Friends, perhaps one of you is an excellent specialist in plumbing, carpentry, or you are a generalist and can do everything. In this case, it is quite natural that you would like to set up your own workshop in your country house.

When carrying out serious large-scale tasks or orders from clients, one drill is not enough, and you will probably come to the decision to purchase a drilling machine. It will help you perform many jobs where you need to make holes in wood, metal, and other materials from which blanks for products are made.

Drilling machine for home workshop

A furniture maker must drill holes for fittings, a mechanic must drill holes for fasteners: bolts, screws, rivets, and so on. When choosing a drilling machine for such functions, you will inevitably encounter a number of questions, which we will talk about today.

BUY A DRILLING MACHINE

How to choose a drilling machine

First of all, you need to decide in what mode the work will be done at the machine:

- Craftsmen planning to use the machine frequently and for commercial purposes should pay attention to the line of professional-class models with a power of 600 W or more.

- For those who will use the machine for domestic purposes, simple models with a power of up to 600 W are suitable.

Important parameters:

Another important point to consider is the characteristics of the holes being made:

- For home use, drilling machines are chosen that make holes with a diameter of up to 16 mm.

- For drilling large diameters, there are models that make holes from 20 mm to 60 mm. Most often, such units are indispensable in production.

- Hole depth. The more powerful the unit, the thicker the material it can process.

Connecting the device to the network:

- 220 V – standard power of a household outlet;

- 380 V - as a rule, this power is used in factories or in specially equipped workshops.

The following characteristics influence the productivity and comfort of work:

- Equipment weight. The lighter the equipment, the easier it is to move it from place to place or take it to field sites.

- Speed shifter.

- The light sight allows you to quickly and accurately position the workpiece before processing.

Check to see if consumables are available. If they are delivered only to order, this can complicate the work.

Secondary parameters:

The protective transparent casing is a nice addition to the new unit. It does not affect productivity or quality of work.

If desired, the accessory can be ordered separately or made from scrap materials. Instead, it is safer to use special safety glasses.

A good half of the drilling machines have mounting holes on the base, but you can easily make them yourself.

Drilling machine cutting tools

When working with drilling machines, basically the same equipment is used as for drills. Most often, these are twist drills made of carbide steel, which can drill holes even in hardened steel parts. And also drills made of high-speed steel, which belongs to the group of alloy steels with a high degree of resistance to brittle fracture.

120° Pointed Carbide Twist Drills

Wood should be drilled using special equipment with a pointed sharpening, if the diameter of the holes does not exceed 12 mm. Larger holes can be drilled into wood using a Forstner bit.

Types of wood drills

In addition to drilling holes, as I mentioned above, you can perform threading and reaming of holes, countersinking. There is special equipment for this: taps, countersinks, reamers, but this function can also be performed by special drills, for example, a countersink drill.

Purchase machines for your home workshop and all the equipment for them in our online store of building materials “Kuzmich24”. An extensive selection of drills for metal, wood, concrete and tile can be found in the “Consumables” section of the catalog.

Best Vertical Drilling Machine

The Einhell BT-BD 701 is a consumer-grade machine designed for precision hole machining in small and large workpieces.

Characteristics:

- Belting;

- power 630 W;

- voltage 220 V;

- spindle stroke – 60 mm;

- spindle speed – 220-2450 rpm;

- weight – 35 kg.

Pros:

- number of gears – 12;

- ease of operation;

- a transparent shield prevents chips from flying away during operation;

- the vice firmly secures the workpiece to the work surface;

- fixation available at any angle;

- processing of large-sized workpieces is provided;

- the rigid frame is attached to the working surface with special bolts.

Minuses:

- applicable drills with a diameter from 3 mm to 16 mm;

- there is no supply of cutting fluids;

- drilling depth of workpieces – up to 60 mm;

- noise during operation.

BISON ZSS-450

Next in our TOP is the ZUBR ZSS-450 drilling machine.

It is equipped with a 450 W asynchronous motor with copper winding and a huge margin of wear resistance and has 12 speeds for working with workpieces made of any materials.

The machine has a work table that is adjustable in height, tilt and axial direction. There is also a vice for secure fixation. So it is great for drilling holes in workpieces of any size and shape. By the way, the maximum diameter of the drill installed in the chuck of this machine is 16 mm.

Among other features of the ZUBR ZSS-450, it is worth noting the transparent casing to protect the operator from chips when drilling. It also has an electromagnetic switch that will stop operation in case of an emergency.

Thanks to its compact size, this machine can easily fit on any table. And its cast iron base will provide it with a stable position while working.

Owners respond mostly positively to this machine, noting that it would be an excellent purchase for personal use at home or in the garage.

- Power: 450 W.

- 12 operating speeds.

- Drill D: 1.5 - 16 mm.

- Speed: 220 – 2450 rpm.

- Spindle stroke: 50 mm.

- Vise.

- Rotary table.

- Tilt angle adjustment.

- Emergency stop.

- Dimensions: 670 x 430 x 260 mm.

- Weight: 32 kg.

Best magnetic drilling machine

Proma MDMR-100 is a professional-class machine.

Used in metalworking production. Characteristics:

- power 1800 W;

- stroke – 220 mm;

- voltage – 220 V;

- dimensions – 59*30*37 cm;

- magnet dimensions – 20*9.4*6 cm;

- weight – 22 kg.

Pros:

- The diameter of the drill used is up to 32 mm.

- The processed material is metal.

- Built-in lubricating coolant supply system.

The swivel base is made of a powerful magnet. It reliably adheres the device to the material and surface on which the equipment is located (if it is metal).

- Convenient handle for carrying the unit.

- Reverse function.

- Electric motor overload protection.

- Limiter of the maximum rotating torque on the shaft.

- Ergonomic body.

Minuses:

- High price. But it is justified by the functionality of the equipment.

- Noisy at work.

Drills for mini machine

mini drilling machine with console

In most cases, microboards for radio devices are made using such equipment. The board is located on fiberglass, which is destructive to drills. It is enough to make no more than a hundred holes and the drill must be sharpened or thrown away. It is not possible to sharpen a micro drill with a diameter of 0.5 mm with your own hands. There are drills made of hard alloys that can withstand work on fiberglass. You can find micro diameters from 0.5 to 2 millimeters, the diameter of the tail section is standard for all - 2 mm. This drill is enough for several thousand micro holes. But they need to work very carefully, avoiding lateral pressure, which instantly breaks the fragile instrument.

Attempts to install a micro drill in a hand drill lead to its failure. It will serve well in a drilling machine for many years.

Videos on how to make a mini drill yourself:

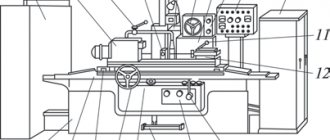

Best Horizontal Drilling Machine

PEMAL Malbork DWMA-25 is a longitudinal drilling machine designed for making and milling holes in wood and wood-based plastics. Assigned a class of specialized equipment. Finds application in small furniture and woodworking industries.

Characteristics:

- voltage – 400 V or 50 Hz;

- drive motor;

- electric motor power – 2.2 kW;

- speed – 2800 rpm;

- working surface size – 60*29.5 cm;

- weight – 260 kg;

- Dimensions: 92*72*126 cm.

Pros:

- depth of holes made – up to 16 cm;

- milling length – up to 17 cm;

- distance between the working surface and the tool – up to 1.5 cm;

- deviation in the vertical plane – up to 45o;

- processing of large workpieces;

- increasing the working area of the table;

Stops - limiters and cam clamp firmly fix the workpiece of any size and modification.

Minuses:

- diameter of the tool used – up to 25 mm;

- noisy operation;

- requires qualified personnel for operation and maintenance;

- inconvenient for transportation.

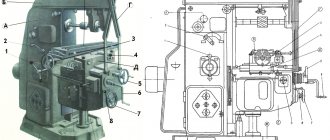

Device, type and parameters

Common types of drilling equipment are a stationary vertical drill press, a horizontal drill press, or a portable benchtop drill press. The type is selected depending on the volume of work. For a home workshop, a good option is to install it on a table. Elements and nodes:

- a metal frame on which a stand is mounted vertically;

- vertical column with spindle head;

- rotating spindle;

- drill chuck.

Skillfully used drilling equipment enriches the workshop, simplifies drilling, countersinking, and grinding of parts; the user will be able to produce creative objects. Thanks to the device, the craftsman independently repairs metal and wooden products and makes decorative crafts. Among drilling machines, desktop ones are popular; they are lightweight and easy to use, and have a list of operations:

drilling holes of different diameters;- countersinking of holes;

- grinding of internal surfaces;

- polishing of cylindrical cavities and outer surface;

- cylinder honing;

- hole milling.

The best drilling machine for your home workshop

SOROKIN 20.505 - tabletop drilling unit is designed for processing through holes. Assigned a household use class. Characteristics:

- key cartridge;

- operating power – 370 W;

- Belting;

- spindle cone B16;

- desktop – 19*19 cm;

- overall dimensions – 57*41*26.5 cm;

- weight – 25 kg.

Pros:

- versatility: processing wood, metal and plastic;

- number of speeds – 5;

- economical single-phase motor;

- refers to high-precision equipment;

- the casing protects working units from unwanted access and damage;

- drilling depth adjustment;

- table height adjustment;

- the ergonomic case is convenient when carrying the device;

- use of a clamping mechanism;

- work with large-sized workpieces;

The transparent shield protects the operator from chips without covering the work area

. Cons:

- no supply of lubricating and cooling liquid is provided;

- noisy working process;

- components are made to order only.

Design

At first glance, the scheme seems complicated, however, it is not. In fact, the mini machine is not very different from the classic one; it is smaller in size with some nuances in the design layout.

Since this equipment is not large in size, it should be considered as a desktop one. A homemade version of equipment is usually slightly larger than a purchased one, due to the fact that when assembling it yourself, it is not always possible to optimize the design by selecting small-sized components. But even in this case, the homemade machine will have small dimensions and weight no more than 5 kg.

Assembly video

Elements of a drilling machine

To assemble a mini device with your own hands, you will need the following:

- Bed;

- Transitional stabilizing frame;

- Bar for moving;

- Shock absorber;

- Height adjuster handle;

- Engine mount;

- Engine;

- Collet (or cartridge);

- Adapters.

It is worth noting that we are describing a homemade mini drilling machine, assembled from improvised materials with your own hands. The factory design is distinguished by the use of specialized components that are almost impossible to make yourself. The basis of a mini drilling unit, like any other, is the frame. It serves as the base on which all the nodes will be held. The frame can be a handy device, for example: the skeleton of a microscope; stand for linear measurements with a digital indicator.

Or you can make it yourself, for example, a light wooden frame - by connecting the boards with self-tapping screws, or a heavy and stable one - by welding a steel profile to a metal sheet. It is better when the weight of the frame is higher than the main weight of the other components, this increases the stability of the unit and reduces its vibration during operation.

Electric motors from cassette recorders, printers, disk drives and other office equipment can serve as motors. A chuck or collets are selected as a fastening for drills. However, the chuck is more universal, while the collet allows for the installation of drills of only certain sizes.

Motors for PCB Drilling Machines

Another interesting scheme based on spare parts from a CD-ROM and a hair dryer with automatic adjustment of the engine speed depending on the load.

Homemade bed

When making a steel frame with your own hands, you can screw legs under it to fix its position. The stabilizing frame can be made, for example, from a lath or angle, but it is better to use steel. You can choose any type of bar for moving that is most convenient, but it is better to combine it with a shock absorber. In some cases, the shock absorber itself may be such a bar. The functions of these parts are to vertically move the equipment during operation. You can make a shock absorber yourself, remove sliding slats from office furniture, or purchase them in a store. The height adjuster handle is installed on the body, stabilizing the rail or shock absorber. The engine mount is mounted to a stabilizing frame, which can be, for example, a simple wooden block. It is needed to bring the engine to the required distance and securely fix it. The engine is then mounted directly onto the mount. A chuck or collets are directly attached to the motor, to which adapters used to install drills are attached. Adapters are selected individually, depending on the motor shaft, its power, drill type, etc. In conclusion, we can say that the assembled mini drilling machine can be constantly modified during operation. For example, you can stick an LED strip on the chuck to illuminate the samples being drilled.

[Show slideshow]

Best drill press for drill

Enkor 20090 is a stand used to secure the drill. It is used both in utility workshops and in small industries. Characteristics:

- weight – 7 kg;

- dimensions – 57*26*8 cm.

Pros:

- steel body;

- cast iron base;

- light weight for easy transportation;

- ergonomic body;

- a rigid vice holds the drill tightly;

- drilling depth limiter;

- drilling depth measurement scale;

- The painted body is not subject to corrosion.

Minuses:

- No vice included.

Operating principle of mini drilling machine

When the electric motor starts, it drives the spindle. The electric motor power of a desktop micro-model can range from 150 to 300 W. A belt drive is most often used, but in the smallest models a gear drive is also possible. The speed is changed by moving the handle.

The drill is inserted into a small jaw or collet chuck that holds the end of the tool firmly. The jaw chuck is clamped with a key, the collet chuck is clamped automatically.

The installed drill is lowered towards the workpiece when the feed handle is pressed. It resembles a lever and is located to the right of the head. The head returns to its original place independently, under the action of a built-in spring. On some, the drill can be locked at any point using a tightening lever.

There are drilling devices equipped with a mechanism that regulates the drilling depth. It starts like this: the required depth of the future hole is marked on the side of the part. The chuck is lowered until the end of the drill reaches the mark. The tightening handle is tightened, restraining further advancement of the drill.

Best drilling machine for aluminum profile

OMERSAN KDM-201 is a high-performance universal machine for working with aluminum profiles. Characteristics:

- operating power of the drilling unit - 400 W;

- drilling unit speed - 2500 rpm;

- number of electric drives – 1 piece;

- power of the main unit – 1100 W;

- speed – 3000 rpm;

- in the main unit there is a cutting disc for aluminum;

- number of cutting discs – 1 piece;

- dimensions – 65*50*80 cm;

- weight – 31 kg.

Pros:

- Completely processes aluminum profile workpieces, 1 piece at a time;

- processing at an angle of 90 and 45 degrees;

- ergonomic body;

- small dimensions and streamlined body allow the unit to be installed in any production;

- high speed of production cycles.

Minuses:

- high price;

- management requires special knowledge;

- work only with aluminum profiles.

Best Bench Drill Press

Einhell BT-BD 501 is designed to work with materials of varying densities and hardness at different speeds. Characteristics:

- operating power – 500 W;

- Belting;

- stroke – 50 mm;

- speed – 280 to 2500 rpm;

- weight – 22 kg;

- operating voltage – 220 V.

Pros:

- number of speeds – 9;

- accuracy in operation is ensured by a special scale with different-caliber divisions;

- transparent screen protects from chips;

- processing of tall workpieces;

- versatility in working with a variety of materials;

- ergonomic handle and body;

- light weight;

- fixing the desktop at different angles expands the functionality of the device;

- fastening the machine with bolts to the working base;

- the size of the tools used is 16 mm;

- does not require specialized skills in management and maintenance;

- magnetic cartridge.

Minuses:

- noise during equipment operation;

- There is no supply of cutting fluids.

Zitrek DP-82

The TOP drilling machine Zitrek DP-82 continues.

It has a 400W motor and is used for drilling holes in metal products, hard plastic materials and wood.

The machine is equipped with a spindle with a stroke of 50 mm, into which a chuck with a drill with a diameter of up to 13 mm is inserted. It has 9 operating speeds ranging from 500 to 2620 rpm, which allows you to choose the best option for processing a particular material.

The workpiece table of this machine is adjustable. It can be adjusted in height and angle. And special grooves in the base of the machine allow you to install clamping equipment to process larger workpieces.

For safe operation, the machine chuck is covered with a transparent screen. It protects against chips and work debris without obstructing your view. There is also a belt drive protective cover and an emergency stop button for emergency shutdown of the machine.

Those who have already purchased the Zitrek DP-82 speak generally positively about it, noting its low cost, high drilling accuracy and compact size.

Overall, a great inexpensive option for personal use at home or in the garage.

- Power: 400 W.

- 9 operating speeds.

- Drill D: up to 13 mm.

- Speed: 500 – 2620 rpm.

- Spindle stroke: 50 mm.

- Table height adjustment.

- Tilt angle adjustment.

- Emergency stop.

- Dimensions: 400 x 450 x 260 mm.

- Weight: 17 kg.

The best metal drilling machine

The Metalmaster TDR-20

radial drilling machine is intended for making and subsequent abrasive processing of holes in metal workpieces.

Assigned professional class. But the compact body will ergonomically fit into a small workshop.

Characteristics:

- voltage – 750 W;

- spindle cone – MK-3;

- voltage – 380 V;

- weight – 354 kg.

Pros:

- number of speeds – 5;

- diameter of the tool used – up to 20 mm;

- scale for adjusting hole depth;

- end milling diameter – up to 16 mm;

- face milling diameter – up to 63 mm;

- use of a vice;

- holes for mounting in the base;

Adjusting the spindle speed makes it possible to accurately select the operating mode for a specific workpiece

- moving the node along a straight path;

- low vibration level during operation;

- processing of different-sized workpieces;

- moving the coordinate table.

Minuses:

- high price;

- requires operator qualification;

- no supply of cutting fluids;

- components to order.

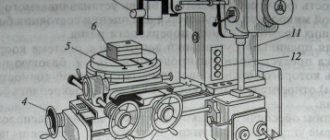

What devices are relevant for installing and fastening workpieces?

You must work on a drilling machine in compliance with technology and safety rules. Never hold the workpiece with your hand; not only will you not get dimensional accuracy, but you may also get injured.

What devices exist for this? A machine screw vice is installed directly on the machine's work table. If you have chosen a machine model that does not include such a vice, be sure to buy one. This will not cause large expenses, but your small pieces of metal and wood will be securely fastened. Some machine tool manufacturers, such as Anchor, include a vice as part of the package.

Machine screw vice for drilling machine

In parts with complex configurations, a vice with a rotary table (rotary jaw) will help you drill holes. If you plan to produce your product in small series, then with such a vice you will significantly increase productivity due to the fact that the workpiece can be rotated relative to the spindle in different planes and at the desired angle without reinstallation.

Rotary machine vise

The universal vice for drilling devices has great advantages over conventional vices. Their design with an additional surface for parts also allows the part to be rotated without expanding it to work on a different plane.

Workpieces with rounded shapes - balls, pipes - require the use of a vice with recesses on the jaws for clamping cylindrical and spherical elements. These are so-called prism vices, designed for more reliable installation of such parts during drilling.

Vise with prismatic jaws for round parts

On machines with T-slots, several types of additional tables can be mounted on the table, for example, a cross table, a box table. They serve to move workpieces in opposite directions (longitudinal and transverse), as well as to install them in different planes.

Parts larger than 10 cm may not fit in the vice. Then you will need special clamps for metal workpieces, and for wooden workpieces - additional stops and guides, or clamps.

The best wood drilling machine

The Hitachi B 16 RM machine has been assigned a specialized class. Often purchased for home use and small-scale production.

Characteristics:

- key cartridge;

- available material for processing - wood;

- voltage – 220 V;

- power - 750 W;

- Belting;

- available drill diameter – up to 16 mm;

- rotation speed – from 250 rpm;

- rotation stroke – 85 mm;

- weight – 71 kg.

Pros:

- number of speeds – 12;

- two-dimensional XY laser sensor for precise marking;

- drilling depth regulator;

- microswitch for additional protection against injury;

- convenient speed switch;

- handle for feeding the cartridge left-handed and right-handed;

- ergonomic body;

- durable cast iron work surface that allows the machine to tilt at an angle of 45 degrees.

Minuses:

- no supply of liquid cooling system;

- noisy at work.

The best drilling machine for concrete

KS-350 is an updated and modernized model of a concrete drilling machine. Belongs to the class of professional equipment.

Characteristics:

- power – 330 W;

- drill speed – 100-650 rpm;

- weight – 34 kg;

- Dimensions: 105*38*25 mm.

Pros:

- the diameter of the holes made is 5-35 cm;

- electronic and mechanical protection of the electric motor;

- three-speed gearbox;

- smooth adjustment of drilling speed;

- adjusting the angle of the bed;

- level;

- double-sided carriage gearbox;

- the base plate is fixed with anchors or vacuum;

- roller feed.

Minuses:

- a similar model is assembled according to the consumer’s order;

- the operator and mechanic must have certain knowledge and experience;

- components and consumables only on order;

- relatively high cost;

- makes noise and vibrations during operation.

The best glass drilling machine

The horizontal portable MultiDrill is designed for making holes in glass sheets or workpieces.

Assembly takes place in Italy using automated equipment. Suitable for small-scale and large-scale production. Characteristics:

- power supply – 220 V or 50/60 Hz;

- drill fastening – straight tail;

- weight – 8 kg.

Pros:

- number of speeds – 5;

- steel spindle;

- high-precision spindle alignment;

- steel stable base;

- attaches to suction cups;

Thickness range of the processed material – from 4 to 20 mm

- drill size – 4-75 mm;

- compact dimensions;

- availability of components and consumables on order from official dealers;

- supply of lubricant and cooling fluid, which can be replaced with water;

- processing of fabric of any size.

Minuses:

- Only special diamond drills are suitable;

- noisy in operation.

Signs by which drilling machines are characterized

For a detailed classification, a set of characteristics is used; each operational and physical-mechanical characteristic of a drilling machine can serve as the basis for classifying it into one group or another:

- by the degree of accuracy of processing and carrying out certain procedures;

- depending on the number of spindles included in the equipment design;

- in terms of mounting arrangement, these can be floor, tabletop and hanging models;

- based on the level of automation and operating power of the equipment.

When choosing a functional device, it is necessary to carefully study the complex of operational and practical characteristics of each model, which will allow you to efficiently and quickly carry out the necessary measures and process materials.

The best drilling machine made in Russia

BISON ZSS-550 is intended for making non-through high-precision holes.

Characteristics:

- available drill size – up to 16 mm;

- key type cartridge;

- spindle cone – MK-2;

- power – 550 W;

- processed material – metal;

- no coolant system is provided;

- voltage – 220 V;

- weight – 48 kg;

- number of speeds – 5.

Pros:

- adjustment of the depth of the holes being machined is ensured by an ergonomic lever with plastic pads;

- multi-level speed modes are the key to convenience and productivity of work;

- a translucent plastic cover protects against chips and opens the view;

- stable base;

- functionality of the desktop due to its movement.

Minuses:

- impossibility of making through holes and processing them;

- size of attached holes up to 16 mm;

- noisy running;

- processing only metal workpieces.

Types of drilling machines, features and differences of equipment

Home equipment is intended for drilling blind or through holes, while the material being processed can be plastic and metal, wood and other materials depending on the type of machine model:

- vertical drilling, for processing small workpieces made of durable materials;

- radial drilling, suitable for large parts and elements;

- horizontal drilling, performing deep drilling with rotation of the workpiece.

A separate group includes multi-spindle devices; such a mini drilling machine is necessary for drilling small-diameter holes, which helps to carry out various types of work necessary on the farm.