Information about the manufacturer of the woodworking combined machine BDS-4

The manufacturer of the universal sharpening machine BDS-4 is the Vitebsk grinding machine plant Visas , founded in 1897.

Since 1940, the company has specialized in the production of sharpening equipment and today is the only manufacturer in the CIS of machines for the manufacture and sharpening of any cutting tool. The plant's products are used in more than sixty countries around the world.

It also produces woodworking equipment.

Machines produced by the Vitebsk sharpening machine plant, Visas

BDS-4 combined woodworking machine. Purpose, scope

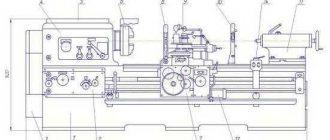

The semi-industrial 3-operational combined woodworking machine BDS-4 is designed for complex processing of parts from various types of wood.

The BDS-4 machine has a simple design: an electric motor with a two-stage pulley and a planing shaft (spindle) with a take-up pulley are connected by a V-belt. The planing shaft (spindle) has two rotation speeds - 2400 and 4000 rpm when rearranging the V-belt.

A receiving pulley and a circular saw (disc cutter) are attached to the end of the planing shaft.

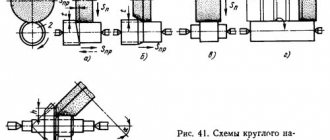

The machine performs the following operations:

- Planing (jointing) on a plane up to 200 mm in width and up to 3 mm in depth in one pass at a workpiece feed speed of up to 2 m/min. Knife shaft rotation speed - 4000 rpm;

- Planing along the ribs (edge) at an angle from 0 to 45°;

- Sawing along and across the fibers of boards up to 50 mm thick at a workpiece feed speed of up to 1.0 m/min. Circular saw rotation speed 2400 rpm;

- Milling with a disk cutter with a depth of up to 16 mm at a workpiece feed speed of up to 2 m/min;

- Sharpening the tool with a grinding wheel.

The main positive advantages of a universal machine

The universal machine has a wide tabletop, which is very convenient when working at home. Another good thing is that the cost of home equipment is affordable for most Russian buyers. Such a purchase will be profitable and useful for use at home. Sub-data machines Performed operations:

– cutting lumber along the grain, – cutting lumber across the grain, – planing, – drilling, – milling, – tool sharpening Spare parts kit:

– circular saws – cutters – drill chuck – tools

The universal household woodworking machine model SUBD-1B is designed for processing lumber in everyday life (sawing wood along and across the grain, jointing, drilling, milling, and sharpening tools).

Reliability – Easy to set up – Easy to service High performance – Wide range of capabilities

Technical characteristics - universal household woodworking machine subd 1

Indicator DBMS-1B Maximum width of jointing in one pass, mm 250 Maximum width of the cut layer in one pass, mm 3 Maximum cutting height, mm: – longitudinal sawing 55 – cross-cutting 45 Depth of drilling and milling (grooving), mm 85 Largest diameter of the disk saws, mm 200 Idle speed, rpm: – knife shaft 4560+-200 – saws 2850+-200 Largest diameter of the tool shank clamped in the chuck, mm 16 Number of knives of the knife shaft, pcs. 2 Feed in all operations Manual Overall dimensions, mm, no more than 800x600x400 Weight of the machine with all accessories, kg, no more than 85 Power: – voltage, V 220 – frequency, Hz 50+-10 – alternating current Rated power of the electric motor, kW 1.5

Price, rub (excluding VAT) 10.600

Subd 4 read on.

Composition of the combined machine BDS-4

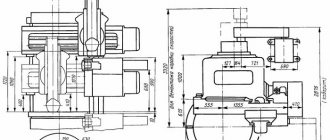

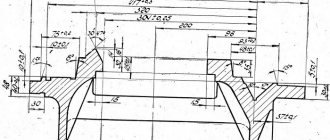

The machine consists of a frame on which the main shaft (spindle), which is a blade shaft, is mounted in rolling bearings.

A pulley is mounted in a cantilever on the shaft, to which rotation from the electric motor is transmitted through a V-belt drive. The electric motor pulley is a two-stage one, providing two rotation speeds of 2400 and 4000 rpm. The spindle rotation speed is selected by transferring the V-belt on the electric motor pulley. The speed of 2400 rpm is better for working with a circular saw, the speed of 4000 rpm is suitable for planing.

The frame is equipped with planing tables with a knife shaft guard and a saw table. The tables are height adjustable.

Universal woodworking machine

Usage: in woodworking, in particular, to ensure the operation of sanding floors. The essence of the invention: the frame 1 consists of two parts, on one of which there is a supporting fixed table 3, and on the other there is a receiving movable table 4 and a knife drum 5 with a drive 6, which has a seat for installing a saw or cutter. In the lower part of the frame there is a place for installing a knife or sanding drum 7, while it is equipped with a control handle 10 and a running system consisting of two rollers 8 and a third roller 9. When re-equipping the machine for scraping floors, part of the frame 1 with a supporting fixed table 3 and the saw table 4 is separated from the other part. Then this part is equipped with a knife or sanding drum 7, a handle 10 and a running system. 2 ill.

The invention relates to the woodworking industry, in particular to woodworking machines, and can be used for processing lumber at home, sharpening tools, and also for sanding floors.

A universal woodworking machine is known, containing a frame with a place made in it for bearing units for installing a knife drum, a receiving movable table mounted on it, supporting a fixed table, a knife drum and a drive mounted on the frame, connected by a V-belt drive, and the knife drum is equipped with a seat for installing a saw or cutter, or grinding wheel (universal woodworking machine model DBMS-1 (2Yaa.999.503). Operation manual, Cheboksary, Prompribor TU 25-02.190274-83). The disadvantage of the known woodworking machine is the inability to perform the operation scraping floors. The technical result of the invention is to expand the technological capabilities of the machine, in particular, providing the ability to perform the operation of scraping floors. In Fig. 1 shows the layout of the machine for performing basic wood processing operations; in fig. 2 layout of a machine for scraping floors. A universal woodworking machine consists of a split frame, consisting of two parts 1, interconnected by bolts (not shown) installed in holes 12, made respectively in both parts of the frame, a receiving movable table 2, a supporting fixed table 3 and a saw table 4 with a guide angle, mounted on the frame, a knife drum 5 and a drive 6, connected by a V-belt drive, while the knife drum is equipped with a seat 11 for installing an additional replaceable tool: a saw, a cutter or a grinding wheel. In the lower part of the frame with a receiving movable table there is an additional space (bearing unit) for installing a knife or sanding drum 7. In FIG. 2, in addition, the frame with the receiving movable table is equipped with a running system consisting of two rollers 8 located on the same axis, and a third, located second in the direction of travel and made with pressure in the form of a cylindrical compression spring 13 installed between the frame 1 and the running part of the roller 9 , and the handle for moving the machine 10. The moving parts of the machine (knife drum, drive, V-belt drive, additional replaceable tool) in both layouts are protected by special casings that ensure safe operation (not shown). A universal woodworking machine operates as follows. When the machine is configured to perform basic wood processing operations (sawing along and across the grain, planing, milling, tool sharpening), the machine operates using the traditional method. When re-equipping the machine into a layout for carrying out the operation of scraping floors, part of the split frame 1 with a supporting fixed table 3 and saw table 4 is separated from the part of the frame with a receiving movable table 2, a knife drum 5 and a drive 6. Next, this part of the frame is equipped with a knife or sanding drum 7 , for which a place is provided in the lower part of the bed, as well as a handle 10 for moving the machine and a running system consisting of two rollers 8 located on the same axis and a third roller 9 located second in the direction of travel and made with pressure. The machine is ready for the floor scraping operation. The knife or sanding drum 7 is driven by the drive 6 via a V-belt drive. The movement of the machine in the plane of the surface being processed is carried out directly by the work performer.

Claim

A universal woodworking machine, in the frame of which a knife drum is installed in bearing units with a seat for installing a saw or cutter, connected to the drive through a V-belt drive, while on the outer side of the frame there are receiving movable and supporting fixed tables, characterized in that the frame is made of two parts, one of which is intended to accommodate a supporting fixed table, and the other a receiving movable table, and a knife drum with its drive, while it has additional space for installing a knife or sanding drum inserted into the machine, and the machine is equipped with a moving handle and a running a system consisting of two rollers located on the same axis and a spring-loaded third one installed in the direction of travel.

DRAWINGS

,

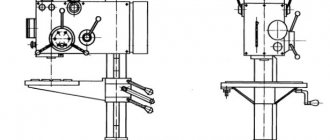

BDS-4 General view of the combined machine

Photo of the combined machine BDS-4

Photo of the combined machine BDS-4

Photo of the combined machine BDS-4

Photo of the combined machine BDS-4

Location of components and controls of the BDS-4 machine

- Machine support legs

- bed

- Knife shaft bearing

- Planing reception table

- Thrust bar

- Electric motor

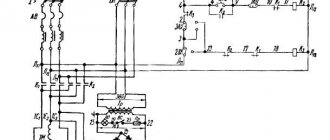

- Electrical cabinet

- Circular saw guard

- Knob for adjusting the height of the infeed planing table

- Handle for adjusting the height of the receiving planing table

- 220 V mains switch

- Start button

- Stop button

- Planer table position clamp screws

Preparatory operations

Sharpening angles for wood cutting tools

Adjusting knives in the planing drum of the BDS-4 machine

Bar for calibrating knives in the planing drum of the BDS-4 machine

The knives must be installed so that they protrude 1 mm beyond the dimensions of the knife shaft. When installing, control the uniform alignment of the knives along the entire length of the shaft.

Start tightening the bolts holding the knives from the middle of the wedge, and align the knives along the gauge bar. Before starting work, be sure to check that the knives are securely fastened. After turning on the jointer, make sure it is operating normally. It is necessary to monitor the operation of the knife shaft bearings. If the temperature rises, the bearings must be replaced.

Universal woodworking machine DBMS-1B and its description

Maximum width of jointing and thicknessing in one pass, mm 250 Maximum cutting height, mm 55 Maximum thickness of the cut layer in one pass during planing, mm 3 Maximum thickness of the cut layer in one pass during thicknessing, mm 1 Maximum depth of drilling and milling (grooving), mm 85 Electric motor power, kW 1.5 Overall dimensions, mm 750x555x370 Supply voltage, V 220 Weight of the machine with all accessories, kg 90 Saw rotation speed, rpm 2810 Knife shaft rotation speed, rpm 4500 Number of installed knives, pcs 2

Subd 4 machine

Before being allowed to work independently, a woodworking machine operator (hereinafter referred to as a machine operator) must undergo an internship for 2 to 14 shifts (depending on the nature of the work and the qualifications of the employee) under the supervision of a specially appointed person. violations by the machine operator of regulatory and legal acts (documents) on labor protection that could or have led to injury, accident or poisoning; during breaks in work for more than six months; receipt of information materials about accidents and incidents that occurred in similar industries - unscheduled. 5. The machine operator must have a clear understanding of the dangerous and harmful production factors associated with the performance of work, and know the basic methods of protection against their effects.

use, when performing work, personal protective equipment issued in accordance with industry standard standards for issuing personal protective equipment to workers and employees of enterprises”:

Universal household woodworking machine, DBMS-4B

Designed for woodworking in domestic conditions. It is a reliable assistant for performing various carpentry and joinery work during the construction of cottages, garden houses and farmsteads.

The greatest width of jointing and thicknessing in one pass, mm - 250 The greatest height of cut, mm - 55 The greatest thickness of the cut layer in one pass when planing, mm - 3 The greatest thickness of the cut layer in one pass when thicknessing, mm - 1 The greatest depth of drilling and milling (grooving), mm - 85 Electric motor power, kW - 1.5 Overall dimensions, mm - 750x555x370 Supply voltage, V - 220 Weight of the machine with all accessories, kg - 90 Saw rotation speed, rpm - 2810 Knife shaft rotation speed, rpm - 4500 Number of installed knives, pcs - 2

This concept implies connecting various industrial facilities to the Internet - machines, sensors, automated process control systems (APCS), capable of interacting with each other without human intervention.

Mail.Ru Group sees the industrial Internet as a huge market and a growth point.

“Our expertise and technology can be very useful to us in this.

These days, the whole world is becoming more and more digital, and industry is a huge part of the economy, where new technologies can provide a big leap,” said Denis Anikin.

IIoT is expected to help businesses improve productivity and reduce costs. According to him, the company intends to grow this business into a “separate serious direction” and enter the foreign market with it.

Technical characteristics of the combined machine DBMS-4

| Parameter name | DBMS-4 | VZ-335 | |||||||||||

| Sawing with a circular saw | |||||||||||||

| Workpiece length when sawing, mm | 0..4000 | ||||||||||||

| Workpiece width when sawing, mm | 5..300 | ||||||||||||

| Cutting depth range, mm | 55 | 80 | |||||||||||

| Vertical movement of the saw table, mm | 80 | ||||||||||||

| The largest diameter of the saw blade, mm | Ø200 | Ø200..Ø315 | |||||||||||

| Saw mounting diameter, mm | 32 | 32, 50 | |||||||||||

| Saw rotation speed, rpm | 28100, 4500 | 3000, 4500 | |||||||||||

| Dimensions of the working surface of the saw table, mm | 720 x 170 | 750 x 400 | |||||||||||

| Largest cutter diameter, mm | Maximum milling depth, mm | ||||||||||||

| Jointing (planing) | |||||||||||||

| Workpiece length during jointing, mm | 400..4000 | ||||||||||||

| Maximum jointing (planing) width, mm | 250 | 10..250 | |||||||||||

| Maximum depth of layer removed in one pass when planing, mm | 3 | 3 | |||||||||||

| Diameter of the cutting part of the knife shaft, mm | 86..88 | ||||||||||||

| Knife shaft rotation speed at idle speed, rpm | 2810, 4500 | 3000, 4500 | |||||||||||

| Dimensions of planing knife, mm | 260 x 30 x 3 Steel 65G | ||||||||||||

| Number of planing knives in the knife drum | 2; 4 | 3 | |||||||||||

| Width and length of planing tables, mm | 320 x 720 | 335 x 810 | |||||||||||

| Reismus | |||||||||||||

| Maximum and minimum thickness of the workpiece during thicknessing (Lifting height of the thicknessing table), mm | 50 | 120 | |||||||||||

| Minimum length of workpiece processed during thicknessing, mm | 400 | ||||||||||||

| The amount of lifting of the thicknessing table, mm | 120 | ||||||||||||

| Workpiece feed speed in thicknesser mode, m/min | manual | 5 | |||||||||||

| Dimensions of the working surface of the thicknessing table, mm | 700 x 260 | ||||||||||||

| Maximum thicknessing width, mm | |||||||||||||

| Maximum thickness of the cut layer during thicknessing, mm | 3 | ||||||||||||

| Drilling. End milling | |||||||||||||

| Workpiece length when drilling, milling, mm | 200..4000 | ||||||||||||

| Maximum diameter of drill, cutter, mm | 3..20 | ||||||||||||

| Rotation speed of drill, cutter, min | 3000, 4500 | ||||||||||||

| Dimensions of the working surface of the table, mm | 390 x 190 | ||||||||||||

| Drilling depth, mm | 85 | 150 | |||||||||||

| Amount of longitudinal and transverse movement of the table, mm | 110 x 100 | ||||||||||||

| Lathe device | |||||||||||||

| Turning spindle rotation speed, rpm | — | 1600 | Maximum length of the workpiece during turning, mm | — | 100..800 | The largest diameter of the workpiece during turning in centers, mm | — | 80 | The largest diameter of the workpiece when turning on a planar washer, mm | — | 300 | Weight of turning device, kg | — |

| Electrical equipment of the machine | |||||||||||||

| Type of supply current | ~220V / ~380V | ~380V | |||||||||||

| Number of electric motors on the machine, pcs. | 1 | 1 | |||||||||||

| Electric motor, kW (rpm) | 1,1 (2810) | 3 | |||||||||||

| Dimensions and weight of the machine | |||||||||||||

| Machine dimensions (length x width x height), mm | 750 x 555 x 475 | 100 x 900 x 900 | |||||||||||

| Machine weight, kg | 90 | 475 |

Related Links. Additional Information

- Directory of woodworking machines

- Directory of manufacturers of woodworking machines and equipment

- Directory of manufacturers of household woodworking machines

- Directory of chipper manufacturers

- Classification of woodworking machines

- Machines for longitudinal cutting of lumber

- Sawmill frames. Classification

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Choosing a woodworking machine for your home workshop

In addition, the advantage of using a universal machine is that it can be used to make truly unique things from wooden material that are quite difficult to find on store shelves. Using universal machines is quite easy.

On the domestic market, one can single out Russian products that are not inferior in quality to analogues from abroad, but at the same time their cost is much lower. After purchasing, it is recommended to immediately choose a place for comfortable work with the woodworking machine.

This could be a space in a garage or shed that can easily be converted into a workshop.

Often people worry that they don't actually know how to use such devices. The fact is that working on universal or special machines for wood processing is quite simple.

Application of household woodworking machine

A household machine opens up many possibilities. With its help you can make any parts for furniture, gazebos, fences, doors, etc. Almost all types of woodworking can be done using a universal machine. The productivity of such a machine is lower compared to a special one, but it is also suitable for small production.

The advantage of using a universal machine is that you can, if you wish, make unique things that you would never find on sale.

To conveniently use a household machine, you need to provide a comfortable non-residential space, which can be a barn, workshop or garage. Russian-made equipment meets all standards and does not require special skills. Even a person without the appropriate qualifications will be able to learn and independently understand the technology of working with a household machine.

The main thing is to follow safety precautions. Modern machines are made from high-strength alloys, this is a guarantee of their proper operation. You can process any type of wood, including hardwood.

The universal machine is equipped with a motor powered by the home network. The device is equipped with a special thermal relay that protects against overheating. This device prevents overloading of the machine and ensures stable operation for many years.