A water well is a hydraulic device for extracting domestic and drinking water from deep aquifers. It is an important element of the water supply system of a private house, cottage or group of houses/cottages. Many people have heard the concept of “artesian well”. So, this is a type of water intake well, the one for which you need to obtain permission.

The task of all water wells is to use special equipment to lift water from the depths and deliver it to a pump or to a house.

Well operation principle

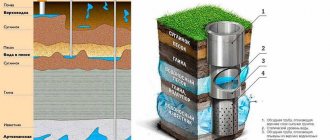

Like a well, the water in it is in an aquifer. Using an installed pump, it is supplied to the top. To strengthen the excavation a casing pipe is installed , for which plastic, steel, perforated or asbestos-cement products are used. If this is not done, then the soil will begin to crumble from the walls, which will cause the well to subsequently cease to function.

The well has the following operating scheme:

- Water is supplied from the aquifer, which first passes through the filter, and then enters the workings of a circular cross-section;

- The turned on pump forces liquid through the water pipe;

- After which the water enters the receiver and moves through the water supply system.

Although the pattern may vary, it all depends on the type of pump used.

Abyssinian well

The igloo well or Abyssinian well is another simple and affordable type of hydraulic structure in terms of financial costs. It consists of a narrow 1…1.5” pipe, at the end of which there is a filter and a needle-shaped tip. The projectile penetrates the soil to a depth of 10...25 meters to the aquifer, thereby bypassing the unstable high water.

To create a needle well, two-meter pipes are taken and sequentially driven into the ground. As they deepen, the pipe sections are connected to each other using threaded connections. Either a manual or electric pump operating on the vacuum principle is installed on the pipe itself.

After organizing water intake, the well is pumped to obtain clean water. It will be suitable for drinking purposes within a day. It is recommended to do a chemical analysis of its composition in a SES or hydrogeological laboratory. As practice shows, after all the preparatory and preventive manipulations with the Abyssinian well, the water will meet sanitary standards.

Advantages

A simple and efficient design that meets the need for small quantities of good quality water, has the following advantages:

- The service life of the well is at least three decades.

- Small dimensions allow you to drill a well in the basement of a private house.

- The possibility of contamination from soil horizons is excluded.

- No permits required.

Flaws

The negative aspects inherent in this type of source include the following disadvantages:

- Since the Abyssinian well is made from a one and a half inch pipe and involves drawing water only with the help of a pump. Surface pumps are not effective beyond ten meters depth.

- The design requires regular cleaning of the pipe from silt and sand.

- The ability to install an Abyssinian well is only available in soft soil conditions.

- The Abyssinian design is picky about the quality of the water carrier and will not work on quicksand; uninterrupted efficiency is possible only on a layer of coarse sand.

When an Abyssinian well becomes clogged, a bailer is used - a cylindrical vessel to extract dirt, silt, and sand.

Types of drilling workings

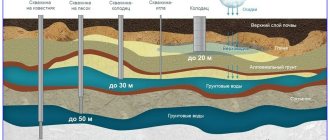

The Abyssinian well is a driven well, which is the simplest option. To equip it on the site, the water layer must have a depth of up to 12 meters .

The quality of its water depends mainly on the structure of the soil. If necessary, such a production can be arranged in the basement. A sand well, the design of which is in great demand, is suitable only for personal use. The water from it is characterized as technical in its properties, therefore it is used only for bathing or watering the garden. On average, the aquifers in this well lie at a depth of about 10-50 meters.

By the way, drilling work in such formations can be done with your own hands, the main thing is that there is no shale passing through the area within a few meters. It is unlikely that you will be able to pass it without the help of professionals.

Of course, sand wells have some disadvantages . The main disadvantage of such production is the interruption of water supply. The problem is related to seasonal changes in the level of life-giving moisture. In addition, it needs to be maintained periodically, especially for summer residents who need water only in the summer. In this situation, the filter located in the well becomes silted over time. This is why the water rise must be regular. In addition, the service life of such a well is no more than 15 years.

Artesian production, although considered the most expensive, is the most effective method of centralized water supply. To drill it, large equipment is used, which allows it to go deeper by about 200–300 meters .

Water from an artesian well is better and of higher quality than from a sand well. Also, the filter in it hardly gets clogged. It is mounted at the bottom of a supply pipe with a diameter of 219 mm. This production guarantees a 99% constant supply of life-giving moisture, and its service life is 50 years.

True, such wells also have disadvantages. For example, sometimes it is necessary to install additional filtration systems, since the water may contain various iron compounds. In addition, as mentioned earlier, its arrangement is expensive. You will also have to obtain permission to drill such a mine and coordinate the project.

Do you need a license to build a water well?

A license is required to construct a well with a depth of more than 50 meters. Before submitting an application for licensing, you need to collect a package of documents. The steps are as follows:

Obtaining permission for geological exploration of subsoil.

Registration of work with the authority.

Receiving technical specifications for work.

Development of a project for prospecting and exploration of subsoil. It then undergoes geological examination.

Coordination of design documentation.

Assessing water volumes, its quality, conducting chemical and bacteriological studies. Collection of data on water flow.

Creation of a hydraulic structure project.

Obtaining a sanitary epidemiological report from Rospotrebnadzor.

Supervision of all work.

Examination, registration and licensing of wells.

The entire process of licensing a well is not quick and quite labor-intensive, on average it takes 6-12 months. Licensing is carried out by a special commission, which then issues permits.

Selecting the necessary equipment

The most important stage in the development of a well is the selection of equipment, since its period of operation and quality of work will depend on it. Basically you should pay attention to the choice:

- caisson;

- hydraulic accumulator;

- head;

- pump

Caisson

It is necessary to protect the mouth from external negative influences.

Such a device serves as a kind of container that protects the upper meters of the mine shaft from the effects of low temperatures in the ground. A sealed caisson container can also be used as a technological volume for installing various equipment that services the well. Installing automation, cleaning filters and other devices in it allows you to save space in the house.

Recent Entries

Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives make Secrets of growing seedlings from the Japanese, who are very sensitive to the soil

Caissons are made from different materials: plastic, metal structures or concrete castings. The installation of this equipment is especially suitable in our climatic conditions, because during severe winters the soil in the dacha area freezes to a depth of one and a half meters. Therefore, horizontally running pipelines must be located below the freezing level.

The coffered hatch installed on the top of the device is usually insulated with sheet foam. A ladder can be placed inside the equipment.

Pumping devices

The pump is the main element of the entire system. It can be of the following types:

- Submersible. This vibration pump is a budget option. It is rarely used for arranging a water supply system, since its productivity is too low. Moreover, it can even destroy the walls of the well.

- Centrifugal. This unit is specialized equipment for water supply from excavations.

- Surface. It is used only when the dynamic level of life-giving moisture in the well does not fall below seven meters.

Today there are many models of well pumps . Their parameters are selected based on the characteristics of the well and water supply system.

By the way, if the pump breaks down, you will not only have to purchase a new one, but also pay for lifting the broken one and installing the purchased one. That is why you should be more serious when choosing a manufacturer.

Hydraulic accumulator design

This well equipment is used to prevent water hammer and regulate the pressure of pipeline contents.

The hydraulic accumulator also maintains a minimum fluid level in the system. During normal operation, inside this device there is a supply of life-giving moisture, and a minimum pressure is also maintained. When using a hydraulic accumulator, the pump turns on less often and wears out less.

The design of such a device is similar to a compensation tank , which is used in heating systems. But the hydraulic accumulator is made from other materials; they do not come into contact with water and do not change its quality. The membrane in it is created from food grade rubber.

Casing head

This device is designed to protect against debris getting into the barrel. In addition, it serves as a support for the suspension of the water-lifting column and pump. The head is made of metal or plastic. In the first case, it can withstand up to 500 kg, and in the second - up to 200 kg. The connection must be sealed using a rubber gasket.

Details

How to find water on the site

When choosing suitable equipment for the source, they carry out exploration work to determine the construction site. The site must provide uninterrupted fluid intake.

There are two main ways to choose a place:

1.Using a pot. This method has been known for a long time; it was used in villages. The determination method does not require financial investment. You will need a clay pot with a volume of one liter containing dry silica gel granules. The pot filled with pebbles is weighed, the weight must be remembered. The pot is wrapped in cloth and buried in the soil about half a meter. A day later, the pot is removed and weighed. The difference in weight will show the amount of liquid that the pebbles have absorbed. So the pot is placed in different places on the site; the place in which the water is located closer to the upper edge of the earth is determined by weight.

2.Through observation. In order not to resort to the services of companies to find out the hydrological features of the site, an observation method is used. In places where moisture lies high to the surface, fog accumulates in the morning. On a warm day, midges swarm over this place.

Features of the design of water intake sources

Before constructing a well, it is necessary to make a diagram of it. Externally, it is a shaft in the form of a circle, but in practice it is a complex structure, because it is necessary to strengthen the walls of the well from destruction. For these purposes, a casing pipe is used. Wells have a simple principle of operation. A pump is lowered into the shaft, with the help of which liquid is taken from the well. The pump itself is connected to the water supply pipeline.

The scheme for constructing a well:

1.Choose a location for the well.

2.Dig a pit, which has a circumference of about two meters and a depth of about two meters. When the aquifer is reached, the walls of the shaft are strengthened: with concrete or wood lining. This serves as protection against collapse during cold weather.

3. Drilling equipment is placed in the center of the pit and a well is drilled. In a private house, a well is made with your own hands, using a tripod, a bailer, a cable and a casing pipe.

Attention! The performance of the structure, the type of soil, and the depth of the well horizon influence the choice of source type.

Features of drilling a well

The bailer is attached to a cable, which is hung over a tripod. The first section of the casing pipe is installed at an angle of 90 degrees from it. It should be installed under strict supervision. The bailer is lowered inside the pipe, pulled to the surface, and thrown again. Under its weight, it breaks the soil. When the bailer drops about 50 centimeters, the device is raised to clear the soil, then work continues.

The process is carried out until the required depth is reached, gradually increasing the casing.

Attention! To drill a well, you can hire a specialized team that, using special equipment, will quickly drill a well, but it will be expensive.

Gravel filter

The bottom of the source is strewn with gravel to protect against the penetration of limestone particles with sand into the water. The filter layer contains medium and small sized particles. Typically, about two buckets of gravel are required.

Installation of a water seal

A water seal is installed to protect the well from rain and melt water.

It is built using clay that was dug out when the mine was dug. Fiber shavings are used as reinforcement, which are added to the clay about five percent of the entire mixture. The clay should be diluted like thick sour cream, add shavings and mix. Next, this solution is poured into the gap around the casing, which has a conical shape. The clay will take one week to dry.

Casing filter

The filter is placed on the casing from below, before it is immersed in the soil. Holes with a cross section of 3 millimeters should be drilled 2 meters from the bottom of the pipe. Wrap the wire in this place in a dense layer, without overlap. The ends of the stainless wire are welded to the pipe.

Another way to organize a filter is to install a special mesh at the end of a pipe with holes. This method will be cheaper. The mesh will last about ten years, and the wire filter will last up to fifty years.

Artesian well drilling technology

If you know what an artesian well is, it will be easier to understand the process of drilling it. This is done in two ways :

- Using a large drilling rig based on a truck (for example, GAZ-66 or ZIL-131).

- Using a portable drilling rig. It is chosen if large equipment cannot enter the drilling site.

In practice, several drilling methods are used. The most common is the rotational method with direct flushing; its share is about 90% of all drilling volumes. The process includes the following steps :

- The drilling machine destroys and erodes rock in the working area using specialized tools and drilling fluid. The waste is washed into a special pit.

Portable water drilling rig Source drillingrig.com

- As a result of the operation of the installation, generation is formed. Its diameter exceeds the diameter of the casing pipes by 40-50 mm.

- When the excavation reaches the aquifer, casing pipes are lowered (planted) into the well, connecting them into a column.

- When casing, pipes with threaded connections are used. They come in metal or plastic. Casing is needed for two reasons: it prevents the well from crumbling and prevents contamination by groundwater.

- A drill head with a smaller (30-50 mm) diameter is lowered into the prepared column. It opens the aquifer and flushes the well with clean water.

- The owner is invited to lift the drill rods to measure the depth of the well. Drill rods are hollow equipment that serves to transmit rotation and at the same time supply drilling fluid.

- The rest of the equipment, filters, and pump are being installed.

Heavy equipment Source puls-rf.ru

Aquifers

To understand the principle of operation of a well, you need to know what aquifers are.

Groundwater accumulates in rocks: sand, clay, stone. Rock that is sufficiently saturated with water in a liquid (not frozen) state is called an aquifer. Water is extracted from these horizons.

The driller's job is to drill the canal so as to touch the aquifer. Under the influence of reservoir pressure, the water will rise, and it can be pumped out. These features of the soil structure determined the speed with which water wells replaced the traditional well.

The advantages of drilling are as follows:

- Ability to quickly go deep.

- High performance - the greater the depth, the higher the pressure, the faster the level in the intake pipe is restored.

- Safety - there is less risk of deformation of the mine shaft when it hits quicksand or an underground flow.

Water quality

Typical protocol for chemical analysis of water from an artesian aquifer:

Since the water is in limestone, it is saturated with calcium and magnesium salts. That is, with an increased concentration of hardness salts. Unfortunately, this is the norm, not the exception. It is not advisable to direct hard water into heating and heating systems; scale will quickly damage the equipment. A good example is scale in a kettle. To make water drinkable and safe for equipment, filters are needed.

An increased content of dissolved iron is the second pattern. At the SanPin norm of 0.3 mg/liter, the average iron content in artesian water is 2 mg/liter. Western and northern directions are characterized by even higher concentrations - more than 3 mg/liter.

The 3rd and 4th places are shared by hydrogen sulfide (when the water has a pungent odor) and manganese.

Modern water treatment systems easily cope with their functions, bringing water to drinking standards (photo 10).

Main characteristics

Depending on the purpose of the well, an analysis will be required for a number of parameters that describe the level of abundance of the aquifer and the rate of restoration of the water resource after water intake. This data is necessary to determine whether it can fully solve the problem of providing water in a particular case. In general, all types of water intakes are characterized by the following parameters:

- Piezometric level. The depth is measured from the soil surface to the exposed aquifer.

- The level of water conductivity of a well is measured in cubic meters, which the water intake point can produce within 24 hours.

- The dynamic level is calculated during the active use of the well; the level to which the water rises along the length of the pipe is checked and recorded.

- The establishment of the indicator based on the statistical level of the well occurs an hour after the cessation of water intake. During this period, the bottomhole pressure comes into balance with the pressure of the formation located above the aquifer, the water level is fixed, and it stops rising.

- Based on the static and dynamic characteristics of the well, the debit of the water intake point is calculated . It is calculated as the ratio of extracted water to its inflow. Find out the main characteristic showing how much water a well can produce in a specific time period.

Wells with a high level of water yield have a difference in dynamic and statistical levels that does not exceed a meter. Artesian wells are characterized by equal static and dynamic levels.

As you can see, the types of water intake structures have their pros and cons. What is suitable for a large village may not be effective for individuals and vice versa. When choosing a well type, it is necessary to take into account not only economic features, but also geological parameters and hydrogeological conditions.

Drilling methods

Commonly used drilling methods include:

- screw;

- manual;

- shock-rope;

- rotary.

The manual method is the most labor-intensive. It involves the rotation of a small auger with attachments and involves drilling to a depth of no more than 10 m.

It is possible to drill deeper, and there are even examples when they drilled to 25 m, but this is a very labor-intensive process that takes a lot of time and effort. Today, manual drilling is fading into the background, since due to the shallow depth of occurrence, only untreated water can be obtained, unsuitable for drinking.

The screw version is one of the most modern today. It is possible to make a hole in the ground up to 80–100 m, with a well diameter of up to 60 cm. All this allows you to create a reliable well design, which will have a casing pipe and a main pipeline for lowering the pump underground. The casing will protect against soil displacement and will protect the pipeline from breakage.

Using mechanical drilling with an auger, mining into limestone is possible if the water in these layers is shallow. Work up to 80 m can take up to 2–3 days.

Rotary drilling technology assumes the possibility of construction at great depths. This scheme is similar to the operation of a hammer drill, where waste soil is brought to the surface through constant washing.

Rotary drilling is one of the most expensive, but the most reliable. As a result, we obtain the design of a well for water with a depth of up to 300 m inclusive. Upon completion of the work, the well must be pumped by draining the water for 24 hours (this time will be required to pump out the dirt). Then you can lower the equipment and install the head.

Finally, cable percussion drilling. This method appeared earlier than all of the above. The principle of operation of the shock-rope system is to construct a triangle , at the top of which there is a “glass” tending downward, which, under its own weight, falls at high speed to the ground and breaks it. Removal of waste soil is carried out using the same glass, which has a cavity inside.

The video shows how a well is drilled using the percussion-rope method:

?t=59

One of the main advantages, despite the labor-intensive work process, is the high-quality opening of the aquifer, which does not imply its contamination at the time of passage by the drilling rig.

Casing

The durability of an artesian well depends on the quality of the casing strings, which are assembled from individual casing pipes. When the casing is subject to through corrosion or destruction, the water intake unit ceases to perform its functions.

- Steel pipes

The casing consists of individual pipes with a diameter of 133 or 159 mm, connected to each other via threads (photo 4 on the left).

The first manifestations of through corrosion – fistulas – will appear on threaded connections. The later this happens, the more durable the well.

According to calculations and operating experience, through corrosion is not dangerous for 25–30 years.

The coupling threaded connection lasts 10 - 15 years longer (photo 5).

Obviously, the thinner the pipe wall is, the faster it will rot. For steel pipes, the minimum wall thickness is 4 mm with an optimal value of 4.5 mm (photo 6).

For an artesian well, a diameter of 133 mm is sufficient for one cottage, and 159 mm for several houses.

Pipes with a diameter of 159 mm are used as a conductor (diagram 2).

— HDPE pipes

HDPE (low-density polyethylene) plastic pipes are used for internal casings, connecting them with threads (photo 4 on the right). Recommended wall thickness is 7.5 mm or more.

Since the material is not subject to corrosion, the service life of the pipes is more than 50 years.

The applied diameters are 117 and 125 mm.

— uPVC pipes

uPVC plastic pipes can be used as an external (main) casing with an installation depth of up to 100 meters. The minimum wall thickness for diameters 125 mm, 140 mm and 170 mm is 7.5 mm, 8 mm, 8 mm, respectively. The column is assembled on a socket threaded connection (photo 7).

The material is not subject to corrosion, the service life is more than 50 years.

The use of pipes with a wall thickness of 6 mm or less is unacceptable.