Low magnetic steel

Low-magnetic steel is used for the manufacture of machine parts, instruments and devices that should not be magnetized (rings of electric generators, compass boxes, electrical resistances, etc. [2]

For low-magnetic steels of some grades, melt control of the magnetic permeability of the metal has been introduced. The control of non-metallic inclusions is also becoming more complicated. For some grades of stainless steel for electroslag and vacuum arc remelting, standards are established not only for scoring on the GOST 1778 - 62 scales, but also limits for the total number of inclusions of a certain size. [3]

Anchor chains made of low-magnetic steels - welding. [4]

It is advisable to use the TT10K8B alloy for roughing and semi-finishing of stainless, low-magnetic steels and some grades of heat-resistant steels and alloys. It is characterized by increased resistance to thermal and mechanical cyclic loads. [5]

Bimetals of the first group have a passive component made of invar, and an active component made of low-magnetic steel. The materials of both components have good mechanical properties. Due to their high resistivity, these bimetals are suitable for direct heating by current. Bimetals of the second group have a passive component from invar, and an active component from tombac. These bimetals have high thermal conductivity and lower resistivity. They are used in installations where the bimetal is heated by heat transfer. [7]

Now in [8] for steels 40, 50, EI405, 40Kh, low-magnetic steel and some other metals, the constancy of the octahedral shear stress during metal destruction during the cutting process for various values of m has been established experimentally. [8]

EI-181), as well as brass, duralumin, etc. It is advisable to make coupling bearings from the above-mentioned non-magnetic and low-magnetic steels or from plastics in order to limit the entry of ferromagnetic particles of coupling filler into the bearings. Materials for plastic bearings can be phenolics, melamine-based plastics and alkyd resins. [10]

If the installation of these vertical tie rods is difficult, it is advisable to provide continuous steel strips (plates) of low-magnetic steel with a thickness of 4 - 10 mm, covering the entire rod and both yokes. Since these strips overlap both yokes and are fastened to the yoke beams, when lifting the active part of the transformer, they absorb all the forces without subjecting the magnetic circuit to deformation. [eleven]

In cases where the cabinet elements represent a closed circuit for electromagnetic fields generated by the power busbar located inside the cabinet, making them from bent profiles of non-magnetic or low-magnetic steel will reduce the local heating of this circuit to acceptable limits. [12]

Table data 13 are valid for the following conditions: a) if the number of inputs is more than three (inputs for a current of 5000 A - regardless of their number), they must be installed on a plate made of low-magnetic steel; b) inputs for currents of 1600, 2000 and 3200 A, with a number of no more than three, allow installation on a steel plate with inserts made of low-magnetic steel with a width of less than 60 IMM; c) the connection of inputs to the taps of the transformer windings and busbars must be made with copper flexible connections. When connecting flexible links to contact plates, steel fasteners must be used. [13]

Table data 13 are valid for the following conditions: a) when the number of inputs is more than three (inputs for a current of 5000 A - regardless of their number), they must be installed on a plate made of low-magnetic steel; b) inputs for currents of 1600, 2000 and 3200 A, with a number of no more than three, allow installation on a steel plate with inserts made of low-magnetic steel with a width of less than 60 IMM; c) the connection of inputs to the taps of the transformer windings and busbars must be made with copper flexible connections. When connecting flexible links to contact plates, steel fasteners must be used. [14]

The inactive part of the magnetic circuit in most cases consists of a number of elements designed to rigidly fix the active part, reduce vibration and noise, create support for the windings, ground the magnetic circuit and other purposes. The materials for the manufacture of elements of the inactive part are various structural and low-magnetic steels, as well as insulating materials. The design of the inactive part of the magnetic circuit largely depends on the entire design of the active part and its dimensions. [15]

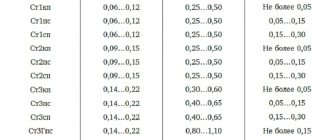

Low-magnetic steel grade 45G17YUZ for sheet and profile products

| Home → Science → Developments → Steels and alloys → Low-magnetic steels → Low-magnetic steel grade 45G17YUZ for sheet and profile rolled products |

Steels based on the C-Fe-Mn-Al alloying system

FSUE "TsNII KM "Prometey" together with the Central Research Institute Chermet named after. I.P. Bardin developed a technology for the production and processing of steel grade 45G17Yu3.

Applications:

- Shipbuilding (for example, as a low-magnetic material for all-prefabricated hulls of scientific research vessels of the "Rainbow" type - project of the Western Design Bureau).

- Construction.

- Electrical engineering (transformers, etc.)

- Mining industry (trays for transporting rock, etc.).

Advantages:

- Steel has a stable austenitic structure at normal temperatures, which is preserved under any deformation and hardening.

- Steel is well welded by all types of welding and is easy to machine.

Rainbow-class research vessel

Basic physical and mechanical properties of steel grade 45G17Yu3

- Magnetic permeability, G/E< 1.01

- Modulus of normal elasticity, MPa 1.75×10 5

- Density, kg/m 3 7600

- Yield strength, MPa 390-510

- Relative elongation, % > 30

- Impact strength, KCV+20 o C, J/cm 2> 200

Steel is supplied in the form of rolled sheets in thicknesses of 2-60 mm and profiles of various sizes.

For marine engineering products, grades 45G17Yu3, similar in composition to steel grades 40G18Yu3F and 80G20F2YU, have been developed:

Marine engineering product

Advantages:

Steels 40G18Yu3F and 80G20F2Yu have a high yield strength, which is ensured by dispersion strengthening, namely the release of dispersed vanadium carbides after heat treatment, austenitization and aging.

Developments are protected by Russian patents

Cooperation proposals:

- Technical and technological documentation for the production and processing of semi-finished products.

- Adaptation of manufacturing and processing technologies for semi-finished products to the Customer’s requirements.

- Technical support during the development at the Customer’s enterprise of technologies for the production and processing of semi-finished products (rolled sheets; long products).

Request form You can send a request for this development by filling out the following form:

| Contact person (full name) * |

| Name of the organization * |

| Organization Profile |

| Email mail * |

| Phone (+x xxx xxxxxxx) |

| Your request * |

| Your comments |

| * fields are required |

Low-magnetic steel 45G17Yu3

Low-magnetic steel 45G17Yu3

I will sell low-magnetic steel 45G17Yu3 from stock in St. Petersburg from a warehouse in St. Petersburg: Sheets 45G17Yu3 with a thickness from 5mm to 35mm, factory cutting. Forgings (squares) 45G17Yu3 250x250mm, Circles (rods) with diameters of 50mm, 60mm, 80mm, 90mm, 100mm. Lengths from 2000mm to 5000mm. Manufacturer's certificates. The sheets are new and from the state reserve, all in excellent condition. Forgings and wheels are also from reserve, in excellent condition. Sending to any region of the Russian Federation, delivery to a transport company. Shipment immediately after receipt of payment. Contact number Alexey Nikolaevich Email for applications

City: St. Petersburg

Organization/contact person: LLC Baltic-Steel

Telephone: 8(921)969-77-99

Description

Steel 45G17Yu3 is used : for the production of rolled sheets up to 60 mm inclusive and strip bulbs used in various metal structures and equipment in shipbuilding; long and shaped rolled products; forgings and stampings; light-loaded structures of ship hulls, ships and marine equipment products (sheet and profile parts of surface ship hulls, forgings welded into the hull, chains and chain devices, winches, capstans, axles, drums, bolts, nuts, studs, gears and worms for low-speed mechanisms , frames, casings, hatch covers, rescue devices, doors, cable hangers, pilot post spools (in a nitrided state, ballasts, ship engine housings); transformer parts.

Note

Low-magnetic steel of austenitic class. Magnetic permeability μ ≤ 1.01 gs/e. Cold forming, as well as mechanical cutting, slightly changes the magnetic permeability of steel, but the value of this characteristic after these technological operations does not exceed 1.01 gf/e, if the cold deformation does not exceed 50%. The magnetic field of products increases sharply in the presence of scale, which is ferromagnetic. Scale must be completely removed. Steel cannot be used for friction parts and parts operating in aggressive environments.

Tenders and applications - Steel sheet, hot rolled in the St. Petersburg region

- 10/03/2019 at 11:47 PP MFZ will purchase: Steel sheet, hot-rolled 100 length: 2000x6000 steel: st 3, in the following volume: 1 piece respond to application

- 09/24/2019 at 11:09 The Chirchik Mash LLC wishes to purchase: Steel sheet, hot-rolled 100 steel: GOSTG2S-12 GOST 5520-79, in the following volume: 10600 kg Steel sheet, hot-rolled 36 steel: GOSTG2S-12 GOST 5520 -79, in the following volume: 7600 kg Steel sheet, hot-rolled 60 steel: GOST 19903-74 09G2S-12 GOST 5520-79, in the following volume: 4233 kg Steel sheet, hot-rolled 14 steel: GOSTG2S-12 GOST 5520-79, in the following volume: 7000 kg Steel sheet, hot-rolled 8 steel: GOSTG2S-12 GOST 5520-79, in the following volume: 22600 kg Steel sheet, hot-rolled 8 steel: GOST 19903-79 art.Z sp.5 GOST 14637-89, in the following volume: 7000 kg Steel sheet, hot-rolled 16 steel: GOST 19903-79 art.Z sp.5 GOST 14637-89, in the following volume: 4000 kg

Is stainless steel magnetic: magnetic properties of stainless steel

Considering the fact that stainless steel today is produced in a wide variety of brands, it is impossible to unequivocally answer the question of whether it is magnetic or not. The magnetic properties of stainless steels depend on the chemical composition and, accordingly, on the internal structure of the alloys.

A portable metal analyzer allows you to quickly determine the content of chemical elements and make a conclusion about the quality of stainless steel

Designations

| Name | Meaning |

| Designation GOST Cyrillic | 45G17Yu3 |

| Designation GOST Latin | 45G17Ju3 |

| Translit | 45G17Yu3 |

| By chemical elements | 45Mn17Al3 |

| Name | Meaning |

| Designation GOST Cyrillic | Yu3 |

| Designation GOST Latin | Ju3 |

| Translit | Yu3 |

| By chemical elements | Al3 |

| Name | Meaning |

| Designation GOST Cyrillic | EI839 |

| Designation GOST Latin | EI839 |

| Translit | EhI839 |

| By chemical elements | — |

What determine the magnetic properties of materials?

A magnetic field with a certain level of its intensity (H) acts on bodies placed in it in such a way that it magnetizes them. In this case, the intensity of such magnetization, which is designated by the letter J, is directly proportional to the field strength. The formula by which the intensity of magnetization of a certain substance is calculated (J = ϞH) also takes into account the coefficient of proportionality Ϟ - the magnetic susceptibility of the substance.

Depending on the value of this coefficient, all materials can be included in one of three categories:

Directions of action of magnetic moments of neighboring atoms in substances of different magnetic nature

Stainless steels with good magnetic properties

Stainless steel, in which the following phase components predominate, has good magnetic properties:

- Martensite is a ferromagnet in its pure form.

- Ferrite - this phase component of the internal structure of stainless steel, depending on the heating temperature, can take two forms. This structural form becomes ferromagnetic if the steel is heated to a temperature below the Curie point. If the heating temperature of the stainless steel is above this point, then high-temperature delta ferrite, which is a pronounced paramagnet, begins to predominate in the alloy.

From all of the above, we can conclude that the stainless steel that is magnetic is one in which martensite predominates in its internal structure. Like regular carbon steels, these alloys react to magnets. By this feature they can be distinguished from non-magnetic ones.

The ability of stainless steel to magnetize does not affect its corrosion resistance

Stainless steels, in which ferrite or its mixture with martensite predominate, are most often also classified as ferromagnetic, but their properties may vary depending on the ratio of the phase components of their internal structure.

Stainless steel, the magnetic properties of which can change, are mainly chromium and chromium-nickel alloys, which may belong to one of the following groups.

Steels with a martensitic internal structure, which, like conventional carbon steels, can be strengthened by quenching and tempering. Such stainless steel, in addition to general engineering enterprises, is actively used in everyday life (in particular, cutlery and cutting tools are made from it). The most common grades of such magnetic steels, products from which are produced with heat treatment and can be subjected to finishing grinding and polishing, include 20Х13, 30Х13, 40Х13.

Steel grade 30Х13 is less ductile than alloy 20Х13, despite its similar composition (click to enlarge)

This category also includes the 20Х17Н2 alloy, which is characterized by a high chromium content in its chemical composition, which significantly enhances its corrosion resistance. Why is this stainless steel popular? The fact is that, in addition to high resistance to corrosion, it is characterized by excellent workability using cold and hot stamping and cutting methods. In addition, products made from such material are well welded.

A common ferritic-type magnetic steel, which, due to the low carbon content in its chemical composition, is softer than martensitic alloys, is 08Х13, which is actively used in food production. Such stainless steel is used to make products and equipment intended for washing, sorting, grinding, sorting, and transporting food raw materials.

Mechanical properties of steel 08Х13

A popular brand of magnetic stainless steel, the internal structure of which consists of martensite and free ferrite, is 12X13.

Corrosion resistance of steel grade 12Х13 (other name 1Х13)

A. Smelting with complete oxidation

III. Charge

3.1. The charge is made up of scrap iron, cast iron, coke or scrap electrodes. No more than one basement is allowed.

3.2. The melts are blended based on the yield in the first sample after melting (approximately): carbon for steel 45G17Yu3 - 0.75%; carbon for steel 40G18Yu3F - 0.70%; carbon for steel 15G20Yu3 - 0.50%; chromium no more than 0.5%.

IV. Melting and oxidation period

4.1. During the bale, 0.40-0.80% of carbon is oxidized.

4.2. Phosphorus is removed to a content of no more than 0.010%.

4.3. The carbon content at the end of the bale when using metallic manganese should be: steel 15G20Yu3 - not lower than 0.08%; 45G17Yu3 - approximately 0.45%; 40G18Yu3F - approximately 0.40%. When metallic manganese is partially replaced with medium-carbon or high-carbon manganese, the carbon content for grades 45G17Yu3 and 40G18Yu3F can be lower, in such a way that after adding manganese, the carbon content is approximately at the lower limit.

V. Melting of manganese

5.1. After downloading the oxidizing slag, approximately 1/3 of manganese and a slag mixture of lime 12 kg/t and spar 3 kg/t are added. Melting of manganese is carried out at high voltage. To speed up melting and avoid overheating, the metal is vigorously stirred. Manganese is added in 2-3 doses, preventing the bath from becoming dirty. After melting the manganese at the temperature specified in clause 6.6., the furnace is switched to a reduced voltage, the slag is deoxidized with coke, silico-calcium, ferrosilicon and aluminum powders mixed with lime and spar until the manganese oxides are reduced and a light green or light-colored slag shard is obtained. Then the slag is downloaded.

VI. Refining

4.1. After downloading the slag, a new one is made from lime - 13 kg/t, electrocorundum or sludge. Instead of electrocorundum, lump high-alumina product ChMZ according to STU 42-210-64 or Tikhvin corundum according to TU 48-01-33-71 can be used.

4.2. After melting the slag mixture, a metal sample is taken for chemical analysis, the furnace is compacted and a deoxidizing mixture is added, consisting of: coke powder - 1 kg/t; silicocalcium or ferrosilicon - 0.7 kg/t; aluminum powder - 0.5 kg/t; lime - 1-1.5 kg/t. After 10-15 minutes, the slag and metal are mixed and the second mixture is added: silicocalcium - 0.3 kg/t; coke - 0.3 kg/t; aluminum powder - 1.0 kg/t. Ferrovanadium grades VD1 and VD2 for alloying steel 40G18Yu3F is introduced after melting the slag mixture.

6.3. The slag should be fluid during refining and light gray by the end of refining. The FeO content in the slag before release is no more than 0.80%.

6.4. Refining duration is 30-60 minutes. In cases where the duration of refining is more than 60 minutes, the slag is downloaded before release, new lime (lime - 15 kg/t, spar - 5 kg/t) or aluminous is added in accordance with clause 6.1 and the metal is poured into the ladle.

6.5. Before the metal is released, aluminum is loaded onto the bottom of the ladle in a basket, which is made of rods with a diameter of no more than 22 mm.

Non-magnetic stainless steels

Stainless steels that are not magnetic include chromium-nickel and chromium-manganese-nickel. They are usually divided into several groups.

The most popular brand of such stainless steels, which occupy a leading place among non-magnetic steel alloys, is 08Х18Н10 (international analogue according to AISI 304 classification). Steels of this type, which also include 08Х18Н10, 08Х18Н10Т, 12Х18Н10Т, 10Х17Н13М2Т, are actively used in the production of equipment for the food industry; kitchenware and cutlery; plumbing equipment; containers for food liquids; refrigeration equipment elements; containers for food products; medical supplies, etc.

Composition and application of austenitic steels

The great advantages of such stainless steel, which does not have magnetic properties, are its high corrosion resistance, demonstrated in many aggressive environments, and manufacturability.

Steels of this group, the most popular grades of which are 08Х22Н6Т, 08Х21Н6М2Т and 12Х21Н5Т, are distinguished by a high chromium content and a low nickel content. To give such a stainless steel the required characteristics (an optimal combination of high strength and good ductility, resistance to intergranular corrosion and stress-corrosion cracking), elements such as copper, molybdenum, titanium or niobium are introduced into its chemical composition.

Chemical composition of some industrial grades of austenitic-ferritic steels (click to enlarge)

In addition to the above, stainless steels that are not magnetic include alloys with an austenitic-martensitic and austenitic-carbide structure.

How to Determine Whether Magnetic or Non-Magnetic Steel is Stainless

Considering all of the above, we can draw the following conclusion: even if steel has magnetic properties, this does not mean at all that it cannot be classified as a stainless-type alloy. There is a fairly simple way to check whether magnetic steel is stainless steel. In order to determine this, it is necessary to clean the surface area of the product being tested to a metallic shine, and then apply a few drops of concentrated copper sulfate to this area.

Low-magnetic steel 45G17Yu3

Low-magnetic steel 45G17Yu3

I will sell low-magnetic steel 45G17Yu3 from stock in St. Petersburg from a warehouse in St. Petersburg: Sheets 45G17Yu3 with a thickness from 5mm to 35mm, factory cutting. Forgings (squares) 45G17Yu3 250x250mm, Circles (rods) with diameters of 50mm, 60mm, 80mm, 90mm, 100mm. Lengths from 2000mm to 5000mm. Manufacturer's certificates. The sheets are new and from the state reserve, all in excellent condition. Forgings and wheels are also from reserve, in excellent condition. Sending to any region of the Russian Federation, delivery to a transport company. Shipment immediately after receipt of payment. Contact number Alexey Nikolaevich Email for applications

City: St. Petersburg

Organization/contact person: LLC Baltic-Steel

Telephone: 8(921)969-77-99

Steel 45G

Home->Directory->Steel grade->Structural steel

Steel 45G2 Steel 45

Structural alloy steel 45G

Brand 45G – purpose

Structural alloy manganese steel 45G is used for the manufacture of parts - driveshafts/crankshafts, anchor bolts, gear/spline shafts, gears, friction discs, brake levers, axles, connecting rods, and other products.

Steel 45G - domestic analogues

| Rolled metal grade | Substitute |

| 45G | 40X |

| 50 | |

| 50G2 |

Material 45G - characteristics

| Brand | Classification | Type of delivery | GOST | Foreign analogues |

| 45G | Alloy structural steel | Long products | 4543–71 | There is |

Brand 45G – technological features

Heat treatment

| Mode | Cooling medium | t, 0С |

| Hardening | oil | 850 |

| Vacation | air | 600 |

Forging

| Type of semi-finished product | t, 0С |

| Ingot | 1190–820 |

Welding

| Weldability | Welding methods | Recommendations |

| Difficult to weld | RDS, ADS | Heating + heat treatment |

Flock sensitivity

Little sensitive.

cutting

| Initial data | Machinability Ku | |||

| State | HB, MPa | sB, MPa | hard alloy | high speed steel |

| normalized | 174–207 | 620 | 0,95 | 0,7 |

Tendency to temper brittleness

Little inclined.

Steel 45G - chemical composition

Mass fraction of elements no more than, %:

| Silicon | Manganese | Copper | Nickel | Sulfur | Carbon | Phosphorus | Chromium |

| 0,17–0,37 | 0,7–1 | 0,3 | 0,3 | 0,035 | 0,42–0,5 | 0,035 | 0,3 |

Material 45G – mechanical properties

| Assortment | GOST | Dimensions – thickness, diameter | Heat treatment mode | t | KCU | y | d5 | sT | sв |

| mm | 0C | kJ/m2 | % | % | MPa | MPa | |||

| Bar | 4543–71 | 25 | Quenching (oil) | 850 | 490 | 40 | 15 | 370 | 620 |

| Vacation (air) | 600 |

Depending on the cross-section of the workpiece

| Section | y | d5 | s0.2 | sв | KCU |

| % | % | MPa | MPa | J/cm2 | |

| Quenching (water) 8400C. Vacation (air) 5700С | |||||

| 30 | 55 | 18 | 550 | 800 | 78 |

| 50 | 55 | 18 | 490 | 760 | 68 |

| 120 | 50 | 16 | 450 | 740 | 59 |

| 200 | 45 | 16 | 430 | 740 | 59 |

| 240 | 45 | 16 | 430 | 740 | 59 |

Hardness, MPa

| Assortment | GOST | Heat treatment | HB 10-1 |

| Rental | 4543–71 | Annealing | 229 |

Temperature of critical points, 0С

| Critical points | Ac1 | Ac3 | Ar1 | Ar3 |

| Temperature | 715 | 735 | 635 | 710 |

Endurance limit, MPa

| State | t-1 | s-1 |

| sв | ||

| MPa | MPa | MPa |

| 670 | 418 | |

| 770 | 409 |

Brand 45G - exact and closest foreign analogues

| England | Bulgaria | Germany | Italy | China | Poland | USA | France | Japan |

| B.S. | BDS | DIN, WNR | UNI | G.B. | PN | — | AFNOR | JIS |

| 080M46 | ||||||||

| C45 | ||||||||

| C45E |

| 46Mn7 |

| C45E |

| ML45Mn |

| 1045 |

| 1046 |

| G10460 |

| S48C |

Steel 45G – area of application

Material grade 45G is used in mechanical engineering for the manufacture of high-strength parts.

Legend

Mechanical properties

| HRСе | HB | KCU | y | d5 | sT | sв |

| MPa | kJ/m2 | % | % | MPa | MPa | |

| Rockwell hardness | Brinell hardness | Impact strength | Relative narrowing | Elongation at break | Yield strength | Short-term strength limit |

| Ku | s0.2 | t-1 | s-1 |

| Relative machinability factor | Proof of yield strength with 0.2% tolerance when loaded to plastic strain value | Torsional endurance limit (symmetrical cycle) | Endurance limit under compression-tension (symmetrical cycle) |

| N | number of deformation/stress cycles sustained by an object under load before fatigue failure/crack appears |

Weldability

| No limits | Limited | Difficult to weld | |

| Heating | No | up to 100–1200С | 200–3000С |

| Heat treatment | No | There is | annealing |

You can buy 45G structural alloy steel in St. Petersburg by calling +. Specialists will place your order and advise you on the assortment, prices, and delivery conditions.

Steel 30KhGT Steel 35KhN1M2FA Steel 40 Steel 40G Steel 45KhN Grade A20 Grade A30 Steel 08 Steel 08kp Steel 08ps Steel 08Yu Steel 09G2 Steel 09G2S Steel 10 Steel 10G2 Steel 10G2BD Steel 10G2S1 Steel 10kp S hoist 10ps Steel 10Kh14G14N4T Steel 10KhNDP Steel 10KhSND Steel 12GS Steel 12K Steel 12Kh18N10T Steel 12Kh2N4A Steel 12KhN2 Steel 12KhN2A Steel 12KhN3A Steel 14G2 Steel 14G2AF Steel 14Kh2GMR Steel 14KhGS Steel 15 Steel 15G Steel 15G2AFDps Steel 15G2SFD Steel 15K Steel 15kp Steel 15ps Steel 15Х Steel 15ХСНД Steel 15ХФ Steel 16Г2AF Steel 16ГС Steel 16К Steel 17Г1С Steel 17ГС Steel 18Г2AFps Steel 18К Steel 18kp Steel 18Kh2N4VA Steel 18Kh2N4MA Steel 18KhGT Steel 20 Steel 20G Steel 20K Steel 20kp Steel 20ps Steel 20Kh Steel 20Kh2N4A Steel 20KhG2Ts Steel 20KhGNR Steel 20KhGR Steel 20KhGSA Steel 20KhN Steel 20KhN2M Steel 20KhN3A Steel 20KhN4FA Steel 20KhNR Steel 22K Steel 25 Steel 25G2S Steel 25ps Steel 25KhGSA Steel 25KhGT Steel 30 Steel 30X Steel 30G Steel 30KhGS Steel 30KhGSA Steel 30KhGSN2A Steel 30KhN2MA Steel 30KhN2MFA Steel 30KhN3M2FA Steel 31Kh19N9MVBT Steel 33KhS Steel 34KhN1M Steel 34KhN3M steel 3 5 Steel 35G Steel 35G2 Steel 40G2 Steel 40Kh Steel 40Kh2N2MA Steel 40KhS Steel 40KhFA Steel 45 Steel 45G Steel 45G2 Steel 45X steel 60S2A steel 60S2N2A steel 60S2ХА steel 60S2HFA steel 65 steel 65G steel 65S2VA steel 70 steel 70S3A steel A12 Steel A40G Steel VSt3kp Ordinary quality steel VSt2kp Ordinary quality steel VSt2ps Ordinary quality steel VSt2sp Ordinary steel new quality VSt3Gps Ordinary quality steel VSt3ps Ordinary quality steel VSt3sp Ordinary quality steel VSt4kp Ordinary quality steel Vst4ps Ordinary quality steel VSt5ps Ordinary quality steel VSt5sp Ordinary quality steel VSt6sp Ordinary quality steel St0 OsV steel ShKh15 steel ShKh15SG steel ShKh4 steel