odor appears at times of heavy load, when most of the devices are activated at once. In such situations, many owners install additional aerators - ventilation valves; they compensate for the lack of air in the system. Installation of such equipment occurs at a level of 1–2.5 meters from the finished floor level.

The installed fan complex will provide a number of advantages:

- A working and independent ventilation system to remove odors from risers.

- Creating a high-quality restriction of water flow, with normalization of air pressure inside.

- Providing functionality for several bathrooms located on different levels in a private house.

Such points will allow the construction of the required riser, taking into account high-quality ventilation and ensuring long-lasting functionality. The resulting sewage system will allow for the use of several full bathrooms.

This is relevant when a private house has independent and multi-level options for placing wastewater disposal. There is only one way out in this situation - the craftsmen can install the system with one vent riser, the exhaust part of which will be combined. But the diameter of such a pipeline must correspond to the cross-section of the working riser or be 50 mm larger.

What it is?

A sewer pipe is an element of a communication system that communicates between the sewer riser and the atmosphere. Wastewater moves along the riser strictly from top to bottom, so when several devices located on different floors are used simultaneously, a vacuum effect occurs inside the riser. A vacuum appears in the system, due to which water is sucked in and the water seal dries out. In the absence of a water plug, unpleasant odors from the sewer penetrate into the room, which greatly reduces the comfort of its use.

Toilet drain pipe

The process of vacuum formation inside the sewer riser is associated with the cross-section of the riser and the volume of wastewater. Many household appliances use sewers to dispose of waste water - toilet, bathtub, sink, washing machine. The maximum volume of simultaneous drainage is at the bathtub, but individually each of the devices cannot completely fill the sewer system. The situation changes when several devices are used simultaneously, and wastewater fills the entire volume of the riser. In this case, due to the rarefaction in the riser, water is sucked out of the siphon with a squelching sound, and an unpleasant odor penetrates into the room.

Important! Installation of vent pipes is not carried out in all houses. The need to install this element is determined by the number of floors of the house, the number of devices that drain into the sewer and the frequency of use, as well as the diameter of the sewer riser.

Installation requirements

Installation and replacement of a drain pipe is a rather complex plumbing operation, which definitely requires a project and experience. In most cases, it is laid strictly vertically and discharged through a ventilation duct in the roof. In rare cases, it is possible to route the fan pipe horizontally through the walls of the upper floors. The following requirements apply to the installation of this element:

- The diameter of the drain pipe must be equal to or greater than the diameter of the sewer riser so that there are no sections in the system with a reduced cross-section.

- It should be discharged into the atmosphere vertically through the roof so that it is 30-50 cm above the ridge, so that fumes and odors can be easily removed through the pipe.

- The beginning of the pipe must pass through the heated part of the house or be thermally insulated, and its upper part must be exposed to the cold. Due to this temperature difference, additional pressure is created inside the system.

Remember that, in essence, sewer pipes are a continuation of the sewer riser, so they are made from special sewer pipes. If the lower part of the pipe passes through an unheated room, it must be insulated.

Diameter

There are no special requirements for calculating the diameter of sewer pipes; for multi-apartment residential buildings, it should be equal to the diameter of the sewer riser itself. But for individual construction, it is allowed to use pipes with half the diameter compared to the main riser, so only air will pass through the drainage part of the pipeline, and it has several times lower density than the drained water at the bottom of the sewer network.

A 50 mm drain pipe is well suited for sewerage of an individual private house

Basically, when constructing an individual residential building, to calculate a separate sewer line, which includes a sink with a pipe with a diameter of 50 mm, a cistern with a hole of 70 mm, a main pipe from the toilet of 100 mm and a common riser, also of 100 mm, They use a fan pipe with a diameter of only 50 mm. Practice shows that this diameter is quite sufficient to maintain constant pressure and provide constant ventilation of the sewer system.

Manufacturing materials and installation of a sewer drain pipe

The drain pipe is a continuation of the riser, so it is assembled from materials similar to it, most often they are PVC polyvinyl chloride or PP polypropylene. If we consider the further path of the system from the riser to the roof, it consists of the following elements:

Fan pipe. The standard outer diameter of polymer riser pipes is 110 mm, their inner diameter, taking into account the wall thickness, is approximately 105 mm. A ventilation pipe with a typical outer diameter of 100 or 110 mm is installed on the roof. To connect the outlet pipe of the riser to the ventilation pipe, the following types of ventilation pipes are used:

- Sections of ordinary PVC sewer pipes, inserted directly into the riser pipe or connected to it through tees at different angles in case the ventilation outlet is too far from the riser pipe.

- Rigid drain pipes of various configurations with an outer diameter corresponding to the sewer riser and inserted into its socket have an elastic cuff at the other end.

- Corrugated pipes with a number of elastic cuffs (Fig. 1), designed for connection to a cut 110 mm riser without a socket, have one elastic membrane with a hole at the second end. This design is most often used to connect toilets.

- Corrugated pipes with two rigid pipes, one of which is inserted into the socket of the riser, and the second is put on top (inserted inside) of the ventilation pipe (sometimes attached to it with a clamp). This design is most often used when ventilation passes through the roof.

Rice. 4 Ventilation outlets on the roofs of a two-story house and their connection

Ventilation tube. It is a regular pipe section, located either separately or in a unit of a special design, designed for ventilation through the roof.

Protective cap. Typically, ventilation is vented to the roof and closed on top with an umbrella or deflector - a special cap that performs the following functions:

- Protects the channel from birds and debris getting into it.

- Strengthens traction by redirecting wind flows, as a result, the efficiency of the hood increases by 15 - 20%.

- Protects the riser from precipitation, clogging with snow and icing.

- Reduces the likelihood of backdraft.

Rice. 5 Dependence of the diameter of the sewer riser on the volume of discharge and design features of communications according to SNiP 2.04.01-85

Installation of the riser and output to the roof

Current building codes (SNiP 2.04.01-85 * “Internal water supply and sewerage of buildings”) recognize the mandatory installation of a vent riser for houses with 2 or more floors, however, experts are confident that in a one-story private house such a design can significantly increase the level of comfort and eliminate unnecessary hassle. Taking into account the purpose of sewer pipes, it becomes clear that their need directly depends on the degree of risk of blocking the flow of the sewer, and therefore on the amount of wastewater entering the system. Thus, when using the house as a summer vacation spot with short-term residence and having a minimum amount of plumbing and drainage points, you can completely do without a drain pipe.

Various options for bringing the vent pipe to the roof

For a full-fledged residential building, which has a toilet, bathroom or shower, several taps, a washing machine and a dishwasher, a drain pipe is, if not mandatory, then, in any case, a very desirable addition to the sewer system.

Installing a sewer drain pipe is not difficult. In fact, the vent part of the system consists of individual outlets for drain points and a vent riser. If the house has a large area and several bathrooms or toilet rooms are located at a considerable distance from each other, several vent risers can be installed in order to eliminate the laying of long horizontal pipelines, in which the traction force is reduced. When connecting several outlets with one drain pipe, it is better to place the supply pipelines with a slight slope.

The intense movement of gases through the pipe and their effective removal from the system is facilitated by a temperature difference - the initial section of communications is located in a heated room, and the final section is located outside the house.

Fan pipe fastening

Since the main part of the drain pipe is a vertically located line, it is important to take care of its secure fixation. Fan pipes are attached to the walls using metal clamps. In some cases, it is recommended to soundproof fan risers using materials specially designed for this purpose (for example, mineral wool rolls or slabs).

The outlet of the vent pipe to the roof requires special attention. It can be carried out through a riser located inside the house or using a pipe fixed to the outer wall of the house. It is optimal to bring the vent riser directly to the roof , since exit to the attic is not allowed by existing codes and regulations, and installing the structure under an overhang increases the risk of pipe destruction when ice or snow mass falls off the roof.

In order for the system to work effectively, it is important to follow certain rules.

- The height of the vent pipe above the surface of the pitched roof must be at least 0.5 m, above an unused flat roof - 0.3 m. And if the roof is in use, then the height of the pipe must be at least 3 m.

- If there are several pipes leading to the roof (general ventilation, chimney from a fireplace or stove, etc.), the fan pipe must be higher than all the others. Otherwise, unpleasant odors will be able to enter the room. For the same reason, it is strictly forbidden to combine the fan riser with a general ventilation system or with a chimney.

- The distance from the windows to the drain pipe should not be less than 4 m.

- It is preferable to carry out the drain pipe in the place where the maximum number of drain points is located, without moving the pipe for aesthetic reasons.

- It is not recommended to install decorations or other additional elements on the fan pipe. Their presence can contribute to the formation of condensation and, accordingly, icing and a decrease in the diameter of the passage. In this case, gas removal will be less efficient.

To cover the topic in as much detail as possible, the sewer ventilation scheme in a private house is described in another of our articles.

If you decide to make your own shower stall, then you will find our article about installing a shower drain under tiles useful.

And how to assemble a finished cabin, read this link https://okanalizacii.ru/santeh_vodoprov/kabina/ustanovka-dushevoj-kabiny-svoimi-rukami.html

Functional sewerage system without sewerage units

Sewage in a private house without a drain pipe is carried out in one-story buildings with a usable basement, but the installation of a toilet and bathtub takes place only on the first floor, not far from the riser and discharge into the external sewer network.

Sewer water seal

In this case, the consumption of a washbasin or house cleaning system is not dictating; such an amount of wastewater from sanitary appliances occurs irregularly and is not capable of affecting the operation of the system.

A private home is often equipped with grease traps; the equipment reduces the concentration of fats and organics in wastewater. Installing such equipment requires regular flushing of pipes with hot water. Air valves will help compensate for the lack of oxygen.

The valve outlet is connected to the main pipeline from the washing with fittings; the difference in elevations protects the equipment from flooding during flushing of the pipeline.

Related video: Fan pipe for sewerage in a private house

https://youtube.com/watch?v=HkdNv_ydf8w

Selection of questions

- Mikhail, Lipetsk — What discs should I use for cutting metal?

- Ivan, Moscow - What is the GOST for rolled sheet steel?

- Maxim, Tver - Which racks for storing rolled metal products are better?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals without the use of abrasives mean?

- Valery, Moscow - How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Errors when creating fan ventilation

Fan ventilation is simple communications; anyone can handle their installation. But at this very moment, some owners of country real estate make mistakes. We list the most popular of them:

- Many owners of private houses find it difficult to install a drain pipe through the roof. In order not to bother with cutting a hole, installing an iron sleeve and securing the pipe itself, they vent the ventilation into the attic space. Such a system will not be able to effectively cope with its task. All gases from the sewer will accumulate in the attic, and after that they will definitely penetrate into the house.

- In addition, they don’t want to put the pipe on the roof; many owners install it along the outer wall. This design will promote the formation of enormous amounts of condensate.

- In order to expand the hood, quite often a weather vane is mounted on the top of the vent pipe. Such an additional design not only does not contribute to greater traction, but much more often interferes with the escape of gases from the sewer. In addition, weather vanes will increase the formation of condensation, which will fall into the sewer. And in winter, accumulated water can freeze and reduce the diameter of the pipe, accordingly, reduce draft.

When installing a vent pipe onto the roof, it is quite common to see an error in its placement. The exit should not be located under the overhang. In this case, there is a huge risk of cutting off the pipe when snow or ice melts.

Pipe materials

A sewer pipe for a sewer system in a private house with a height of two, three or four floors is a decisive factor; in its absence, the hydraulic valves of the upper sanitary fixtures must be calculated for additional load. In this calculation, it is necessary to take into account the second flow rate from the devices, the cross-section of the pipeline, local resistance and pipe material.

Depending on the temperature of the discharged water, as well as the requirements for the working strength of pipelines, specialists select and install the following pipes:

- Plastic, modern polymer or metal-plastic for the installation of gravity lines.

- Plastic, metal-plastic pipes of low noise series for pressure pipelines.

Why extend the riser to the roof?

Figure 1. Sewage system in an apartment building: 1 - Exhaust ventilation pipe; 2 - Riser; 3 - Bath; 4 - Washbasin; 5 - Sink tank; 6 - Toilet; 7 - Outlet pipe; 8 - Revision; 9 - Sink or sink in the kitchen; 10 - Hydraulic valve; 11 - Floor siphon; 12 - Issue; 13 - Inspection well from the yard network; 14 - Yard network; 15 - Control well; 16 - Connecting well; 17 - Inspection well of the street network; 18 - Street network.

Of course, we will talk about the ventilated part of the sewer riser - the decompression or vent pipe. It is designed to serve as a connecting element between sewer communications (centralized or local) and the atmosphere. The vent pipe helps solve two extremely important problems:

- Compensation for decompression, that is, the vacuum created by the flow of waste liquid moving inside the pipe (Figure 2.1). The magnitude of the vacuum can reach emergency thresholds, at which water is sucked into the sewer from the water seals of sinks, shower trays and even toilets. Of course, decompression may not reach a critical level with insignificant water removal. However, during large volley discharges from several plumbing points, the waste flow can almost completely block the cross-section of the pipeline. Such a water “piston”, falling inside the riser at high speed, will cause a significant decrease in pressure in it. The result is broken water seals of siphons, which cuts off direct access of harmful stench from the sewer to the premises.

- Free removal from sewers of gaseous products resulting from the breakdown of human waste (Figure 2.2). Conditions of abundant moisture, heat and organic matter are almost ideal for the development of a variety of microorganisms. When processing organic raw materials, they release significant volumes of gases such as methane and hydrogen sulfide. Their concentrations in a confined space are fire and explosive, and accidental entry into a living space can pose a serious threat to human health.

How to Determine What Installation Requires

The drain pipe is an optional, but highly desirable element of the sewer system, which perfectly stabilizes its operation. It is considered that installation is necessary for all houses with a height of more than one floor

However, when designing a sewer system, it is important to take into account other minor factors:

Diameter of sewer pipes. If the diameter of the sewer riser pipes is less than 110 mm, then sewer pipes must be installed, since to fill the full volume of the riser, it is enough to drain the toilet and bathtub at the same time.

If the septic tank is located in close proximity to the house. Even if the house is one-story, but the wastewater tank is too close to it, you need to protect yourself with the help of a vent valve. If the layout of your home means there will be multiple bathrooms or baths that could potentially be used at the same time, then it is best to reduce the risk of a vacuum in the system. If the house has plumbing fixtures that have a large volume of waste water, for example, a swimming pool, jacuzzi, large bathtub.

Remember that the amount of wastewater is affected not only by the number of plumbing fixtures, but also by the intensity of their use. If the building has two bathrooms located above each other, but only one family lives in it, then it is unlikely that a drain pipe will be needed, but it certainly will not be superfluous.

When designing sewer systems for private houses, it is necessary to take into account many factors, ranging from the number of floors and devices that drain water into the riser, ending with the diameter of the pipes. Fan pipes are divided into categories based on shape, diameter and material used to make them. The diameter of the drain pipe depends on the diameter of the sewer riser. Based on the material, they are divided into the following types:

- Metal. Traditionally, the communication elements of the sewer system were made of cast iron. This is a fairly strong, durable and relatively inexpensive alloy. The disadvantages of this material are heavy weight and low ductility.

- Plastic. Nowadays, cast iron fan pipes are gradually being replaced with plastic ones, since this material is much more plastic and easier to process. Plastic models are lighter, cheaper and much more practical than cast iron, so they have almost displaced cast iron from the plumbing market.

Please note! When installing or replacing a drain pipe, you can connect cast iron sections with plastic ones; the main thing is to choose the correct diameter of the pipes so that in no case is there a reduction in the cross-section in the system.

How is installation done?

Let's consider how to install a sewer pipe in a private house, the diagram and technological requirements for performing the work. First of all, you need to understand the procedure. To do this, you need a diagram of the upper floor, on which you need to mark the areas where the pipe passes through the floors, rafter system and roof. It should also be noted what components, materials and devices will be needed. After this, all the necessary supplies are purchased, and the work begins. Let's take a closer look at the question:

You may also like: Sewer ventilation in a private house - methods, rules and regulations

Selection of pipeline material and size

All old sewer systems were created from cast iron pipes. There were simply no others, and the available materials had undoubted advantages:

- strength;

- durability;

- high noise insulation ability.

However, cast iron pipes have serious disadvantages:

- high weight;

- fragility;

- susceptibility to corrosion;

- the possibility of organic matter sticking to the internal walls, which contributes to the formation of blockages.

Plastic pipes are free from all these disadvantages; their only weak point is high sound conductivity. They are easy to process and connect, and all the necessary components and fasteners are available for sale. In addition, they are cheaper, which often determines the choice of users.

Pipeline sizes are an important issue. According to SNiP, fan pipes should not have a smaller diameter than the main (working) part of the riser. If the system is assembled entirely at once, then the fan section is usually made of identical pipes. If the fan pipeline is connected later, then it is necessary to connect pipes with a size corresponding to the diameter of the riser (usually it is 110 mm). This is the requirement of SNiP, but for owners of private low-rise buildings, the diameter of the drain pipe can be slightly reduced. This is due to the short length of the riser and small values of pressure drop when draining wastewater.

Installation features

Installation work consists of arranging passage points through the floors and roof. The assembly of the pipeline itself does not cause any problems, so installation consists of creating holes, installing special passage units in them, sealing and sealing the gaps. It is important to determine in advance the passage points, which should be as close as possible to the ridge of the roof.

It is possible to make a sewer riser in a private house without access to the roof. This option involves leading the pipe through the wall. The principle of operation is the same, only the location of the fan pipeline changes. As a rule, this method is used when diverting a pipe from a toilet, when there is no need to carry out complex work and punch holes in several floors and the roof. In such cases, the pipe is taken out through the wall and raised vertically, so that the exit is not at the level of windows or balconies. Ideally, it should be raised as high as possible so that the bad smell can be immediately dispelled by wind currents and does not bother people.

Example of roof ventilation outlet

How to bring a pipe to the roof

For roofing coverings, special passage units of various designs are available for sale. They allow you to arrange a pipe outlet for any type of roof and slope angle. The work process takes place in stages:

- a hole is made in the roofing sheet, the diameter of which is 1-1.5 cm larger than that of the fan pipe;

- a rubber cap of the seal is pulled on top of it, in which a hole of the appropriate size has been made in advance;

- the sole of the passage unit is placed on the roof surface, coated with silicone sealant along the edges;

- the sole is fastened along the perimeter with roofing screws, trying to press it as tightly as possible to the covering;

- A strip of sealant is once again applied over the seam.

Installation from inside the room consists of filling the gap with a heat insulator (usually using polystyrene foam or polyurethane foam). After this, finishing work is carried out (if there is such a need).

Check valve installation

A check valve is usually installed in the sewer systems of private houses. It is located behind the toilet and serves to cut off the possible passage of gases from the system into the room. When the drains pass, it opens, and then closes and tightly blocks the cross-section of the channel. In addition to cutting off biogas, the valve also performs other tasks:

- prevents the flow of water from the system if the pipe slope is incorrectly selected;

- ensures inaccessibility of passage to the premises for rodents.

Installation of a check valve is carried out similarly to the assembly of any elements of a sewer system - the valve has standard connecting pipes with a rubber seal.

In more detail: Non-return valve for sewerage - what, where, when?

There are also fan valves that are mounted externally and equalize the pressure in the system when a vacuum occurs. They can work in parallel with check valves or separately from them (independently). Such a valve partially performs the functions of a drain pipe and is useful for an apartment where it is not possible to change the entire structure of the riser. It is effective when a vacuum occurs, but is useless when there is excess biogas pressure in the sewer system. To install a vent valve, it is necessary to insert a tee into the gap in the horizontal pipeline, into the vertical part of which the valve is inserted.

Operating principle of a fan pipe

With intensive drainage of water, the flow rate in the sewer system sharply increases, resulting in the formation of a zone of rarefied pressure. Since, according to the law of physics, the pressure in a closed system tends to equalize, water from outlets and siphons rushes into the rarefaction zone, causing unpleasant and rather loud rattling and squelching sounds in the kitchen and bathroom. Fan pipes for sewerage ensure immediate air flow into the rarefied zone, thereby eliminating the possibility of water “sucking in” from the hydraulic seals.

Toilet bowls are often cited as the main reason for the formation of vacuum, but it should be remembered that the flow rate can also increase significantly when operating a washing machine that drains water under pressure. If we answer the question why a sewer pipe is needed in one phrase, we can say that such structures prevent the drainage flow from blocking the general lumen of the sewer riser.

Installation of a sewer pipe in the house

Another function of the drain pipe is to remove gases formed in the sewer system. Otherwise, they can enter the room, causing a lot of trouble.

How to check

When purchasing an existing country house or cottage, you can easily check and make sure whether a drain pipe is present in the sewer system. So, if you suddenly flush the water from the toilet, it should not disappear from the water seals of the plumbing fixtures located above. But the characteristic appearance of squelching sounds in the siphons of sinks and bathrooms leads to the conclusion that not everything is in order with the sewage system in the house and this can subsequently lead to the appearance of unpleasant odors in the premises.

To check for the presence of a drain pipe in the sewer system of a house, you need to flush the toilet.

What is a fan pipe and its purpose

A drain pipe is a pipe section located at the highest point of the sewer system, which ensures its connection to the ventilation outlet. Depending on the design of the sewer system, the drain pipe can be located vertically or at an angle to the riser pipeline and perform the following functions:

- Ventilation. In any sewer system with the presence of fecal waste, unpleasant odors appear, and when they decompose, explosive gases are released. Ventilation helps to avoid these problems, thereby ensuring comfortable and safe living.

- Support for water seals. When a large amount of wastewater is discharged, it carries air with it and a vacuum is formed in a closed riser, breaking off the water seals. Access to the riser pipe of atmospheric air from ventilation prevents this phenomenon.

- Plumbing connection. Sometimes the device is not used for its intended purpose, because the diameter of the toilet drain pipe is just as suitable as for venting. Therefore, it is often used to connect this type of plumbing to the inlet sewer pipes.

Rice. 2 Schemes for connecting a sewer hood on the roof through fan corrugation and an insulated pipe section

Principle of operation

Any plumbing fixture in an apartment or residential building is connected to the sewer through a water seal - a water plug that prevents foreign odors from entering the room. All pipelines coming from sinks, bathtubs, showers and toilets are connected to the central riser, which runs from top to bottom through the entire building and has the largest diameter.

When simultaneously draining water from plumbing fixtures into the riser, there is a high probability that a situation will arise where the passage channel is completely clogged with a water plug. The column of water carries along air and, as a result of the vacuum in the closed riser, the water seals of the plumbing fixtures break (more precisely, one of them with the least amount of liquid or the one closest to the riser), leading to the appearance of foreign odors in the room.

The sewer pipe allows you to connect the sewer system with atmospheric air, as a result of which the resulting vacuum draws in air masses from outside, rather than water seals inside the premises.

Rice. 3 Examples of connecting a toilet using a corrugated pipe

Installation rules

To properly install a fan riser, you must comply with the following requirements:

- The outlet of the riser should not go into the attic, but into the street. If sewer gases escape into the attic, it will smell bad and the humidity will increase (which will lead to mold).

- The diameter of the drain riser must be no less than the diameter of the sewer riser. More is acceptable, but not required.

- The pipe outlet should not be located close to a wall or near other structures (windows, balconies). Otherwise, stains from gas emissions may appear on the wall, and an unpleasant odor will be felt in the rooms near the outlet.

- The outlet should not go under the roof overhang, otherwise in winter the pipe may be damaged (due to ice or melted snow).

- For private houses, it is enough to use 1 vent riser. Lines from all plumbing points must be cut into it using tees, crosses and adapters.

- There must be a temperature difference between the lower and upper points of the pipelines (it’s warm at the bottom, cold at the top).

- The fan riser can be laid in the ventilation shaft, in one box. However, it should not be connected to ventilation ducts leading to residential premises and chimneys (according to SNiP).

- It is permissible to connect several sewer pipes to one drain riser.

Installation rules (video)

Types of scheme

According to the “direction” of the output, there are 2 options for laying:

- Horizontal - when the pipe is discharged not through the roof, but through the wall. The method is relatively rare and can only be used in private construction, in cases where for some reason the output cannot be made through the roof. In this case, a grille is installed on the hole, not a deflector.

- Vertically - the most common option: the riser is led up through the roof.

Vertical passage, in turn, is divided into 3 more subtypes:

- An outlet with a slope of 90 degrees: a branch is made from the riser at a right angle, from which there is then another branch, and from this there is a straight section extending above the roof.

- An exit with a slope of 45 degrees: a branch is made from the riser at an angle of 45 degrees, another branch is made from it, and from this there is a straight section extending above the roof.

- Vertical outlet: The riser simply continues until it exits above the roof.

The exhaust pipe exits through the roof: how is it done and what height should it be?

The section of the vent riser located outside, above the roof, must meet certain requirements:

- The height above the roofing material of the roof in use must be at least 3 meters.

- The height above a flat roof that is not in use must be at least 30 cm.

- The height above the pitched roof must be at least 50 cm.

- The horizontal distance between the pipe outlet and the nearest window (balcony) must be at least 4 meters.

- The outlet should be covered by a deflector on top. It is needed to prevent debris, insects, birds, and precipitation from getting inside.

If it is possible to draw a line through the pediment, it is better to implement this option rather than passing through the roof. In this way, you can save yourself from troublesome work with roofing material and further sealing.

How is the output through the roof made? (video)

Installation errors

The installation of a ventilation riser for a sewer system may be carried out with errors. Of the most common:

- Dismantling the riser (intentionally or unknowingly) in apartments (multi-storey buildings).

- Output under the roof overhang.

- The use of pipes of different diameters when creating a sewer system.

- Output of the riser to the attic.

- Fastening the riser to the external wall of the building.

Do you need soundproofing for a drain pipe?

Sound insulation is needed if the pipe passes through living rooms. In this case, the noise of water and air will be heard in the rooms. The pipeline itself will also make noise due to vibration and resonance.

Noise insulation of areas passing through non-residential premises is not required. If the riser is laid in the wall, and the thickness of the partition is small, then at the construction (repair) stage it is recommended to perform at least “light” sound insulation.

Ideally, the issue of sound insulation should be addressed at the design and construction stage of the building. The riser needs to be “hidden” in a separate box (shaft), or planned so that it does not pass through the living quarters. It is also recommended to use special “silent” pipes (thick-walled polypropylene products).

The sound insulation process itself is carried out using “shells” or roll insulators that are wound onto the pipeline. The thicker the layer, the more effective the insulation will be.

Is it necessary to insulate the drain pipe?

Insulation of fan risers is necessary more often than sound insulation - because warm, moist air, rising up the pipe, will condense on the walls and freeze. As a result, the pipeline freezes, becomes clogged, and stops working properly.

Insulated section of pipeline in the attic

It is necessary to insulate areas passing through unheated rooms (attic, basement).

Insulation is done in the same way as sound insulation: using rolled heat insulators or “shells”, which are fixed around the pipe.

Replacing a drain pipe: operating rules

It is necessary to replace the pipe (a section or the whole) if it is damaged or severely clogged (important for old cast iron structures).

In short, the replacement process is divided into 2 stages:

- Dismantling the old line.

- Installation of a new line.

The main rule of work when replacing a riser in apartment buildings: before replacing a section in your apartment, you must notify your neighbors about the time of the work. During this period, residents will not be able to use the toilet, sink, sink, bathtub, or washing machine.

Briefly, the dismantling process looks like this:

- The riser is completely turned off.

- All connections to the riser are cut off.

- The riser itself is dismantled.

After this, a new line is installed, to which the taps are connected in series.

How to choose, install and hide a corrugated hood in the kitchen?

Is it necessary to insulate the air duct, and how and with what is this done?

Related Posts

How to do without a drain pipe

Installation of a drain pipe involves its exit in individual and multi-apartment residential buildings through the roof; if this condition is easily achievable in municipal construction, then in the private sector there are great difficulties in implementing this plan, which also promises considerable financial costs. Since the riser and drain pipe in a private house pass through all the rooms and into the attic through the roof, they will spoil the aesthetic appearance of the rooms, take up excess space, and create inconvenience when using the property.

Therefore, it is rational to use in this case a sewerage system installed without exhaust through the roof, and it exists in the form of a vacuum valve. The device is placed at the top point of the sewer riser, it works according to the following principle.

If there is no drain into the sewer, the sealing gasket hermetically seals the passage channel, preventing the flow of fetid air from the riser into the room. As soon as the water is drained, the elastic diaphragm inside the vacuum valve is retracted due to the vacuum, thereby opening the access of outside air to the riser. The pressure inside the pipeline is equalized and due to this, the hydraulic seals do not fail.

Thanks to the use of a vacuum valve, sewerage without a drain pipe, with the same operating efficiency, brings a number of significant advantages to the consumer from a constructive and financial point of view.

Rice. 10 Appearance and operating principle of the vacuum valve

What is a fan pipe

The drain pipe is a continuation of the sewer riser and belongs to the class of gas exhaust ventilation equipment.

Purpose and functions

The vent riser is designed to drain foul-smelling gases accumulated in the circuit beyond the boundaries of the household.

But this is not its only function, it:

- Normalizes the pressure in the system, which prevents the failure of water seals in the siphons of plumbing fixtures while simultaneously discharging a large volume of waste.

- Muffles the sounds of wastewater movement in the pipeline.

Design and principle of operation

From a technical point of view, the vent riser is a natural continuation of the waste pipeline. Essentially, this is a piece of pipe connected to the sewer main and extending beyond the boundaries of the roof structure of the house.

The contour and outlet pattern of the fan pipe is determined by the structural features.

The principle of operation of the drain riser is based on the difference in atmospheric pressure inside the sewer circuit and outside. Gases formed during biological decay naturally rush upward and... Since the design of the siphons of plumbing fixtures provides a kind of barrier in the form of a water seal, they exit out along the path of least resistance - along the drain pipe. If it is absent or blocked, these gaseous emissions will be carried out through the water seal and enter the room.

Design solutions for installing and venting pipes to the roof

When designing a house or carrying out reconstruction, it is important to choose the correct location of the system and individual sewerage units. Only in this case will the sewer outlet in a private house function, regardless of the weather outside the window

If we are talking about a large temperature difference inside and outside the building, especially when the house is used all year round and the climate has a long period of negative temperatures, then the craftsmen install a unit inside the building or connect electric heating.

Design solutions for installation

Installation should be carried out inside the building, leading the riser above the level of the roofing. This will eliminate problems with freezing and provide a reason to provide the necessary functionality, regardless of weather conditions. In this case, the sewerage system will meet a number of regulatory requirements:

- Removal of unpleasant odor.

- Condensation and freezing of pipes are excluded.

- Full functionality without water hammer during peak flow times.

In a situation where the home owners do not have the necessary free space to install a fan unit indoors, experts advise installing the unit to the outside wall, sewing up the structure, and insulating it with mineral wool. An additional heat source in this design is a heat cable.