At what speed should you drill into metal with a drill?

It is impossible to say exactly the number of revolutions, since it depends on many factors (which I will discuss below), and also, even knowing the number of revolutions, how do you install them on a drill, because it seems that no drill determines the number of revolutions, it turns out that you need to drill “at eye”, I will give recommendations at the end of the text.

What determines the speed of drilling metal?

Type of metal

Namely, what kind of metal will you drill, because there are a lot of them and they all have different physical parameters. For example, aluminum is softer than copper, and these two metals are softer than iron.

Metal type

Each type of metal also has its own type, it depends on the manufacturing method and the impurities of other metals in the alloy. For example, bronze and brass have different properties. And steel has many types from soft to hard.

Metal processing

Also an important factor, since metal processing can soften or harden the metal, so hardening the metal increases the strength so much that it is necessary to use special drills or temper the metal.

Drill quality

Drills are also made from different materials and have different tips; the drilling method largely depends on the quality.

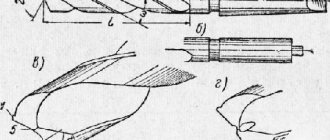

Shape and type of drill sharpening

Each type and type of metal has its own drill shapes and method of sharpening them; for example, for soft metals it is necessary to ensure free flow of chips.

Drill diameter

The selected drilling speed largely depends on this parameter, even for average values; if the speed is incorrectly selected, the drill will either break or “burn.”

_______________________

Each drill has its own drilling speed table, for example in this format:

The table shows that the smaller the diameter of the drill and the softer the metal, the higher the drilling speed, and vice versa, the larger the diameter of the drill, and accordingly the size of the cut surface is also larger, and the harder the metal, the lower the drilling speed.

_________________________

If you don’t know what type of metal you have, but have at least determined the type, and also don’t understand what kind of drill and what sharpening angle it has, then use the following recommendation.

When installing a drill with a diameter of 12-16 millimeters into a drill, start drilling at the lowest speeds and gradually increase them, at the moment when it is visually visible that the metal is cut best by the drill, and stop at approximately these speeds.

If the drill has a diameter of 6-10 millimeters, then start with medium speed, closer to 11 reduce it below average, and closer to 6 increase it. You also need to visually evaluate how the metal is drilled; if the drill burns or whistles, then reduce the speed, and if the drill does not produce chips, then increase it.

From 5 millimeters in diameter and below, set the speed closer to high, but do not start drilling at high speeds, as the drill may immediately become dull.

While drilling, water the area with water or a mixture of water and oil; I don’t recommend simply cooling the drill in water from time to time; you need to cool the drilling area.

General principles of drilling + (Video)

As already mentioned, drilling is the most common activity for a repairman, and therefore it is important to immediately learn a few basic rules associated with this activity.

- Use of suitable tools. There are many drills, each of which is designed for a specific type of material. Therefore, you should not try to drill concrete with a wood drill and vice versa. It is also important to consider the conditions in which the tool will be used. For example, industrial drills cannot be used for interior repairs (this is simply unsafe). It is also important to take into account resistance to moisture: for outdoor work you will need a tool of class IP34 if the climate in the area is humid and IP32 if you have to work in good weather. IPX2/ can be used indoors

- Correct markup. Before starting any work, it is important to carefully and accurately mark the drilling locations with a marker. You can also put paper tape under the marker to prevent the drill from slipping on the material.

- Selecting the required drilling speed. Here everything depends equally on both the material and the diameter of the blade. If we are talking about very thin drills (with a diameter of less than 3 mm), then you need to work at low speeds, less than four hundred per minute. For other drills, the following rule applies: the thinner the drill, the higher the drilling speed required.

It is also important to ensure that the handle is securely attached to the shaft of the hand drill. The drill must also not be allowed to skew.

How to drill in the right place

To drill in the right place, you need to use a special device called a core. It is made of durable steel grades, has a cylindrical shape and has a small point at its end. Before performing work, you need to take a core, place its tip on the surface, and hit its opposite end with a hammer. As a result, a recess is formed on the surface of the material in which it is necessary to drill.

Recommendation for using coolant

| Material | Hardness | Coolant pressure (bar) | ||||||||||||

| Coolant flow (l/min) | ||||||||||||||

| Replaceable powder steel heads | Carbide replacement heads | |||||||||||||

| BHN | KG | N mm 2 | Ø 9.5- 13 | Ø 13.5- 17.50 | Ø 18-24 | Ø 25- 35 | Ø 35.5- 48 | Ø 48.5- 65 | Ø 66- 114 | Ø 9.5- 13 | Ø 13.5- 17.50 | Ø 18-24 | Ø 25- 35 | |

| Free machining steel | 100-250 | 38-88 | 370-870 | 12,8 | 8,3 | 9,6 | 7,9 | 6,9 | 3,5 | 6,2 | 20 | 16,5 | 16,5 | 15,2 |

| 9,6 | 11,4 | 19,7 | 30,3 | 53 | 125 | 167 | 12,2 | 16,3 | 25,2 | 41,5 | ||||

| Low carbon steels 1010, 1020, 1025, 1522, 1144 | 85-275 | 30-96 | 300-940 | 11,8 | 6,2 | 6,6 | 5,5 | 5,2 | 2,8 | 4,5 | 17,5 | 11 | 11 | 11,8 |

| 9,5 | 9,8 | 15,9 | 26,5 | 45,4 | 114 | 144 | 11,4 | 13,3 | 20,6 | 36,5 | ||||

| Medium carbon steels 1030, 1040, 1050, 1527, 1140, 1151 | 125-325 | 46-111 | 450-1090 | 11,4 | 5,9 | 6,2 | 5,2 | 4,8 | 2,8 | 4,5 | 17,2 | 9,7 | 10,4 | 10,4 |

| 9,1 | 9,8 | 15,5 | 22,7 | 45,4 | 114 | 144 | 11,3 | 12,5 | 20 | 33,8 | ||||

| Cast steel 4140, 5140, 8640 | 125-375 | 46-129 | 450-1265 | 11,4 | 5,2 | 5,5 | 4,8 | 4,2 | 2,4 | 3,5 | 16,5 | 9,3 | 9,7 | 7,9 |

| 9,1 | 9,1 | 14,8 | 22,7 | 41,6 | 106 | 125 | 11,1 | 12,3 | 19,3 | 30 | ||||

| High strength steels 4340, 4330V, 300M | 225-400 | 77-139 | 600-1365 | 10,7 | 4,2 | 3,5 | 2 | 2 | 1,7 | 2 | 14,5 | 5,2 | 4,1 | 3,1 |

| 9,1 | 8,3 | 11,7 | 19 | 30 | 87 | 98 | 10,4 | 9,1 | 12,6 | 18,8 | ||||

| Structural steel A36, A285, A516 | 100-350 | 38-121 | 370-1180 | 11,4 | 5,9 | 5,5 | 3,8 | 3,5 | 2 | 3,5 | 15,8 | 9 | 7,9 | 6,9 |

| 9,1 | 9,8 | 14,8 | 23 | 38 | 98 | 125 | 10,8 | 12 | 17,5 | 27,8 | ||||

| Tool steel H-13, H-21, A-4, 0-2, S-3 | 150-250 | 50-88 | 500-870 | 10,7 | 4,2 | 3,5 | 2 | 2 | 1,7 | 2 | 14,5 | 5,2 | 4,8 | 3,4 |

| 9,1 | 8,3 | 11,7 | 19 | 30 | 87 | 98 | 10,4 | 9,1 | 13,6 | 19,7 | ||||

| Heat-resistant alloys Hastelloy B, Inconel 600 | 140-310 | 49-101 | 480-990 | 10,7 | 4,5 | 3,8 | 2,4 | 2 | 2 | 3,1 | 16,5 | 11,4 | 12,4 | 11 |

| 9,1 | 8,7 | 12,1 | 18,9 | 30 | 98 | 125 | 11,1 | 13,5 | 21,9 | 35,4 | ||||

| Titanium alloys | 140-310 | 49-101 | 480-990 | 10,7 | 4,5 | 3,8 | 2,4 | 2 | 2 | 3,1 | 16,5 | 11,4 | 12,4 | 11 |

| 9,1 | 8,7 | 12,1 | 18,9 | 30 | 98 | 125 | 11,1 | 13,5 | 21,9 | 35,4 | ||||

| Stainless steel 1.4016 (400 series 416, 420) | 135-275 | 49-96 | 480-940 | 11,8 | 5,9 | 5,2 | 3,8 | 3,5 | 2 | 3,1 | 22,7 | 16,5 | 17,9 | 17,2 |

| 9,5 | 9,8 | 14 | 23 | 38 | 98 | 117 | 13 | 16,3 | 26,3 | 44,2 | ||||

| Stainless steel 1.4301 (300 series 304, 316) | 135-275 | 49-96 | 480-940 | 11,8 | 5,9 | 5,2 | 3,8 | 3,5 | 2 | 3,1 | 22,7 | 16,5 | 17,9 | 17,2 |

| 9,5 | 9,8 | 14 | 23 | 38 | 98 | 117 | 13 | 16,3 | 26,3 | 44,2 | ||||

| High quality Super Duplex steel | 300-500 | 104-139 | 1020-1365 | 11,8 | 5,9 | 5,2 | 3,8 | 3,5 | 2 | 3,1 | 22,7 | 16,5 | 17,9 | 17,2 |

| 9,5 | 9,8 | 14 | 23 | 38 | 98 | 117 | 13 | 16,3 | 26,3 | 44,2 | ||||

| Hardened steel | 300-500 | 104-139 | 1020-1365 | 10,7 | 4,2 | 3,5 | 2 | 2 | 1,7 | 2 | 14,5 | 5,2 | 4,8 | 3,4 |

| 9,1 | 8,3 | 11,7 | 19 | 30 | 87 | 98 | 10,4 | 9,1 | 13,6 | 19,7 | ||||

| Nodular cast iron - gray and white cast iron | 120-329 | 44-104 | 430-1020 | 11 | 4,5 | 4,2 | 2,8 | 2,4 | 2 | 2,4 | 15,5 | 7,2 | 6,2 | 6,2 |

| 9,1 | 8,7 | 12,5 | 19 | 34 | 98 | 106 | 10,7 | 10,8 | 15,4 | 26,5 | ||||

| Aluminum casting | 30-180 | 10-62 | 100-600 | 14,5 | 12,4 | 15,8 | 11 | 8,6 | 3,5 | 5,5 | 24,1 | 22 | 21,7 | 19,6 |

| 10 | 14 | 23 | 34 | 61 | 125 | 159 | 13,4 | 18,8 | 29 | 47,2 | ||||

| Forged aluminum | 30-180 | 10-62 | 100-600 | 14,5 | 12,4 | 15,8 | 11 | 8,6 | 3,5 | 5,5 | 24,1 | 22 | 21,7 | 19,6 |

| 10 | 14 | 23 | 34 | 61 | 125 | 159 | 13,4 | 18,8 | 29 | 47,2 | ||||

| Aluminum bronze | 100-250 | 38-87 | 370-855 | 12,8 | 8,3 | 9,7 | 8 | 6,9 | 3,5 | 6,2 | 20 | 16,5 | 16,5 | 15,2 |

| 9,6 | 11,4 | 19,7 | 30,3 | 53 | 125 | 167 | 12,2 | 16,3 | 25,2 | 41,5 | ||||

| Brass | 100 | 38 | 370 | 11 | 4,5 | 4,2 | 2,8 | 2,4 | 2 | 2,4 | 24,1 | 22 | 21,7 | 19,6 |

| 9,1 | 8,7 | 12,5 | 19 | 34 | 98 | 106 | 13,4 | 18,8 | 29 | 47,2 | ||||

| Copper | 60 | 21 | 200 | 12,8 | 8,3 | 9,7 | 8 | 6,9 | 3,5 | 6,2 | 20 | 16,5 | 16,5 | 15,2 |

| 9,6 | 11,4 | 19,7 | 30,3 | 53 | 125 | 167 | 12,2 | 16,3 | 25,2 | 41,5 | ||||

| Fiberglass, carbon fiber-graphite | 100-250 | 38-88 | 370-870 | 12,8 | 8,3 | 9,6 | 7,9 | 6,9 | 3,5 | 6,2 | 20 | 16,5 | 16,5 | 15,2 |

| 9,6 | 11,4 | 19,7 | 30,3 | 53 | 125 | 167 | 12,2 | 16,3 | 25,2 | 41,5 | ||||

Calculation of pressure and quantity of coolant

| Tool length | ||||||

| 3×D | 4×D | 5×D | 8×D | 10×D | 12×D | 15×D |

| see table | 1,3 | 1,5 | 2 | 3 | ||

Example

25mm diameter hole using replaceable powder steel plate, a steel alloy with a strength of 450-1265 N/mm2.

5×D: 4.8 bar, 22.7 (l/min)

12×D: 4.8 bar×2 = 9.6 bar, 22.7 (l/min)×2 = 45.4 (l/min)

15×D: 4.8 bar×3 = 14.4 bar, 22.7 (l/min)×3= 68.1 (l/min)

Technologies for drilling holes in metal used in everyday life

In everyday life, three technologies are used for drilling holes in metal. Workpieces and sheets are clamped using clamps and a vice. Most often, ordinary household drills and cylindrical twist drills are used at home.

Conventional drilling

This metal drilling technology is familiar to everyone.

- Marking is taking place.

- The hole is marked using a hammer and center punch.

- The workpiece is clamped in a vice or using a clamp.

- A drill of the required diameter is inserted into the drill chuck and clamped.

- The tool is centered.

- Drill a through or blind hole.

Photo No. 3: drilling metal at home

Reaming

Metal drilling is a technology aimed at increasing the diameter of a previously made hole. To do this, take drills of large diameters.

At home, holes usually have to be drilled in stages, gradually increasing the diameter of the tools used. This is due to the fact that in many cases the power of a household drill is not enough to drill large diameter holes in thick workpieces. In addition, the step-by-step approach reduces the axial pressure on the drills. This significantly reduces the likelihood of breakdowns.

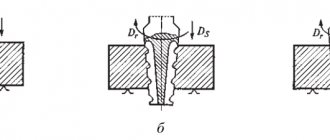

Image No. 1: the principle of drilling large diameter holes in thick metal at home

Reducing the diameters of the deep parts of the holes

In this drilling technique, a shallow, large-diameter hole is first drilled and then smaller tools are used. The technology looks like this.

Image No. 2: technology for reducing the diameters of holes in metal

How to avoid dulling drills

During use, a metal drill may become dull if it begins to get very hot when rotating. As a result of such heating, the strength of such a tool is lost. It is worth noting that the heating process occurs due to friction, therefore, the faster the amplitude of rotation of the drill chuck, the stronger the heating will be.

Therefore, in order to prevent such a tool from overheating during work, it is recommended to make holes in metal surfaces at low speeds (no more than 1 thousand revolutions per minute). If it is necessary to drill a thick workpiece, then it is recommended to use a special lubricant or paste that will provide additional cooling of the tool. Lubricant can be added directly to the place where drilling is carried out. You can also dip the drills themselves in lubricants or pastes. If you don’t have special lubricants at hand, then you can use ordinary machine oil.