Used metalworking machines

Technical characteristics, description and passport 2M55

2M55 radial drilling machine is designed for drilling, reaming, countersinking, reaming, boring holes, tapping threads, trimming ends with a cutter, as well as performing other similar operations when processing various body parts.

The 2M55 machine has a two-column layout of the machine part, which makes it possible to create a rigid structure of the unit that does not allow the spindle axis to shift when clamping the column. A special center-type column clamp creates a braking torque that guarantees high-performance drilling.

To rotate the column, little force is required at the smallest drilling radius, which also ensures high productivity and reduces operator fatigue.

A wide range of speeds and spindle feeds of the 2M55 radial drilling machine ensures highly productive work with any combination of processed materials, tools, and sizes.

The machine of this model has an automatic shutdown mechanism when the specified drilling depth is reached. Spindle balancing is ensured by a special counterweight, allowing convenient adjustment from the workplace if the tool weight changes.

The machine has the following advantages compared to the previously produced model:

- tightening of the clamping of the column due to the developed cone, which allows working at high cutting conditions; increasing the volume of the working space by increasing the strokes of the hose along the column and the head along the hose;

- achieving the specified accuracy and achieving accuracy outside the slab thanks to the two-column layout and developed sleeve guides;

- reduction of time for re-aligning the hose in height due to the increased speed of its movement and the fast action of the clamp;

- increased maintainability thanks to a new design of column guides;

- the absence of mechanisms at the upper end that require maintenance, which ensures ease of operation of the machine and improves its appearance.

Technical characteristics of the drilling machine 2M55

Areas of application and technical features of the machine

The 2M55 machine, the design of which was developed in the famous Odessa design bureau "ARS", is used to perform such technological operations as:

- drilling and reaming holes;

- countersinking;

- deployment;

- boring pre-made holes;

- internal thread cutting;

- trimming the ends of parts, etc.

Due to the versatility of the radial drilling machine model 2M55, it is successfully used in enterprises that produce products in single, small and medium series, and in assembly shops of enterprises working in the field of heavy transport engineering. The technical capabilities of the machine allow it to be equipped with additional devices and tools, thanks to which this device can be used in large-scale production.

The massive base of the 2M55 machine allows you to place two tables and work with large parts

An important advantage of using the apparatus in question is that the workpiece remains stationary, and all movements are made by the spindle assembly with the cutting tool fixed in it. This design feature of the 2M55 model saves time and also eliminates the need to move large and heavy parts across the equipment workbench.

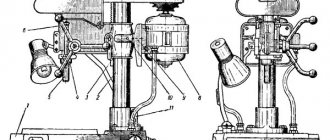

Radial drilling machine 2M55

The 2M55 radial drilling machine has found application not only in single and small-scale production, but also in serial and large-scale production, provided that it is retrofitted with specialized devices.

The manufacturer and founder of the production of machine tools is located in Ukraine, the city of Odessa. Production has been established since 1946.

Purpose

As the name suggests, this model performs operations related to the processing of holes. Using various tools, holes are processed using: drilling and reaming, countersinking and counterbore, and then reaming. Also on the machine, the ends are processed by trimming and threads are cut in the body of the part.

Radial drilling machines 2M55, the equipment of which can be expanded with specialized devices, perform operations of turning grooves inside holes, cutting holes on a metal sheet, and can also carry out high-speed processing.

The main advantage of radial drilling machines is the absence of movement of the workpiece during processing. Heavy or large parts are installed once, and processing is carried out by moving the tool over the surface of the part. This method reduces the loss of time for reinstallation and eliminates the inconvenience of turning.

Decoding the name of the machine

The marking is deciphered as follows:

- 2 – second group according to classification – drilling;

- m – subjected to modification;

- 5 – this is a subgroup (type) – radial drilling;

- 5 – permissible value parameter – size when drilling on improved steel 50 mm.

Technical parameters and characteristics

Radial drilling machine 2M55, the technical characteristics of which reflect the following parameters:

- accuracy class – N according to GOST 8-71;

- maximum permissible drilling size: cast iron – 63 mm;

- steel – 50 mm;

- swing - 1600 mm;

- cone on the spindle for tool mounting - Morse 5 according to GOST 24644-81;

- number of switchable speeds – 21;

- setting speed range – min 20 min-1, max 2000 min-1;

- number of innings – 12;

- feed range – 0.056-2.5 mm/rev;

- feed force when cutting, max – 20000 N;

- torque - 7000 N•m.

Parameters of electrical elements:

- general network, current - three-phase alternating;

- electric motor power:

- main - 4000 W;

- sleeve drive - 2200 W;

- column clamp - 500 W;

- drill clamp – 500 W;

- coolant stations - 125 W;

- speed switching – 150 W;

- feed switching – 150 W;

- Dimensions of the machine, LxWxH - 2545x1000x3315 mm;

- equipment weight - 4.1 tons.

Passport details

The passport of the radial drilling machine contains additional characteristics:

- column clamp – hydraulic;

- sleeve clamp – electric;

- Clamp of the drilling unit on the sleeve is hydraulic;

- There are no accelerated submissions.

Download the passport (operating instructions) of the radial drilling machine 2M55

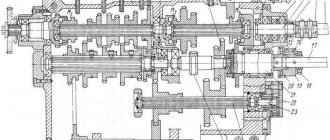

Kinematics

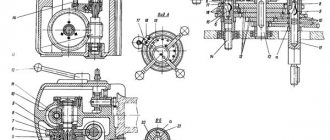

Kinematic diagram of the 2M55 machine

The kinematic diagram of the 2M55 machine ensures the movement of four chains:

- the main movement is the revolutions on the spindle;

- working feeds;

- movement of the drilling unit along the sleeve;

- movement of the sleeve along the column.

Electrical equipment

On the 2M55 machine, the electrical diagram shows the control of the working parts. The electrical circuit diagram is shown in the figure.

Electrical diagram of the 2M55 machine

- Safety of work on the machine is ensured by locks.

- If the control device is in the on state, then power will not be supplied to the engine until the control handle is set to the neutral position.

- Switching gears is impossible while the hydraulic preselector is operating. The signal is not supplied to the spool coil.

- The movement of the hose along the column is limited by two limit switches.

By supplying power to the electrical circuit, the main engine and the hydraulic motor are turned on, and the machine goes into setup mode.

Clamping and release of the drilling unit and column are hydraulic. The electrical circuit controls the hydraulic spool coils. The possibility of separate spinning of the drilling unit is organized.

You can only rotate the sleeve and move the drilling head manually by pressing the release button. The movement of the hose along the column is carried out by a separate M2 engine.

The circuit provides a preselective preset of spindle rotation speeds and working feeds. These operations are performed while the machine is running. At the end of processing, the signal from the relay is sent to the M5 engine. It moves the switching mechanism until the positions of switch B11 are matched with switch B13. After this, switching to the specified modes occurs.

The spindle has reverse rotation.

The load on the spindle motor is monitored using an ammeter IP1.

Controls

For the 2M55 machine, the operating manual describes how to control the machine.

Machine controls 2M55

The figure shows the following controls located on the drill head:

- accelerated spindle approach, connection of working feed – 5;

- drilling depth setting – 6;

- feed blocking during thread cutting – 7;

- latch for regulating the lowering of the coolant valve – 8;

- spinning the drill head – 9;

- spinning the column together with the drilling head – 10;

- column clamp together with drilling head – 11;

- connection between the dial and the feed mechanism -12;

- dial fine adjustment -13;

- ammeter (load indicator) – 14;

- counterweight spring tension regulator – 15;

- pre-dial indicator – 16;

- sleeve rise – 17;

- spindle shutdown – 18;

- pre-dial handle – 19;

- main engine start – 20;

- lowering the sleeve – 21;

- feed preset – 22;

- stop button – 23;

- reverse – 25;

- local lighting – 26;

- turning on mechanical feed – 29;

- precise manual feed – 30;

- coolant valve – 31;

- flywheel for drilling unit movement - 32.

Cooling system

A container for coolant is located in the cavity of the plate. The coolant is supplied to the cutting zone, to the tip, by a pump through a hose. Depending on the dimensions of the part, you can adjust the height of the tip.

Technical parameters and characteristics

Radial drilling machine 2M55, the technical characteristics of which reflect the following parameters:

- accuracy class – N according to GOST 8-71;

- maximum permissible drilling size: cast iron – 63 mm;

- steel – 50 mm;

- swing - 1600 mm;

Pinol:

- cone on the spindle for tool mounting - Morse 5 according to GOST 24644-81;

- number of switchable speeds – 21;

- setting speed range – min 20 min-1, max 2000 min-1;

- number of innings – 12;

- feed range – 0.056-2.5 mm/rev;

- feed force when cutting, max – 20000 N;

- torque - 7000 N•m.

Parameters of electrical elements:

- general network, current - three-phase alternating;

- electric motor power:

- main - 4000 W;

- sleeve drive - 2200 W;

- column clamp - 500 W;

- drill clamp – 500 W;

- coolant stations - 125 W;

- speed switching – 150 W;

- feed switching – 150 W;

Dimensions:

- Dimensions of the machine, LxWxH - 2545x1000x3315 mm;

- equipment weight - 4.1 tons.

Radial drilling machine 2M55

- Description

- Comments

- Reviews

The 2M55 radial drilling machine is designed for drilling, reaming, countersinking, reaming, boring holes, tapping threads, trimming ends with a cutter, as well as performing other similar operations when processing various body parts.

The machine has a two-column layout of the machine part, which makes it possible to create a rigid unit structure that does not allow the spindle axis to shift when clamping the column. A special center-type column clamp creates a braking torque that guarantees high-performance drilling.

To rotate the column, little force is required at the smallest drilling radius, which also ensures high productivity and reduces operator fatigue.

A wide range of spindle speeds and feeds ensures high-performance work for any combination of processed materials, tools, sizes, etc.

A preselective remote electro-hydraulic device allows you to change modes with their preliminary selection. The machine has an automatic shutdown mechanism when the specified drilling depth is reached. Spindle balancing is ensured by a special counterweight, allowing convenient adjustment from the workplace if the tool weight changes.

Radial drilling machine 2M55 technical characteristics

| Characteristic | 2M55 |

| Largest drilling diameter in medium-hard steel, mm | 50 |

| Spindle overhang (distance from the spindle axis to the generatrix of the column), mm. | 450 — 1500 |

| Distance from the lower end of the spindle to the plate, mm. | 470 — 1500 |

| The greatest vertical movement of the hose along the column, | 680 |

| Maximum axial movement of the spindle, mm. | 350 |

| Spindle taper | Morse 5 |

| The greatest weight of the tool controlled by the counterweight at the highest permissible tightening, kg. | 30 |

| Number of spindle speeds | 19 |

| RPM limits | 30 — 1700 |

| Spindle drive electric motor power, kW. | 4,5 |

| Power of the electric motor for moving the sleeve, kW. | 1,7 |

| Machine dimensions, mm. | 2625 x 968 x 3265 |

| Weight 2M55 2M55 machine, kg. | 4100 |

Comments and questions:

Reviews about 2M55:

The manufacturing company reserves the right to change the configuration and place of production of the product without notice!

Please note that the information on the site is not a public offer!

Other characteristics of 2M55

In operation, the 2M55 radial drilling machine, the description of which was given above, as you can see, is quite convenient. This is determined primarily, of course, by its excellent technical characteristics. Characteristics of the 2M55 machine

| Parameter | Meaning |

| Spindle overhang ranges | 450-1500 mm |

| Distance from spindle to surface | 470-1500 mm |

| The greatest movement of the hose along the column in the vertical direction | 680 mm |

| Maximum axial spindle movement | 350 mm |

| Revolutions | 30-1700 mm |

| Spindle motor power | 4.5 kW |

| Sleeve motor power | 1.7 kW |

The technical characteristics of the 2M55 radial drilling machine, therefore, are very good. This model is equipped with a control system that makes it easy to automate any operation performed.

It comes, of course, complete with a 2M55 radial drilling machine and a passport. From this document you can learn more about the characteristics of the unit. Also included with the passport are instructions for operating this equipment and safety rules when working on it.

Technical characteristics and diagram of the 2M55 radial drilling machine

The 2M55 radial drilling machine, the technical characteristics and diagram of which will be presented below, is used to make holes in metal and other structural materials. Using countersinks and reamers, we achieve high drilling accuracy and quality of the machined surface. Taps are used to cut internal threads. Using through and end cutters, holes are bored.

The use of the 2M55 machine is possible for processing cases. It is used for individual production of parts, and is also integrated into technological processes of serial and mass production. Equipped with conductors and auxiliary devices, they create a specialized unit that processes large workpieces in continuous production.

- Technical characteristics of technological equipment for drilling

- Design features

- Performing drilling work on a machine

- Features of the design of machine components

- Desktop

- Support column

- Power supply for drill head

- Machine illustrations and specifications

Technical characteristics of technological equipment for drilling

The manufacturer of the machine is the Odessa Radial Drilling Machines Plant. The specified device has been produced since 1974.

When making holes in 45 steel, the maximum diameter of the drill used is 50 mm.

It is allowed to drill holes at a distance of 400 mm.

- The height of the spindle to the table is 450…1600 mm.

- Displacement from the spindle axis to the support post is 375…1600 mm.

- Tool rotation speed 20…2000 rpm.

- Drive power 5.5 kW.

- Equipment weight 4.7 tons.

Design features

The layout of the device is made in a two-column form. The result is a rigid structure. It does not allow the spindle axis to move when the column is fixed. For rigid installation, a special clamp is used to ensure reliable installation. Therefore, drilling can be carried out with a high tool feed rate.

21 spindle rotation speeds allow you to select the optimal drilling mode for a wide variety of types of structural materials, as well as the types of tools used.

When drilling to a given depth is completed, the machine will turn off the feed of the actuating tool into the depth of the workpiece.

The work of the counterweight is to balance the loads on the drill column, which makes it easier to set up the equipment even when using a fairly heavy tool.

Performing drilling work on a machine

Rotation from the electric motor is transmitted to:

- elastic coupling that smoothes vibration;

- a clutch that allows you to engage the gear in “soft” mode;

- a gearbox with movable gear blocks (4 pcs.).

The presence of a ring gear in the gearbox allows for reverse rotation of the spindle. It turns on after the clutches stop. For every two forward speeds there is one reverse speed.

In double gear blocks, it is possible to move the slider so that there is no engagement in the third intermediate position. Then the operator can rotate by hand without much effort (there is no gearing, no need to rotate the gear blocks).

A feed clutch is used to move the spindle vertically up and down. A worm gear is used here: a worm wheel and a worm. They carry out the movement of the spindle quill in forward and reverse directions (changed by turning on the reverse motor).

When reversing the spindle feed motor, a dog-type safety clutch is used. If the maximum moving force increases, it is switched off. This technical solution allows you not to overload the tool (prevents its breakage) when drilling holes.

Features of the design of machine components

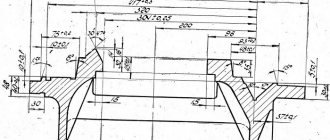

Desktop

The base plate is made as a modified cast iron casting. For reinforcement, the structure is provided with longitudinal and transverse ribs. Special T-shaped grooves allow the use of different methods of fixing workpieces. You can install:

- Three-jaw chucks, cylindrical parts are fixed in them. Then axial drilling will be performed with high precision.

- Four-jaw chucks are designed for fixing asymmetrical parts on the table.

- Pneumatic or eccentric clamps are used for positional fastening of a special shape.

Support column

A conical ring is used to fix the column. During axial movement, the cone clamps the cylinder, preventing it from rotating in the sleeve. Involuntary rotation of the column is impossible. It is firmly fixed.

Power supply for drill head

A cable is laid inside the column. To ensure that electrical energy is transferred at any turn, mercury current collectors are used. They uninterruptedly conduct current to the engine and control unit. To prevent evaporation of the current-carrying liquid (mercury), a complex hermetic design of the current-collecting device is provided.

Instructions for assembling the machine and installing components are available in the passport attached to each product. The current price of the device is also indicated there.

Video: radial drilling machine 2M55.

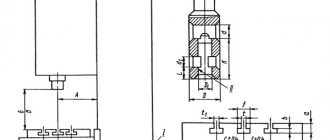

Machine illustrations and specifications

For your reference, diagrams and drawings of the main components of the machine are provided. Using them, you can understand what structural elements it consists of.

Power supply for drill head

A cable is laid inside the column. To ensure that electrical energy is transferred at any turn, mercury current collectors are used. They uninterruptedly conduct current to the engine and control unit. To prevent evaporation of the current-carrying liquid (mercury), a complex hermetic design of the current-collecting device is provided.

Instructions for assembling the machine and installing components are available in the passport attached to each product. The current price of the device is also indicated there.

Video: radial drilling machine 2M55.

Radial drilling machine 2M55

Point to image to enlarge

- Description

- Characteristics

- Reviews

Description of the radial drilling machine 2M55

Despite its half-century history since the start of production, the 2M55 radial drilling machine occupies a leading position in the line of equipment with an expanded processing area. The ability to obtain a group of holes without reinstalling the product confirms its uniqueness in its size range when processing body parts.

Design

The foundation of the 2M55 machine is a cast iron plate with stiffeners. A rotating steel frame is mounted into the base bushing installed on the slab, along which the traverse-sleeve moves. A unit for vertical movement of the sleeve is mounted on the top of the column.

A working quill with a spindle, a counterweight, feed mechanisms and rotation speed control is mounted on the sleeve guides. Horizontal movement of the spindle head is hydraulic. The controls are located on the head cover. The control panel for moving the traverse is on the base of the column.

Workpiece fastening

The workpieces to be processed, depending on their dimensions, are installed on a support plate or on a work table. To drill holes in long parts, it is possible to install two work tables. The workpieces are secured with special threaded clamps or pneumatic devices.

When drilling several holes on body parts, a jig template is used. Its geometry coincides with the geometry of the finished product. Before drilling, the workpiece and jig are rigidly mounted on the machine plate.

Types of processing, tools

On a 2M55 radial machine, holes with a maximum diameter of 50 mm are machined. Processing depth – 400 mm. The following tools are used in the cutting process:

- spiral drills, auger drills - for drilling, reaming holes;

- countersinks - for semi-finishing;

- reaming – for finishing reaming;

- counterbore – for finishing the surface.

Before the drilling operation, the pre-marked centers of the holes are punched or processed with end tools. After drilling, the edges of the cut are chamfered with countersinks.

Where can I buy

It is necessary to purchase metal-cutting equipment in Moscow from representatives of manufacturing enterprises. If you buy a 2M55 radial drilling machine from SK-STROYAVTO, you will receive high-quality equipment at a reasonable price and a factory warranty.

Technical properties

The technical characteristics of this model are as follows:

- Using this equipment, you can drill a maximum hole with a diameter of 5 cm;

- the accuracy category of the unit is N - normal;

- the sleeve with the drilling head can rotate 360 degrees;

- the traverse is capable of moving in the vertical direction to a distance of 75 cm;

- the edge of the spindle can be placed relative to the desktop at a distance from 45 cm to 1.6 m;

- the desktop has dimensions of 2.555x1 m;

- the weight of the machine is 4.7 tons;

- the minimum possible distance from the spindle assembly to the column is 375 mm, the maximum is 1600 mm;

- with the help of a traverse, the head can move a distance of 1.225 m;

- the spindle can move in the vertical direction to a distance of 40 cm;

- This model is equipped with six electric motors. The main one, responsible for performing basic operations, has a power of 4.5 kW.

Taking into account all these characteristics, the 2M55 model was able to gain such popularity among manufacturing enterprises of various types.

Pros and cons of the 2M55 radial drilling machine

The scale of production in modern times has increased significantly, not least due to the massive use of working machines.

Machines are used to perform a wide variety of work. Starting from ordinary milling or drilling, and ending with the processing of complex parts in several steps. Fortunately, their technical characteristics allow this.

Radial drilling machine 2M55

We will now look at the operation scheme and technical characteristics of the 2M55 machine, one of the best radial drilling tools of units, whose effectiveness has been tested by time.

1 General information

The 2M55 radial drilling machine began to be produced at the Odessa Machine Tool Plant. Its mass production began in the second half of the twentieth century. Since that time, technical specifications and basic electricity. The layout of the machine has changed a little, but the principles by which it works remain completely the same.

It is not for nothing that we focus on the fact that the machine model 2M55 is of the radial drilling type. This point has a huge impact on the way he works. Yes and el. the scheme also changes significantly depending on the design of the machine. You just need to look at his passport to be convinced of this.

The fact is that standard machine models are practically stationary. That is, the spindle on them is in a fixed state. Of course, they can be successfully used for:

- drilling;

- boring;

- countersinking;

- thread cutting, etc.

Email the diagram and even the basic technical characteristics of the unit allow this. But standard machines also have their disadvantages. They consist of rather constrained spindle movements.

The base plate serves as the base of the 2m55 unit

That is, you can drill with it without problems, but if you need to process a heavy, durable workpiece with many necessary working areas, then troubles begin.

You will have to constantly move the part in a vice, shift it relative to the stationary spindle, which is extremely difficult and inconvenient. First of all, this inconvenience is associated with a simple loss of time.

After all, large parts themselves are heavy. To fix them again, it is necessary to unclench the vice, remove its fastening from the table (and the scheme of their fastening is most often based on tightly tightened bolts) and then remount it in a new position.

As you can see, the number of actions that are spent on the simplest work algorithm is quite large. A completely different situation occurs when a radial drilling machine is used, in particular model 2M55, 2M55F2, etc.

1.1 Benefits

The radial drilling machine has many advantages. They relate to both technical characteristics and many other parameters. To verify this, just look at the product data sheet.

The passport will provide you with all the necessary data, right down to the grade of metal that was used to create this or that element. Also included in the passport is a basic email address. machine diagram and its structure.

The 2M55 radial drilling machine itself differs from others in its ability to move the spindle head in several directions at once.

Electrical unit of the machine 2M55

First of all, the spindle can be moved by moving along the rack. It is mounted on a rail in a separate housing, along with the engine and all necessary equipment.

The lath itself is attached to the column, as the workers call it. The column is the main mounting frame for the machine and its motors, as well as the main mechanism for manipulation. The column can both lift the rail from one level to another and rotate it horizontally.

As a result, we have an extremely functional and at the same time powerful mechanism, whose electronics. the circuit allows it to be used for a wide variety of work applications.

The spindle can be adjusted by the rotation angle, lift height and specific coordinate on the frame. You can also adjust the speed of its rotation, the strength and even the direction of rotation.

At the same time, the 2M55 machine and its subsequent models 2M55F2 are equipped with an extremely comfortable and wide table or stand.

Machine model 2M55, model 1976

This table has an impressive area, which gives the worker some room for maneuver. By combining good spindle mobility of a radial drilling machine and a large table area, experienced craftsmen manage to increase the processing speed of complex parts several times.

1.2 Features of the 2M55F2 machine

The 2M55F2 machine is slightly different from its basic model. We will not describe all its subtleties and nuances; we will note only the most important ones.

But the main differences lie on the surface, and you can see them without even looking at the product passport. The fundamental difference between the 2M55 and 2M55F2 machines is the presence of CNC in the second model.

CNC is a numerical software module. Many modern machine tools are equipped with CNC modules as this allows for even greater performance improvement at the final stage.

A modern version of the 2M55 machine

Email The layout of the 2M55F2 machine also has differences, but the main nuances again relate to the presence of a software module.

CNC on the 2M55F2 machine can significantly reduce the presence of a person and the expenditure of his effort on processing the part. After all, he now only needs to configure the device, give it the correct coordinates and observe the work.

The machine itself will move the spindle to the desired location and begin processing.

The only problem with CNC is their high cost and the need to use precision measuring instruments, coordinate tables, etc. in the load.

2 Design and principle of operation

Let's turn to the design of the 2M55 machine. In fact, it will be quite easy to disassemble it, because although the machine has a rather complex electrical circuit, it itself consists of several main blocks with parts.

Drilling machine. Types and device. Operation and Application

A drilling machine is equipment designed for processing holes in metal and other materials.

The device has a similar principle of operation to a hand drill, but has a more sophisticated design that allows for precise adjustment.

This equipment is produced in various modifications depending on its purpose. To ensure drilling, consumables are installed in the machine - drills, taps, reamers or cutters.

Where is the drilling machine used?

Drilling machines are common in production and household use. They can be found almost everywhere. Car enthusiasts, as well as professional mechanics and carpenters, often have such machines at their disposal. There is practically no repair company that does not have a drilling machine among its equipment.

The use of this equipment allows you to perform various functions:

- Drilling holes.

- Scan.

- Diameter expansion.

- Countersinking of the part.

- Thread cutting.

Machine device

Any drilling machine consists of an electric motor, a chuck for fixing the bits installed on the spindle, and an adjustment mechanism. Depending on the complexity of the design, different amounts of adjustments can be made.

The simplest machines allow you to process holes in one position only vertically.

More complex designs have an adjustable stand for fastening workpieces, which allows you to set them at the desired angle by making holes obliquely.

In drilling machines, rotation is often transmitted from the motor to the chuck not directly through the shaft, but using a drive belt. Another interesting design solution is that the frame for adjusting the drilling depth moves not the workpiece to the chuck, but the chuck with the motor to the surface being processed. Even the simplest machine design allows you to precisely adjust the processing depth.

Thanks to the rigid fixation of the shaft rotating with the attachment, parts are processed with high precision and without the formation of runout, as happens when using a hand drill.

In addition, the power of machines is significantly higher than that of hand tools, so they are able to work with thicker and heavier attachments. This ensures faster processing of parts.

Classification of machines by implementation

Based on their implementation, machines can be divided into four groups:

- Vertical drilling.

- Radial drilling.

- Horizontal drilling.

- Multi-spindle.

Vertical drilling machines are one of the very first to be used in production. They come in a variety of designs and are usually capable of machining holes up to 50mm in diameter.

This equipment allows adjustment only in the vertical plane. The part itself is fixed or laid motionless. A gear drive is used to raise or lower the spindle with chuck and drill. As a result, the vertically mounted motor, connected to the spindle via a belt, also moves.

The electric motor is usually protected by a casing that blocks the entry of chips.

Radial drills work on almost the same principle as vertical drills. The column for their fastening is made of a round shaft, which allows adjustment not only up and down, but also to provide horizontal movement.

In fact, using such equipment, you can adjust the lowering point of the drill on the machine itself, rather than moving the workpiece on a table or plate.

Often the radial installation weighs several tons, and is found only in large enterprises and workshops.

Horizontal drills are typically used to make deep holes. As a rule, this is heavy equipment that has a rail with a platform for laying the workpiece.

The design of the machine allows you to move the workpiece onto the drill or, conversely, direct the chuck with the motor to the workpiece. This allows you to comfortably work with workpieces of various weights and sizes.

Multi-spindles can perform multiple tasks. Each operation is done in stages. Such machines are difficult to confuse with other varieties. Their peculiarity is that they have several cartridges. As soon as one of them has completed the required amount of work, a quick adventure is carried out on the other, in which the required drill, cutter or reamer is attached.

Radial drilling machine 2M55

Specifications

- Largest drilling diameter in medium-hard steel, mm 50

- Spindle overhang (distance from the spindle axis to the generatrix of the column), mm. 450-1500

- Distance from the lower end of the spindle to the plate, mm. 470 – 1500

- Maximum vertical movement of the hose along the column, 680

- Maximum axial movement of the spindle, mm. 350

- Morse spindle taper 5

- The greatest weight of the tool controlled by the counterweight at the highest permissible tightening, kg. thirty

- Number of spindle speeds 19

- RPM limits 30 - 1700

- Spindle drive electric motor power, kW. 4.5

- Power of the electric motor for moving the sleeve, kW. 1.7

- Machine dimensions, mm. 2625 x 968 x 3265

- Weight 2M55 2M55 machine, kg. 4100

The 2M55 radial drilling machine is designed for drilling, reaming, countersinking, reaming, boring holes, tapping threads, trimming ends with a cutter, as well as performing other similar operations when processing various body parts.

The machine has a two-column layout of the machine part, which makes it possible to create a rigid unit structure that does not allow the spindle axis to shift when clamping the column. A special center-type column clamp creates a braking torque that guarantees high-performance drilling.

To rotate the column, little force is required at the smallest drilling radius, which also ensures high productivity and reduces operator fatigue.

A wide range of spindle speeds and feeds ensures high-performance work for any combination of processed materials, tools, sizes, etc.

A preselective remote electro-hydraulic device allows you to change modes with their preliminary selection. The machine has an automatic shutdown mechanism when the specified drilling depth is reached. Spindle balancing is ensured by a special counterweight, allowing convenient adjustment from the workplace if the tool weight changes.

Some distinctive features of the equipment

Studying the technical data sheet of this model, one can note some of its distinctive characteristics:

- The spindle of the unit is equipped with a counterweight. This allows the operator, when using tools with unusual weight, to adjust their operation without leaving his usual workplace;

- Having studied the passport of the drilling machine, it is clear that it has a unique structure. This allows you to use a minimum of physical force to rotate the columns;

- for efficient operation of the equipment, it does not require too frequent scraping of its guide elements;

- When the working tool reaches the required depth during drilling, its rotation stops. This is due to the presence of a special mechanism in the design of the machine;

- This model is characterized by high performance. This is possible thanks to the braking torque, which is generated by a specific clamping of the column;

- Having studied the equipment passport, it is clear that it is equipped with an electro-hydraulic preselective mechanism. It can be controlled remotely and the required drilling mode can be specified in advance, if necessary, changing it at any appropriate moment;

- if the column is clamped, the spindle axis does not move. This is possible due to the fact that this drilling machine is highly rigid.

Drills, countersinks

Radial drilling machine 2M55 after overhaul

- Description

- Comments

Radial drilling machine series 2M55 after a major overhaul. The price includes VAT. The warranty is 6 months.

Repair of the following components and components:

1. Mechanical part.

- Foundation slab (flushing the coolant reservoir, restoring the T-slots and slab plane).

- Base.

- Columns, replacement of bearings. The column is not polished .

- Hydromechanical column clamping device.

- Reducer for moving the hose, mechanism for lifting the hose and clamping the hose on the column, repair of stops for stopping the hose in extreme positions.

- Sleeve sliding guides, stops limiting the movement of the drilling head.

2. Drill head:

- Sliding and rolling guides.

- Clamping mechanism.

- Friction clutch and brake mechanisms of the main drive and spindle reversal, repair of the friction clutch control cylinder.

- Speed boxes.

- Feed boxes.

- Feed mechanism (mechanical, manual).

- Manual movement mechanisms.

- Electrohydraulic mechanism for preselector control of the gearbox and feeds.

- Spindle.

- Spindle unit counterweight.

- Cooling systems (replacement of the electric pump, replacement of coolant supply and return elements).

- Hydraulic column clamping system (change of hydraulic equipment, control equipment).

- Hydraulic system and lubrication system of the drilling head (change of hydraulic equipment, control equipment).

- Lubrication systems with replacement of the plunger pump and gland seals.

- Mechanical protection.

3. Electrical part. Change of the following equipment and components:

- Electric motors: main drive, hose movement, column hydraulic clamping, tool cooling, speed set drive, feed set drive.

- Electrical wiring.

- Ballast control equipment

- Limit switches, protective equipment,

- Electrical fittings for lighting the work area.

The design of electrical equipment, controls, protective equipment, and safety devices must comply with the requirements of PUE, GOST, (Inter-industry rules for labor protection during cold working of metals) POTRM-OO6-97” and passport specifications.

The machine is connected, you can check it in operation. Let's consider carrying out a major overhaul for your radial drilling machine.

Customer Reviews

I purchased a machine for my production. Delivery in a short time. The quality is excellent. The design of electrical equipment, controls, protective equipment, and safety devices comply with the requirements of the PUE.

Electrical equipment

On the 2M55 machine, the electrical diagram shows the control of the working parts. The electrical circuit diagram is shown in the figure.

Electrical diagram of the 2M55 machine

- Safety of work on the machine is ensured by locks.

- If the control device is in the on state, then power will not be supplied to the engine until the control handle is set to the neutral position.

- Switching gears is impossible while the hydraulic preselector is operating. The signal is not supplied to the spool coil.

- The movement of the hose along the column is limited by two limit switches.

By supplying power to the electrical circuit, the main engine and the hydraulic motor are turned on, and the machine goes into setup mode.

Clamping and release of the drilling unit and column are hydraulic. The electrical circuit controls the hydraulic spool coils. The possibility of separate spinning of the drilling unit is organized.

You can only rotate the sleeve and move the drilling head manually by pressing the release button. The movement of the hose along the column is carried out by a separate M2 engine.

The circuit provides a preselective preset of spindle rotation speeds and working feeds. These operations are performed while the machine is running. At the end of processing, the signal from the relay is sent to the M5 engine. It moves the switching mechanism until the positions of switch B11 are matched with switch B13. After this, switching to the specified modes occurs.

The spindle has reverse rotation.

The load on the spindle motor is monitored using an ammeter IP1.

Radial drilling machine 2M55

Are you here

Table of contents

- The device of a radial drilling machine

- Radial Drilling Machine Controls

- Kinematic diagram of a radial drilling machine

- Plate, base and column of a radial drilling machine

- Drilling machine gearbox

- Drilling machine feed box

- Technical characteristics of the radial drilling machine

The 2M55 radial drilling machine is widely used not only in repair shops, but also in large-scale production. The following types of work can be performed on the machine:

- Drilling;

- Reaming;

- Countersinking;

- Deployment;

- Tapping threads

Using fixtures and special tools, the machine can perform work typical of boring machines

Design of a radial drilling machine 2M55

- Plate

- Base

- Cooling system

- Current collector

- Sleeve

- Lifting mechanism

- Sleeve clamp mechanism

- Gearbox

- Hydro station

- Clamp

- Drill head

- Friction clutch

- Machine speed box

- Machine feed box

- Worm shaft

- Feed mechanism of the machine

- Manual movement of the drill head

- Drill head clamp

- Hydro preselector

- Hydraulic preselector drive

- Hydraulic panel

- Command controller

- Headstock

- Counterweight

- Pump

- Master cylinder

- Hydrocommunications

- Lubrication system

- Electrical equipment for the column

- Electrical equipment for the hose

- Electrical equipment for head

Controls of the radial drilling machine 2M55

- Cooling pump switch

- Input switch from ABB catalogue;

- Accelerated approach of the spindle head and inclusion of mechanical feed

- Turning on the stop to adjust the required drilling depth

- Locking the feed mechanism when cutting threads

- Drill head release

- Column and head pressing

- Column and head clamp

- Connection of the dial with the machine feed mechanism

- Fine adjustment of the dial to the required drilling depth

- Load indicator

- Counterweight spring tension handle

- Signal lamp

- Sleeve lift control

- Disconnecting the spindle head from the gearbox

- Pre-speed knob

- Starting the main engine

- Control of lowering the sleeve and stopping the sleeve when lifting

- Pre-feed handle

- Community stop button

- Start reversing clutch control

- Light switch

- Mechanical feed switch handle

- Flywheel firebox manual feed spindle

- Coolant switch-on edge

- Drill head movement flywheel

Machine illustrations and specifications

For your reference, diagrams and drawings of the main components of the machine are provided. Using them, you can understand what structural elements it consists of.

Specification for the machine diagram:

Control drawing:

Republished by Blog Post Promoter

Equipment design

The radial drilling machine model 2M55 consists of:

Machine design 2M55

The function of the base of the radial drilling machine is performed by a massive plate. A plinth is mounted on it for installing a rotating column. On a column made of steel there is a sleeve with a working head, the movement of which is ensured by a special mechanism.

Access to adjust the pressure in the hydraulic system is from the rear of the machine

The working head is a separate mechanism that includes several structural elements: a spindle assembly, a counterweight, a feed and speed box. This unit moves along the traverse manually, and is fixed in the required position using a special clamping mechanism.

Removed machine head