A burr is a tool for a variety of jobs that require precision. Without it, it is impossible to imagine cutting, grinding, polishing, engraving, seam processing, plumbing and much more. Over the entire history of burrs, the design of this tool has not undergone significant changes.

A shank pin having a cutting part and a “leg” with which it is attached to the chuck. Used on large processing machines, small milling cutters, and also used with drills, screwdrivers and engravers. Allows you to perform work efficiently, cleanly and accurately with almost no spark.

A wide range of shapes, sizes, cutting surface profiles and materials from which burrs are made make them indispensable in the automotive, ship and machine tool industries, in the production of metal, plastic, ceramic and wooden products, in jewelry, as well as in electronics and printing and dentistry.

Using a burr you can:

- With great precision process surfaces, external and internal, corners, bevels and grooves of mechanisms, even in hard-to-reach places;

- Remove scrap and bur from workpieces, welded parts and seams. The wear resistance of the burr is 100 times higher than that of the grinding wheel;

- Cut hardened steels (hardness greater than 70 HRC Rockwell);

- Perform fine engraving and grinding work on any metals, ceramics, glass.

The technical requirements will be different in each individual case. Let's look into them.

There are burrs

Made from tool carbon steel

With markings U - carbon instrumental, numbers from 7 to 13 - percentage of carbon, A - high-quality.

For example, U10A is a common steel grade with 10% carbon content for the production of burrs.

The durability of such burrs is relatively low, the resource is limited, but they process products made of soft materials without great intensity of work. The price is very affordable;

Made of high-speed steel R6M5

Such a tool is much more expensive, but it can be used to process carbon steels, medium-alloy steels and other hard materials.

It is more resistant to high temperatures, inevitable when working at high speeds, and therefore deforms little, ensuring high precision of work;

Carbide

Made from tungsten carbide (VK25, VK30) and other carbides of refractory metals, from mineral ceramics, such burrs can easily take high-strength steels and cast iron.

Carbide burrs are most common in enterprises where work with burrs is carried out almost continuously;

Diamond

A professional tool, distinguished by its special durability and maximum price. Easily bores the toughest materials.

Often used for finishing shaped holes. After working with diamond burrs, there are practically no traces of processing visible on the product, it becomes extremely smooth;

Milling glass with a diamond burr - video

Abrasive

They are divided into two types: with a metal working head, which is coated with abrasive, and completely made of abrasive - electrocorundum.

In factories, burrs often work non-stop. To increase heat and wear resistance and extend the life of the tool, manufacturers of carbide burrs use additional coating.

Coating options:

- TiN with a hardness of 2400 HV;

- TiAlN, with a hardness of 3400 HV.

Even when using carbide cutters, it is necessary to use a special cutting fluid (coolant). Strong heating of the tool affects the accuracy and quality of processing. It also leads to rapid wear of machine engines. Coolant significantly reduces the heating of the burr and, as a result, further extends its service life.

Varieties

Metal burrs are used in metal processing. If everything is clear about the shape of the equipment, then choosing the material from which it is made is more difficult. To avoid mistakes, you need to study general information about what burrs can be made of.

Types of burrs for metal

Carbon steel

The most common type of attachments for electric drills used in processing metal surfaces. In their production, cheap, accessible material is used, which determines the low price for the finished equipment. Advantages:

- low price;

- wide selection of shapes.

Flaws:

- the quality is significantly worse than other materials;

- fragility;

- low quality.

The working part, made of carbon steel, is quickly ground down during active work.

Diamond coated

Diamond-coated metal burrs are used for many jobs. Advantages:

- Used for processing metal surfaces, glass, ceramics.

- Diamond coating is applied to equipment for drills and engravers. They are used to carry out jewelry work.

- High precision of work performed.

The disadvantages of diamond-coated cutters include their high cost. After working with this type of equipment, the results of rotating the burr are invisible on the surface being processed.

Abrasive tool

It is an abrasive material that is fixed to the working part of the cutter. It can be of any shape, size. The best abrasive material for the manufacture of this type of equipment is electrocorundum. Burrs with abrasive are used for processing wood, metal, glass, and ceramics.

Electrocorundum

With carbide head

The purpose of this type of equipment is the processing of cast iron, alloy steel, and titanium-based alloys. Advantages:

- the ability to process any type of metal;

- durability, wear resistance.

The disadvantages of these metal burrs include their high price. They are installed on high-power equipment to achieve maximum performance and accuracy.

Classification of burrs by type of cutting head

Burrs vary in design. Depending on the technological tasks at hand, the shape of the cutting part of the tool is also selected. The correctly selected type of burr greatly facilitates the work, makes the geometry accurate, and the result close to ideal.

Type A – cylindrical burrs. Universal. Ideal for flats, burrs and holes.

Type B – cylindrical burrs with an end. Unlike type A burrs, they also have an end with a section. Versatile, excellent for surface treatment and sampling.

Type C – spherical cylindrical burrs. For surfaces and radii. The rounded end is a rational solution for smooth curves.

Type D – spherical burrs. Excellent processing of internal holes, bearing seats and contours.

Type E – oval burrs. They are ideal for rounded corners and smooth paths.

Type F – hyperbolic burrs with a spherical end. Proven solution for molded parts with soft contours.

Type G – hyperbolic burrs with a point end. For chamfering, forming precise angles, engraving.

Type H – flame-shaped burrs. Ideal for processing molded curved parts.

Type J – 60% conical burrs. The best option for countersinking at a given angle.

Type K – 90% conical burrs. For edges, chamfers, countersinking.

Type L – spherical conical burrs. For difficult places.

Type M – conical burrs. For hard-to-reach places, delicate tasks and spot drilling.

Type N – with reverse cone. This carbide burr is reliable and convenient for corners and hidden recesses.

For woodworking

Processing wooden blanks does not cause such difficulties as working with metal. Using cutters for wood drills, you can carry out both rough and finishing processing of workpieces. For hand tools, cutters are used whose shank has a diameter of 8 or 12 mm. When processing different wood materials, different types of cutters are used. Types of wood cutters:

- Moulded. Used for rounding corners.

- Disk. Used for cutting various grooves and grooves.

- Fillet - to create semicircular grooves.

- V-shaped. Used for cutting grooves on flat surfaces.

- Tenon - for making dovetail grooves.

- Edging - for processing the edges of products.

- Cylindrical - for processing flat surfaces.

- End - for the production of recesses and recesses.

- Conical - chamfers the edges.

- Drills designed for making holes in wood.

To perform various technological operations, the required type of tool is selected. When working with cutting tools, you must follow safety rules. During the processing process, pieces of the processed material fly off, and the cutting tool may break. For safety reasons, you should wear safety glasses and gloves.

Originally posted 2018-07-04 08:34:07.

Working section profiles

Standard sharpening. Has one long notch. Suitable for cast parts, welds, alloys, brass, steel, including resistant heat-treated steel. Allows you to make large allowances. The shavings are long. Efficiency is optimal.

Double sharpening. It has cross-shaped notches on the working surface, resulting in the formation of teeth. Universal type. Suitable for working with any materials. Reduces burr vibration, allowing for better control of the process. Provides high cutting speed. Leaves a clean, smooth surface. The teeth formed as a result of notching are straight and multi-directional. A burr with this sharpening produces small chips.

Large sharpening. It has one wide notch (width and angle may vary). Great for soft materials such as aluminum and where large volumes need to be removed. Fast work with large chips.

Purpose

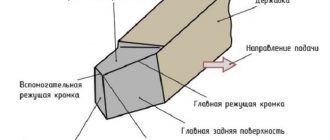

Humanity has been using this tool for many years. They constantly tried to modernize it. However, the design of such a device has not undergone major changes. As before, the cutter, or burr, consists of two parts: a shank for mounting in the chuck, as well as a cutting part that processes the part.

To carry out technological operations using a device, tools are used that can create a rotary cutter speed of about 60,000 rpm. The use of a burr and hand tools allows you to process and grind hard-to-reach surfaces.

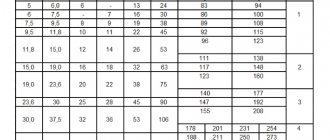

Three tooth size options

- F - fine tooth

- M – middle tooth

- C – large tooth

Taking into account the surface profile, the tooth size designations look like this:

Now, knowing the characteristics of burrs based on materials of manufacture, profile types and types of notches, we can choose the right tool for the job, as well as “read” the markings of any burr.

The State Standard of the Russian Federation establishes the technical uniformity of units of measurement, standards of sizes, types, designations, steels, alloys, roughnesses and their permissible errors. So, according to GOST R 52780-2007, we will understand the marking of Borfrez S 10 20 M 06 40 GOST R 52780 - 2007 as follows:

- Spherocylindrical burr (type C),

- diameter of the cutting part - 10 mm,

- length of the cutting part - 20 mm,

- medium tooth, shank length - 6 mm,

- shank diameter - 40 mm.

The figure shows a spherical burr with standard sharpening.

When purchasing a burr in a store, you should definitely check for markings on the tool leg and on the packaging. Responsible manufacturers who produce quality products must label the product. The absence of such indicates, most likely, the low quality of the product.

Areas of use

Carbide cutters are distinguished by great functionality. They are widely used in many industries:

- Machine tool industry.

- Car manufacturing.

- Electronics.

- Jewelry.

- Printing.

The miniature dimensions of the working part of the tool make it possible to process the surface of complex parts, for example, matrices. A certain type of cutter allows you to perform other technological operations:

- Draw beautiful patterns.

- Make inscriptions.

- Grind hard-to-reach holes.

- Process complex and deep grooves.

In domestic conditions, carbide metal burrs help home craftsmen carry out a large number of operations. Having secured the cutter into the chuck of an electric drill, you can do the following:

- Cleaning the weld seam.

- Boring the hole.

- Deburring.

- Sanding the metal surface.

- Leveling the surface of the part to perfect condition.

Control and test methods

Burrs, despite their apparent simplicity of design, are very precise, durable tools that experience enormous loads. Its quality should be at its best.

Since the burr market is overflowing with offers from a variety of manufacturers, often seeking to increase production volumes at the expense of quality, control over compliance with GOST is necessary.

Large enterprises that regularly use burrs usually purchase them from several trusted suppliers. And they are periodically compared with compliance samples.

The quality of the material, the strength of the soldering of the leg and the working head, precise alignment, ideal geometry, the ratio of the bakelite base and high-quality abrasive - all this matters for the operation of the burr.

There are several control methods:

- Visually, with a magnifying glass and caliper, check the appearance and roughness;

- Using a microscope and using laser centerers, it is checked whether the burr has any deviations in alignment;

- Durability is tested using electrical or pneumatic equipment. The total length of the test milling is 3000 mm if d burrs < 10 mm, and 10000 mm if d > 10 mm.

After the test work, there should be no chips or chips left on the burr and it should remain suitable for work.

A simple quality check of a carbide burr can be carried out at home.

Review abrasive uniformity and grit calibration using a magnifying glass. Is the connecting seam between the working part and the pin strong enough or is the soldering done poorly, with large gaps.

You can, by holding the burr in the drill chuck, turn on the tool at high speeds - the asymmetrical shape of the rotating cutter, noticeable even to the eye, will indicate incorrect alignment.

Do not work with low-quality or worn burrs! This may cause damage and injury.

How to choose an engraver for manual work

When choosing an engraver, you need to pay attention to:

- Power - the higher it is, the easier it is for the engraver to process hard materials.

- The size of the collet is important for selecting accessories. The principle of its operation is the same as that of milling cutters, and the most common diameter is 3.2 mm. In addition, there are collets with diameters of 2.4, 1.6 and 0.8 mm.

Tip: Try to choose tools with a set of collets so that you can use a variety of attachments.

- The number of revolutions of the device and the ability to regulate them are a very important factor when choosing an engraver. This is due to the fact that there are nozzles that are prohibited from being used at high speeds or, conversely, they are optimally used at high rotation speeds of the main shaft of the device.

Wood cutters for engravers for performing figured carvings

Advice: we recommend giving preference to engravers with high speeds, as well as the ability to adjust them, because they can use different types of attachments, which significantly increases the range of their capabilities.

- Complete set - it is best to purchase models as complete as possible, although the price will be higher. For example, if the kit includes a flexible shaft, it will make engraving work much more convenient. You can hang the engraver itself on a hook, and carry out the entire process using only a flexible shaft.

Set of cutters for wood engraver

- Attachments - the more varied they are, the better, thanks to them you can perform a wide variety of engraving work on any material. Even if you don’t need some at this time, you won’t have to overpay later.

Attachments for a wood engraver allow you to complete any work you have in mind.

- Packaging – this factor also matters. It’s very good when both the engraver and its accessories come in a convenient case.

- Weight – we recommend purchasing a lightweight tool, since holding a heavy one during long grinding operations will be quite uncomfortable.

While working, be sure to use safety glasses to prevent sawdust from getting into your eyes (see also the article “Disc cutter for wood - types and type of installation. Location and fastening of teeth”).

The process instructions are as follows:

- Select the necessary nozzle so that you can get exactly the pattern you had in mind. For example, cylindrical ones are used for flat ones, and rounded ones for hollow ones. There are also special attachments that are usually used for rare types of work.

Tip: using drop-shaped attachments makes it possible to carry out your plans as accurately as possible, thanks to changing the angle of inclination.

- Make a drawing with your own hands on a wooden surface or transfer it from paper. When working with wood, the fine detailing depends only on the width of the tool and your hand.

Tip: If you don't want to draw on the surface, use a thin film of polyester onto which you draw your sketch and then adhere it to it.

- Start engraving. After turning on the tool, carefully lower the engraver onto the surface. Take your time, all your movements should be slow and smooth. To obtain an image in 3D format, you need to make too deep cuts. It’s better to go over the drawing lightly first, and then a second round if you don’t like something.

Spiral burrs for wood engraver 3mm

- At the last stage, you can cover the surface with paint, then the design may become more noticeable. At the same time, make the surrounding background a different color, highlighting it. Paint or clear varnish can also protect the material from wear and tear.

What is laser engraving on wood?

This is the name for the process of burning a wooden surface using a laser. In this case, it is possible to obtain a high-quality image, which cannot be achieved using the classical method. For example, the device allows you to display even the smallest details of a drawing.

Mini laser device for wood engraving

What is it used for?

Today laser engraving is used to create:

| Souvenirs and gifts | Burnt designs, inscriptions or logos look beautiful, harmonizing and emphasizing the natural color of the surface. The technology allows you to transfer photographs, paintings and portraits onto wood, making such a gift doubly pleasant, which will definitely take pride of place in your apartment or house. |

| Decorative elements | With the help of laser engraving you can create spectacular products for the interior. Their originality will only emphasize the style of the owners. |

| Advertisements | Now it’s not difficult to create a sign, sign or stand with the company logo on it. |

Unlike classic burning on a surface, the laser does not come into contact with it. Therefore, it is possible to create a pattern on thin or easily deformable elements.

Advice: the surface of products that are subject to abrasion must be varnished after laser treatment.

The final result of laser wood processing is influenced by its species and pre-treatment. Although, even with the worst parameters, you will get the most detailed drawing with a durable relief image that will give the product a presentable appearance.

Wood carving with an engraver installed on a CNC machine

Recommendations from professionals

- Don't rush to start the learning process with heavy drawings.

- Take the tool in your hand and feel it, trying to make a few lines with it.

- Choose the most comfortable position for yourself - this is a very important factor.

- Once you are comfortable with the engraver, try making simple inscriptions by first applying them to the surface of the wood.

- The main thing is to take your time, no one is forcing you to do everything at once in one sitting.

- Make sure that your hand does not get tired, otherwise after a while you will simply ruin your work.

The photo shows a wood engraving tool with a flexible shaft

Conclusion

Working with a hand-held electric engraver may remind you of working with a burner; you will also have to carefully trace the outline of a pre-applied design. When choosing a tool, take into account our recommendations so that your image turns out to be as realistic as possible (see also the article “Attachments for wood drills and their types. Grinding and polishing. Milling. Cutting”).

For more complex parts, it is best to use CNC machines or a laser device. The video in this article will give you the opportunity to find additional information on the above topic.

Source: https://rubankom.com/obrabotka/ruchn/160-graver-po-derevu

Exploitation

So, when starting work, it is important to remember the correct choice of standard size for the type of processing that is to be done - roughing, finishing, sphere, plane, etc.

For example, you should not use a spherical burr with a coarse cut to grind an internal sharp groove. To do this, it would be better to take a conical one with a double notch.

A carbide cylindrical burr with a double fine cut will make the plane ideal, while a spherical burr in this case can only ruin the workpiece. The harder the metal being processed, the smaller the cross-section of the burr should be - this is one of the basic principles of operation.

Failure to comply with this rule will lead to clogging of the grooves between the burr teeth, overheating of the tool, its rapid wear and poor quality work results.

The smaller the diameter of the burr, the higher the rotation speed should be. As the diameter of the tool increases, the number of revolutions per minute of the engine should decrease.

Use the maximum permissible speeds of the required modes. Otherwise, beating, chipping, and premature wear of the teeth are guaranteed.

When clamping the shank in a chuck or collet, a minimum area must be left free. This reduces vibration and minimizes the risk of shank breakage.

The force of pressure on the burr does not increase its efficiency, but increases the load on the tool and equipment. This may cause them to fail. Don't push!

It is necessary to remember the safety rules, protection of the organs of vision, hearing, and hands from possible damage. The eyes are the most vulnerable organ and to protect them you need to choose safety glasses wisely.

Special impact resistance markings on glasses will help you choose them correctly.

Existing designations for mechanical strength:

- S - high strength;

- F - for spent particles with a speed of 45 m/s;

- B - for spent particles with a speed of 120 m/s;

- A - for spent particles with a speed of 190 m/s.

In our case, when working with burrs, the speed of flying particles is no higher than 45 m/s, which means glasses with the letter F will be enough.

Some pro tips

If you want to increase the operating time of a burr for metal processing, you must follow several rules:

- When a metal surface is processed, the working part must be in full contact with the workpiece.

- The shank must not touch the workpiece. The burr may break.

- When processing the surface, it is necessary to avoid strong pressure on the tool. This can lead to overheating of the cutter and its breakage.

- The device should only be used on high-speed equipment. This will prevent the tool from jamming in the metal. High speed will make it possible to more thoroughly process the surface of the grooves.

- To prevent severe wear of the device, the working head must be lubricated with a special lubricant during operation. It will improve sliding and also reduce pressure on the tool.

- To reduce wear on the cutting head, a special suspension can be used. It contains synthetic engine oil. During processing, the tool is constantly lubricated with this composition.

- Do not start work with a worn burr. You will have to expend a lot of physical effort. Moreover, the cutter itself, as well as the equipment used, may break.

All pages of the document GOST R 52780 2007 for burrs

Material and design

The burr is a composite tool: the working part is attached by soldering to a cylindrical shank made of medium-carbon alloy steel type 30KhGSA. She may be:

- Made of tool carbon steel (U10A, U12A), often intended for drilling. The durability of such a tool is low, so it is used when processing relatively soft materials. For example, with such a burr on an engraver you can create designs of tiles or ceramic cups. The second option is that such work is rare in the household, which makes purchasing an expensive cutter impractical.

- Made of high-speed steel type R6M5. The tool will cost more, but the possibilities of its use are significantly expanded. The high red resistance of high-speed steels makes it possible to effectively process almost all grades of carbon and medium-alloy steels. At the same time, the thermal deformation of the working part is insignificant, which has a positive effect on the accuracy of the work.

- Carbide burrs, the working part of which is made of metal-ceramic type VK25 or VK30 (also found in tungsten-free carbide alloys or mineral ceramics). This tool can be used to grind high-strength heat-resistant and stainless steels, as well as cast iron.

- Extra-resistant burrs with diamond-coated working edges. They are a professional tool and are used in large-scale operations of this kind. They differ in maximum cost.

The equipment in question can be used on any equipment that is equipped with a rotating working head, and the chuck is capable of reliably securing the burr shank (the diameter of the tail part is most often standard: 6 or 8 mm, although engraving cutters have smaller sizes). Such equipment includes a high-speed electric drill, as well as a high-speed grinding or drilling machine.

The only condition is that the burr is not a power tool, but a dynamic tool, and is adapted for use with a spindle speed of at least 60,000...65,000 min-1.