Not a single industrial sector can do without the use of rolled metal - metal blanks that have been processed on a machine. The shape of the workpiece can be very different. Its choice depends on the application in which industry it is intended.

There are many types of rolled metal. But the most popular of them are the following:

- rolled metal products;

- shaped;

- sheet and pipe products.

It’s easy to guess what sheet and pipe products are from the name. Therefore, it is advisable to consider the differences between shaped and long products.

Classification of rolled metal products

Long-rolled metal products

There are long-rolled, pipe, sheet and shaped rolled metal, but it is long-rolled metal that has the greatest variety of subtypes. Basically, these are not final products, but semi-finished products intended for the manufacture of certain structures and parts.

There are 3 groups of long products:

- Metal products with a simple cross-section: hexagon, circle, square, strip. These elements are most often made of carbon steel and can have any size - from small to very large;

- Shaped (curly) rolled metal products for general and special purposes. Channels and angles are especially in demand due to their wide range of applications. A channel is a beam with a cross-section in the shape of the letter P. The shelves of the channel are on one side of the wall. Channels can be special steel, hot-rolled, bent, perforated, unequal, with edges located at a certain angle and with parallel edges. The corner has a cross-section in the shape of the letter “L”. The edges can have different sizes and thicknesses;

- Reinforcement (corrugated and smooth) used to reinforce reinforced concrete structures and wheels. This category, according to some sources, may belong to the second group, which is not a mistake.

You can distinguish simple rolled products from shaped ones if you know the clear rule prescribed in the technical documentation. A section of a simple rolled metal product cannot be intersected tangent to any of the points located along the contour of this section. A section of a shaped product can intersect at least one tangent to a contour point.

There are several more classification features, knowing which makes it easier to choose the right position.

By surface treatment method

- Matte;

- Mirror;

- Polished;

- Calibrated.

According to GOST

- First grade. Long-rolled metal does not require additional processing, because characterized by maximum physical and technical parameters.

- Second class. For further use it is processed under hot pressure;

- Third class. Processed by cold mechanical means, cutting.

To size

- Large. Round products with a cross-sectional diameter from 80 mm, square with a cross-section from 70 mm, reinforcing profiles, corners with flange sizes from 90 mm, I-beams (regular and lightweight), column profiles, channels, hexagonal and strip steel, rails, etc. . Large-section products are made from carbon steel or low-alloy structural steel.

- Average. Shaped profiles used in a specific industry, narrow-gauge rails, rolled products with a section in the shape of a circle, square, hexagon, I-beams, strips, etc.

- Small. Today you can buy long rolled metal products in the form of precise, neat blanks of very small sizes: round with a diameter of up to 30 mm, square with a cross-section of up to 10 mm, angle steel with a flange size of up to 50 mm, rods, strip steel, channels. Small rolled products are sold in the form of coils and rods.

In addition to steel used to create large rolled metal products, high-alloy and stainless alloys are suitable for the production of medium and small rolled products.

Today, rolled metal products are in great demand. The most popular products are round pipes, angles, beams, sheet metal, circles and more.

This is interesting: Comparison of metal and fiberglass reinforcement: determining which is better

Rolled blanks

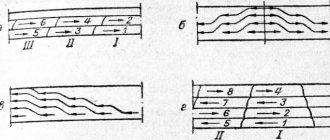

In Fig. 2.11. the main rolling methods are shown.

Fig.2.11. The main methods of rolling: a – longitudinal; b – transverse; c – screw.

During longitudinal rolling, the metal, under the influence of frictional forces, is drawn into the gap between the rolls rotating in different directions. Almost 90% of all rolled products (sheets and profiles) are produced by longitudinal rolling.

During transverse and helical rolling, the workpiece is deformed by rollers rotating in one direction. During helical rolling, in addition to rotational motion, the metal also receives translational motion. This type of rolling is used to produce pipes. In Fig. 2.12. a range of longitudinal rolling products is presented.

In our country, almost all products obtained by rolling are standardized. The standards provide dimensions, cross-sectional area, weight per unit length of the profile and permissible deviations from the nominal dimensions. The standards for profiles (beams, channels, angles, etc.) used for the manufacture of various structures also provide the moment of resistance, moment of inertia, radius of gyration, etc.

Rice. 2.12. Range of rolled products: 1 – circle; 2 – square; 3 – hexagon; 4 – strip; 5 – leaf; 6 – segment steel; 7 – oval steel; 8 – triangular steel; 9 – isosceles corner; 10 – unequal corner; 11 – T-beam; 12 – channel; 13 – I-beam; 14 – rail.

All rolled products, depending on their shape, are divided into four main groups: long steel, sheet steel, pipes and special types of rolled products.

Depending on the purpose, long products are divided into general purpose profiles (round timber, square, strips, angle, channel, I-beam, etc.) and special purpose (rails and profiles for automotive and tractor manufacturing, construction, carriage building, etc.) purposes.

The main technological operations of rolling production are: preparation of the starting metal; heat; rolling; rental finishing.

Preparing source metals (ingots and billets) for rolling involves removing various surface defects, which increases the yield of finished products.

Heating of ingots and billets before rolling should ensure their high ductility, high quality of the finished product and obtaining the required metal structure.

When rolling, the initial and final temperatures, the specified compression mode are controlled, the roll settings are checked, and the dimensions and shape of the rolled product are checked.

Finishing of rolled products involves removing scale and cutting into dimensional pieces.

Rolling of sheets and strips is carried out in smooth rolls. Reducing the thickness of the rolled metal in each pass is achieved by bringing the rolls closer to a given distance.

Rolling of long and shaped metal (square, circle, channel, rail, etc.) is carried out in calibrated or grooved rolls, i.e. On the working surfaces of the rolls, recesses (streams) of the required shape of the rolled product are made. The gap between two recesses in the rolls is called a caliber.

If rolled products are produced with pre-heating of the billets, then it will be hot rolled, and without heating, it will be cold rolled. Cold rolling is used primarily for the production of sheets and strips with a thickness of less than 3 mm.

After rolling, the product is subjected to straightening (especially sheet metal on roller straightening machines) and cutting into dimensional pieces on various cutting machines (scissors, presses, etc.).

There are sheet rolling, profile and pipe rolling production.

Rolled sheets in the automotive industry are used to make bodies and many suspension and frame parts.

Profile metal is used as blanks for stamping production in the manufacture of various parts with complex configurations of engines, gearboxes, axles, etc., as well as during repairs for the manufacture of new or repair parts through mechanical and heat treatment.

2.3. Blanks produced by forging and stamping

Forging and stamping are characterized by uneven deformation. To estimate the amount of deformation during forging and stamping, the forging coefficient is used, which is expressed.

K0c=F2/F1=H/h>l, (2.1.)

where F1 and F2 are the cross-sectional area of the forging before and after it, respectively.

The task of forging and stamping production is to produce blanks (sometimes parts) of the required shape and size with a given surface finish and physical and mechanical properties.

Forging and stamping are classified as forging processing methods. Forging is the process of obtaining workpieces by applying impact loads to the metal surface with a special tool (sledgehammer, hammer, striker). In free forging, the metal between the flat strikers in mechanized forging and between the sledgehammer and anvil in hand forging flows freely to the sides. Open forging is very labor-intensive and complex and is usually used to produce blanks for stamping production in order to give the required shape close to the finished part (for example, steel crankshafts and other parts).

All large forgings weighing up to 250 tons or more are produced using the open forging method. Small and medium forgings are processed in small batches. The starting materials for free forging are ingots, blooms, blanks and rolled rod blanks.

The tool used in open forging is shown in Fig. 2.13.

It is advisable to use open forging in the individual production of forgings of complex configurations.

Advantages of free forging:

- versatility in terms of weight, shape and size of workpieces;

- lower costs for technological equipment;

- possibility of using low-power forging machines.

For mass production of forgings, stamping is used, the productivity of which is tens of times greater than with open forging, and the qualifications of workers can be significantly lower. Due to this, significantly greater dimensional accuracy and surface cleanliness are achieved, which reduces allowances for subsequent machining. Stamping can be volumetric and sheet, hot or cold.

Rice. 2.13. Tools for open-loop forging: a – strikers; b – crimping; c – basting, pinching and rolling; g – axes; d – firmware

The most typical open forging operations are shown in Fig. 2.14.

Rice. 2.14. Open forging operations: a – upsetting; b – distribution, c – disembarkation; g – broach; d – acceleration; e – firmware.

In hot die forging, the shaping of forgings is carried out in dies, the working cavities (streams) of which allow the flow of deformed metal only in a certain direction and to certain sizes, as a result of which the forced production of a given shape and size of the forging is achieved. Hot stamping produces forgings of various shapes and sizes from steel, non-ferrous metals and alloys. The hot stamping process consists of the following operations:

- cutting blanks;

- heating of workpieces;

- stamping itself (in several transitions or operations);

- trimming flash and cleaning burrs;

- heat treatment;

- editing and calibration;

- surface finishing.

Stamping can be carried out in open and closed dies. In open dies, the forging is obtained with a flash - some excess material in the original workpiece, displaced during stamping into the flash groove. In closed dies, the forging is flash-free. In Fig. 2.15. designs of open and closed dies are shown.

Rice. 2.15. Stamping in open (a) and closed (b) dies: 1 – upper half of the die; 2 – lower half of the stamp; 3 – forging configuration; 4 – store; 5 – bridge.

In open dies, along the entire outer contour of the stamping stream along the dividing line of the upper and lower halves of the die, a special narrow flash groove is made, through which excess metal is squeezed into the cavity (magazine) and a flash is formed, which, after receiving the workpiece, must be removed by punching, cutting or chipping. As the metal flows into the flash groove, the pressure increases, which forces the metal to fill the entire cavity of the die groove, ensuring good formation of the forging. Metal waste in scrap can be up to 10...20% of the mass of forgings. When stamping in closed (flareless) dies, the metal is deformed in a confined space. In this case, metal consumption is reduced by up to 20% and the cost of trimming the flash is eliminated. However, closed dies are difficult to make for parts with complex shapes, are very expensive to manufacture and quickly fail. In addition, high volumetric accuracy is required when producing the preform. Deviations in a larger direction lead to an increase in the size of the resulting workpiece and rapid failure of the dies, and in a smaller direction - to the appearance of defects due to incomplete filling of the die groove.

Cold die forging is performed in both open and closed dies and is a highly productive, efficient process for manufacturing small and precise blanks and parts from steel and non-ferrous metals and alloys, with high surface finish, while the metal is hardened (hardened) and its mechanical and physical properties change.

The main operations of volumetric cold stamping are volumetric forming, extrusion (pressing), calibration, upsetting and embossing (Fig. 2.16).

Volume molding is an operation in which a workpiece is obtained by compression in an open or closed die.

Cold extrusion is the production of solid and hollow thin-walled products from a thick workpiece by extruding metal into the gap between the punch and the matrix. It is performed in direct, reverse or combined ways.

Rice. 2.16. Cold die forging operations: a – volumetric molding; b,c,d – cold extrusion; 1 – punch; 2 – matrix; 3 – product.

Cold calibration is used to obtain accurate dimensions and reduce the roughness of workpieces produced by hot die forging or casting.

Cold heading is used to form local thickenings of workpieces of the required shape (bolt heads, rivets, screws, and other parts).

Embossing is the operation of obtaining a corrugated surface on parts.

Sheet stamping is a method of producing flat and three-dimensional thin-walled products from sheet, tape or strip using stamping with or without heating. The production of blanks from sheets with a thickness of 0.1 ... 5.0 mm is usually done by cold stamping, and when the thickness of sheets is more than 5 mm, hot stamping is used.

Advantages of sheet stamping:

- the ability to manufacture strong, rigid, thin-walled parts of simple and complex shapes;

- high process productivity;

- economical metal consumption;

- simplicity of the process;

- possibility of mechanization and automation of the process.

Sheet stamping produces parts of bodies, frames, containers, suspension arms and other parts.

All sheet stamping operations can be divided into separation (separating one part of the workpiece from another) and form-changing (producing products of complex shape by moving elementary volumes of metal from the original workpiece without destroying it).

Separation operations:

- cutting – sequential separation of a part of the material from the original workpiece along a straight or curved line;

- cutting is a one-time separation of material from the original workpiece along a closed contour, with the separated part being the product.

- punching - making holes along a closed contour inside a part by separating part of the material.

Form-changing operations:

straightening is used to eliminate irregularities and curvatures, flat parts after cutting or punching;

- bending can be single-angled (V-shaped); multi-angle;

- drawing - an operation that turns a flat workpiece into a hollow part or blank;

- broaching – drawing with thinning, used for the manufacture of hollow thin-walled parts;

- flanging and flanging - operations for forming a bead along the outer contour of the workpiece or along the contour of a previously made hole;

- molding - changing the shape of a workpiece through local deformations.

In Fig. 2.17. the main separation operations of sheet stamping are shown, and in Fig. 2.18. – form-changing operations of sheet stamping.

2.4. Powder metallurgy blanks.

This type of blank is used to produce parts that cannot be produced by other methods. For example, from refractory metals (tungsten, molybdenum, vanadium, etc.), from metals that do not form alloys with each other, from metals and non-metals (copper and graphite, graphite and asbestos, copper and asbestos and others).

Blanks are produced from powders of various metals, or metals and non-metals (graphite, silica, asbestos, etc.) using powder metallurgy. The mixture of powders is pressed in molds under pressure (1...6) * 103 kgf/cm2 and then sintered

Rice. 2.17. Separation operations of sheet stamping: a – cutting; b – cutting; 1– punch; 2 – matrix; 3 – product; 4 – waste.

Rice. 2.18. Form-changing operations of sheet stamping: 1 – punches; 2 – matrices; 3 – products or semi-finished products at a temperature below the melting point of the main component.

This method produces such car parts as: copper-graphite sliding bearings for starters and other components, brake pad linings, clutch disc linings, magnets, contacts, copper-graphite and graphite brushes, and other parts.

This method provides the possibility of complete automation of the process, minimal waste of raw materials, high accuracy and quality of products that do not require subsequent mechanical processing.

Features of the production of long rolled metal products

In addition to physical characteristics and size, the price of long rolled metal depends on the method of its manufacture.

Hot rolled metal

Hot Rolled Round Bar

Heating the workpiece before placing it in the rolling mill speeds up the manufacturing process. The products obtained in this way are characterized by a uniform structure and reduced internal stress. This makes further machining easier.

Hot rolling is used to create large-sized products, profiles from simple alloys and other parts, the production of which is difficult without heating.

Cold rolled metal

Cold rolled metal

The main feature of products produced by cold rolling is surface hardening. The method is suitable for the production of small-format profiles; it improves the physical and mechanical parameters of the product.

At the end of the manufacturing process, long rolled metal products must be marked. The marking contains all the geometric data, information about the accuracy of processing, the metal used and the manufacturing method.

The production methods for long products are regularly adjusted and improved to ensure that the products meet the stringent (and constantly growing) requirements for finished products. Maximum precision and the highest performance characteristics are required in mechanical engineering, shipbuilding, and the construction of strategic facilities. The use of new generation technology makes it possible to easily solve problems that seemed impossible one or two decades ago.

If the manufactured rolled products are intended for use in industries requiring special properties of the metal (corrosion resistance, other characteristics), this must be taken into account at the production stage. Special components are added to the metal and special surface treatment is performed.

Characteristics and features of pipe products

Pipes are a fairly common category of rolled products. Main characteristics of these products:

- total length;

- wall thickness;

- internal and external diameters;

- type of material;

- preparation method.

Most pipe products are round, but square and flat pipes are also produced. There are several manufacturing methods:

- rolling;

- pressing;

- casting;

- welding.

The main part of metal pipe products has a round cross-section.

Depending on the specifics of the manufacturing process, pipes can be seamless or welded. Seamless ones are used for transporting gases and liquids under pressure above 1 MPa. Welded pipes are created by folding a strip (rolled strip), laying it end-to-end and overlapping, and welding the seam. These products are used to move gases and liquids at low pressure.

Steel pipe: GOST, diameter, weight, wall thickness (read more)

Requirements for pipe products are regulated by the following documents:

- GOST 10705-80 – electric welded pipes;

- GOST 10704-91 – straight-seam products;

- GOST 8732-78 – seamless pipes;

- GOST 3262-75 (TU) – water and gas pipelines;

- GOST 8645-68 – rectangular profiles;

- GOST 8639-82 – square profiles.

Pipes are used in the gas and oil industries, mechanical engineering, and construction. They are used for laying various pipelines, for the manufacture of industrial cylinders and vessels.

Equipment

To understand how different parts are made, you need to know what equipment is used during technological processes. Rolling is carried out on the following machines:

- Wire mechanisms. With their help, wire with a diameter of up to 10 mm is produced.

- Slabs - designed for processing long rectangular products.

- Bloomings - used in the manufacture of large square products. In addition to square sections, mechanisms can make blanks of various shapes.

- Pipe rolling are industrial machines that are used to create metal pipes of different diameters.

Before rolling begins, the metal is heated using industrial furnaces and fed through cutting shears to rotating shafts.

Execution technique

Experts distinguish two methods of rolling:

- Metal ingots are heated and fed to special clamping mechanisms. The surface of the workpiece is cleaned of formed defects. The workpieces are heated again and fed through the rotating shafts again.

- An industrial method that involves continuous casting without interruption. Molten metal is fed under rotating rollers. This method is suitable for processing non-ferrous metals.

Next, the products are subjected to turning, grinding, milling, boring, drilling, and cutting. Stages of rolling aluminum alloys:

- The sheet passes through movable rollers to create smooth surfaces.

- The metal is milled.

- Aluminum sheets are placed on the workpiece on both sides.

- The part is heating up.

The last stages are annealing and cold rolling.

Rolling is a technological operation by which metal parts of different sizes and shapes are produced. There are several processing methods. Products made using this processing method are popular in various industries.

What is included in the concept of “shaped rolled products”?

According to GOST 535-2005, shaped metal products include metal products in which some tangents to the section contours intersect this section.

- I-beam is a hot-rolled product with a cross section in the shape of the letter “H”. It is manufactured with the internal edges of the shelves - parallel (GOST 26020-83 and STO ASChM 20-93) or located at an angle (GOST 8239-89). These metal products are used mainly in mass housing construction; they are rarely used for the construction of private houses.

- Channel is a hot-rolled product with a cross section in the shape of the letter “P”. It is manufactured with the inner edges of the shelves - parallel or inclined - in accordance with GOST 8240-89. The areas of application of rolled metal are individual and mass construction, the construction of various frame structures, small forms - canopies, greenhouses, gazebos.

- Corner. Hot rolled equal flange angles are regulated by GOST 85009-83, unequal flange angles are regulated by GOST 8510-86. The side size of an equal angle angle is in the range of 2-25 cm. The angle is intended for construction, mechanical engineering, manufacturing of production equipment, and household appliances.

This is interesting: Corrugated aluminum sheets: types, application, GOST

Distinctive features

Rolled metal is made from various steel alloys. It is divided into two main types:

- shaped;

- long products.

How are they different? In simple terms, the shaped type includes hollow metal elements. This means that in cross section they have a solid non-convex geometric figure. Prominent representatives of this variety are corners, channels and profiles. The varietal type includes metal elements that do not have a cavity. That is, they are convex in cross section. You can imagine rolled metal products by looking at a metal rod.

Rolled pipes: types and characteristics

Pipes have a round or profile (different from round) cross-section, are made seamless or with a welded seam (straight - one or more, spiral.

- Round pipes. Seamless hot-rolled products are used in areas that require high resistance to various types of influences, for example, for the transmission of media under pressure. Cheaper and more common products are welded pipes. One of the varieties of welded pipe products - VGP pipes (water and gas pipes) - is widely in demand in housing and communal services for organizing pipeline systems for water, heat and gas supply.

- Profile pipes – rectangular and square. These metal products are not used for transmitting gaseous and liquid media. Profile pipe products are in demand in frame construction, for the manufacture of canopies, greenhouses, and gazebos.

Table of main rental characteristics

| Rental name | Basic GOSTs | Size range | Main Applications |

| Long products | |||

| Hot rolled circle | 2590-2006 | Diameters – 5-300 mm | Production of fasteners, blanks for cold deformation |

| Cold-deformed circle | 7417-75 | Diameters – 3-100 mm | Manufacturing of fasteners and other parts on automatic machines |

| Hot rolled square | 2591-88 | Side size – 8-200 mm | Fastener production, construction |

| Cold-deformed square | 8559-75 | Side size – 3-100 mm | Manufacturing of parts for automobile and mechanical engineering |

| Hot rolled hexagon | 2879-2006 | Diameter of inscribed circle – 8-103 mm | Production of fasteners, machine parts and mechanisms |

| Band | 103-2006 | Thickness – 4-80, width – 10-200 mm | Production of bent profiles, pipes, construction, installation of grounding loops, decorative, finishing works |

| Shaped products | |||

| Corner | 85009-83 | Side size of equal angle angle – 20-250 mm | Construction (production of various metal structures, reinforcement of reinforced concrete elements), production of machines, mechanisms, industrial equipment, racks for pipelines |

| Channel | 8240-89 | Channel wall height – 5-40 cm | Construction, installation of span structures, production of frames for finishing materials, production of advertising media |

| I-beam | 8239-89 | Wall height – 10-60 cm | Civil, industrial, infrastructure construction |

| Sheet metal | |||

| Hot rolled sheet | 19903-2015 | Thickness – 0.5-160.0 mm | Production of pipes, bent profiles, production of decking, continuous fencing, rolling for cold-rolled sheets, boiler building |

| Cold rolled sheet | 19904-90 | Thickness – 0.35-5.0 mm | Automotive and mechanical engineering |

| Pipe rolled products | |||

| Round seamless | 8732-78 | Outer diameter – 20-550 mm | Transfer of liquid and gas media at high temperatures and pressure, creation of metal structures |

| Round electric-welded straight-seam | 10704-91 | Outer diameter – 10-245 mm | Organization of water, gas, heat supply systems |

| Profile welded | 8645-68 | Length – 15-230 mm, height – 10-150 mm | Frame construction, production of stairs, fences |

Types of rolled metal

Different types of rolled metal can be distinguished based on the following characteristics:

- production features: hot rolled (produced at temperatures above the recrystallization temperature), cold rolled (produced at temperatures below the recrystallization threshold);

- alloy used: black (from cast iron and carbon steels), non-ferrous (from aluminum, copper, titanium, nickel, cadmium, tin, other metals), stainless;

- surface treatment method: can be matte, mirror, polished, calibrated.

There are also several types of rolled metal based on the type of finished product:

- sheet - sheet steel, tape;

- high-quality - made on special machines, with a cross-section of different shapes (circle, hexagon, strip, square);

- shaped - with a complex cross-sectional shape (rails, channels, angles);

- rolled pipes - welded, cold-drawn, hot-rolled pipes, which can have a round, oval or rectangular cross-section.

Application of long products

The varietal type is, in fact, a semi-finished product from which finished products are obtained through further processing. This material is widely used in construction. It is used to produce structural elements of buildings and structures, as well as many other products.

After additional processing, the following is made from varietal-type blanks:

- parts for various mechanisms;

- fasteners;

- bent profiles.

Rolled profile profiling technology

Types of varietal products

The main feature of this type is that its cross section has a simple geometric shape. It is divided into the following varieties:

- simple;

- fittings

There are several types of simple rental:

- round;

- square;

- hexagonal;

- strip.

Reinforcement is a set of simple elements that are connected to each other. Reinforcement is used in the construction of reinforced concrete structures in combination with concrete. This product allows you to enhance the properties of concrete or serve to stretch it.

Types of fittings

Depending on the quality of the surface, such rolled steel is divided into the following groups:

- 1GP – a product that does not require further surface treatment;

- 2GP – a product whose surface requires hot pressure treatment;

- 3GP is a product whose surface is processed using a cold method, which involves mechanical cutting.

Application of steel circle

Steel circle is one of the most common types of products in question. This product is made in the form of a steel rod with a round cross-section. The standard diameter of a steel circle varies from 5 to 270 mm. However, if necessary, the diameter of the circle can be increased to 330 mm.

The steel circle has found wide application in mechanical engineering. In this area of industry, it is used for the manufacture of various bushings, shafts, axles and other parts included in the design of machines. In addition, it is used in the manufacture of fences, forged products, including fences, bars on windows and doors, and other products.

Application of steel circle in the manufacture of gratings

The use of squares and hexagons

The square type of product, like the hexagonal one, is the same steel rod having either a square or hexagonal cross section. Their sides have standard dimensions, ranging from 6 to 200 mm. Manufacturing products of larger sizes is possible only upon individual order.

These types are most often used in construction. Structural elements of gates, fences, benches and other structures are made from them.

Application of strip products

Steel strips are used in the manufacture of metal structures, as well as bent profiles, for example, corners. Strip products are used in the manufacture of automobile springs, various cutting tools, or as structural elements that work in tension. Sectioned rolled metal strips are also used in the manufacture of pipes and various decorative elements.

Classification

By profile size

Based on profile size, long products are divided into:

- large

- round steel with a diameter of 80-250 mm, square steel with a side of 70-200 mm, periodic reinforcing profiles No. 70-80, corner steel with a flange width of 90-250 mm, channels and I-beams, regular and lightweight, with a height of 360-600 mm, special wide-flange I-beams and column profiles up to 1000 mm high, hexagonal steel up to No. 100, railway rails 1 m long with a weight of 43-75 kg, strip steel up to 250 mm wide, etc.; - medium

- round with a diameter of 32-75 mm, square with a side of 32-65 mm and hexagonal up to No. 70, steel periodic reinforcing profile No. 32-60, I-beams up to 300 mm high, channels with a height of 100-300 mm, narrow gauge rails P18 —P24, strips with a cross-section up to 8×145 mm, various shaped profiles for industrial purposes, etc.; - small

- round steel with a diameter of 10-30 mm, square steel with a side of 8-10 mm, periodic reinforcing profile No. 6-28, corner steel with a flange width of 20-50 mm, channels No. 5-8, strip steel up to 60 mm wide, hex steel up to No. 30 and a variety of industry profiles in equivalent sizes.

Flat rolled products

- plate steel (thickness over 4 mm);

- hot-rolled sheet steel (thickness less than 4 mm);

- cold rolled thin sheet steel (thickness less than 4 mm).

Flat products include coiled steel, sheet steel, tin, and strip.

Long products

Wire rod, grinding balls and other types of rolled products for which the tangent to any point of the perimeter of its cross section does not intersect this section.

- simple (circle, square, hexagon, flat strip);

- Shaped (angle, channel, I-beam, rails, special profiles for shipbuilding and other types of rolled products in which the tangent to at least one point of the cross-section perimeter intersects this section).

Also, shaped rolled products are divided into

- rolled products for general (mass) consumption (square, circle, strip steel, hexagon, corner profiles, channels, I-beams, z-shaped profile);

- rolled products for special purposes (railway rails, tram rails, profiles for car rims, springs, mine fastenings, tractor spurs, sheet piles, triangular profiles, wedge, oval and rhombic profiles).

Pipes

Pipes are divided into

- seamless;

- welded;

- shaped;

- pipes of variable section.

Thin-walled, precision, capillary and high-precision pipes are also distinguished.

Special profiles

- Shaped precision profiles are produced by hot and cold rolling and drawing on mills.

- Bent profiles, made from sheets and strips 0.2–20 mm thick, are used in various industries and for domestic purposes. Compared to hot-rolled ones, bent profiles provide greater accuracy, are thinner, and can have a closed shape that cannot be obtained by rolling.

Application of shaped steel

Depending on the scope of application, shaped products are divided into two types:

- mass purpose;

- special purpose.

The greatest demand, of course, is for mass-use rolled metal. This type includes the following products:

- steel corners;

- steel channels;

- steel I-beams.

Rolled steel profiles for special purposes are used primarily in the construction of railway and tram tracks, mine workings, as well as in other special industries.

Application of corners

Corners are the most common type of product that has found widespread use. The standard width of their shelves varies between 20-250 mm. The wall thickness most often depends on the previous value and can range from 5 mm to 12 mm.

Metal corners are used in various industries

Application of channels

A channel is a type of shaped metal product whose cross section is shaped like the letter “P”. These products are used in almost all industrial sectors. Without them, it is impossible to build a building, create a car, or make any other equipment.

Channels have different cross-sectional heights, which directly affects the strength characteristics of the products.

Application of I-beams

I-beams are products made in the shape of the letter “H”. They are most often used in construction, in particular, in the construction of various structures and bridges.

In addition, I-beams are used in the machine-building and carriage-building industries.

The height of their shelves ranges from 100 mm to 1000 mm, and the width from 55 mm to 400 mm. Based on the size range, I-beams are divided into the following types:

- standard;

- wide flange;

- columned

Shaped metal products

Shaped metal products have a complex shape and come in the following varieties:

- Channel is a U-shaped profile in cross section, made by hot rolling. Due to its ability to withstand high longitudinal and transverse loads, the channel is widely used in mechanical engineering, as well as in the reinforcement of reinforced concrete, the construction of metal structures, and anchor posts.

- I-beam (beam) is a shaped rolled product with an H-shaped cross section, made of carbon or low-alloy steel. The shape contributes to high rigidity and load-bearing capacity while reducing weight, which allows the use of I-beams when installing floors and as supporting elements.

- An angle is a metal plate bent lengthwise, used in the automotive industry, carriage building, mechanical engineering, as well as in construction for installing reinforced concrete lintels and connecting metal and wooden products.

Separately, we can highlight rails - a special type of rolled metal that is used in the construction and repair of railways.

What is rolled metal made of?

Various types of steel and alloys can be used in its production. These include:

- carbon steel or so-called ferrous metal;

- alloy steel, the strength and performance characteristics of which are improved by adding various chemical components;

- stainless steel;

- aluminum;

- copper;

- tin.

This is not a complete list of materials used in the manufacture of rolled metal. A huge selection of metals and forms of manufactured products allows them to be used in a wide variety of industries. Parts of any shape can be made from this material, ensuring their resistance to any loads and temperature conditions.

Both long and shaped metal products are used in almost all industries. However, their difference lies in the fact that the high-quality type is used as blanks, including for the production of shaped types.

Video on the topic: Production of long products

Cold rolled sheets and coils

Bolt cutters: what they are, types and application

Cold rolled sheet is the basis for many applications and production. This is a very convenient material to process, store and transport, from which you can obtain a wide range of high-quality products for a wide variety of purposes.

Production

The production process, at its core, is a continuation of the processing of hot-rolled steel. To obtain a cold-rolled steel coil, a hot-rolled strip is first produced from a special steel billet, which is descaled and prepared for the next stage.

Cleaning methods can be different: etching, shot blasting, combined method. For unalloyed steels, softening annealing can be additionally carried out.

Then the prepared steel is rolled on a special mill (reversible or continuous) under high pressure. No temperature is applied here, which is why the process is called cold rolling. The resulting strip of cold-rolled steel is rolled into a roll and sent for finishing processing: annealing, galvanizing, etc.

Assortment

Steel and the sheets that are produced from it have a number of key characteristics that determine their suitability for specific applications and production:

- Thickness. It ranges from 0.35 to 5 mm;

- Steel grade. Determined by GOST requirements;

- Rolling precision. There are three main classes: AT - increased accuracy, BT - normal and VT - high;

- Quality finish. There are 4 groups: from IV (regular finish) to I (extra high);

- Edge type. There are sheets with trimmed and untrimmed edges;

- Density. It can be normal (PN), improved (PU), high (PV) and especially high (PO);

- Finish coating. Additionally, rolled products can be coated with different compounds.

Our company offers cold-rolled steel (in sheets and coils), manufactured in accordance with GOST 16523 st08ps and GOST 9045 st08yu/08ps (VG, SV, OSV, VOSV) with a thickness of 0.5 to 3 mm, from warehouses and directly from plants.

Steels 08Yu and 08PS /sp belong to high-quality structural steels, which are used in various industries and differ from each other in the proportions of their constituent components. They have a good balance of strength and ductility. Such steel can be easily stamped, welded and cut, which is very useful for any industry related to metal processing.

We can offer the service of cutting rolls into sheets and strips according to customer sizes.

Application area

Today, the main areas of application of cold-rolled steel in coils and sheets are mechanical engineering and construction. The high strength of the sheets and the ability to manufacture them with very small tolerances also allows them to be used in shipbuilding and instrument making.

The strength of cold-rolled sheets is well known in construction. Here such sheets are used not only as corrugated sheeting, but also as wall and roof coverings.

The possibility of galvanizing sheets and applying polymer coatings to them also allows us to significantly expand the scope of application of this material.