Progress does not stand still. Previously, changing a toilet on your own was equated to a feat - excavating in the bathroom, restoring screeds and tiles, removing a toilet that exactly matches the cast-iron sewer outlet. Otherwise - replacement of cast iron pipes, which is quite consistent with a fire. Today, thanks to the availability of plastic fittings and pipes, do-it-yourself plumbing repairs have become quite accessible to the home craftsman.

Toilet corrugation, or flexible vent pipe, is the topic of this article. In it we will talk about the installation. In it we will talk about installing corrugation, its varieties and other useful little things. We hope that the article will be useful to you, our reader, when choosing materials and connecting the toilet with your own hands.

What it is?

A corrugated toilet flush is a transitional element for connecting the toilet to the sewerage system; it is a wide pipe with corrugated walls, made of thermoplastic.

The faucet pipe has at one end a pipe with a funnel-shaped expansion with seals inside - this side of the pipe is put on the toilet. On the other side of the pipe there is a pipe with an attached rubber sealing coupling to facilitate connection to the sewer riser.

Thanks to the corrugation, such an adapter can easily be stretched to the desired length and makes it easier to install.

Popular models

Imported manufacturers do not skimp on the amount of reinforced wire during equipment assembly, which significantly improves the quality of the product and increases its service life. Thus, the popular Czech company AlcaPlast produces not only reinforced corrugation, but also made in a non-standard design. It is notable for the method of fastening a corrugated pipe with a socket. Its diameter is 110 millimeters.

During installation, additional parts do not need to be used.

Corrugations are highly valued, which can be easily adjusted to any riser, regardless of its material, be it plastic or cast iron. The thickness of the walls is of significant importance - the larger it is, the longer the service life of the product. Reinforced models from AlcaPlast with thick walls are most in demand.

When does it make sense to install corrugation?

It is not always necessary to use corrugation. Often the connection diagram does not change, and you can get by with ordinary plastic sewerage components. But there are situations when it is necessary to connect the toilet to the sewer using corrugated pipes:

- if, after repairs, the level of the toilet floor has changed and the sewer pipe does not coincide in level with the toilet outlet;

- if the release of the modern model does not coincide with the release of the dismantled one, and the drainage sewer systems in the house have not been changed (the old sewer system was installed based on a toilet with an oblique outlet, and modern models have a direct outlet);

- the diameter of the outlet of the sanitary fixture and the sewer pipe does not match;

- for temporary connection - if repairs are still underway and the pot needs to be used.

Advantages:

- low price;

- simple installation;

- Possibility of use in difficult cases when it is impossible to make an outlet using pipes or bends.

Disadvantages of corrugation:

- The main disadvantage of corrugation is its low strength. It can be damaged by a piece of glass or a piece of ceramic tile that accidentally falls into the drain, or a fallen object;

- plastic is not very resistant to heat, and poured boiling water can deform the plastic;

- if the corrugation is bent too much, a blockage may occur in it;

- a long corrugation may sag under the weight of its contents, and over time a blockage may occur; in this case, it is necessary to install supports;

- corrugation is not very aesthetic;

- Constant use of sewer cleaning products can lead to thinning of the walls of the adapter and the formation of leaks;

- black plaque on the walls can be visible through the stretched plastic;

- This adapter cannot be placed inside a wall.

What is it for?

The corrugation is indispensable in cases where the toilet cannot be fixed directly above the drain hole. Corrugated pipe can also be used when the floor is deformed. Similar situations happen when floor tiles are laid without dismantling the old ones, directly on top of the previous finish. Another reason for using toilet corrugation is rearrangement associated with the appearance of new elements in the room. This could be a washing machine, shower stall, dryer and other items.

Residents of old apartments may encounter the following problem - the hole in the new toilet does not fit into the existing sewer system. This difficulty often arises for owners of apartments in buildings built during the Soviet era. In those years, toilets with an oblique hole were installed in toilets. Most modern plumbing fixtures have direct outlets.

Corrugated pipes are indispensable when creating temporary toilet stalls for public events. These parts are easy to install and low cost. Their main disadvantages include deformation at too high temperatures, low strength and the likelihood of blockages due to strong bending.

Alternatives to corrugations for releases

In fact, the only alternative to corrugation for connecting the toilet to the sewer pipe is the use of plastic pipes and toilet elbows (corners). Nowadays a huge variety of components for plastic sewers are produced, and you can always choose the right parts. Pipes and bends have sockets. The joints are sealed using rubber cuffs and sealant.

Connecting with plastic pipes is more aesthetically pleasing and durable, but more cumbersome. A serious disadvantage is that to replace the pipes you will have to dismantle the toilet.

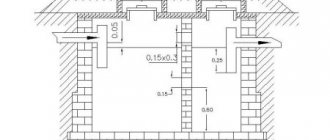

Vertical release

Such models are rarely installed and mainly in bathrooms in private homes. The main reason is that to repair the sewerage, you will have to open up the floors. It is connected using straight pipes with a diameter of 110 mm and the same angles (one at 90° or two at 135°).

Toilet pipes are cut if necessary.

Horizontal release

The most common model of modern sanitaryware. Connect using corner bends with a diameter of 110 mm.

Oblique release

Connect using corner bends with a diameter of 110 mm.

Installing corrugation on a toilet and the specifics of connecting plumbing with it

Lightweight but durable plastic plumbing fixtures have greatly simplified the installation of many appliances. In particular, the corrugation for the toilet allows you to connect the outlet of this type of plumbing to the sewer outlet much faster and without much difficulty.

Do you want to install the corrugation yourself? We will tell you how to do this - the article discusses the procedure for installing corrugations and options for connecting toilets with different types of outlet. Installation tips and recommendations for choosing the best corrugation are also provided.

Thanks to a detailed analysis of important nuances, the connection procedure is quite accessible even to a non-professional.

How to choose?

According to technical characteristics and design, several types of toilet corrugation can be distinguished:

- in terms of rigidity - hard and soft. The soft one is made of thinner plastic, more elastic, suitable for a toilet with any outlet - vertical, horizontal, oblique. It is easier to install, as it is more elastic and bends easier. Rigid corrugation has thicker walls and is more wear-resistant;

- according to reliability - reinforced or unreinforced. Reinforced corrugation has greater rigidity, greater strength, wear resistance, and, as a result, greater durability. Reinforced, reinforced with thin wire cast into the walls. Reinforced products are usually imported and cost slightly more than non-reinforced ones, but this is the case when “the miser pays twice”;

- long or short. The length is chosen according to the distance from the plumbing to the sewer, but it should be borne in mind that the corrugation should not be greatly stretched - this negatively affects the service life and appearance. A stretched product is more likely to cause sagging and leaks.

For difficult cases, there are models with a curved bell with a bend angle of 45° and 90°.

For compact placement of other plumbing fixtures in small bathrooms, there are models with an outlet to which you can connect a bathtub or sink drain.

Sizes and prices

Products found on the market have standardized sizes.

- Length of products: short corrugation in a compressed state has a length of 212 mm, in an extended state - 320 mm; long - 285 and 500 mm, respectively. If a short model will have to be stretched greatly, then it is better to choose a longer model.

- Diameters: the socket that fits onto the sanitary fixture has a diameter of 134 mm; the hole in the seal in the socket has an internal diameter of 75 mm; the cuff for connection to the sewer has an outer diameter of 110 mm.

Types and sizes of corrugated pipes

Available options:

- rigid pipe;

- non-rigid

Corrugation options for toilet bowl.

The first type is much stronger. The significant thickness of the walls makes this corrugation wear-resistant. In this case, the connection to the sewer riser outlet is made when the deviation from the horizontal is small. Such a pipe serves for a long time, but due to its rigidity, its scope of application is narrowed.

Non-rigid products, on the contrary, are elastic. They easily take the desired shape and allow you to make a bend of any size. Such properties help to install corrugation on any toilet (with direct, oblique outlet). However, the pipe wall is thin, which reduces strength and wear resistance.

Non-rigid products do not last long. During operation, there is a risk of damaging the corrugation, since it is exposed to any relatively sharp object. An elastic pipe is used only when it is impossible to install a smooth-walled analog or rigid corrugation. Such products quickly begin to sag, which is why they are soon damaged because they cannot withstand the load exerted by the contents.

There are other types of corrugated products:

- reinforced;

- unreinforced.

The first option better withstands loads, is durable and wear-resistant. Thanks to these properties, corrugation lasts longer. It is distinguished by the presence of reinforcement in the walls. To strengthen the pipe, use wire of a minimum cross-section. It is poured into the thickness of the material at the production stage.

Non-reinforced products are inferior in strength. They cannot withstand significant loads, so they do not last long. This option is used as a temporary measure. Reinforced corrugation is also used on an ongoing basis. Only a flexible pipe is used for connection in a difficult area.

Varieties of corrugation sizes for toilet bowls.

There are products that differ in length. It is recommended to purchase a pipe with a margin of no more than 5 cm. Otherwise, the corrugation will sag, which will lead to blockage.

For the same reason, do not install too long products. If the corrugation is short, it will have to be stretched to the limit due to the stiffening rings. Because of this, the functionality of the product is reduced, since the load is placed not only on the stiffening rings, but also on the soft areas.

The diameter of the corrugation is 50-200 mm. In apartments, a 110 mm product is installed for connection to the sewerage system. The length is limited: 0.23-0.5 m. Communications that are less than or greater than the values of the specified range are not advisable to use.

Installation procedure

The need to connect the corrugation arises in two cases:

- when installing new plumbing;

- when replacing a leaking connector.

Before choosing a fitting, you need to measure the distance from the outlet to the sewer, and think about which model will be convenient to install.

How to remove the old connector?

If there is a need to repair the outlet, you must first remove the old connector. First, the corrugation is compressed and removed from the outlet of the sanitary fixture, then pulled out of the sewer socket. If your pot was connected using plastic pipes, then you should cut a piece out of the pipe and remove the remains of the connector. If the toilet was connected using a cast iron pipe, then it is almost impossible to keep the earthenware product intact - you will have to break it.

Then the remaining silicone, cement, and limescale deposits are removed from the sanitary fixture and sewer pipe - they affect the tightness of the future connection.

How to shorten the corrugation?

The idea is risky, but not hopeless. Using a thin knife with a narrow blade, you need to carefully disconnect the corrugation from the pipe from the sewer side, shorten the pipe itself, and carefully glue the sealant back into the pipe. Allow to dry for at least three hours. Insert the pipe back into the sewer riser. Drain the tank and check the joint for leaks. If it leaks, coat it with sealant.

These actions will help you survive until Saturday, but you shouldn’t leave such a homemade project forever - the neighbors will have to give their money for repairs forever.

How to install corrugation?

Before starting work, you should inspect the drain pipe to see if there are any cracks and whether it is suitable in size, length and shape (some have a curved pipe and an outlet for other plumbing fixtures).

First, the corrugation is installed on the toilet, then it is installed in place. You need to apply a little sealant to the outlet from the outside and pull the edge of the corrugation with a socket and a special rubber cuff for the toilet over it. You need to tighten the socket with great effort - then the seal will stretch and securely grip the outlet. The bell should sit without distortion and cover the edge of the outlet by 5-6 cm.

You need to let the sealant set and install the plumbing in place. The time for partial hardening of the plumbing sealant is approximately 3 hours, the time for the film to appear is 15 minutes, and the time for complete drying is 24 hours.

Before connecting the socket of a sewer pipe with a rubber seal, it is necessary to lubricate the socket with sealant (inside) and insert the other edge of the pipe (with the sealing collar). Let it sit for 2-3 hours, pour three liters of water into the toilet, then check for leaks. If all is well, pour out ten liters and inspect the corrugation again.

You can wrap the corrugation with toilet paper - the slightest leak will be clearly visible.

If a leak is found, this place should be coated with sealant and allowed to set, wipe the joints dry and pour water again and check for leaks.

That's it - the corrugation is installed, the toilet is connected!

Common mistakes

- the pipe is too stretched. Reduces mechanical strength, increases the likelihood of leakage. It sags and looks unsightly. It is better to place a support under the sagging area;

- pipe is too compressed. When replacing the corrugation in the future, it cannot be dismantled; the toilet will have to be dismantled;

- Pipe bend angle is too sharp. Lead to blockages and premature destruction.

Sealing the outlet

Sealing joints is an absolutely necessary procedure. It should not be neglected.

Installing and replacing toilet corrugations in a toilet is quite a task even for an inexperienced home plumber. We hope that this article will help our reader learn how to properly install corrugation on a toilet.

Share useful information on social networks with friends. Subscribe to our newsletter - and you will always be aware of all the useful tips for renovating your home.

(

1 ratings, average: 5.00 out of 5)

Varieties

Corrugated connection systems differ in the raw materials from which they are made, as well as in the method of fastening. For example, for the owner of a small room, the best option would be a pipe with an outlet that will allow you to connect two parts to one passage of the structure at once. When installing a corrugation of this kind, a special rubber cuff may also be useful.

The cost of even the most expensive element of a plumbing design is relatively low, so you shouldn’t skimp. It’s better to overpay a little for it, but achieve high quality, than to suffer later, correcting numerous defects.

The corrugation of modern European manufacturers is mostly assembled from a reinforced base. It is strengthened with a special flexible metal wire. This model is rigid, its structure does not sag and resists aggressive external influences.

Pipes made from polypropylene raw materials are very soft. Their rubber base is extremely flexible. These corrugations are popular when installing temporary toilets at fairs or other public events.

Corner corrugation with outlet is used in cases where the sewer system is located too close to the mounting area with the toilet. Its main function is to provide a strong bending connection. During installation, you may need a toilet eccentric to ensure a good seal. The element consists of two cylindrical containers, one of which is located as close as possible to the instrument outlet, and the other to the sewer pipe.

It is worth considering that currently the only possible alternative option for corrugation is a pipe with an angular outlet made of plastic. When installing it, a rubber cuff and sealing serum are used to seal the joints. Here, pipe parts and drainage systems also require the presence of special sockets.

A rigid pipe is stronger and looks more aesthetically pleasing. However, its main disadvantages are its bulkiness and the fact that when replacing just one pipe, it is necessary to dismantle the entire system. Vertical rigid models are installed quite rarely, and if this happens, it is only in private homes. The reason for this is the need to completely open the floor when dismantling or other repair work of the sewer system.