During vehicle repairs, in construction areas, and during unloading and loading, a device such as a hydraulic bottle jack may be useful. Due to their versatility, jacks are used everywhere. Without this thing at the service station, I can’t imagine what you were doing.

However, sometimes you have to tinker with the jack. Previously, I didn’t know how to fill it with lubricant and what substance would be the optimal solution for this. This is what my next review will be about.

Basic properties of hydraulic oil

The type of oil to be poured into the hydraulic jack depends on the problem that the device must solve.

The operation of certain structural parts depends on the viscosity of the hydraulic fluid used. The oil should not be very liquid, and the density should be average. With a high viscosity index, the jack can be used when the temperature drops significantly. It is very important that the device is equipped with a special filter. Passing through it, the oil will be cleansed of harmful impurities and accumulated gases.

If you correctly determine what kind of oil to pour into a hydraulic jack, it is possible to ensure the longevity of the parts of the device, as well as prevent their increased wear.

High-quality oil for hydraulic equipment has several positive properties:

- Has excellent antioxidant characteristics.

- Not afraid of temperature fluctuations.

- Atmospheric influences do not affect the initial properties of the liquid.

- Increases the life of the system.

- Doesn't foam.

If you incorrectly determine what kind of oil to pour into a hydraulic jack, it is very easy to damage the device. It will require major repairs, as well as large financial costs.

Oil change recommendations

Before replacing or adding working fluid, carefully read the jack operating manual and follow the recommendations contained therein.

It is not recommended to pour brake fluid or alcohol-containing compounds into hydraulic jacks - they can destroy the material of the rubber gaskets and seals used in the structure of the device.

Pour oil into the jack in small portions, making sure that no air bubbles form in the liquid. After refueling, it is necessary to bleed off the air that did get inside along with the oil. To do this, you need to fully inflate several times (raise to maximum and then lower). After this, the plug is tightly installed in the filler hole.

Do not disassemble check valves or blocking valves unless absolutely necessary. Valve springs and balls require special care.

Use only special high-quality compounds to fill the jack. Saving on quality will not only significantly reduce the service life of tools. Fluids not intended for hydraulic jacks reduce the safety of operation of these devices and cause accidents.

Timely maintenance and the use of high-quality oil for a hydraulic jack will ensure a long service life of its operation.

Oil for hydraulic jacks

Hydraulic jacks have become quite widespread. They can be used to lift various heavy loads. The operating principle of the design determines that the required pressure is created by supplying special oil to the working chamber. Periodic maintenance includes changing the oil in the hydraulic jack, as over time it can lose its properties. That is why you need to pay attention to what characteristics oil for hydraulic jacks should have.

Pneumatic jack: nuances

This type is characterized by high productivity. The main basic part is a compressor operating from the network. The load is lifted by a hydraulic mechanism and compressed air. The jack is capable of lifting a load with a maximum weight of 50 tons. Since the cost of such a device is very high, they are used only in special convoys. For such a jack and normal operation of the compressor, compressor oil would be the best option.

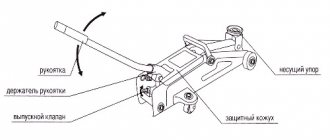

Diagram of a pneumatic jack.

A conventional air cushion is filled with vehicle exhaust gases that come from the exhaust pipe.

The pillow inflates and lifts the car.

The positive side of this type of jack is that it can be used on the worst roads, and the lifting occurs much faster than when using other types.

Basic properties of hydraulic oil

The main thing that is required from such an oil is to transfer energy during control, movement and drive. This liquid is an indispensable assistant in the maintenance of bridges, production mechanisms, gateways and various devices that require lubricant.

Hydraulic oil

There are different types of hydraulic oils:

- oil for industrial equipment and transport;

- marine oil;

- aircraft oil;

- oil for shock absorber and hydraulic brake systems.

Each type of liquid has its own composition, and therefore there are also classifications “A”, “B”, “C”:

- “A” – mineral oil without additives;

- “B” – with anti-corrosion and antioxidant additives;

- “B” is a purified oil containing anti-corrosion, anti-wear and antioxidant additives.

Scope of application of hydraulic jacks

hydraulic jack

Although jacks are most often used in everyday life to replace tires on cars, the range of their use is much wider:

- lifting car bodies during repairs;

- raising the bridge span;

- tension of high voltage power lines;

- laying water pipes directly through the ground without digging trenches;

- spring compression;

- movement of large building blocks, large parts and mechanisms.

The fundamental differences between jacks and other lifting mechanisms:

- small size;

- ease of operation;

- reliability and durability;

- During operation, the mechanism is located only under the load.

Types of hydraulic jacks

Hydraulic jacks are available in a variety of types: bottle, diamond, rack and pinion, rolling, two-level and others. In addition, within the model range they may differ in design and type of drive.

Example of a bottle jack

The bottle jack is the simplest variety among its fellows. In it, the working cylinder is located vertically, like a bottle. Bottle models are small in size, which allows them to be widely used by motorists on the road.

A rolling jack consists of a frame that holds the entire mechanism. The load is lifted through the operation of a hydraulic piston and lever system. To make this type of jack mobile, it was equipped with wheels. When a weight is lifted directly, the wheels shift relative to the frame, and then the load is applied only to it.

Example of a rack jack

On a rack and pinion jack, the load is lifted through gradual movement of the load among large and small platforms. These platforms are installed on the rack, and the pressure is transmitted by a connecting rod. At the beginning of the lifting, the handle of the rack jack is in a vertical position, and the load is applied to a large platform. When the lever gradually lowers, the connecting rod rests on a small platform, and it already transfers the entire load to the upper stop. When the limit is reached, the pressure stops in the small area, the handle begins to rise again, and from it the lower stop.

Why oil

Not all liquids have a positive or at least neutral effect on the metal of which the tool is made. Water, acids, alcohols and many other liquids cause a natural oxidation reaction, and as a result, corrosion and rust. Some compounds react faster, others slower. Some can completely corrode either metal, or rubber or Teflon gaskets and seals. When choosing which oil to pour into a hydraulic jack, you should be careful, since even in this category of substances there are undesirable mixtures (more on this below).

Essentially speaking, a properly selected oil will not only not harm the system, but will also protect its components from abrasion and oxidation. Working in such a liquid, the mechanism retains its original qualities for many years. With regular maintenance, even the most budget tool will easily last longer than an expensive one if the latter is not taken care of.

Having talked about the effect of various mixtures on the mechanism, and more or less argued the choice of fluid, it is time to move on to the main topic and show what kind of oil is used in hydraulic jacks. With examples and essentially about what can and even should be poured into the system.

Types of Oil You Can Use as Jack Fluid

And so, let's return to the question of what kind of oil can be poured into a hydraulic jack. When it's obvious that you need to change your jack oil, the next challenge is determining the type of fluid that's appropriate for your hydraulic jack. There are several parameters that you should keep in mind when you go to the store to buy e-liquid.

- Viscosity.

This is one of the most important aspects of the fluid used in a hydraulic system. The viscosity of a hydraulic fluid is measured in centistokes (cSt) at 1000 °C (SAE) or 400 °C (ISO).

They are added to hydraulic fluid to ensure longevity. Some of the additives allow the jack to perform better in different conditions. Here are some of the most popular supplements.

-Anti-corrosion. Reduces the appearance of rust from oxidation by forming a protective layer - Anti-wear. Increases the durability of hydraulic equipment and components -Antioxidant. This allows the equipment to operate for a long time without the need to change oil - Antifreeze. Allows the socket to operate in very cold places

- Fire resistance;

- Hydrolytic stability;

- Heat resistance.

How can I replace oil?

What kind of liquid should I put in the jack? ATF (automatic transmission fluid) can be used as an alternative to hydraulic oil depending on the viscosity of the fluid. However, some problems arise when using ATF as a hydraulic fluid. For example, additives in ATF can destroy hydraulic seals.

Unlike hydraulic oils, which are not designed to foam at high pressures, automatic transmission fluid is prone to foaming when exposed to very high pressures. Finally, some cylinders are designed to handle certain fluids. And when this fluid is not used, the full potential of the cylinder is not revealed. If it's a small manual hydraulic jack, you can use ATF. Otherwise, refrain from using it.

Automatic transmission fluid can function as hydraulic fluid. Use it if you are stuck and don't have the manufacturer's recommended oil.

There are several vegetable oils that can be used as hydraulic fluids. These include oils derived from sunflower seeds, soybeans and canola. The performance of these oils depends on the type of additives and base oil chosen. Vegetable oil has several advantages over its mineral counterparts when used as a hydraulic fluid.

Benefits include higher flash points of 3200°C, they are non-toxic, have higher lubricity and are biodegradable. Some of the limitations of vegetable oils include low oxidation stability and poor low temperature performance. In addition, vegetable oil is quite expensive.

You have to be very careful when looking for hydraulic fluid substitutes. If you use the wrong fluid, the seals can swell. So don't replace unless you're sure what you're doing.

Oil quality

Most hydraulic fluids are measured at a typical ISO grade. However, there are some hydraulic fluids with anti-wear properties. You might come across AW 46 oil. What does this mean? AW oils will perform the same as their ISO counterparts. The main difference is that anti-wear hydraulic fluids contain different additives to reduce corrosion. Anti-wear oils ensure there is no metal-to-metal contact in the system.

Zinc is a widely used additive in anti-wear oils because it extends equipment life. Another reason to use zinc supplements is that they have both anti-wear and antioxidant properties. Anti-wear hydraulic oils are recommended for use in harsh conditions.

If you use fluid that is too thick, the machine may not be able to pump the oil out of the reservoir effectively. This may lead to cavitation. On the other hand, using thinner oil may cause internal slipping inside the jack, reducing its effectiveness.

A hydraulic jack operating in a cold zone will perform best with a low hydraulic jack oil level of 32. If the hydraulic system manufacturer has specified the grade of oil to be used, it is advisable to use that grade. The manufacturer tested the system to determine which grade was best for the jack.

In addition to reliable control of all types of contaminants, the behavior of hydraulic fluids in flow plays a decisive role in operation and especially at extreme temperatures. These properties are described by the viscosity index (VI) and affect the reliable lubrication of all components. VI is calculated from kinematic viscosity at 40 and 100 degrees. A low VI value means poor lubrication in the cold and a sharp drop in viscosity in the heat.

If the fluidity of the lubricant used is insufficient, that is, too viscous, fatigue reactions and wear occur. The result is slow response times and increased power consumption. A stable lubricant should perform well even at high temperatures. If the hydraulic oil becomes too thin, there is a risk of wear and cavitation. High quality base oils used with naturally high VI and additives ensure the best response and maximum performance at all temperatures.

Material selection

Car enthusiasts often wonder what kind of oil is needed for a jack.

It is necessary to fill the jack with high-quality oil that meets the following indicators:

- the lubricating fluid must be well filtered;

- the level of foaming is as low as possible;

- the viscosity index and temperature maximum are selected extremely high;

- high rate of anti-corrosion protection.

A fairly common question is what kind of oil is poured into a hydraulic jack. There are several varieties on sale:

- Glycolic.

- Petroleum or mineral.

- Synthetic.

The cheapest option is petroleum or mineral oils. However, before pouring them into a rolling jack, it is worth taking into account the relatively low performance characteristics.

In some cases, used engine oil is refilled. It is necessary to use special oil, as it ensures long-term operation of the device. The lubricant should be changed at the moment when the device begins to work incorrectly.

Recommendations

Those companies that produce motor lubricants sometimes additionally produce hydraulic fluids for cars and trucks. These fluids can be used to fill not only the jack, but also the brake systems. In addition to the usual special oil, industrial types of oils are sometimes used (such as I-12A, I-30A, I-50A). However, here you need to be careful and have a good understanding of cars, or carefully study this topic: some oils are extremely viscous and are not suitable for every device. They can also damage the jack by causing corrosion.

In general, the device can work even if you just pour water into it, but the surface will quickly become covered with rust and it will most likely be impossible to return to its previous operation. Those who like to pour regular machine oil into jacks will encounter the same problem, just later: regular machine oils also cause water to accumulate in the device. Over time, it will also fail.

In order for the forklift to work properly, the hydraulic solution must be changed regularly. It is inconvenient to work alone - here it is better to take someone as an assistant

Before you start pouring liquid, it is important to first carefully study the instructions for using the device and do everything as indicated in it, since depending on the type of device, changing the liquid may take place differently. Unless absolutely necessary, it is better not to completely disassemble the device again, as there is a risk of losing the ball or damaging the valves

It is strongly recommended not to fill the jack with liquid that contains alcohol. The use of alcohol-containing liquids will also lead to corrosion and further inoperability of the device. In addition, no valves other than the outlet valve should be opened. By opening the check valve or overload valve, you can harm the bearing or spring, so even in such a simple operation as changing the oil in the device, you should be extremely careful and careful.

It is recommended not to spare money on filling. It’s better to buy something more expensive, but with positive characteristics (viscosity, composition), then it will need to be changed less often, and the lift will last longer, since it will not rust or deteriorate in a short time. Experts do not recommend mixing expensive and cheap liquids, as this will only worsen the effect.

Once there is less oil than the unit requires, you will immediately notice how much more difficult it will be to lift heavier objects. This is the first signal that you need to top up or change the special solution. Once the primary signs of a malfunction have been detected, it is advisable to eliminate it as quickly as possible, then the device will always be in optimal operating condition, and the car owner will be able to avoid accidents that may occur due to a malfunction of the device.

For information on how to bleed a hydraulic jack, see below.

Fundamental characteristics

What kind of oil to pour into a hydraulic jack is determined depending on the tasks assigned, taking into account the characteristics of the liquid.

The viscosity of hydraulic oil determines the ease of movement of individual parts of the mechanism; accordingly, it should not be too liquid or too dense.

The higher the viscosity index - this is a temperature indicator - the better, so the unit will be able to operate at low temperatures.

Filterability is also important: oil should pass through the filter easily, while simultaneously being cleaned of gases and foreign impurities.

What kind of oil to pour into a hydraulic jack : something that will provide reliable protection of the unit from wear, something that is compatible with the materials from which the individual parts are made, and what is recommended by the manufacturer of the unit.

Good oil for hydraulic equipment does not oxidize and does not change its operating properties when the temperature or chemical composition of the environment changes, which increases the service life of both the technical fluid and the unit. Bad oil is harmful to your equipment and can result in your hydraulic equipment needing repairs.

Compound

Almost all oils intended for hydraulic equipment are produced by refining base oils produced during the refining of petroleum fractions. Modern technologies include hydrolytic and extraction purification. To improve the quality of oils, special functional additives are added, thanks to which the liquid does not form foam and protects parts from oxidation and corrosion.

What kind of oil should be poured into a hydraulic rolling jack in the summer season? Anything, but in winter it is better to use synthetics, which will retain all their properties even at sub-zero temperatures. However, during non-working hours it is better to send the unit to a warm room.

How to fill a hydraulic jack with oil is indicated in the instructions for it. Usually the procedure is repeated at least 2 times a year; with intensive use of the unit, more frequent maintenance is required, up to monthly. When changing the fluid, it is necessary to flush the system, and sometimes repair the hydraulic valves.

Hydraulic fluid in a jack - why is oil better?

The robust design and special weight distribution on the lever and inside the jack, as well as its hydraulic basis, make it much easier for a person to work with large and bulky loads. With the help of such a jack, for example, you can lift an entire truck or container with cargo, as well as a small platform.

As already mentioned, the main working element of the jack is hydraulic fluid, which is poured inside into a sealed container. It allows you to lift loads of almost any weight, depending on the properties. There are several types of fluid that are poured into a hydraulic jack, each of them has its own characteristics.

Overview of species

Today, several types of this product are used. Many people believe that, in principle, there is not much difference in how to fill the jack. You can fill in any product that is intended specifically for hydraulic equipment and tools, in particular for jacks. This is partly true, but each type of oil has its own specific properties that may be useful or even necessary in certain conditions. There are currently several different types of oils on the market with different characteristics.

Material selection

Before you begin the oil filling process, be sure to study the operating instructions for this particular brand of equipment. The fact is that in some cases the technologies may differ slightly from those presented above.

Before use, be sure to remove excess air from the device. In some cases, a check valve cannot remove everything. Some trickery needs to be used. To do this, the hydraulic jack is first raised and then lowered to a minimum. You need to perform such manipulations approximately 2-3 times. As a rule, all excess is gone during this time.

There is no need to open the valves used in the device yourself, as this can lead to a violation of the integrity of the entire mechanism as a whole.

There is no need to pour any liquid into the equipment. Under no circumstances should liquids containing alcohol be used. The brake is also not suitable for these procedures. There is a wide range of hydraulic oil on the market. This is exactly what you need to use. It has optimal fluidity and viscosity indicators. In some cases, you can use alternatives, but those recommended by the device documentation.

So, now everyone knows how to change the oil in a hydraulic jack. As is clear, there is nothing complicated in this process. The most important thing is self-confidence, and everything else will follow.

Manipulations with heavy loads are carried out not only in industry, but also in everyday life. And one of the ways to carry out this manipulation is to use a jack. All jacks are divided into two categories - mechanical and hydraulic. The latter have a much greater carrying capacity, and 2 tons of your car is not the limit for them. But, like any other complex device, the jack fails from time to time.

Material selection

Car enthusiasts often wonder what kind of oil is needed for a jack.

Advice: choose only high quality oil and never mix it with any other fluids, including brake or other types of lubricants. Mixing will cause breakage and risk of cargo loss during the working process.

It is necessary to fill the jack with high-quality oil that meets the following indicators:

- the lubricating fluid must be well filtered;

- the level of foaming is as low as possible;

- the viscosity index and temperature maximum are selected extremely high;

- high rate of anti-corrosion protection.

To refill jacks, liquids of the I30A, I40A or I50A brands, used in the operation of industrial machines, are used. The best option is special hydraulic oil.

Qualitative characteristics of the liquid

The most important indicator of high quality hydraulic oil is its viscosity. It determines how easily the parts of the device will move. That is why, when choosing a liquid, they strive to use the optimal viscosity value. The properties of the liquid are influenced by the temperature index (viscosity index). It should have high values .

Hydraulic oil never oxidizes. It has excellent anti-corrosion characteristics, which increase the service life of the jack.

It is very important that the liquid has high filterability. In other words, it should easily pass through a filter that will cleanse it of harmful impurities. The lubricant must not form foam. The working environment must be easily freed from oxygen, as well as other accumulated gases.

Read also: Power supply for cordless screwdriver

Useful tips

If a complete change of hydraulic fluid has been made, it is necessary to bleed the air. Simply raise the jack to its maximum height and lower it. It is advisable to repeat the operation several times.

Do not pour brake fluid into the system. Check valves must not be opened. If you don’t know how to do this, you can damage the device’s bearings and springs.

Before using the equipment, be sure to read its technical description. If you follow the operating rules and fill only high-quality lubricant, you can extend the service life of the hydraulic jack. Read about the 3T rolling jack here.

Features of the composition

Almost all grades of hydraulic composition are produced by refining base oils obtained from the processing of petroleum fractions. Currently, advanced manufacturing technologies are used:

- hydrolytic cleaning;

- extraction purification.

To improve the quality of the liquid, special functional additives can be added to it. Thanks to the additives, the composition does not foam and provides reliable protection of parts from corrosion and oxidation.

In the warm season, you can fill the jack with any oil, but in winter, preference should be given to synthetics. It will not freeze even in severe frost, which allows you to operate the equipment at any time.

It is recommended to store the equipment itself in a warm room, which prevents the composition from freezing. In severe frosts, you should work for a minimum of time so that the liquid does not harden and the equipment does not deteriorate.

The hydraulic fluid in the jack must be changed at least twice a year. If the equipment is used with great intensity, the fluid should be changed more often. For particularly intensive use, it is necessary to fill in a new composition every month. In this case, it is necessary to wash all equipment mechanisms. Such maintenance significantly increases service life, and the risk of breakdowns is sharply reduced. It is worth noting that repairing a hydraulic jack will cost a pretty penny, so it is better to spend money on oil than on expensive repairs.

Thus, oil is an important component in the operation of all kinds of equipment. Therefore, maximum attention should be paid to its use and correct selection.

How to choose oil for a hydraulic jack?

In order to determine the type of oil that will then be poured into the hydraulic jack, you should understand some of the differences between the different groups of these lifts before filling them with oil.

Hydraulic jacks, depending on the design features, are divided into the following groups:

- bottle jacks;

- rolling jacks;

- toe jacks.

Depending on the group and design, each jack has its own maximum lift, which requires the maximum level of compression from the hydraulic fluid.

Types of oils produced

Today there are many different brands of oil known. We will be most interested in an oil that suits both the car and the jack. Oils are divided into several groups. The main ones are:

- motor;

- transmission;

- flushing;

- hydraulic.

Each option has its own purpose. They are not interchangeable.

To reduce wear on parts in a car's gearbox, gear oil is used. This is a very high quality liquid. As a result of the work, a kind of film is formed on the parts, which has high strength. The film remains on the parts for a very long time. An oil change is required after 50,000 km.

Hydraulic. This liquid is used for a variety of purposes. But most often it is used for the hydraulic system of trucks. This liquid has also found application in passenger cars. This is the oil that is best suited for hydraulic jacks. Hydraulic fluids are divided into three groups:

Read also: Automatic charger electronics circuit, 1988 release

Table of characteristics of motor oils for jacks.

- oil;

- synthetic;

- Glycolic

They can be used for a wide variety of technical devices:

- ships;

- aircraft;

- marine equipment;

- shock absorbers;

- jacks;

- engines.

Bottle jack device

As can be seen in the figure, the hydraulic bottle jack consists of the following parts:

Fig 1. Bottle jack structure : 1. Main piston 2. Lever 3. Rod 4. Suction valve 5. Shut-off valve 6. Oil storage tank. 7. Working chamber. When a force is created on the lever (2), the rod (3) creates pressure, as a result of which the valve (5) opens, and the liquid flows into the working chamber (7). When the lever is lifted up, the shut-off valve (5) closes and liquid is drawn into the pump cavity from the oil storage tank (6) by opening the pressure of the suction valve (4). By pumping liquid from the reservoir (6) into the working chamber (7), the main piston (1) is raised.

The work design uses the well-known Pascal's law: The pressure exerted on a liquid or gas is transmitted to any point without changes in all directions.

The design of a bottle jack is quite simple; we pump liquid from one reservoir to another, and thereby build up pressure in the second, thereby raising the working piston.

Types, properties and characteristics of hydraulic bottle jack

Jacks are divided into several types, the first division is based on the number of rods (half-rams):

- Single-stem bottle, the most common type Fig. 2.

- Double stem bottle Fig 3.

Fig 2. Single-rod jack

There is also a division based on the operating principle of the pump pumping liquid:

- Manual, activated by user pressure on the lever

- Large pumps designed to lift enormous masses are driven by a separate drive, hydraulic pump or hydraulic station.

Read also: Welding inverter Resanta Sai 220 reviews price

Fig 3. Double-rod jack

Properties:

Load capacity , an important parameter that determines the maximum lifted weight. The parameter depends on the volume of the working chamber and strength characteristics. Bottle-type devices have a load capacity from 2 to 100 tons.

Minimum lifting height , otherwise called minimum pick-up height. This is the height at which the load must already be in order to be able to place a jack under it. Please pay attention to the minimum height if you are selecting a device for a car. If you have low ground clearance, then a bottle-type device due to its high design will not suit you.

Maximum lift height. The height to which a load can be lifted. The bottle ones have a special feature: on the support platform there is a retractable screw that increases the minimum and maximum lifting height.

General procedure for changing oil in a bottle jack - step-by-step instructions

Despite the fact that the procedure for replacing the working fluid in the equipment is quite simple, there is a certain procedure:

- First you need to remove the old substance, and the device must be disassembled and thoroughly cleaned. Check rubber elements for wear.

- Assemble the jack and lower the rod until it stops.

- Turn the valve head counterclockwise and press firmly on the stem.

- Remove the plug from the top of the cylinder and fill in lubricant using a grease gun (syringe). It is necessary to ensure that there are no air bubbles.

- The oil level should be just below the bottom edge of the filler hole.

- Place the plug in place and bleed the jack without load. If necessary, add lubricant to the required level and pump again.

How to fill oil into a rack-and-pinion jack?

Despite the fact that rack and pinion jacks come in very impressive sizes, this does not in any way affect the process of changing the oil, and it can happen as easily as with other mechanisms.

The next step is to find the neck where the oil should be poured. It can usually be found right on the hydraulic fluid tank. A protective plug (sometimes a bolt) is always located on this neck so that no external factors affect the substance. The plug or bolt must be unscrewed and pulled out of the hole. Next you will need an oil can, the nozzle of which is inserted into the neck, and you can immediately start pouring oil. When the liquid is completely filled and begins to flow out, the hole is firmly closed back with a plug.

What lubricants should not be poured into the jack?

Theoretically, any lubricant can ensure the full level of operation of the jack. Even if you pour water inside, the jack will perform its stated functions. On the other hand, this will not last long, because corrosion will quickly develop on the parts of the device and the mechanism will become unusable.

There is another fairly common misconception. Some people think that hydraulic jacks can be filled with brake fluid. Such actions are strictly contraindicated, since the substance is very hygroscopic and can accumulate moisture and thereby provoke corrosion. These two tips will ensure the safety of the mechanism and ensure its full functioning.

Oils recommended for use in hydraulic jacks

The standard fluid for filling into the mechanism is spindle oil I20A. This product is universal and can be used at any time of the year. The situation is somewhat different with industrial lubricants VMGZ, I12A, I30A, I40A or I50A. These compositions will be quite effective only in the warm season, but only for specific device models.

Such options are the most common due to their practicality and low cost. If possible, it is worth purchasing specific compounds, especially for hydraulics. The liquid has a low level of viscosity, and they also combine properties and capabilities that meet all requirements.