The comfort and safety of the people in the building depends on how the water supply system is arranged. The pipes used as pipeline material are of great importance. Their quality is strictly regulated by GOST standards. The diameters, wall thickness, length of the pipe, its chemical composition and density are standardized. To equip a good, durable system, you need to familiarize yourself in detail with all the technical characteristics of the product.

Polymer pipes, along with steel ones, are used for the installation of water supply networks for various purposes.

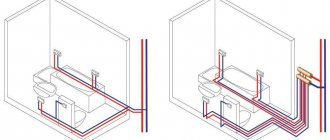

Plumbing in a private house

During the construction and major renovation of buildings, special attention is paid to various types of communications, including water supply. Not only the comfort of residents, but also safety (especially in the case of hot water supply) depends on how the water supply and drainage system works. Therefore, before repairing or laying a pipeline, you should familiarize yourself with all the features and possible difficulties that may arise during installation or operation.

The choice of equipment and materials is also important. The modern market for plumbing equipment can offer many options, varying in their technical qualities, price and dimensions. In order to select the right products, determine the clear requirements and load level for the future system and select the appropriate product in accordance with them.

Traditional metal pipes are widely popular. They are made of cast iron, carbon steel, aluminum. Each material, having some features, has its own operating conditions, differs slightly from others in its scope of application and installation method.

In addition to such equipment, plastic pipes have also gained popularity relatively recently. Their main advantage is their low price, so they provide significant competition to the above-reviewed products. They, just like metal ones, are classified according to the material of manufacture. There are pipes made of polyvinyl chloride, low- and high-density polyethylene, polypropylene and other polymers. Each type is used in different cases for arranging systems that differ in purpose.

Plastic pipes are used to provide drinking water to private houses, especially country houses.

To decide which type is right for you, you need to familiarize yourself with the characteristics of each of them in more detail.

Comparison of metal-plastic and polypropylene systems

The choice of pipes depends on the conditions of use of the pipeline, installation capabilities, and project budget.

We recommend that you read: Types of decorative linings for heating pipes

Comparative characteristics of the main parameters of pipelines made of metal-plastic and polypropylene.

| options | metal-plastic | polypropylene |

| wall thickness, flexibility | the walls are thin, the products are elastic, bend easily and take the desired configuration | The walls are thick, due to which the products almost do not bend |

| likelihood of blockages | absent at any water condition and temperature | absent at any water condition and temperature |

| diameter | from 16 to 63 mm | from 16 to 125 mm |

| maximum pressure in water pipes | 25 atmospheres | 25 atmospheres |

| maximum pressure in heating systems | 10 atmospheres | 7 atmospheres |

| Maximum temperature | 110 degrees | 95 degrees 110 degrees for PN25 |

| thermal conductivity | low | low |

| frost resistance | absent | absent |

| resistance to temperature changes | low, the product delaminates and becomes unusable | high |

| installation | connecting components using the threaded method using seals does not provide impeccable strength, there is a possibility of leaks | welded connections provide high strength to the entire structure without leakage |

Criteria for choosing between metal-plastic and polypropylene

When deciding on the choice of products for installing a water supply system, you should proceed from the following criteria:

- Purpose of the future design. To meet the needs for cold water, it is advisable to choose polypropylene pipes. They are cheaper and will not leak. Metal-plastic pipes and reinforced polypropylene pipes are suitable for supplying hot water.

- Quality of material. The efficiency and service life of the water pipeline depends on this. When purchasing pipes, it is important to evaluate their appearance, read the markings, technical documentation and certificates.

- Technical specifications. Pipes must meet operating requirements.

- Installation of a structure made from both types of pipes is not extremely difficult. If necessary, you can do it yourself if you have basic skills and tools. The system of metal-plastic pipes should be assembled in such a way that there is free access to the threaded connections.

- The cost of metal-plastic pipes and their components exceeds the cost of a similar project using polypropylene.

Thus, most often when arranging a cold water supply system, both materials are chosen.

For hidden water pipes, it is recommended to use polypropylene. For supplying hot water - metal-plastic or reinforced polypropylene.

Metal pipes: production and standards

Metal pipes have been used as elements of communication systems since the nineteenth century. They remain relevant today due to their high technical qualities and reasonable cost.

The production of such pipes can be carried out using different methods depending on the material:

- welding;

- casting.

The quality of absolutely all metal pipes, regardless of the manufacturing method and materials, is regulated by GOST standards.

Usually the standard number is indicated on the pipe body in the form of several numbers.

For example, for steel pipes it is 8734. After these four numbers, two more are written - 78, 75, 71, 85 or 81. These numbers are also part of the GOST standard number.

The most common metal pipes for water pipes are steel

What's the difference between them? Each GOST is responsible for a specific product parameter. For example, material, quality, wall thickness, diameter, chemical composition of the product. Steel water and gas pipes are produced under GOST standards 3262-75 (these are high precision products), 10704-91 (electric welded products), 1050-88, 380-88.

Plastic pipe products: main features

Plastic pipes are manufactured mainly by extrusion, as well as by stitching.

The first method is a technological process during which the molten polymer material is placed in an extruder - a special apparatus, inside of which there is a mold into which the plastic mass is pressed under high pressure (if it is hot extrusion). After the workpiece takes the desired shape, it is cooled and tested for compliance with all GOST standards, because the quality, chemical composition and diameter of plastic parts, as in the case of metal ones, are regulated by these standards.

Such products are classified according to the material from which they are made, according to the production method, and according to the width of the walls (thin-walled, thick-walled).

Copper pipes

Meda is an even stronger material than steel. Its service life can reach 70 years. Copper pipes have a number of advantages:

- strength;

- resistance to mechanical damage, temperature fluctuations, pressure;

- beautiful appearance, which allows you to “play up” the pipes in the design of the room.

However, despite the advantages, copper pipes are not the best option. Firstly, their cost is quite high. Secondly, the installation of such pipes is often difficult. Thirdly, they are presented in a limited edition on the plumbing market. Well, fourthly, before installing copper pipes you will have to carry out a system cleaning procedure.

Classification of steel pipes

Steel pipes are most often used as parts of hot and cold water supply systems. This is explained by its ability to work with media at high temperatures without deforming or losing its performance characteristics. Such a pipe can be manufactured in several ways, one of the most common is welding.

Steel pipes can be electric-welded and produced using seamless technology

Electric-welded steel pipes are divided into 4 groups depending on the technical properties and chemical composition of the alloy:

- A. This group includes products made from alloys of calm, boiling and semi-boiling steel grades St2, St3. The quality of this product, the production process, as well as chemical and mechanical properties are regulated by GOST 380-710;

- B is a group that includes pipes made from the same alloys as the pipes of group A, but the composition of the alloy according to this marking may include more varieties of steel;

- B. This group is the largest. It includes all grades of steel ;

- D is a group to which products belong that are not regulated by the GOST standard (in terms of chemical composition), however, are subject to standardization and testing of hydraulic characteristics. Such pipes are subject to use in water supply systems under high pressure conditions.

The parameters regulated by GOST standards can be seen in the table below.

Table 1

| Group | Standardized quality indicators | ||

| Chemical composition | Mechanical properties | Hydraulic test | |

| A | — | + | + |

| B | + | — | + |

| IN | + | + | + |

| D | — | — | + |

GOST steel water pipes of all groups, as can be seen from the table data, must undergo quality tests.

All produced pipes undergo quality control, welds, if any, are carefully checked

More details about these test data can be found in the following table.

table 2

| steel grade | Wall thickness, mm | Impact strength KCU, kgf*m/cm² (MJ/m²) at t0 | ||

| +20 | -20 | -40 | ||

| (no less) | ||||

| St3ps3, St3sp3 | 5-9 inclusive St.9" 25" St.25 | 6,0 (0,59) | — | — |

| 5,0 (0,49) | — | — | ||

| 3,0 (0,29) | — | — | ||

| St3ps4, St3sp4 | 5-9 inclusive St.9" 20" St.25 | — | 2,0 (0,2) | — |

| — | 1,5 (0,15) | — | ||

| — | — | — | ||

| Low alloy steel | All walls | — | — | 2,5 (0,24) |

Wall thickness and diameter are also standardized.

Table 3

| Pipe outer diameter | 478-720 | 820-1020 | 1120-1420 |

| Limit deviations along the cut oblique | 2,5 | 3,5 | 4,5 |

Advantages and disadvantages of each type

Which products to give preference depends on the scope of application, the project budget, the availability of skills, and on installation equipment, technical and structural characteristics.

Metal-plastic

Metal-plastic pipes are wear-resistant and reliable, due to their composition. They consist of an inner layer made of food-grade polyethylene PE-X, a reinforcing film glued to it, aluminum foil that allows it to retain its shape when heated, and a top layer of thick polyethylene.

Two layers of polyethylene make the pipes both strong and flexible; in addition, the products have many advantages:

- They successfully withstand very high temperatures up to 95 and briefly up to 110 degrees, pressure up to 25 atmospheres at temperatures up to 25 degrees, up to 10 atmospheres at 95 degrees.

- The inner layer remains absolutely smooth throughout operation, no plaque forms on it, regardless of the temperature and purity of the water, which avoids blockages.

- Operation of water pipelines made of metal-plastic pipes is possible for 50 years or longer with proper installation and optimal quality of materials.

- They are light in weight, elastic and allow the installation of water pipes of any configuration.

- The structure assembled from them does not spoil the interior of the room.

- To assemble a system made of metal-plastic, you do not need special equipment; if necessary, you can do it yourself using available tools.

- Products are sold in coils; you can buy a single pipe up to 200 meters long. This is good because the number of connecting lines and adapters will be minimal.

- Pipes are connected in different ways: with threaded compression fittings and crimping.

We recommend that you read: How to make a manifold for polypropylene pipes?

Metal-plastic pipes are suitable for assembling a system of the most complex configuration.

Despite a large number of advantages, metal-plastic products have disadvantages:

- The cost of the pipes themselves and components is higher compared to polypropylene and polyethylene analogues.

- They have a diameter ranging from 16 to 63 millimeters, therefore they are not used for arranging large-sized structures.

- When used for hot water supply, they cannot withstand pressures exceeding 10 atmospheres; at higher pressures, the system gradually loses its tightness.

- Temperature fluctuations inevitably lead to leaks at the joints, so the products are not suitable for creating a hidden water supply structure, for example, in walls.

- Over time, pipes will leak at threaded connections in any case, even without temperature changes and installation defects.

- When the temperature in the room drops to below zero and the water in the pipes freezes, the entire water supply system will become unusable.

- Ecologically flawed.

- Susceptible to the negative effects of ultraviolet radiation, high temperatures from 150 degrees, and damage.

The specifics of installation require the use of special sealing gaskets.

Note! In general, metal-plastic pipes are quite reliable, suitable for heating and hot water supply systems; if used correctly, they will last a long time, but over time they require additional sealing.

Polypropylene

Products made from polypropylene are suitable for cold water supply systems and providing drinking water to the facility. They do not emit harmful substances and are non-toxic.

The advantages of polypropylene products include:

- wide range of pipe diameters from 16 to 125 millimeters;

- no leaks;

- ability to withstand pressure up to 20 atmospheres;

- immunity to active chemical elements, oxidation by chlorine.

Important! The disadvantage is considered to be minimal flexibility, which complicates the installation of the water supply system.

Connecting components by welding requires the use of special tools and equipment, which often requires professional skills.

Under conditions of simultaneous exposure to high temperature and pressure, the service life of products inevitably decreases.

We recommend that you read: Installation of standard and non-standard connections of metal-plastic pipes

Polypropylene pipes often undergo linear expansion when operating in hot water transportation conditions, the material becomes soft and stretched, which inevitably increases the length of the pipes and they bend.

Products are classified into four groups:

- PN10 – for cold water pipelines with temperatures up to 20 degrees;

- PN16 - for cold water supply and hot water with a water temperature not exceeding 60 degrees;

- PN20 – for hot water supply, can withstand temperatures up to 80 degrees;

- PN25 – suitable for temperatures up to 95 degrees, suitable for hot water supply and heating systems.

Products from the third group are reinforced with fiberglass or aluminum foil (reinforcement process), due to which they do not deform when heated.

Reinforced polypropylene

Reinforcement is carried out to reduce linear expansion; thanks to a reinforcing layer of aluminum foil or fiberglass, reinforced pipes are able to withstand higher pressures and temperatures than conventional polypropylene.

The structure of reinforced products is homogeneous and is not subject to delamination.

Practically inflexible pipes complicate the installation of a water supply system and require the use of additional adapters.

Note! Reinforced polypropylene pipes are not suitable for heating systems requiring coolant temperatures above 120 degrees, and for use in rooms with a significant fire hazard.

Stainless water supply

The main disadvantage of metal plumbing systems is their susceptibility to the development of destructive processes associated with corrosion. To solve this problem, modern manufacturers manufacture water pipes in accordance with GOST with a special zinc coating or from stainless steel.

For ease of installation, stainless steel pipes are equipped with threads

The last type is the most reliable. Such a pipe is usually produced with threads. The connection of such water pipes occurs through the use of special fittings - cylindrical connecting elements. This type of communications is perfect for meeting household needs . Thanks to the convenient connection method, they are popular in apartments and houses where welding is not possible, and it may be necessary to disassemble the pipeline or replace its parts.

This equipment is very popular, since such water pipes can be connected in several ways, including without threads. To do this, use a welding machine or flanges.

Another solution is a copper plumbing system. The production and technical qualities of such products are regulated by GOST standard No. 52318. Copper pipe is characterized by a relatively high cost, which, however, pays off with extraordinary durability.