Modifications of the desktop drilling machine 2С125-01:

— drilling machine 2С125-01. Has an accuracy class according to GOST - N, normal. Installed on a stand, workbench, cabinet. Previously, the machine was produced under the name SN-16.

- 2С125П-01. Has an increased accuracy class, for high-precision drilling operations, for blind and through depth drilling

— the machine can also be placed on its own stand for convenient operation.

Tabletop vertical drilling machine 2С125-01 price – 124,000 rubles.

The machine is new, 1 year warranty, pre-sale preparation.

Brief description of the components of the machine 2S132, 2S132K, 2S132Ts, 2S132PF2I

The machine column is a hollow box-shaped cast iron casting. A drilling head and a lifting table with three T-shaped slots, in which overhead cross tables are fixed, are manually moved along the dovetail column guides: mechanized - on a mod. 2S132PF2I, floating with manual control - on a machine mod. 2S132K. An electric pump is installed on the foundation slab, inside the column. The base plate serves as a reservoir for the coolant.

The drilling head is a box-shaped cast iron in which all the main assembly units of the machine are mounted: speed box, feed box, spindle, feed mechanism, spindle counterweight and speed and feed switching mechanism.

The feed mechanism is driven from the feed box and is designed to perform the following operations:

- Manual or automatic approach of a tool fixed in the spindle to the part;

- Manual feed advance;

- Manual or automatic spindle retraction upward;

- Manual feed used in thread cutting.

The overhead mechanized cross table is designed to move the workpiece installed in a fixture on the working surface of the table in the longitudinal (along the X axis) and transverse (along the Y axis) directions.

The mechanized cross table provides fast movements, positioning in specified coordinates, as well as working feed of the workpiece for easy straight-line milling.

The table contains drives for the longitudinal movement of the table along the slide guides, the transverse movement of the slide along the base guides, as well as the protection of the longitudinal and transverse guides.

The floating table is designed for processing parts using a copier or marking and consists of three main parts: a table, a slide and a base.

The table moves along the slide in the longitudinal direction on roller needle bearings. The slide together with the table moves transversely on the same roller needle bearings. Roller needle bearings make it easy to move and set the table into the desired position.

Modifications of drilling machines 2С132

To process holes of different diameters, basic vertical drilling machines of the following models are used: 2С132. The last two digits of each model number indicate the largest hole diameter in mm that this machine can drill into 45 steel workpieces.

Based on the above basic machine models, the following modified models were created:

- 2С132 (SB50) - basic model of a vertical drilling machine;

- 2S132L (SB50R) - vertical drilling machine on a round column;

- 2S132K - coordinate vertical drilling machine with a floating cross table;

- 2S132PF2I - coordinate vertical drilling machine with a floating cross table and digital control (CNC);

- 2С132Ц, 2С132ЦП - vertical drilling machines with automated control (control is carried out using pre-configured cams and buttons).

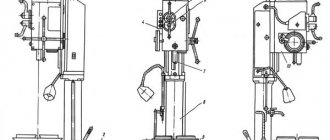

Design and operating principle of 2С125-01:

The bed for drilling work is made of cast iron; this design, due to its weight and stability, makes the machine more rigid and prevents large vibrations when processing parts. Thread taps can be used to cut metric threads from M5 to M22. To limit the thread length or feed depth, the 2S125-01 vertical drilling machine has a mechanical limiter. You can install a workpiece with a maximum size of 320x320 on the workbench, if its reinstallation is not required. The parts are secured using clamps, a rotary vice, and a dividing head in the grooves of the table. The maximum height of the part installed on the work table is 580mm. The column of the 2S125-01 metal drilling machine is round and can be rotated in both directions to expand the technological capabilities of the machine. In addition, we can offer tools, bushings, taps with Morse taper 3, directly inserted into the quill.

Characteristics

The vertical drilling machine 2S125 has a reversible AC motor with an industrial frequency of 50 Hz, which increases the capabilities of material processing, especially when cutting threads with machine taps. The main technical characteristics are as follows:

- rotation speed – from 90 to 2800 rpm;

- number of speeds – 9;

- limits of hole diameters in steels of low and medium hardness – from 3 to 31 mm;

- thread cutting limits – from M3 to M22;

- maximum workpiece height – 900 mm;

- the distance from the spindle axis to the column is 320 mm.

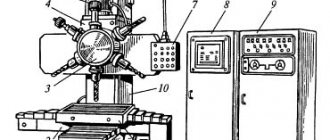

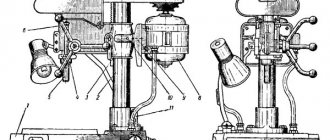

General view of the vertical drilling machine 2S125

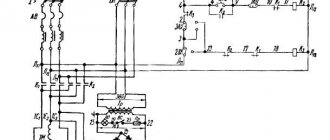

Model 2C125 has a three-phase electric motor designed for connection to an industrial three-phase electrical network of 380 V. Depending on customer requirements, the manufacturer can install a working electric motor with a power of 1.1 or 1.3 kW with a rotor speed of 1110 or 1360 rpm, respectively.

For ease of operation, the vertical column has a rectangular table, which can either rotate around the column or move vertically along it using a rack and pinion gear. When placing a workpiece on a table, its maximum height size is limited to 500 mm. The maximum weight of the workpiece placed on the table should not exceed 100 kg.

The table and base of the device each have three T-shaped fastening grooves for installing fastening devices. The width of the groove is 14H12. The distance between the grooves is 80 mm.

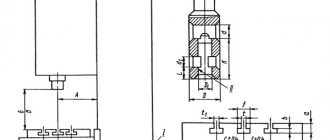

The spindle has a manual feed, with a maximum travel height of 150 mm. The height is controlled by the drill depth indicator on the front of the drill head. To prevent spontaneous lowering of the spindle, the machine is equipped with a spring counterweight.

To fasten the working tool, this model is equipped with an internal Morse taper 3. This allows you to quickly change the working tool for various technological operations.

General view of the vertical drilling machine 2S125

Machine 2S125 - side view

Machine 2S125 - front view

The modification of the 2C125-04 model has the ability to automatically feed the spindle, which is important when cutting threads in holes with machine taps.

Technical characteristics of the drilling machine 2С125-01:

| Ø drilling in steel, mm | 31 |

| Ø thread, mm | M5 – M22 |

| Work table, mm | 320x320 |

| T-slot, pcs. | 3 |

| Part height, mm | 580 |

| Width (depth) of the part, mm | 320 |

| Machine spindle, Morse taper | III |

| Quill offset, mm | 150 |

| Electric motor | 1.5kW, 380V, 50Hz |

| Torque, Nm | 140 |

| Number of speeds, pcs. | 9 |

| Spindle frequency, rpm | 90 – 1800 (*up to 2800m) |

| Accuracy class according to GOST | N, *P |

| Surface roughness, Ra | 6,3 – 1,6 |

| Dimensions 2С125-01, m | 0.8x0.4x1.4 |

| Weight 2С125-01, kg | 320 |

2A135 Universal vertical drilling machine. Purpose and scope

The 2A135 vertical drilling machine replaced an outdated machine in mass production. The new model provides more convenient control of the feed and feed box. Improved ergonomics. The 2A135 machine was replaced with a more advanced model

The universal vertical drilling machine, model 2A135, is designed for work in repair and tool shops, as well as in production shops with small-scale production; a machine equipped with accessories can be used in mass production.

Vertical drilling machine 2a135, with a nominal drilling diameter of 35 mm, is used in enterprises with single and small-scale production and is designed to perform the following operations: drilling, reaming, countersinking, countersinking, reaming, threading and trimming ends with knives.

Allows processing of parts in a wide range of sizes from various materials using tools from high-carbon and high-speed steels and hard alloys.

Drilling operations on machine 2a135

Design features of the drilling machine 2A135

The presence on the machine of a nine-speed gearbox with a control range of 68-100-140-195-175-400-530-750-1100 rpm, an 11-speed feed box with a control range of 0.115 to 1.6 mm per revolution and electric reverse provides selection of standard cutting modes for hole diameters up to 35 mm when drilling, reaming, countersinking, countersinking, reaming, threading, and also allows the use of cutting tools equipped with carbide.

The presence of mechanical spindle feed on machines, with manual control of work cycles.

Allows processing of parts in a wide range of sizes from various materials using tools from high-carbon and high-speed steels and hard alloys.

The machines are equipped with a device for reversing the main motion electric motor, which allows them to cut threads using machine taps while manually feeding the spindle.

The machine has high rigidity, strength of working mechanisms, drive power and a wide range of cutting speeds and feeds, allowing the use of cutting tools equipped with carbide. The presence of an electric reverse, controlled both automatically and manually, provides the ability to cut threads with manual approach and withdrawal of the tap.

The design of the vertical drilling machine model 2A135 provides for automatic switching on of the feed movement after the cutting tool is quickly brought to the workpiece and automatic switching off of the feed when the specified drilling depth is reached.

The specified drilling depth for blind holes is ensured by a special stopping mechanism with a stop. This mechanism is also a safety device that protects the feed mechanism from damage due to overload.

The machine spindle is mounted on precision rolling bearings. The lower support consists of a radial ball bearing of class AB. The upper support has one class B ball bearing.

The plant provides the possibility of changing the drive pulleys of the belt drive, which allows you to set the limits of the spindle speed in accordance with the technological tasks.

To reduce auxiliary time on the machine model 2A135, it is possible to turn the feed on and off using the same steering wheel that manually moves the spindle quickly.

Placement category 4 according to GOST 15150-69.

Analogues of vertical drilling machines 2A135, currently produced:

- 2T125, 2T140, 2T150 – manufacturer: Gomel Machine Unit Plant

- 2AS132, 2AS132-01 – manufacturer: Astrakhan Machine Tool Plant

- 2L125, 2L132, 2L135, LS25, LS35 – manufacturer: Lipetsk Machine Tool Enterprise (PJSC STP-LSP)

- MN25L, MN25N-01 – manufacturer: Molodechno Machine Tool Plant