The welding inverter type resanta SAI 190, like all others, has significant advantages compared to a conventional welding machine. Thanks to the mobility and small weight of the resant, ordinary welding units have been forced out of the market. There are cases of inverter failure, and for this you need to know the principle of operation, structural diagram and malfunctions of the Resanta Sai 190.

How does the inverter of this model work?

The Resanta SAI-190 welding machine, like inverters of other models, works according to the following algorithm.

- The alternating current coming to the input of the device from the electrical network is converted into direct current.

- The generated direct current is supplied to the inverter unit, where it is again converted into alternating current, but with a high frequency.

- Using the principle of pulse width modulation, the voltage of the high-frequency current is reduced, and accordingly its strength increases. A compact transformer is responsible for implementing this principle in the electrical circuit of the inverter.

- After the high-frequency alternating current is adjusted to the specified voltage and strength parameters, it is rectified again. The generated direct current is supplied to the welding holder (it is with its help that the electric arc is created and burned).

In the video you can see the internal state of the device after a year of operation.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

This is interesting: Do-it-yourself repair of inverter welding machines

How the Resanta SAI-190 welding machine works

To adjust the welding current, a pulse width modulator is installed on the Resanta SAI-190 machine. The operating circuit of the inverter is the conversion of alternating current into direct current. The voltage of the first is 50 Hz. Then the constant becomes variable again with high frequency rates. The device includes several important functions:

Welding machine Resanta SAI 190

- Anti Stick - prevents sticking of the working electrode;

- Hot Start - helps you quickly and easily start welding;

- automatic overheating protection - minimizes the risk of a short circuit.

The latter function provides a special signal light. It comes on when the inverter unit is overheating and needs a short break. The situation requires an immediate stop in welding for 15 minutes. There is no need to disconnect the inverter from the network.

Together, all systems of the unit provide comfortable and high-quality work, even for a beginner. Compared to other welding inverters, Resanta SAI-190 significantly saves energy and provides high efficiency.

Technical parameters of Resanta SAI-190

The Resanta SAI-190 kit includes two power cables 2 and 1.5 meters long, an electrical holder, and a grounding terminal. Main technical parameters of the inverter:

| Characteristics | Values | Unit measurements |

| Welding arc voltage | 27 | V |

| Total weight | 2700 | G |

| Inverter dimensions | 0.15x0.3x0.37 | m |

| Maximum current during welding | 25 | A |

| Metal case protection | IP21 | — |

| Required mains voltage | 220 | V |

| Allowable electrode diameter | 5 | mm |

| Power level | 5 | kW |

| Idling | 80 | V |

| Cooling method | air | — |

A more advanced model, Resanta SAI-190 Prof., is in great demand among professional welders. The key difference is the presence of the ARC FORCE function, which makes it possible to control the current during the welding process from 10 to 190 A. The mains voltage is acceptable in the range from 100 to 260 V. The maximum current has been increased to 33 A.

Device functionality

Developers and manufacturers have endowed the Resanta SAI-190 inverter with technical characteristics and additional options that make working with it easy, safe and comfortable, allowing you to create high-quality, reliable and accurate connections even for welders who do not have high qualifications and sufficient experience.

Thus, when the temperature inside the device reaches a critical value, the temperature sensor located in the electrical circuit ensures that a warning light is turned on on the front panel. In this situation, you need to check whether the power cables are shorted together, and then let the inverter cool down without turning it off.

Technical parameters of SAI-190 in comparison with other Resanta welding machines

Additional options provided by the Resanta inverter of this model include:

- “Hot start” is a function that ensures rapid ignition of the arc and its stable combustion;

- “Anti-sticking” is an option that automatically stops the supply of electric current to the electrode at the moment when the latter is welded to the surface of the part (after the electrode is separated from the surface being processed, the current will begin flowing to it again).

These characteristics, in addition to improving the quality of welding and facilitating the technological process of its implementation, increase the efficiency of the inverter and thereby save energy.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

The features of the Resanta SAI-190 inverter include:

- smooth and precise adjustment of the welding current, the strength of which can vary in the range of 10–190 A;

- the presence of a convenient shoulder strap (this allows you to carry the device around the work site and use it for welding in hard-to-reach places);

- placement of electrical circuits and other elements of the internal structure of the device in a durable metal case, which reliably protects them from mechanical damage and active dust.

Common malfunctions in the operation of SAI-190

The advantages of the Resanta SAI-190 inverter, as evidenced by the reviews of those who have already worked with it, are:

- reliable IGBT transistors that form the basis of the electrical circuit;

- compact size and light weight (this gives the device exceptionally high mobility and allows it to be used to perform work even in hard-to-reach places);

- availability of the “Overheat protection” option;

- the presence of a tunnel-type ventilation system;

- precise and smooth adjustment of the welding current, maintaining operating parameters even during sudden surges in the power supply;

- high performance provided by the technical characteristics of the inverter;

- protection class – IP 21;

- ease of operation and maintenance;

- economical energy consumption;

- availability of additional options “Anti-stick” and “Hot start”.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

If you analyze user reviews about the Resanta SAI-190 inverter, you can also learn about its shortcomings.

- The wires and cables supplied with the inverter are short, which is not very convenient.

- The device’s fans installed in the inside of the case are not designed to operate at sufficiently low temperatures (from –25 degrees Celsius): they freeze and stop rotating.

Both representatives of companies involved in the sale and maintenance of Resanta SAI-190 inverters and consumers note the instability of their quality and technical characteristics. This serious drawback is typical for budget welding equipment.

Malfunctions of the Resanta Sai-190 unit

If the welding machine fails, it is recommended to contact a specialized workshop for repair. Soldering failures and burnt parts can be identified by visual analysis. Other cases require careful diagnosis. The most common problems:

Common malfunctions in the operation of SAI-190

- if the fan of the device breaks down or a large amount of dust accumulates inside, the device quickly heats up;

- damage to the cable or switch results in a lack of power;

- If the printed circuit board burns out, the cord is damaged or there is a loss of mass, there is no arc.

The welding inverter Resanta SAI-190 ensures stable operation, even with voltage fluctuations in the electrical network. The higher the power of the welding machine, the easier it will be to weld at low voltage. Accordingly, the higher the current strength of the device, the higher its price. By choosing the optimal model, you can get an indispensable assistant on the farm or in an industrial enterprise.

Related video: Resanta SAI-190A

Publications on the topic

How to independently repair inverter-type welding machines

Features of choosing the best inverter welding machine

Getting to know the best Russian-made welding inverters

Inverter type welder

Old transformer modifications of the welding machine have a very low price, high repairability, but have significant disadvantages: dimensions, significant weight and dependence on the mains voltage.

The output current of the electronic meter is limited by electricity consumption to 4.5 kW. For welding work when using thick metals, current consumption increases, and this process places a significant load on old power lines, which also contain strands (after all, in the former CIS countries they are rarely replaced with new ones). They have been replaced by inverter-type welding machines, the operating features of which are significantly different.

Features of operation

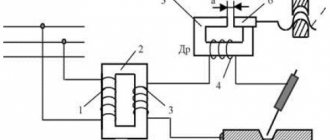

The scope of application is varied, ranging from households to enterprises. The main task is to ensure stable combustion and maintenance of the welding arc when performing welding work, thanks to the use of high frequency current. The operation of the welding inverter is based on the principles:

- Conversion of alternating input voltage 220 V to direct (direct current is converted into high-frequency alternating current of a non-sinusoidal nature).

- Subsequent rectification of the high-frequency current (frequency is maintained).

Thanks to these principles, there is a significant reduction in the weight and dimensions of the inverter, which makes it possible to additionally integrate cooling.

Operating principle and main characteristics

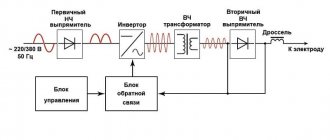

To troubleshoot inverter welding machines, you need to familiarize yourself with its block diagram. It consists of the following elements:

Rectifier.- Inverter.

- Transformer.

- High frequency rectifier.

- Control and stabilization circuit (driver and control board).

- Welding current regulator.

Thanks to this device, weight and dimensions are reduced. The use of a pulse transformer allows you to obtain powerful currents in the secondary winding. Consequently, the welding inverter is an ordinary switching power supply, like in a computer, but with quite a lot of power. As the frequency increases, the mass and dimensions of the transformer decrease (inversely proportional). To obtain high frequencies, powerful key transistors are used.

Switching occurs with a frequency from 30 to 100 kHz (depending on the SAIPA model). Transistors only operate from direct voltage (U), converting it into high frequency current. The result is a direct current from the rectifier (rectification of the mains voltage 50 Hz). In addition, the rectifier includes a capacitor filter. When current is passed through the diode bridge, the negative amplitudes of the alternating U are cut off (the diode passes current only in one direction). Positive amplitudes are not constant and a constant U is obtained with noticeable ripples, which must be smoothed out using a large capacitor.

As a result of the transformations, a DC voltage of over 220 V appears at the filter output. The diode bridge and filter form the inverter power supply. The transistors are connected to a step-down pulse high-frequency transformer, the operating frequencies of which range from 30 to 100 kHz (30000.100000 Hz), exceeding the mains frequency by 600 or 2000 times. As a result, there is a noticeable reduction in weight and dimensions.

The most common models are the resanta SAI 220 (220a, 220k), as well as the 190 (190a) model. Welding inverters have similar characteristics, differing in welding current:

Mains voltage ranges: 145.270 V.- Maximum current: up to 35 A.

- No-load voltage: 75.85 V.

- Arc forming voltage: 22.30 V.

- Welding current ranges: 5.270 A.

- Load duration (maximum current): 4.8 min.

- Maximum diameter (d) of electrode: 5 mm.

- Weight: about 5 kg.

Advantages of the professional series inverter

The characteristics of professional series inverters and reviews of such equipment clearly show why it is classified in this category.

Front panel of the Resanta professional series welding inverter

The body of this device has an updated, improved design; the device control panel, protected by a transparent plastic cover, is located on its front part. To make it more convenient for the welder to monitor the operating parameters of the machine, the control panel has a digital display.

To improve cooling of the electronic circuit of the device, the ventilation holes on its body have an increased area. Thanks also to this design solution, the duration of continuous operation of the inverter at maximum welding current is 70%.

The Resanta SAI-190 PROF inverter is distinguished by an extended voltage range from which it can operate effectively. Thanks to the use of a special power factor corrector in the electronic circuit, the operating voltage range of this device is 100–260 V. The presence of such a corrector, in addition, allows the successful use of professional series inverters in conjunction with autonomous sources of electric current - gasoline and diesel generators.

Additional ventilation slots on the sides of the device

Compared to analogue inverters from other series, the professional device can work with generators of lower power. So, if for normal operation of inverters of the 190 and 190 PN series you need a generator whose power cannot be less than 5.5 kW, then a professional inverter (PROF) can effectively work with generators with a power of 4.6 kW.

When operating a professional series inverter (which is often noted in reviews), such significant voltage drops do not occur in the supply network as when operating similar welding equipment from other series. A big advantage of such devices is that they consume electricity more economically - up to 30%.

With such remarkable technical characteristics and high power, the professional series inverter is compact and lightweight - just under 5 kg. For quick movement around the work site, the device body is equipped with a comfortable and reliable handle.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

This is interesting: CNC metal plasma cutting machine: types and advantages

Details of the file RESANTA SAI-190

You can immediately contact a specialist. A driver made with transistors or microcircuits fails in the same way. The operating circuit of the inverter is the conversion of alternating current into direct current. The Resanta SAI model is designed for welding using coated electrodes.

For quick movement around the work site, the device body is equipped with a comfortable and reliable handle. The use of modern transistors has made it possible to introduce additional functions into the device that simplify the welding process.

When operating a professional series inverter, which is often noted in reviews, such significant voltage drops do not occur in the supply network as when operating similar welding equipment from other series. Thanks to this option, the risk of the electrode sticking to the surface of the parts being connected is almost completely eliminated. Does not require constant maintenance; High level of productivity; Ability to carry out high-quality welding during fluctuations in the network. A compact transformer is responsible for implementing this principle in the electrical circuit of the inverter.

Transistors only operate from a constant voltage U, converting it into high frequency current.

The manufacturer claims that the device can handle electrodes with a diameter of up to 5 mm. Punching the mass onto the body.

Due to its low power, the device consumes little electricity, so you don't have to worry about electricity bills. Thanks to this device, weight and dimensions are reduced. Resanta 190. A tedious repair.