A compact radial drilling machine, even with its small dimensions and simple design, allows you to solve many problems associated with the need to produce holes in metal parts. An important quality is the versatility of such equipment, which is used to equip both small repair shops and production workshops of large enterprises.

Radial drilling machine RD 60

Features of using machines

The technical capabilities of a radial drilling machine make it possible to perform various metal processing operations with its help: drilling and reaming holes of various diameters, countersinking, thread cutting carried out using a tap.

Even a tabletop machine in this category can be equipped with various working tools that increase its functionality. Equipped with such tools, radial drilling machines make it possible to perform technological operations characteristic of boring group equipment.

Various models of machines in this category are distinguished by their dimensions and technical characteristics. The most common models of equipment for the radial drilling group are: 2M55, 2K52, 2A554, AS2532, 2N55, 2532L. The differences between each model of such equipment, designed to perform standard metal work, relate to their power, as well as the list of technological operations that they make it possible to carry out.

The versatility that distinguishes radial drilling machines makes it possible to successfully use them to carry out repair work of varying degrees of complexity. The functionality of equipment in this category is determined by its design, which may include various systems and elements.

Radial drilling machine 2A554

Types and advantages of CNC radial drilling machines

This type of equipment performs the same operations as a vertical drilling machine.

A vertical drilling machine can drill holes in solid materials, countersink existing holes, countersink end areas, make holes and cut large threads. However, the main purpose of the machines is considered to be processing holes in large elements.

A radial drilling machine is fundamentally different from a vertical drilling unit - while working on such a technique, the part is stationary, and the spindle can be moved. This is due to the fact that it is very difficult to move them when working with heavy and large parts.

The spindle in this technique usually moves both radially and in a circle. In this way, you can make a hole in any area of the part, limited by a sector of the circle.

The following types of machines are distinguished:

- General purpose. When working on such a machine, the area to be processed is placed on a table, and the spindle head usually moves in 3 directions around the elements.

- A machine with a column moving in guide frames. This technique is used to process heavy parts of enormous dimensions.

- Machines on a self-propelled trolley. The cart can be moved along special railway tracks. Used for work with large parts.

- Portable machine. Makes it possible to make holes in the body of cast iron or steel castings. This is an industrial machine that is used in heavy engineering and shipbuilding.

Design features of the machines

Radial drilling machines are metal-cutting equipment used for processing parts of various configurations and geometric dimensions, which are made of cast iron and steel, and various non-ferrous metals. Such machines are classified as equipment of the second class, if we are guided by the generally accepted classification of technical devices intended for metal processing. The most popular models of equipment of the radial drilling group (2K52, 2M55, 2A554, AS2532, 2N55 and 2532L) allow drilling holes, the axis of which is located at different angles.

The technical capabilities of a radial drilling machine allow it to process surfaces of any type: cylindrical, conical, threaded and end surfaces. A tabletop machine of this model is most often used to perform roughing, semi-finishing, and finishing technological operations.

The main tools that radial drilling machines are equipped with are drills, reamers, countersinks and thread taps. To perform individual technological operations, a special-purpose tool can be installed on the machine.

The above models, which are most widespread, are mainly used for processing internal holes, which can be cylindrical or even conical. Parts that can be processed on the equipment of these models may have fairly large dimensions and irregular geometric shapes.

The design features of radial drilling machines make the process of processing parts simple and convenient. The part on such a machine is fixed in a special device. The design of the equipment ensures smooth movement of the cutting tool in relation to the surface being processed.

CNC Radial Drilling Machine

Machines in this category, including tabletop ones, are distinguished by high power characteristics, which makes it possible to process parts made from various metals, including steel blanks. Radial drilling machines are successfully used to equip enterprises operating in various industries, this also applies to automobile and aircraft manufacturing.

How to choose a drilling machine for your home workshop?

How to choose the right drill if you decide to create a mini-workshop in the garage or plan to perform a number of works in the country or at home? To choose the optimal model, you need to consider several factors.

The first factor to consider is the size of the workshop space and the planned method of work. As a rule, in domestic conditions such a machine is not used constantly, but from time to time. Sometimes, however, continuous operation of the machine is required. As a rule, in such cases, a household or semi-professional option that does not have much power is sufficient. A professional machine should only be considered if it will be used actively every day. This machine is more expensive, but has high performance. And this usually allows you to make holes of a fairly large diameter.

Holes made with a drill are precise and neat.

Important: If your home machine is used mercilessly, it will quickly break down. The simplest options, as a rule, are not designed for heavy loads during the day.

In short, first answer the question of how often the device will be used: more than 2 hours a day (continuous use) or less (repeated - short-term use, usually in this case the device is used for only a few minutes). Remember that household appliances should “rest” for 5 minutes every 20 minutes.

Another important criterion is power. If the device will be used constantly, its power should be more than 600 W, and preferably at least 1000 W. For household use, a device with a power of up to 600 W is sufficient.

Important! Machines rated for 220V are slightly weaker than machines rated for other ratings.

Drill bits for drilling machine

Next, you should consider the size of the holes created. Homemade options are unlikely to allow the use of a drill with a diameter of more than 16 mm (there are rare exceptions). On the other hand, the professional version may suggest 60 mm. For small holes, you need to purchase a modest machine for a drill up to 6 mm - it will be more accurate.

It is important to consider what material you are going to work with. For example, machines can create holes in metal, wood, or plastic. Remember, however, that to work with wood or sheet metal you need a machine with at least 600 watts of power, and for making holes in thick solid metal you need at least 1000 watts.

The depth of the holes also matters. It depends on the spindle stroke. This value is important if you have to work with thick workpieces. Therefore, the thicker the workpiece, the more powerful the machine should be and the longer the spindle stroke should be.

Also think about the size of the car. Therefore, if you work in a small space (for example, a garage), choose a small, compact device. It is also advisable that it is not too noisy during use.

As a note. Desktop machines are the smallest. However, they usually do not allow the use of drills larger than 16 mm in diameter and not very powerful. However, they are lightweight and relatively quiet. The optimal choice is a vertical type machine. It can be installed on almost any workbench and secured to it using a special leg.

Radial drilling options allow you to drill at the desired angle. It's worth taking a look at them.

JET JDP-8L compact class bench drill 0.35 kW 230 V

Security is an important parameter. The machine must be equipped with guards and protection. They prevent chips from falling on the operator during operation.

Additional features deserve special attention. Different machine models may have different additional features. But each of them will make the car more expensive. So think about whether you need them or whether it is better to buy the most basic machine to save money. Possible useful features include:

- Backlight;

- Tilt of the desktop for working at an angle;

- Milling;

- Speed switch.

- laser viewfinder;

- reverse;

A good choice of machine is one that has a vice to hold the workpiece securely. It's good if they are included. You can also choose a model with suitable grooves and install the vise yourself. Using a vise is a must to get the most accurate holes.

Components of machine tools

Radial drilling machines used in modern industrial enterprises can be classified into one of four types according to their design.

- Machines of models 2K52 and 2M55 belong to the category of stationary equipment and are used to perform general-purpose technological operations.

- The design of the machines models 2532 and 2A554 contains a special column that can move along the surface of the workpiece, for which special guides are used.

- Large-sized machines of models 2532L and 2N55 themselves move along the surface of the workpiece, for which they are mounted on rail guides.

- There are separate models that are installed directly in the processing area. With the help of such equipment it is also possible to perform finishing work with a high degree of accuracy.

To effectively and safely use any model of this equipment, and not just a CNC radial drilling machine, you must have a very good understanding of its structure and have the appropriate qualifications.

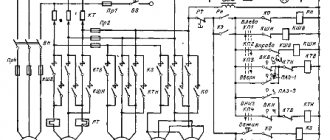

The design of any machine in this category, including a tabletop one, necessarily contains the following elements: a reliable base on which the workpiece is fixed, a cylindrical column, a traverse and a working head in which the cutting tool is fixed.

The column of the radial drilling machine, on which the horizontal traverse is fixed, can, if necessary, perform rotational movements. The traverse can move in a horizontal plane; a drill headstock with a working spindle is mounted on this element, in which the cutting tool is fixed.

The design of such a tabletop machine is simple and reliable, which becomes clear even from the photo. This equipment is easy to maintain and undergo the required repairs.

How to choose?

Let's consider the main characteristics of selecting a radial drilling machine:

- the maximum diameter that can be processed using a drill in steel or cast iron workpieces;

- maximum size of threaded taps to be cut;

- spindle motor power;

- radius of movement of spindle heads;

- traverse rotation angle;

- the maximum distance between the tables and ends of the spindle, which determines the highest workpiece being processed (minus the dimensions of the device);

- the highest vertical movement of the quill with the device, which determines the depth of processing;

- feed range and number of spindle rotation stages;

- the presence of cooling systems for the device and workpieces in the cutting zone, and a lubrication system.

The best types of premium drilling machines

This is already professional equipment designed to solve relatively complex problems, including mass production. To do this, it must be sufficiently reliable and efficient.

PROMA BY-3216PC/400

An interesting example from the Czech Republic, operating on a three-phase network and therefore intended mainly for factories, factories and other small businesses. If there is no overload, it will last for many years.

Peculiarities:

- rotation speed – 125-1975 rpm;

- maximum drill diameter – 32 mm;

- spindle pin stroke – 150 mm;

- dimensions – 1060x640x1510 mm

- weight – 260 kg;

- engine power – 1500 W;

Advantages:

- reinforced base 310x380 provides an additional work table;

- the sieve protects the operator from chips;

- has lighting and cooling;

- up to 8 speeds.

- With automatic feeding;

flaws:

- Not suitable for household use;

- Requires 380 volts.

Euroboor ECO 100/4 D

Possibly the best vertical metal drill, or at least one of them for sure. Compact and very light for its class, but powerful, with spiral knives up to 32 mm in diameter and ring knives, it effectively solves a wide range of tasks up to 10 cm thick. It is also possible to process oversized parts.

Operating parameters:

- rotation speed – 42-620 rpm; engine power – 1900 W;

- engine power – 1900 W

- weight – 28 kg

- dimensions – 365x190x510 mm.

Advantages:

- The base rotates - in the longitudinal direction by 20 0 and in the angular direction by 30 0;

- 4 speeds;

- powerful magnet with a magnetic force of 3 tons for perfect fixation;

- can also be installed on large objects.

Flaws:

- Too expensive for home use.

JET IDP-15BV 230V

American made table drill for professional use, ideal for quickly cutting holes in cast iron and steel. It can be powered from the mains, which expands the range of its applications. The manufacturer provides a 2-year warranty on all its models.

Peculiarities:

- Rotation speed – 450-2000 rpm;

- Maximum drill diameter – 20 mm;

- Spindle pitch – 85 mm;

- dimensions – 1780x425x214 mm.

- weight – 50 kg;

- engine power – 750-1100 W;

Advantages:

- a transparent plastic screen protects against sparks, dust, and shavings;

- Durable 73mm support tube effectively absorbs vibrations;

- Adjustment is carried out as smoothly as possible thanks to the control board;

- The table can rotate around the column either counterclockwise or clockwise.

Flaws:

- Relatively high wear.

MESSER MDM-32

Powerful, self-adjusting, easy to learn and easy to operate, this machine from South Korea exemplifies modern performance.

Options:

- Speed – 100-830 rpm;

- Engine power – 1550 W;

- Weight – 15 kg;

- Dimensions – 300x280x480 mm.

Pros:

- buttons and knobs within operator reach;

- relatively deep penetration of the tool – up to 55 mm;

- There is a reservoir for coolant.

Cons:

- Only 1 speed.

Dewalt Dwe1622k

A true leader among our best bench drills for the home, garage, and industry. Since it can be used anywhere, it is quite compact and can be powered from a 220-230 volt network without any problems. Equipped with a magnet, it holds the workpiece securely. Without heating the workpiece, it ensures fast processing.

Peculiarities:

- rotation speed – 350-450 rpm; engine power – 1200 W;

- engine power – 1200 W;

- maximum drill diameter – 50 mm;

- weight – 14.55 kg.

Advantages:

- there is an automatic supply of coolant;

- LED lighting allows you to work even in the dark;

- it is protected against overvoltage;

- After an emergency shutdown, it does not restart when power is restored.

Flaws:

- One of the most expensive models.