The diamond grinding wheel has long become a common abrasive tool, available even to home users. This became possible thanks to a significant reduction in the cost of production of artificial diamonds, which now cover more than 90% of the needs of the abrasive industry.

Diamond wheels are usually made of metal (steel or aluminum alloys) and a fairly thin layer of an abrasive mixture of bakelite resin with diamond chips is applied to their surface. Such a tool still has unsurpassed hardness.

Moreover, the only material that is close to diamond in this parameter is cubic boron nitride (CBN, Borazon). Diamond grinding wheels are unrivaled when grinding hard alloys, metal-ceramic composites, ferrites and other materials of increased hardness.

Types of diamond tools for grinding according to GOST

Varieties of designs and types of working surfaces of grinding diamond discs are regulated by GOST 24747-90, which fully complies with the requirements of the standards of the Federation of European Producers of Abrasives (FEPA, Federation of European Producers of Abrasives). The specified GOST and the ISO 6168-79 standard, adopted on the basis of the FEPA classification, regulate and code:

- Design and geometric parameters of diamond wheel bodies.

- The shape of the abrasive layer.

- Location of the abrasive layer on the body.

- Design features of individual buildings.

The first group of characteristics according to GOST includes fifteen types of housings, numbered from 1 to 15. The second group includes twenty-six profiles of abrasive layers, designated by one or two Latin letters. The third contains ten ways to place the abrasive on the surface of the body, numbered 1 to 10.

The fourth contains fourteen design features, each of which is assigned one or two Latin letters. Thus, each type of diamond disc is a structural set of standardized elements and has strictly defined geometric parameters.

Their designations and size ranges are also regulated by relevant standards. For example, one of the most common diamond wheels for flat grinding is designated 1A1, which means: (1) a flat wheel without darts; (A) with a linear layer of abrasive, (1) covering the entire height of the peripheral plane (see photo above).

Such an abundance of design features should have given rise to a great variety of varieties of this instrument. In fact, there are a little more than two dozen design options that almost completely cover all the needs of modern production. Below is one of the selections with the most common cases.

Voting for the best diamond blade

Which diamond blade would you choose or recommend?

HUSQVARNA 5748362-03

14.29 % ( 1 )

BOSCH 2608603241

0.00 % ( 0 )

GRAFF GDD 18 350.10

0.00 % ( 0 )

PRACTICE 030-771

14.29 % ( 1 )

BISON 0515001

0.00 % ( 0 )

Hilberg Super Metall 520350

0.00 % ( 0 )

MESSER 01-61-126

0.00 % ( 0 )

MESSER 01-26-230

28.57 % ( 2 )

Diam Granite—Elite 000202

28.57 % ( 2 )

KEOS DBP01.115

14.29 % ( 1 )

Di-Star 1A1R Hard Ceramics (11120048015)

0.00 % ( 0 )

Design of diamond grinding wheels

The basis of a diamond grinding wheel is a body in the form of a disk or its derivatives, one of the surfaces of which is covered with a working layer consisting of a binder, filler and grinding powder.

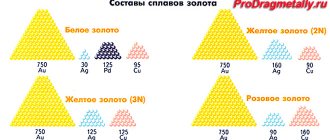

The materials for the housings are structural steels (StZ, St20, etc.), cast aluminum alloys (D16 and AK groups) or combined materials using polymers. The most common diamond wheels come in cup, disc and disc shapes (see picture below).

The housings are attached to the spindle of the equipment using a standard size mounting hole. Depending on the model, the working layer can be located on both external and internal surfaces. This is especially true for cup-shaped tools used for grinding and sharpening cutting edges.

VIEW Diamond wheels on AliExpress →

To ensure that the body does not deform, dissipates heat well and does not generate vibration, the diamond wheel must be used taking into account its design and physical features. Housings made of aluminum alloys have good thermal conductivity and limited strength, but at high cutting speeds and depths they are prone to vibration.

Steel also dissipates heat well and has high mechanical and vibration resistance. Composite ones dampen vibration better than anyone else, but they dissipate heat poorly and are less durable. There are also flexible diamond grinding wheels, popularly called “turtles” because of the texture of their surface.

They have a very thin abrasive layer and are designed for grinding hard mineral materials (concrete, granite, marble, etc.) with hand tools.

Wet cutting

The dry cutting method involves the use of continuous, solid circles. Material processed in this way does not chip. The wet method is more convenient, since water not only cools the surface of the disk, but also cleans the work area, removing dust and fragments of the material being processed.

Universal diamond blades are also available, designed for both wet and dry cutting.

Diamond cutting wheels differ in purpose, type of cutting edge, method of fastening the segments, composition of the segments and other characteristics.

Markings

The standard marking line for diamond wheels includes two parts. The first contains information about the design and geometric dimensions of the product, and the second contains information about the characteristics of the abrasive and binder (see figure below). In addition, manufacturers, in accordance with their regulations, can supplement the right end of the line with other data.

To decipher the type of product, you must use GOST 24747-90 or tables with codes and sketches of the most common designs. In our case, this is a conical disc-shaped diamond wheel with an angle of 20° Ø150 mm, a working layer size of 6×4 mm and a mounting hole of Ø32 mm. The second part of the marking indicates the following parameters of the abrasive layer:

- D126 is the FEPA diamond grain number, which corresponds to the range of 106-125 microns or 120/140 mesh.

- K75 indicates the concentration of grain in carats per cubic centimeter of the working layer.

- B is the FEPA designation for organic binder.

- T—code for ligament hardness. Regulated by GOST R 52587-2006 (see below) and international standards. In our case, the circle belongs to the “very hard” category.

This marking line also includes an indication of operating conditions (m). In addition to it, the maximum permissible values of the peripheral cutting speed and rotational speed, a safety sign and an indicator of the direction of rotation are also applied to the diamond wheel.

Grain

Its main technological parameters directly depend on the grain size of a diamond wheel: grinding performance and cleanliness class.

Therefore, when selecting the grain size, it is important to take into account the combination of these characteristics. During preliminary grinding, a tool with grain size D151 is used, which reduces the number of passes, ensures high productivity and makes it possible to obtain surfaces of class 7 cleanliness (Ra up to 1.4; Rz = 6÷8). When finishing grinding, productivity is not the main criterion, so in this case, diamond wheels with D54 grain are used and as a result, a class 10 surface with Ra = 1.2 and Rz = 1.0÷1.6 is obtained. The depth of cut and, accordingly, the thickness of the allowance removed in one pass also depend on the grain size.

It is recommended to select a grinding depth of no more than 1/3 of the standard grain size. In the example above, in the first case this value will be 0.05 mm, and in the second - 0.018 mm. The photo below shows a diamond grain measuring 10÷15 microns under an electron microscope at 500X magnification.

Diamond concentration (diamond layer size)

This value shows the proportion of diamond grains in the volume of the working part and is measured in carats (0.2 g) per cubic centimeter (ct/cm³).

Typical values for this parameter: K25 (1.1 ct/cm³), K50 (2.2 ct/cm³), K75 (3.3 ct/cm³), K100 (4.4 ct/cm³), K125 (5.5 ct/cm³) and 150 (6.6 ct/cm³) cm³), but products with higher or lower concentration values can be produced. It affects several technical characteristics of a diamond wheel and has a significant impact on its cost. Concentrations above K125 are typical for tools with a hard bond and a small working layer height. In addition, it allows the peripheral geometry to remain unchanged throughout the entire grinding cycle.

In general, the value of this parameter is proportional to the size of the abrasive layer: the lower the concentration, the thicker and wider it is. Diamond wheels with low (up to K25) concentration usually have a wider working layer and fine grain size.

Comparative characteristics of diamond blades

See the product characteristics in the table to make your choice:

| Name | Bore diameter, mm | Circle thickness, mm | Circle diameter, mm | Diamond blade weight, grams | Manufacturer country | Price in rubles |

| 22.2 | 1.6 | 180 | 300 | Russia | From 745 |

| 25.4 | 1.6 | 200 | 360 | Ukraine | From 1500 |

| 22.2 | 1.4 | 115 | 120 | South Korea | From 1310 |

| 25.4 | 1,6 | 250 | 645 | China | From 2673 |

| 22, 23, 25.4 | 1.6 | 230 | 600 | Russia | From 4256 |

| 22.2 | 2.8 | 125 | 160 | Russia | From 1609 |

| 20, 25.4 | 2.7 | 350 | 1194 | Russia | From 7161 |

| 22.2 | 2.2 | 230 | 660 | Russia | From 575 |

| 22.23 | 3 | 150 | 170 | Russia | From 1290 |

| 20 | 3.4 | 350 | 700 | Belarus | From 7161 |

| 22.23 | 2 | 150 | 2180 | Germany | From 7483 |

| 25.4 | 2.4 | 230 | 1710 | Sweden | From 16300 |

Bundles for diamond grinding wheels

The distribution and fixation of diamond grains in the working layer is carried out by means of binders, which are called “binders”.

In practice, three types of base bonds are used: metal, galvanic and organic. For the latter, bakelite is most often used - a thermosetting plastic based on phenol-formaldehyde resins. Bakelite has low thermal conductivity, so tools on bakelite bonds, in the absence of coolant supply, operate at temperatures no higher than 200÷250 °C. Diamond wheels of this type are usually used for fine grinding and finishing of carbide tool blades.

Working layers on metal bonds are best suited for cutting off significant layers of allowance, pre-grinding, profiling, sharpening carbide and cermet plates. The electroplated bond consists of one or more layers of nickel deposited on a metal body coated with diamond powder.

This type of tool is used for cutting and grinding silicon, glass, minerals, as well as in the manufacture of diamond heads, laps and finishing of dies and punches.

Hardness index

The hardness designation is usually used only for bakelite-based diamond wheels.

In the marking it itself is designated by the letter B, and the hardness is graded according to GOST R 52587-2006 and indicated by letters from F to Z. Typically, the lower the hardness, the wider the working part and the smaller the grain size. Such diamond wheels perform fine grinding at low cutting speeds, and in many cases even without the use of coolant. The higher the hardness, the higher the permissible cutting speeds and depths. In such modes, cooling the working area is mandatory.

Accuracy and imbalance classes

According to GOST, the marking of grinding wheels with traditional abrasives must include the designation of accuracy and imbalance classes (the last two positions of the marking line). For diamond wheels, GOST does not provide for these parameters.

Firstly, this is a tool with a small (in relation to the total volume of the body) layer of abrasive composite, and secondly, according to the requirements of state standards, it is manufactured with standardized high accuracy. For example, the face and radial runout of diamond wheels, according to the requirements of GOST 16181-82, must correspond to 7 ÷ 8 degrees of accuracy.

Classification of discs according to processed materials:

- Class 1: concrete, building materials, paving and clinker slabs, brick.

- Class 2: roofing tiles, abrasives, cinder blocks, concrete, sandstone, brick.

- Class 3: reinforced concrete, granite, other hard materials.

- Class 4: wall and floor tiles, ceramic tiles, concrete tiles, slate.

- Class 5: hard and abrasive concrete, plaster.

- Class 6: highly abrasive materials, fresh concrete, asphalt.

The body is made of low-carbon high-quality steel and does not deform at high temperatures; the cutting edge is laser welded - this increases service life and improves productivity.

Combines reliability when working with abrasive materials and high speed of work.

Diamond granules are coated with a layer of alloy metal, the body is made of low-carbon steel;

High concentration of diamond chips, solid edge discs, used for dry cutting only.

Optimal for sampling concrete, making holes, seams and cuts.

Designed for light floor saws, hand-held gas cutters and other mechanisms, used in dry cutting.

Color marking of disks is also accepted, in which each color indicates the material for which the equipment is made:

- green color – granite;

- blue – marble and concrete;

- orange – brick;

- yellow – alabaster, tiles;

- gray – ceramics.

Shape and width of diamond layer

The abrasive layer of a diamond wheel is applied to its end surface or peripheral part in the form of a ring or a solid disk.

The geometric dimensions of the working layer determine the volume of the diamond-containing composite and directly affect the cost of the product. In this case, the height (thickness) is of practical importance only for the durability of the tool. Width, on the other hand, is a key parameter. The area of contact with the surface being processed and, as a consequence, the productivity and temperature conditions of grinding directly depend on it.

The smaller the width, the greater the permissible cutting speeds and depths and the better the removal of spent abrasive and metal chips from the grinding zone. And the larger it is, the higher the accuracy and cleanliness of grinding.

The width of the treated surface in all cases must be greater than the width of the working layer, since only under these conditions can it be ensured that it is uniformly processed and self-sharpening.

Advantages of diamonds over conventional abrasive tools

The hardness of diamond far exceeds the hardness of all abrasive materials known today.

In terms of this parameter, only elbor (borazon) is comparable to it, which has a slightly lower hardness but better thermal conductivity. In foreign technical literature, these two substances are classified as a separate category “superabrasives”, but in our country they are called superhard materials (STM). This is due to the fact that the wear resistance of CBN and diamond tools is much higher than that of abrasive products made from traditional materials.

The main advantage of wheels made of superhard materials is the preservation of the specified profile accuracy when grinding special steels and products made of ceramics and hard alloys. Therefore, diamond wheels are widely used in tool production for precise grinding of axial, pressing and measuring tools.

In addition to extreme precision, this tool has very high productivity. These wheels are also used to cut and process glass, ceramics and mineral construction materials.

Coupling is performed in one of several ways:

- silver soldering circle;

- sintering;

- laser welding;

- galvanic method.

Silver solder

Used for large diameter diamond blades intended for wet cutting on stationary machines - the segment without constant cooling quickly disappears. The solder connection is not heat-resistant, but the cutting part damaged in individual segments can be restored.

Sintering

Pressed polymetallic powder containing diamonds is sintered under pressure with the disk blade at a temperature of 700-1000°C. This is how complex disk segments of medium and small diameters are manufactured. The method increases the service life, but increases the price of the product.

Laser welding

The most durable mounting method. These discs are used for both dry and wet cutting. When dry cutting, the disc is not damaged and retains its shape.

Galvanic method

With this method of fastening diamonds, only one layer can be applied, which prevents the disc from self-sharpening. But the number of cutting elements can be large, and this allows for extremely precise and clean cuts. The technology is used in the production of diamond cutting discs used when working with materials of low hardness.

The size, quantity, quality and method of arrangement of diamonds, the specific composition of the binder - all this determines the combination intended for processing a particular material.

The work of a diamond cutting disc is not cutting, but grinding and crumbling the material being processed. Diamond crystals are held in place by a metal lattice and a binder. When they are ground down, the stones crack and fall out. There is a direct relationship between the hardness of the material and the service life of the disc. With optimal selection of segment and material, a balance between resistance and cutting properties is maintained. As a result, the crystal is used until it is completely destroyed, and then a new, exposed diamond comes into play.

Discs for cutting dense materials must have a soft, quickly crumbling grid. At the same time, the diamonds will just as quickly replace each other, and the segment remains operational as it is ground down. In blades used for cutting soft materials, the grid is resistant to abrasion and the diamonds last longer.

The same factor ensures the correct selection of the bond between which the diamonds are distributed. The bond can be hard (steel and cobalt fills the gaps), soft (including bronze) and medium (tungsten carbide).

A soft binder is used in discs processing hard surfaces - its use when working with soft material leads to accelerated consumption of the segment. Used when cutting granite, reinforced concrete, hard metals.

A solid binder, on the contrary, is intended for processing soft materials: clothes, silicate, asphalt, etc.

For each disk there is a specific marking that describes its characteristics. Some manufacturers indicate in the labeling the type of material for which it is intended for processing:

- B – concrete cutting;

- U – universal diamond discs;

- M – discs for cutting hard materials and marble;

- F – processing of ceramic tiles;

- A – cutting asphalt;

- P – professional diamond discs;

- PP – circles of the highest class;

- PE – inexpensive professional discs.

Use of wheels depending on grit size

The cleanliness and performance of grinding with a diamond wheel directly depend on the grain size of its working layer.

During preliminary grinding, which allows obtaining a 7-8 class of cleanliness, a tool with a grain size from D151 to D107 is used. Finish grinding is performed in the range from D91÷D54, as a result of which class 9 cleanliness can be achieved. For fine grinding (grades 9-10), diamond wheels with grain size D46÷D30 are used. Below is a table of the relationship between grain size in microns and designations according to different standards.

Review of popular models and manufacturers

The main manufacturers of diamond wheels in Russia are enterprises with a long history that produced such tools back in Soviet times.

The oldest enterprise in this industry is St. Petersburg Abrasive, which has its own production of artificial diamonds and diamond micropowder. Industry leaders such as the Tomilino plant and Venevsky plant, which also undergo diamond synthesis, also have Soviet origins.

Several new enterprises, also producing diamond wheels, have already been created in modern Russia. Among them, the leading ones are Crystal Ltd., Intech Diamant and Nioborit. The most common among diamond wheels are models that are used for flat grinding and tool sharpening.

First of all, these are cylindrical and conical flat diamond wheels (case types 1–4 according to GOST 24747-90), cup wheels of types 11 and 12, as well as specialized products for sharpening saw tools.

Diamond wheels have an abrasive layer thickness of only a few millimeters. How durable are they at home if they are used only for sharpening knives and plumbing tools? If anyone can answer this question, please leave your message in the comments.

Main Applications

The use of diamond blades is not limited to cutting hard materials. Using special attachments, the tool can be used for sharpening or grinding surfaces. The circles are installed in tile cutters, gas cutters, wall chasers, angle grinders (grinders), stone cutting machines and other equipment.

Cutting discs are produced specifically for a specific material. For example, a circle for cutting stone allows you to evenly crumble the material along the cut line, without chips or cracks. Wood discs help to quickly produce parts of various shapes due to high precision.

Sanding discs are used for removing paint, grinding surfaces, and roughing operations. They are shaped like a bowl. Sharpening discs are used for sharpening metal tools. The fine-grained coating ensures high quality sharpening.