Even a person who is far from construction can do the insertion of a sewer pipe into a well without the help of professionals; this will save a significant amount of money. To organize wastewater disposal yourself, you need to carefully prepare for the process:

- calculate the distance from the wall to the well;

- select pipes by material and diameter;

- assemble and seal the units.

Design of a system with a sewer well ↑

There are internal and external sewerage systems. The layout of the internal system depends on the number of plumbing fixtures and the features of their connection. The external structure depends on the design of the storage or treatment tank. Wastewater is discharged either into a septic tank or into a sewer well. Here they accumulate or are filtered depending on the purpose of the structure. External systems can be of different types:

- Separate. They consist of several pipelines through which melt water, rainwater, and household waste flow into various reservoirs. This system allows for rational use of water and high-quality purification of household wastewater.

- Semi-separated. There is one reservoir for collecting wastewater, but water enters them through different pipelines.

- General alloy. Such systems are rarely installed in private homes. All waters flow into them - wastewater, melt, rain.

Elements of external sewerage

Self-contained septic tank systems are typically designed to collect and/or filter domestic wastewater. Tanks can be made from different materials. To decide how best to install a sewer into a well, you need to focus on the type of container, the material from which it is made, and the features of the pipes.

Scheme of a system with a sewer well

How to crash into a central water supply if it is blocked?

In this case, the flow of the route is blocked for the duration of the work. The material of the pipes does not matter much, since the principle for any pipe is almost the same. For example, we can consider an insert into a water supply system, the main line of which is made of steel.

In this case, the operation is divided into the following stages:

- Digging a pit and trench. First, a hole of selected dimensions is dug in the same way. If an excavator is used, then after detecting a metal strip, they proceed to work with shovels. It remains to dig 300-500 mm. Then they make a trench to the house.

- The water in the system is turned off. A hole is cut out in the central water supply using an autogenous machine. A threaded pipe is welded to it. A valve is screwed onto the element. After completing this stage, they proceed to the construction of a well above the insertion site.

Any type of plastic pipe does not require the use of any type of welding. In this case, saddle clamps are used - tees, which are assembled from two parts. After installing the element, a hole is made in the plastic pipe. Further work occurs in exactly the same way as with steel pipes.

The experts from the relevant organizations know very well how to cut into a central water supply. If the owners are going to do the work themselves, then care and caution when working with liquid under pressure and compliance with all rules and recommendations is mandatory. If the integrity of the system is compromised, the result of the work will be disappointing. The worst-case scenario is subsequent punishment for arbitrariness.

Features of materials for the manufacture of wells ↑

Filtering or storage tanks are made of concrete, reinforced concrete, metal, and plastic. All these materials have their advantages, and the features of inserting sewer pipes into wells largely depend on their strength and thickness:

Plastic structures

- Concrete and reinforced concrete. The most reliable and practical materials for the construction of storage tanks. They are characterized by high mechanical strength. If properly waterproofed, the tanks will be completely sealed. At the same time, the greatest number of difficulties arise when installing sewerage into a concrete well. The material is thick, durable and difficult to process with tools.

- Metal. Not the best choice for an autonomous sewer system for a private house. Even the highest quality metal tanks last no more than 10-15 years. They quickly collapse under the influence of moisture and chemicals. But it is much easier to arrange the entry into a metal sewer well than into a concrete one. You can always make a hole for the pipe, which will not be much larger than its diameter. This makes it easier to seal the insertion site.

- Plastic. In recent years, industrially produced plastic containers have been increasingly used. They are impermeable to water, do not require additional waterproofing, and tolerate aggressive chemicals well. Problems rarely arise with inserting a pipe into a sewer well, because... ready-made structures are often supplied with all the necessary components. The main thing is not to make a mistake with the diameter.

Welded plastic construction

Causes of leaks

The technology for constructing wells with shafts from modular reinforced concrete structures involves installing rings on a sand-cement mortar. By filling all the uneven joints between the upper and lower rings, the construction mixture should create a reliable barrier against melt and ground water.

Contrary to popular belief, sealing with sand and cement mortar is also necessary for well modules with a locking connection. The presence of the latter prevents the rings from moving, but does not protect the joint from leakage.

When talking about leaks between well rings, people most often remember the deterioration in the quality of drinking water, completely forgetting about the danger of gradual destruction of the well shaft

It should be noted that such primitive waterproofing gives a positive result - the drinking spring shaft remains dry. However, the absence of leaks in the first years of operation is not a guarantee that this idyll will continue forever.

As a rule, even on stable soils, after 4-5 years the surface of the concrete shaft becomes covered with wet spots, which soon turn into dirty streaks and streams. You should not blame yourself or the builders for the fact that the work was done incorrectly. Most often, leakage occurs for completely different reasons:

- Simple mortar is not intended for use in such harsh conditions. Constant humidity, temperature changes and exposure to salts dissolved in water contribute to its cracking and destruction.

- If a well is dug in an area with pronounced seasonal soil movements, then its trunk is subject to regular mechanical stress. As a result, you can observe not only cracks at the joints, but also the mutual displacement of the concrete rings in the horizontal plane.

- In the northern regions, the upper rings are exposed to the forces of frost heaving. Because of this, they can not only move horizontally, but also move up and down.

- Force majeure, expressed in the displacement or subsidence of the rings due to the appearance of quicksand.

- Poor-quality materials - in rings made in violation of technology, various defects may appear over time - through cracks, crumbled areas, etc.

You should take care of waterproofing a well at the stage of its construction - in the future this will save a lot of time and effort

If a well is constructed with the simultaneous laying of rings, then very often even simple sealing with mortar is not performed. In both this and other cases, it will be necessary to carry out a set of measures to ensure reliable waterproofing of joints.

What pipes are used for arranging systems ↑

The features of inserting into a sewer well partly depend on the material and diameter of the pipes. Usually ceramic, asbestos-cement, cast iron, and polymer products are used. There are other varieties, but they are used much less frequently - in exceptional cases.

Option #1: ceramics ↑

It is difficult to imagine a more durable material. It has been used for centuries to make sewer pipes. The most popular diameters are 100-600 mm, material thickness is 20-40 mm, product length is up to 1500 mm. The length of the segments and wall thickness depend on the selected diameter. There are two main types of ceramic pipes - threaded and socketed. You should choose based on the features of the system. The advantages of ceramic products include smooth internal surfaces, resistance to most types of negative influences and ease of installation. There is only one serious drawback - low mechanical strength. Due to the relatively short length of the segments, the system has to be installed with a large number of bends and joints. This negatively affects its tightness.

Ceramic pipes

Option #2: cast iron ↑

Cast iron elements of external sewerage are a classic of the genre. For autonomous systems of private houses, products with a diameter of 160 mm are most often chosen. Material – gray cast iron. It is not afraid of mechanical damage and is resistant to corrosion. When there are temperature changes, cast iron does not lose its performance properties. It can serve for several decades. There are also disadvantages. Due to the rough internal surfaces of pipes, deposits appear on them, which over time become compacted and narrow the diameter. There are also difficulties during installation. This is due to the large weight of the products. When choosing cast iron, you should pay attention to the type of soil. The material does not tolerate contact with saline soils.

Cast iron pipes

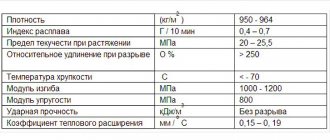

Option #3: plastic ↑

Polymer materials are lightweight, easy to install, and are resistant to chemicals. The most common material for making products is polyvinyl chloride. One of its main advantages is its reasonable price. Depending on the installation conditions of the system, you can select the class of pipes:

- L (lungs). Suitable for laying in shallow trenches - 0.8-2 m.

- N (medium hard). They are used for systems located at a depth of 2-6 m.

- S (hard). Can be used for laying in ditches up to 8 m deep.

For a private home, products with a minimum diameter of 110 mm are suitable. If the system is designed for a large volume of wastewater, you can choose a pipe with a cross-section of 315 mm. An even larger diameter may be required only in cases where a common drainage system is being installed for several houses. It is easy to cut a plastic pipeline into a well and seal it, because For this you can buy ready-made parts and sealing gaskets. If it is necessary to ensure special tightness of the entry point, cold welding is used - special adhesive compositions.

Plastic pipes

How to make an insertion into an internal water supply system?

Sometimes owners need to make a branch from an existing system. In this case, you can use a tee or a curved fitting.

Tee insert

It seems that this task is as simple as possible, but sometimes you can encounter unpleasant surprises. The water is turned off, a section of the pipe is cut out, and a device is installed in its place. However, ease often turns into complexity: installation is difficult due to the proximity of the tee to the wall. For this reason, this method is not very popular now.

Inserting a sewer pipe into a well ↑

- The pipeline is laid from the outlet from the house to the sewer well at a slight slope. The pipe must run in a straight line, without bends or corners. Any bends, dips and differences can cause blockages and disruption of the entire system.

- The depth of the pipeline should be below the soil freezing level, but above the aquifer. If it is not possible to lay pipes at the required depth or the system is installed in an area with a harsh climate, it is additionally insulated with foam plastic.

- Joints and seams are treated with silicone plumbing sealant, and uneven edges of pipe sections are ground to facilitate assembly.

Input of sewerage into a well

- At the point of entry into the well, a hole is made with a slightly larger diameter than the cross-section of the pipe. This is necessary to avoid problems when inserting. If the well is plastic, then special inputs are provided in advance.

- For a septic tank and a differential well, the pipe is cut flush with the inside of the tank wall.

- If the pipes are made of asbestos cement, ceramics or cast iron, they are concreted in the hole. The sealing solution is prepared from cement and sand (1:3), special liquid plasticizers are added. Plasticizing substances are diluted in the proportions indicated on the packaging. Most often, 1 liter is enough per 100 kg of solution.

- Instead of a solution with a plasticizer, you can use ready-made cement paste for cracks and joints in concrete.

Inserting a pipe into a manhole

Sealing the pipe insertion point ↑

- The entry of the sewer pipe into the well is sealed with liquid glass or penetrating compounds.

- For sealing, you can use Hydrotex or Penetron. These are penetrating waterproofing agents. When they react with concrete, they form hydrophobic crystals, improve the structure of the material, and increase its strength.

- To seal HDPE pipes, special kits are used, which can be purchased at hardware stores.

- A drainage sleeve made of crushed stone is created around the well. Select material of large and small fractions, filling them in layers in turn between the walls of the well and the pit.

Types of plastic wells

Some sealing options

When your own sewage system is installed on a site, sealing of all well elements can be done using the following basic methods: painting, plastering or using ready-made sealing compounds.

One of the common methods is painting with a bitumen-gasoline solution . This technique is implemented by layer-by-layer application of the composition. First, a primer layer is applied with a mixture proportion of bitumen and gasoline in equal proportions. The main waterproofing is formed in the form of 2 layers of a mixture of gasoline and bitumen in a ratio of 1:3. When applying external sealant, diluted bitumen (without gasoline) is often used instead of the mixture.

The plastering method is based on applying a cement mortar based on waterproof expanding cement of the VRTs brand; waterproof non-shrinking cement of the VBC brand; There are more than 400 grades of pozzopane cement. The plaster is applied in 3-4 layers, with a total thickness of about 6-8 mm.

One important condition must be observed: after applying such a sealant, it is necessary to ensure that the plaster is moistened for 3-5 days. When this condition is met, the material gradually gains an optimal waterproof, durable structure.