Metal putty

After the primer has dried, the next operation is performed - putty. Corrosion, transforming the metal into oxide, leads to the formation of the so-called. shells And if stripping, priming and converters help stop the oxidative process, then putty is designed to fill the resulting irregularities with a special composition. Due to this, the surface is leveled.

Each putty contains the following components:

- Plasticizer.

- Binder.

- Filler.

- Supplements

On sale you can find dry and ready-to-use mixtures. As a rule, they can be applied with a regular spatula. When the mixture has been brought to the desired consistency, it is applied to the surface, which is then sanded after the putty has hardened.

Treatment with chemicals

Everyone understands why iron parts rust. We list the categories of chemical reagents that help get rid of corrosive formations:

- Rust converters.

- Acids.

Acids are solvents consisting of orthophosphates that help restore rusting products. The technology for using acid is simple. The metal must be cleaned of dirt and dust and treated with acid using a silicone brush.

The chemical interacts with the damaged surface for 30 minutes, after cleaning the product is wiped dry. The acid should not affect the skin, eyes, or mucous membranes, therefore, during such treatment it is necessary to wear special clothing. The orthophosphate mixture has the following advantages:

- Gentle effect on iron.

- Removing rusty deposits.

- Preventing new corrosion.

The entire surface of the metal product is treated with the converter. Active substances create a protective anti-corrosion layer that prevents its development.

Popular converters:

- Berner - for protecting bolts and nuts that are difficult to unscrew.

- BCH-1 neutralizes rust on damaged areas and can be wiped off with a regular rag.

- "Zinkor" cleans from corrosion and prevents further destruction.

- B-52 is a gel converter that helps get rid of different types of rust stains.

- SF-1 - it is used to process cast iron, zinc, aluminum, it prolongs the service life of iron objects for a long time.

Most anti-corrosion compounds are made from toxic components, so you need to protect yourself with respirators, gloves, and goggles.

Characteristics of methods of thermal and chemical-thermal treatment in the restoration of products

It is difficult to exaggerate the role of heat treatment in general in mechanical engineering, and in the field of restoration of parts in particular. It allows you to obtain the necessary operational (wear resistance, hardness) and technological (cutting ability, thermal conductivity) qualities.

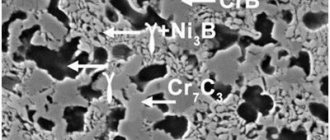

Chemical-thermal treatment is a separate topic. Unlike traditional heat treatment, when carrying out chemical treatment, the product is exposed not only to temperature, but also to a chemical reaction with atoms and ions of other substances. Atoms diffuse to a certain depth inside, thereby changing the chemical composition of the surface layer. The properties of the diffusion layer differ significantly (for the better) from the original material. Thus, boriding (saturation with boron atoms) and cementation (saturation with carbon atoms) significantly increases hardness and helps reduce the coefficient of friction. In practice, silicon, nitrogen, aluminum and other elements are also used as saturating elements.