Where is a roughness meter used?

The device is used for measuring parameters in laboratories, in the mechanical engineering and instrument-making industries and in field conditions where it is necessary to determine the level of roughness of products. The work schedule, nomenclature and range of values are fixed by GOST 2789-73.

Scope of application: laboratories and workshops of industrial enterprises

Operating principle of the device

The simplest surface roughness meter

makes a linear measurement of the parameter. For this, a special mechanical tip is used, which in turn measures the roughness along the surface along an arbitrary line. More modern devices require a comprehensive analysis of the surface, also taking into account its total area. This is achieved through the use of non-contact analysis methods: laser, optics, etc. Such devices are especially effective for working with surfaces that have an impressive area.

The resulting roughness indices are indicated mainly in the form of Ra and Rq. The first is the average absolute deviation from the center line of the surface. The Rq value shows the root mean square deviation. In addition to the listed parameters, other values can also be used, taking into account the height of the peaks and the depth of the valleys. When working with a non-standard type of surface, it is recommended to choose highly specialized devices that are developed specifically for such cases.

Working principle of roughness meter

The profilometer is based on a diamond or carbide needle, which directly determines the unevenness of the product. It is moved along the surface of the part; in the event of any vibrations associated with fixed irregularities, the needle moves vertically. The sensor records this movement and converts it into a current pulse, which is processed by the amplifier and displays all the information about the surface of the product. The device produces the following indicators:

- Ra

– arithmetic mean deviation of the relief from the center line;

- Rz

– height of relief unevenness at 10 points.

The equipment is also capable of demonstrating weighted average, amplitude or total characteristics.

Non-contact profilometers

The meters described below are characterized by additional capabilities: remote scanning - optical or laser - of the surface, as well as prompt data transfer to a computer and printer.

A tool for non-contact measurement and recording of results includes:

- A plate with T-shaped slots in which the metal of the product is fixed.

- Laser scanning head.

- Optical sensor.

- Waveguide.

- Control device with interface for connecting recording devices.

The optical measuring sensor has characteristics that make it possible to measure and display on the monitor a fairly large amount of information: longitudinal and transverse profiles of the scanning path, accuracy, discreteness of the measurement step, current and total counting error, etc. The principle of recording a profilogram on thermal printing roll paper turns this device into full-featured profiler. The measurement process and production are controlled interactively. In this way, the roughness can be re-monitored in some areas of the sample being measured.

An example of a compact type non-contact profilometer is the Mahr MarSurf PS1 profilometer. For this method of transmitting a control signal, an optical sensor is provided in the circuit. Possible fluctuations in the distance between the receiver and the measured surface are automatically compensated by the step cutoff system. The device uses both mains power and a built-in battery drive. The Mahr profilometer data sheet contains a detailed description of the method of using this device. The Mahr non-contact profilometer has a roughness measurement range of 5...15 µm.

Profilometer Mahr Marsurf PS1

Types of profilometers

Instrumentation devices differ in the way they provide information:

- Profilometers

– show information on the screen in real time.

- Profilers

– show information after the completion of measurements in the form of graphs, which are later deciphered and analyzed.

According to GOST 19300-86, profilometers and profilographs are divided into:

- Stationary

– for carrying out measurements in laboratories.

- Stationary-portable

– to control the surfaces of finished products in production.

- Portable

– to control the quality of individual elements during production or objects at construction sites.

Devices are also contact or non-contact:

- Contact

– a diamond needle is used as a probe, which moves along a given line on the surface. The needle vibrates if it hits a bump, which generates an electrical signal indicating the size of the bump.

- Contactless

– This type includes optical and laser profilometers. The first ones work due to shadow projection, light section and interference, the second ones use the method of shifting the radiation frequency.

TIME 3221 – modification of the TIME3220 device, equipped with a remote sensor

Rating of quality profilometers

Optical 3D profilometers

Profile 3D

Model produced by the American company Filmerics. A low-cost 3D roughness imaging product that uses two optical interference techniques, white light interferometry (WLI) and phase shift interferometry (PSI), to determine the degree of surface roughness. It is used in mechanical engineering, materials science, energy, forensics, microelectronics, optics, etc.

Research is carried out in the range from subnanometer to millimeter with minimal costs and labor costs.

The device is equipped with a stage with drives for movement in the X and Y axes, a wide-angle lens with 10x magnification, and a 5 megapixel camera. Capable of producing accurate scanning results with part thicknesses from 50nm to 10mm (WLI) and from 0 to 3 μm (PSI).

On a note! In the international system of units of measurement, μm stands for micrometer.

The error does not exceed 0.7%. Vertical scanning is performed at a speed of 12 μm/sec. The price is to be confirmed with the seller.

Profilm 3D profilometer

Advantages:

- simple;

- reliable;

- accurate;

- inexpensive.

Flaws:

- results are not transferred to the PC.

4.Optical profilometers of the Surfiew Academy series

GL-tech company from South Korea develops and produces white scanning interferometers. The review presents the Surfiew Academy model, which is capable of instantly and with high accuracy determining surface roughness parameters in the range from 1 nanometer to 10 mm.

On a note! In the international system of units, infinitesimal lengths, incl. The wavelengths of visible light are measured in millionths of a meter or nanometers (nm).

The process is much faster than using the confocal method and occurs without damaging the samples under study. The software allows you to convert a 3D image into a 2D format (3D rendering), perform a mathematical analysis of the nature of irregularities: chips, cracks, etc. Linear and area scanning available. Visualization of the process is displayed on the display screen.

Measuring tools of this type are used to assess the roughness of parts after particularly precise processing. The device is equipped with a 0.5-inch single-color camera and white LED backlight. The object table, measuring 12x12 cm, is moved manually. The price is to be confirmed with the seller.

profilometer Optical profilometers of the Surfiew Academy series

Advantages:

- speed of operations;

- high accuracy of results;

- three-dimensional picture.

Flaws:

- solid dimensions and weight;

- requires highly qualified operator.

3.Optical profilometer Swift PRO Duo

Model produced by the British company Vision Engineering Ltd. It is a powerful and simple system for analyzing the roughness of various surfaces. The multi-purpose device uses modern methods of optical analysis and video technologies, allowing it to be successfully used on the production site and within the walls of laboratories.

The impressive functionality makes it possible to use the device in electronics and automotive manufacturing, medical equipment production and the aerospace field.

Swift PRO Duo controls are distinguished by a clear interface, high measurement accuracy in accordance with international standards, 100x magnification of the real image, ease of settings and use. The cost is to be confirmed with the seller.

profilometer Optical profilometer Swift PRO Duo

Advantages:

- ease of use;

- greater measurement accuracy;

- presence of a video camera;

- multifunctionality.

Flaws:

- not identified.

LEICA DCM8 SR

The confocal 3D profilometer from the German manufacturer Leica Microsystems receives the best reviews. The device implements the capabilities of a confocal microscope and an interferometer. In combination with additional functions, this design quickly and accurately determines and displays on the screen the characteristics of the test sample. The results are documented using an image recording system based on a built-in CCD camera and four LEDs.

The device's confocal capabilities facilitate fast and accurate profile analysis of complex surfaces as long as their inclination does not exceed 70°. The device is equipped with a highly sensitive detector (1.4 million pixel resolution), which allows viewing research results in confocal and bright-field modes with a high degree of contrast and focus.

The device has dimensions (height, width, length) of 573x390x569 mm and a weight of 48 kg, and is operated in the ambient temperature range from +10 to +35°C and relative humidity no more than 80%. Implements a number of functions:

- obtaining a 3D relief image;

- determination of profile characteristics with coordinates, thickness, roughness;

- carrying out spectral analysis and colorimetry.

The cost of the device is confirmed with the seller.

profilometer LEICA DCM8 SR

Advantages:

- mathematical image analysis;

- high-definition interferometric study;

- the ability to obtain color images of the results (RGB palette) from four LEDs;

- simple software.

Flaws:

- high price.

1.S neox – 3D optical profilometer-confocal microscope

A new product in the line of devices from the Spanish company Sensofar, it combines the capabilities of a three-dimensional optical profilometer and a confocal microscope. The product is used in various fields:

- in mechanical engineering and aerospace;

- materials science and energy;

- criminology;

- microelectronics and micromechanics;

- optics and semiconductors;

- consumer electronics;

- display manufacturing and watch industry.

The model implements technologies of confocal microscopy, interferometry, and focus measurement. A revolving mechanism with six lenses is used as the main working body. In addition, the equipment includes: a high-resolution camera combined with a display, four LEDs (red, green, blue and white), supporting moving tables of various sizes, including one with manual movement and four with electric drive. The price is to be confirmed with the seller.

profilometer S neox – 3D optical profilometer-confocal microscope

Advantages:

- multifunctional;

- results are fast and accurate;

- compact sizes.

Flaws:

- not identified.

Optical profilometers at an affordable price

5.Optical profilometer MicroProf 100

A small-sized device made in Taiwan for monitoring surface roughness in a non-contact manner. It is interesting because it can simultaneously determine the relief of both planes of the plate under study, i.e. front and back sides of the part. Moreover, the device is capable of determining several parameters at once: roughness, waviness and flatness, as well as examining the difference in thickness over the entire area of the sample and also on both sides.

The device is a desktop version; at the customer’s request, it can be made in a portable version for working with samples on site. The manufacturer assures that the device is quite affordable, but this information needs to be clarified with the seller.

profilometer Optical profilometer MicroProf 100

Advantages:

- compact dimensions;

- multifunctionality;

- double-sided scanning system;

- affordable price.

Flaws:

- not identified.

4.Optical profilometer TAMS

Japanese device for determining roughness from Konica Minolta. Compact, portable, contactless device. Developed in collaboration with the German concerns Volkswagen and Audi. Capable of determining with high accuracy the roughness of the finishing of passenger car bodies in the range from initial matte to final glossy. Using this device, intermediate stages of coating application and processing are controlled: steel, aluminum, E-Coat coating, main and finishing.

On a note! Electrodeposition coating of metal surfaces is called E-Coat.

The model is light and compact. The lower part is an optical scanner. The top of the product is the control panel. Working with the device does not require highly qualified operator. The operating training process lasts exactly as long as it takes to familiarize yourself with the user manual. The price is affordable, but you will have to check it with the seller.

profilometer Optical profilometer TAMS

Advantages:

- simple and intuitive controls;

- lightness and compactness;

- fast and accurate results;

- affordable price.

Flaws:

- not identified.

BW-series

The device determines the level of cleanliness of product processing using modern non-contact technologies: 3D optical and interferometric. Multifunctional, analyzes thin layers, sample geometry, suitable for observing deformation processes.

Suitable for industrial use and laboratory research. Can be used as an optical microscope. Performs studies of smooth and rough samples without changing the operating mode. It operates in a non-contact manner, does not destroy the surface of the sample, and scans at high speed. Has compact dimensions. The average price is quite affordable. The final size will be confirmed with the seller.

profilometer BW-series

Advantages:

- quick results;

- non-destructive research methods;

- compact dimensions;

- affordable price.

Flaws:

- not identified.

2.Smart Projector 224

Optical profilometer from the Italian company SmartVision. Designed to check surface roughness. Measurements are carried out automatically and at high speed. An excellent tool for incoming, periodic and continuous product quality control. Does not require highly qualified operator.

Package Included:

- multifunctional PC (touch screen with high image quality);

- light receiver with double telecentric lens;

- camera with dimensions 419x450x475 mm.

The weight of the equipment is 150 kg. The price is to be confirmed with the seller.

profilometer Smart Projector 224

Advantages:

- contactless technology;

- high speed;

- accurate results;

- does not require highly qualified operator.

Flaws:

- large weight and dimensions.

How to choose a profilometer

To accurately assess roughness indicators, stationary contact profilometers are used. The roughness of surfaces made of hard materials, for example, high-carbon steel, is best determined with equipment that has a diamond probe. For rapid processing and evaluation of data on site, preference should be given to portable devices.

Contact meters have a number of advantages, the main one being high measurement accuracy. Non-contact profilometers may show incorrect values if the surface is dirty.

Types of testers

Obtaining data on the degree of unevenness of any surface and calculating the curvature coefficient are the tasks of mechanical engineers, allowing them to create accurate simulation models. An object that appears smooth to the human eye may not be so ideal to a specialist armed with technology. The ability to determine the frictional stress that occurs between two bodies makes it possible to accurately predict the life cycle of a particular component. Profilometers are used to determine the surface roughness inside brake systems, while ensuring maximum vehicle safety.

Surface roughness is classified according to the ISO 4287 standard from “N12” to “N1”, their measurement begins with a maximum height difference between microscopic slopes, peaks and valleys from 50 µm to 25 nm. The ability to detect irregularities in objects is key for engineers who design high-precision systems and want to predict their performance and expected life cycle:

- determination of the rigidity that occurs between two contacting bodies;

- calculation of friction stress;

- prediction of the risk of vibrations between connected parts;

- based on the detected unevenness, the correct tool is selected for processing workpieces and other objects;

- it is possible to determine whether the lubricated element is rough enough to retain oil molecules.

- predict the operation of brake system components;

- measure the thickness of the film or coating material;

- determine the level of surface reflectivity;

- calculate the accuracy and or CNC tools;

- predict the life cycle, maximum performance limits of a component based on detected cracks or irregularities.

Let's look at the functionality of effective tester models, the most popular on the market:

- The first tools with diamond styluses are the P 6 Stylus from KLA and Tencor. These are original products that were first introduced in the 1940s and operate similar to an LP player. The probe, consisting of a stylus, is held in place by a feedback mechanism and moves across the surface being monitored, while an arm connected to the probe follows perpendicular to the movement, helping to generate the profile waveform. There are several types of probes:

a. mechanical; b. inductive; c. capacitive; d. piezoelectric; e. mechanical skate.

Since the signal is determined by the analog movement of the diamond stylus, its size, radius, clamping force, and probe speed are determining factors for the accuracy and resolution of the equipment. Diamond stylus profilometers are preferred for applications where roughness calculations at the 10-20 nanometer level are required and where the surface is not clean enough so contact methods are more effective because surface reflectivity and color can fool other (optical) devices. The disadvantage of diamond stylus equipment is that it cannot be used on soft objects due to the formation of scratches on them.

- Digital holographic microscopes (time-resolved) are optical testers, they determine surface roughness using confocal chromatic aberration, laser triangulation, coherent interferometry, structural light scanning, optical difference, separation prism, reference mirror and other methods. Although these machines are not as good as the diamond stylus models, they are very accurate down to the micrometer. Their advantages are that they give results very quickly and do not come into contact with the object, so the probe cannot damage or scratch it. With their help, the irregularities of soft materials such as polymers, gels and others are calculated.

- A fiber tester is an instrument in which the detection sensor and data analyzer are located at a distance from each other, but are connected by optical fiber. Using a cable improves signal quality, so an engineer can measure the roughness of objects located in places that are inaccessible for some reason. For example, inside radioactive chambers, cryogenic installations, toxic gas containers that are not intended for long-term maintenance.

Some devices calculate the irregularities of flat and curved surfaces. Recently, testers have appeared that produce a three-dimensional image based on the received data, capable of doing 3D rendering. Such computing is used by both the industrial sector and the scientific community, enabling the success of mission-critical research projects, fundamental manufacturing and process control. Three-dimensional surface measurement metrics (S-parameters) were defined in 1991 by participants at the first EC workshop and have since been developed according to ISO standards to complement traditional 2D metrology R-parameters.

Testers are used to check wear of metals and paintwork. As more and more electronic components are produced using thin film processing technology, some roughness meters have begun to make calculations with great precision, down to nanometers.

Probes typically use a tip with a radius of 2 µm. However, for precision products (a group of alloys with specified physical and mechanical properties), a stylus with a tip in the range from 0.1 to 0.5 µm is often used. Depending on the sensor used, measurement errors may occur, so it is important to check in advance whether a particular tip is suitable. It is important to say a few words about how to choose the right measurement algorithm:

- Using a contact-type apparatus, irregularities are found by contacting the probe with the surface. In contrast, a laser-based sensor emits a beam of light onto the object under study and, thanks to its wave properties, performs the necessary manipulations.

- The correct technique is the key to achieving a successful result. For example, a ground metal part is usually measured perpendicular to the cutting direction so that the tester can more reliably record the characteristics of the object.

- Speed is also a key element of accurate calculations. They are performed slowly at first, then the intensity increases until significant fluctuations from the set values begin. It is important to note that to obtain quality indicators, periodic calibration of the equipment is required.

There are many other areas of scientific research and industrial control that can benefit from the use of an optical profiler. Devices with low spatial resolution but large field of view can be used to measure areas.

All devices consist of at least two parts. The detector determines where the points of interest are located on the sample, and the stage holds the object. In some systems, only one of the parts moves during calculations, in others both.

Where can I buy? Budget new items are purchased in specialized markets. Managers will tell you the points that interest you: how much the required model costs, what they are. You can view the product in the online store by ordering online.

Contact devices

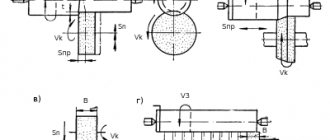

The schematic diagram of a contact profilometer with inductive signal conversion includes:

- Diamond tip stylus.

- Converter.

- Mechanism for moving the probe.

- Electrical signal amplifier.

- Analog-to-digital converter.

- Display or dial indicator.

- Feedback sensors that control the movement of the probe.

- Time relay.

- Measuring range switch.

A typical representative of this class of measuring equipment is the model 296 profilometer, which can be used to measure the roughness of flat surfaces. The main technical characteristics of the device are given below:

- Measuring range of roughness, microns – 0.02…10.0;

- Number of working assessment ranges – 3;

- Systematic error, % - 2;

- Step parameter, mm – 0.004…2.5;

- Result tracking speed, mm/s – 1;

- Power supply: AC mains.

Meter type 296 and similar ones (for example, model 130) due to their large dimensions make it possible to determine the roughness of products in workshop laboratories.

A portable type profilometer that works on the same principle is the Russian device model TR-100, which includes a piezoelectric transducer. It allows control of roughness if the part has not only flat, but also convex/concave surfaces. Calibration of readings to ensure the device is ready for operation is carried out by a unit built into the main circuit. TR-100 has an increased range (0.05...50 microns), but with the same performance values it has a slightly lower accuracy - ±12%.

Description

The operation of the device is based on the principle of feeling the irregularities of the measured surface with a probe (diamond needle) in the process of moving an inductive sensor along the measured surface and subsequent conversion of the resulting mechanical vibrations of the probe into a digital signal.

The delivery set of the device includes an inductive sensor supported on the surface being measured. The sensor is fixed in an electromechanical drive, with the help of which it moves along the horizontal surface being measured. In the vertical direction, to ensure contact of the sensor with the part being measured, the drive with the sensor is installed directly on the part or on a stand on which the part being measured is also installed. The sensor is powered, the drive is controlled, the signal and measurement information are generated and processed using an information-computing unit, made in the form of a board built into a computer, a drive, or an external computer unit. The profilometer is controlled from the drive keyboard or personal computer.

Data from the device can be processed using special software, which calculates roughness parameters, setting the required measurement conditions, displays a profilogram of the measured profile, selects individual sections on it and calculates the values of roughness parameters, selects individual profile elements and determines their geometric parameters (linear dimensions, angles of inclination), and also accumulates and stores measurement results and their statistical processing.

Profilometer

Great Soviet Encyclopedia. - M.: Soviet Encyclopedia. 1969—1978.

See what a “Profilometer” is in other dictionaries:

profilometer - profilometer ... Spelling dictionary-reference book

PROFILOMETER - (from profile and meter) a device that determines the size of irregularities of the processed surface of a product. In a profilometer, the signal is obtained from a sensor with a diamond needle moved along the controlled surface. Profilometer with automatic recording... ... Big Encyclopedic Dictionary

profilometer - noun, number of synonyms: 3 • microprofilometer (1) • profiler (1) • profilometer ... Dictionary of synonyms

profilometer - A device for measuring roughness parameters, showing the values of these parameters or providing their registration. [GOST 27964 88 (ST SEV 6134 87, ISO 4287/2 84)] Topics: surface roughness General terms for measuring instruments EN... ... Technical Translator's Reference

Profilometer - A contact profilometer is a device designed to measure surface irregularities. To assess surface roughness, a special indicator, surface roughness, is often used. A typical profilometer contains a scale on which ... Wikipedia

profilometer - (from profile and meter), a device that determines the size of irregularities of the processed surface of a product. In a profilometer, the signal is obtained from a sensor with a diamond needle moved along the controlled surface. Profilometer with automatic recording ... Encyclopedic Dictionary

PROFILOMETER - (from the French profil profile and meter) a device that automatically determines the size of uneven surfaces. metal surface. In P., the signal is received from a sensor with a diamond needle moving perpendicular to the surface being monitored (see figure). P.... ... Big Encyclopedic Polytechnic Dictionary

profilometer - (see profile + . meter) a device for measuring micro-irregularities of a machined metal surface. New dictionary of foreign words. by EdwART, 2009. profilometer a, m. (... Dictionary of foreign words of the Russian language

profilometer - profilio matuoklis statusas T sritis radioelektronika atitikmenys: engl. profiler vok. Profilmesser, m rus. profilometer, m pranc. profilomètre, m … Radioelektronikos terminų žodynas

profilometer _ atitikmenys: engl. profilometer vok. anzeigendes Tastschnittgerät, n; Profilmesser, m; Profilmessgerät, n;… … Penkiakalbis aiškinamasis metrologijos terminų žodynas

Source

Methods and means for assessing the indicator

A surface can have a variety of indicators; roughness is one of the most difficult to measure. The surface, or more precisely, the indicator under consideration, can be assessed using the two most common methods, which are called qualitative and quantitative.

The features of the qualitative method for determining the indicator under consideration include the following points:

- A visual inspection is carried out in the presence of a standard. This method has been used for many years, but today, due to its low efficiency, it is extremely rare.

- The surface can be checked using a microscope or simply visually. A specialist can most likely determine by touch what class the surface belongs to.

The use of the visual inspection method is only possible if the fineness of the surface treatment is low. Control by the method under consideration determines the use of standards, which must have the appropriate roughness. It is possible to control the indicator only if the standard is made of the same material as the part being controlled. If the control method is insufficiently effective during visual inspection, special microscopes are used. But often visual control is not enough

Roughness can also be controlled using a quantitative method. It is based on measuring the parameter using a profilometer and a profilograph. In this case, the parameters have to be controlled when the tool comes into contact with the surface.

Profilographs are a contact tool used to measure the indicator in question. This technique is based on measuring the indicator by obtaining an image of micro-irregularities in the profile. After obtaining an image, certain calculations are carried out during measurement.

The assessment with this device is carried out as follows:

- It is contact, the surface is felt using a diamond needle.

- This device may belong to the optical-mechanical group of equipment. Similar techniques allow you to take a photograph: the part is felt and the image is applied to the tape in an enlarged form. With the contact method, the test allows you to determine from the 4th to the 11th grade. You can check metal and other materials in a similar way.

Profilometers: types and applications

Profilometers are a technique that involves the use of an instrument that does not provide images. The contact method allows you to make accurate calculations to obtain the desired result. This tool can belong to the contact group and has the following features:

- The equipment belongs to this group because it is checked by feeling the surface with a needle.

- The assessment is carried out by moving the needle along its axis. In this case, the frequency and amplitude of the oscillations are assessed. Their determination makes it possible to determine the roughness class.

- The device belongs to electrical systems, has special sensors and a processor for processing the received information. In this case, complex calculations are not necessary to determine Ra or Rz. The method is suitable for the case when the height of micro-irregularities is in the range from 0.03 to 12 microns. You can test metals and other materials with this device. V.M. decided to determine the indicator under consideration in this way. Kiselev, who developed this remedy.

There are quite a few methods for determining the degree of roughness. Some tools and methods are no longer practically used due to the emergence of more modern tools that can increase the accuracy of changes and reduce the likelihood of error. Some equipment is contact type, others are optical and mixed type. The choice depends on how high the accuracy of the measurements should be.

Measurement methods

The index can be measured by manual comparison with a "roughness comparator" (a sample of known surface roughness), but more generally, surface profile measurement is done using profilometers. They can be contact type (typically a diamond stylus) or optical (such as a white light interferometer or laser scanning confocal microscope).

You may be interested in: Titius-Bode rule: distances between planets and the Sun

However, controlled roughness may often be desirable. For example, a glossy surface can be too shiny for the eye and too slippery for the finger (a good example is the touchpad), so controlled metrics are required. Surface roughness is where amplitude and frequency are very important.

Its value can be calculated either from a profile (line) or from a surface (area). The profile roughness parameter (Ra, Rq, ...) is more common. The area roughness parameters (Sa, Sq, ...) provide more meaningful definitions.