Ways and methods of polishing aluminum

To level out the roughness of the material and level out deep scratches in industrial conditions, complex technologies are used that involve working with chemical reagents. The process is performed using specialized equipment.

Electropolishing

This method involves restoring the coating and polishing aluminum to a mirror finish. The procedure involves processing the product in an electrolyte solution:

- the acid composition is heated in a special bath with an additional lead layer;

- lead cathodes are attached to aluminum;

- a current density of 10-50 A/dm² is passed.

Electropolishing of aluminum

Processing time is on average 5 minutes.

Chemical methods

The process of chemical polishing of aluminum is carried out using a special bath with a steel plate at the bottom:

- the tank is filled with a solution of sulfuric, nitric and phosphoric acids;

- the composition is heated to 90-120°C, depending on the composition of the material being processed;

- the aluminum product is immersed in an acidic environment for 30-45 seconds, then it must be rinsed with water;

- the processing algorithm is repeated 5-6 times;

- At the final stage, treatment is carried out with nitric acid 30%.

The electrochemical method of polishing aluminum involves the combined action of chemical reagents and electricity. In this case, the material being processed acts as an anode electrode, which is connected to a current source. The product is immersed in a reservoir with electrolyte, while the function of the second electrode is performed by copper cathodes.

Decorative etching

This technique for restoring aluminum products is a type of electropolishing. In this case, the workpiece is placed in a solution of phosphoric and chromic acids and exposed to anodes. The electrical voltage increases from 25 V to 40 V, and the ambient temperature during the process changes from 50°C to 80°C. As a result of processing within 15-20 minutes, the surface of the aluminum is covered with a chaotic pattern. Next, the product is thoroughly washed under running water, dried and painted with a special paint for organics.

Electrochemical polishing of metals: description of the process, scope of application

A metal product can be given shine in various ways. To do this, it is not necessary to use special coatings; you can use the polishing method.

It can be mechanical, for example, using sanding wheels, chemical - when the metal is immersed in a special solution, and also electrochemical. In this case, the effects of chemical components and electrical discharges are combined, which trigger certain reactions or enhance them.

Electrochemical polishing of metals can be performed in normal home conditions if you collect all the necessary equipment.

Process description

During electrochemical polishing, the treated metal surface acquires a mirror shine. Existing roughness is also reduced. The process goes like this:

- The part is considered an anode, that is, an electrode carrying a positive charge. It must be placed in a bath with a special composition.

- Another important component is the cathodes, which are necessary for the reaction to occur.

- As a result of exposure, a reaction occurs and dissolution occurs. It is uneven; first, the most noticeable roughness, which protrudes above the surface the most, is removed. At the same time, polishing occurs - the product acquires a mirror shine.

Removing noticeable large irregularities is called macropolishing, and smoothing out small defects is called micropolishing. If these processes occur simultaneously and evenly during processing, the product acquires shine and smoothness. It is also possible that shine will be obtained without smoothing or vice versa. The two types of polishing are not necessarily related.

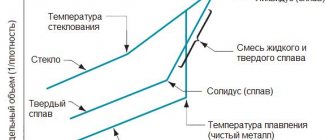

Chemical polishing of metal results in the formation of a special film on the surface of the workpiece during the process. Its composition can be oxide or hydroxide. If it evenly covers the entire surface, this creates conditions for micropolishing. In this case, the outer part of the coating, located on the surface, continuously dissolves.

To be able to carry out micropolishing, it is necessary to ensure that a balance is maintained between continuous coating formation and dissolution; while working with the part, the layer thickness must remain unchanged.

This will allow the electrons of the metal being processed and the composition used to interact in the process without the danger of the metal product dissolving in an aggressive environment.

Macropolishing also directly depends on the film formed. It covers the product unevenly; on protruding irregularities this layer is thinner, so they dissolve faster due to the influence of current.

TIP: the effectiveness of the overall effect of the polishing composition can be increased if you use electrolytes for processing that contain salts of weakly dissociating acids, which increase the overall resistance of the coating.

In addition, the mechanical effect of mixing plays a role. The film thickness or diffuse layer may decrease. Some electrolytes used perform their function only when heated, and a general rule that applies to all compositions is that when heated, neutralization decreases and the rate of film dissolution increases.

Current density and voltage level are also among the factors that have a serious impact on the process. For example, if it is necessary to polish copper products, then a composition with phosphoric acid is selected for it and the maximum current mode is set without the formation of oxygen.

That is why it is important to strictly follow all the necessary parameters in order to achieve high-quality polishing.

Equipment and chemicals

To work with various metals, it is necessary to select the appropriate electrolytes that will help achieve the desired result:

- Most often, compositions based on various types of acid are used - sulfuric, phosphoric or chromic.

- Glycerin can be added to increase overall viscosity if required.

- Sulfureide acts as an etch inhibitor.

- To clean various products after the procedure, various solvents or alkaline agents can be used. Formulations with surfactant active ingredients are often used.

Proportions for creating a chemical composition

Polishing is carried out in special baths. It is important to remember that their components are toxic substances and hazardous to health, especially if heating is used, so all components must be handled with the utmost care, observing the required safety precautions.

Polishing aluminum at home

To restore the characteristic shine of an aluminum surface at home, various folk methods and household chemicals are used.

Tools and devices

What you need to have on hand to get rid of scratches and dullness, and restore the original aesthetics of objects: for this, use a special paste for polishing aluminum. You can also deal with the problem using a number of common cleaning products and kitchen products, including:

- soap solution;

- glass and porcelain cleaning products;

- cream of tartar, table vinegar;

- baking soda, salt, lemon, alcohol;

- sorrel, sour apple, kefir.

In addition, you will need the following set of tools for polishing aluminum:

- fine and medium grit sandpaper;

- felt-coated polishing discs;

- metal brush;

- rags.

When choosing products and devices for polishing aluminum products at home, you should take into account the composition and characteristics of the material being processed. Food-grade aluminum should not be polished with abrasives; gentle methods for eliminating defects are appropriate here.

Pre-cleaning

If you plan to work with a painted part, at the initial stage of the procedure it is necessary to carry out preliminary cleaning, remove coating residues and oxidation particles. For this, various solvents and abrasives are used.

Tartar polishing

Cream of tartar solution copes well with darkening and deposits on metal:

- dissolve cream of tartar in a container of hot water, add lemon juice and bring to a boil;

- moisten a soft cloth in the cooled solution and wipe aluminum objects to a mirror shine.

Polishing of aluminum can be done with cream of tartar.

If the tartar is diluted with a small amount of water to a paste-like consistency, you can obtain an effective remedy for soot, oxidation and various contaminants on metal products.

Application of polish

As a special product for the care of aluminum products, polish has a number of advantages:

- helps quickly eliminate scratches and other visual defects;

- allows you to polish the aluminum surface to a mirror shine;

- does not contain ammonia and other aggressive substances;

- forms a protective layer, provides a barrier against oxidation.

Paste for polishing aluminum in Moscow and other regions is presented in a wide variety of products.

The nuances of using polish:

- The surface is pre-cleaned of paint coatings and dirt using a metal brush.

- Alternately, roughness is eliminated using medium and fine grain abrasives.

- After grinding, a paste is applied to the aluminum and rubbed in a circular motion using a rag until it has a reflective effect.

- Remains of the product are removed with a clean napkin.

To increase resistance to minor scratches and dirt, the surface is varnished after polishing.

Electropolishing.

Achieving a smooth and sparkling surface, high-quality cleaning – this is what characterizes aluminum polishing using electricity. Most electrolytes for electrochemical polishing of aluminum are based on orthophosphoric and sulfuric acid; the remaining components depend on the aluminum alloy. Such electrolytes give a good shine after polishing. The temperature required for the electropolishing process of aluminum is lower than for chemical polishing - about 60-90°C. Polishing time – 3-5 minutes, current density – 10-50 A/dm². In the electropolishing process, lead cathodes are used (for some alloys, stainless steel), duralumin pendants, and electrolyte baths with lead, polyethylene, or fluoroplastic treatment.

Alkaline electrolytes are also used. They are simpler and cheaper; the electrolyte compositions are based on trisodium phosphates, hexamethophosphates, soda ash or caustic soda. The process parameters depend on the composition of the electrolyte and range from: process temperature - 40-80-95°C, current density at the anode 3-20 A/dm², holding time 3-6 minutes. Cathodes must be nickel plated.

Traditional methods of cleaning and polishing aluminum products

To give a shiny look to household items and decorative elements, use various recipes with simple and inexpensive ingredients.

Sour apple

To clean the container from carbon deposits, you need to cut the apple in half and rub the surface well with the half. The acid in the fruit helps to quickly remove soot.

Kefir or cucumber pickle

To combat dark spots, leave the dishes with brine or kefir inside for 12 hours. Next, you need to wash the product in warm water with a soft cloth.

Baking soda

Dilute soda with water to a paste consistency, which is applied to the metal and wiped with a sponge. This method will help to clean the product from plaque and dirt, and polish it to a shine.

Baking Soda - Aluminum Polish

Ammonia and borax

A homemade polishing mixture of borax (15 g) and ammonia (5 g) allows you to restore the beauty of the product and give the thing a mirror-like shine. The composition is applied with a sponge and rubbed well, then rinsed under running water.

Solution for electrochemical polishing of brass

Usage: for electrochemical polishing of copper-zinc alloys (brass). The essence of the invention: the electrochemical polishing process is carried out in a phosphoric acid solution with the addition of organic substances at the following ratio of components, wt.%: orthophosphoric acid (density 1.73 at 15°C) 60.0 - 80.0; N-dibutylamine 0.1 - 1.0; phenetidine chloride 0.3 - 0.8; water - the rest.

The invention relates to the electrochemical processing of metals, in particular to the electrochemical polishing of copper-based alloys: brass, and can be used in instrument-making, machine-building and local industries.

Electrolytes for polishing copper alloys are known, containing solutions of o-phosphoric acid and additives PB-5 with triethanolamine [1] or PB-5 and ammonium acetate [2]. The closest to the proposed invention is a composition containing a solution of o-phosphoric acid with additives corrosion inhibitors PB-5 and triethanolamine. Polishing brass in known electrolytes is accompanied by smoothing of micro-roughness and shine formation. The surface cleanliness increases by 1.5-2 classes. The purpose of the invention is to increase the class of surface cleanliness of brass of various grades, expressed in increasing reflectivity and reducing the height of surface micro-irregularities. This goal is achieved by the fact that in a known electrolyte consisting of a solution of o-phosphoric acid and amine; n-dibutylamine, the addition of phenetidine chloride is introduced at the following ratio of components, wt.%: o-Phosphoric acid (specific weight 1730 at 15°C) 60.0-80.0 n-Dibutylamine 0.1-1.0 Phenetidine chloride 0.3-0.8 Water Rest Phenetidine chloride H2NC6H4OC2H5NCl. Mol.m. 173. Manufacturing plant: Yerevan Chemical Reactants Plant. TU 6-09-08-1180-77. Structural formula of H2HCl Name according to the Geneva nonmenclature - oxyaniline chloride. Phenetidine chloride - aminophenol ethyl ester chloride. Dissolves in acid. In solution it exists in the form of ions: H+2 and chlorine. Phenetidine chloride, adsorbed at high polarization, forms a polymolecular layer on the metal surface, on the one hand, and forms complex compounds with metal ions, on the other hand. As a result, the dissolution rate is higher at the ridges of the asperities, resulting in smoothing. In addition, the dissolution rate is increased by chlorine ions, which form compounds with the components of brass: copper and zinc. This leads to smoothing of micro-irregularities of the surface, increasing reflectivity. Polishing mode. The current is constant. Current density range: 5-100 A/dm2. Process temperature: room temperature: 20-30°C. Time - 5 minutes. Electrolyte adjustment is carried out according to the analysis data on the content of o-phosphoric acid. With the appearance of the electrolyte, the calculated amount of additives is introduced: n-dibutylamine and phenetidine chloride. The service life of the electrolyte is 200 A h/l. The advantage of the proposed electrolyte composition is to achieve a higher quality of polishing brass compared to known solutions for polishing copper alloys, in particular brass, which is expressed in increased reflectivity, surface cleanliness class compared to polishing in a solution of o-phosphoric acid with the addition of PB-5, triethanolamine or PB-5 and ammonium acetate. EXAMPLE 1. For electrochemical polishing of brass, for example L 62, the electrolyte composition is proposed, wt.%: o-phosphoric acid - lot (specific weight 1730 at 15°C) 60.0 n-Dibutylamine 1.0 Phenetidine chloride 0.8 Water The rest Polishing mode: temperature 20°C, electrolysis time 5 min, initial surface cleanliness 8, height of microroughness 0.30-0, 52 microns.a) Current density 10 A/dm2. After electrochemical polishing, the cleanliness class increases to 10, the height of microroughness decreases to 01.2-01.6 microns. Metal removal 1.0 μ/min. Reflectivity 96%. b) Current density 25 A/dm2. After polishing, the height of microroughness is 0.08-0.12 microns, which corresponds to surface cleanliness 10-11. Metal removal 1.4 µm/min. Reflectivity 97.5%. c) Current density 75 A/dm2. After polishing, the height of microroughness is reduced to 0.05-0.08 microns, which corresponds to cleanliness class 11. Metal removal is 1.8 microns/min. Reflectivity 98.2%. EXAMPLE 2. For electrochemical polishing of brass, for example L 68, the electrolyte composition was used, wt.%: o-Phosphoric acid (specific mass 1730 at 15°C) 80.0 n -Dibutylamine 0.1 Phenetidine chloride 0.3 Water The rest Polishing mode: temperature 20°C, electrolysis time 5 minutes, initial surface cleanliness 8, height of microroughness 0.35-0.60 microns. a) Current density 10 A/dm2. After electrochemical polishing surface cleanliness 10-11, height of microroughness 0.07-0.11 microns. Metal removal 1.44 µm/min. Surface reflectivity 97.2%. b) Current density 25 A/dm2. After polishing, the height of microroughness is reduced to 0.05-0.09 µm, which corresponds to purity class 11. Metal removal 1.76 µm/min. Reflectivity 98%.c) Current density 75 A/dm2. After polishing, the height of microroughness is reduced to 0.04-0.08 microns, which corresponds to purity class 11. Metal removal is 2.3 microns/min. Reflectivity 98.2%. EXAMPLE 3. Polishing of brass, for example L-95, was carried out in an electrolyte of the composition, wt.%: o-Phosphoric acid (specific mass 1730 at 15°C) 70.0 n -Dibutylamine 0.5 Phenethidine chloride 0.5 Water The rest Polishing process mode: temperature 20°C, electrolysis time 5 minutes, initial surface cleanliness 8, height of microroughness 0.30-0.32 microns.a) Current density 10 A/dm2.After polishing, the height of microroughness is 0.07-0.09 microns, surface cleanliness is 10-11. Metal removal 0.84 µm/min. Surface reflectivity 96.2%. b) Current density 25 A/dm2. After electrochemical polishing, the height of microroughness is 0.04-0.09 microns, surface cleanliness is 11. Metal removal is 1.56 microns/min. Reflectivity 98.5%.c) Current density 75 A/dm2. After polishing, the height of microroughnesses is 0.04-0.08 microns, surface cleanliness corresponds to 11. Metal removal is 2.2 microns/min. Reflectivity 96.2%. EXAMPLE 4. The composition of the solution for electrochemical polishing of brass, for example L 62, was tested with the following component ratio, wt.%: o-Phosphoric acid 50.0 n-Dibutylamine 1.5 Phenetidine chloride 1.5 Water Rest Polishing process mode: temperature 20°C. Polishing time 5 min. Initial surface cleanliness is 8, the height of micro-roughness is 0.30-0.51 microns. a) Current density is 10 A/dm2. After electrochemical polishing of brass, the height of micro-roughness is 0.26-0.32 microns, the cleanliness corresponds to 9. Metal removal is 0.85 microns /min. Surface reflectivity 80%. b) Current density 25 A/dm2. After polishing, the height of microroughness is 0.25-40.30 microns, cleanliness class 9. metal removal 1.25 microns/min. Surface reflectivity 83%. c) Current density 75 A/dm2. After polishing, the height of microroughness is 0.25-0.31 microns, cleanliness class 9. Metal removal 1.92 microns/min. Surface reflectivity 75%. EXAMPLE 5. For electrochemical polishing of brass, for example brand L 68, the following electrolyte composition was used, wt.%: o-Phosphoric acid (specific mass 1730 at 15°C) 85.0 n -Dibutylamine 0.5 Phenethidine chloride 0.1 Water The rest Polishing mode: temperature 20°C, polishing time 5 minutes, initial surface cleanliness 8, height of microroughness 0.30-0.52 microns. a) Current density 10 A/dm2. After polishing surface cleanliness 8, height of microroughness 0.30-0.35 microns. Metal removal 1.5 µm/min. Reflectivity 76%. b) Current density 25 A/dm2. After electrochemical polishing, surface cleanliness is 9, the height of microroughness is 0.18-0.25 microns. Metal removal 1.4 µm/min. Reflectivity 80%.c) Current density 75 A/dm2. After polishing brass, surface cleanliness is 9, the height of microroughness is 0.17-0.23 microns. Metal removal 1.94 µm/min. Reflectivity 76%. The proposed electrolyte composition can be used for polishing brass at enterprises of instrument-making, shipbuilding and local industries, as well as special-purpose parts. The use of the proposed electrolyte allows increasing the cleanliness of the brass surface by 2-3 classes from 8 to 10-11.

Formula of invention

SOLUTION FOR ELECTROCHEMICAL POLISHING OF BRASSES, including o-phosphoric acid, n-dibutylamine additive and water, characterized in that, in order to increase the class of surface cleanliness, it additionally contains phenetidine chloride in the following ratio of components, wt.%: o-Phosphoric acid (density 1.73 at 15oC) - 60 - 80 n-Dibutylamine - 0.1 - 1.0 Phenetidine chloride - 0.3 - 0.8 Water - Rest

The nuances of polishing aluminum sheet products

Leveling the surface and eliminating scratches on sheet metal is done using a polishing machine. Sequence of work:

- Preparatory stage. The surface is cleaned of paint, dirt and oxide using a metal brush. Use a soft cloth to remove residues and dust deposits;

- Grinding. Medium-grained abrasives correct visual defects, roughness, and deep scratches. Next, using fine sandpaper, level the surfaces to a perfectly smooth state.

The grinding machine allows you to process aluminum to an exceptional shine. The polishing wheel of the device is equipped with various types of attachments depending on the nature of the work and the characteristics of the material.

The nuances of working with a grinding unit:

- the polishing wheel, like the sheet of metal being processed, is moistened with water;

- as a result of friction, heating of the metal plane is observed, under the influence of the rotating circle, roughness is eliminated, small particles of metal and water are formed in the form of a slurry;

- regularly, at intervals of 1-2 minutes, turn off the device, rinse the polishing disc under running water, wash off particles of formations on the metal sheet;

- After leveling visual defects with the help of abrasives, the grinding machine wheel is equipped with a felt attachment and final polishing of the aluminum is performed.

The procedure is completed by treating the surface with a polishing paste, which promotes the formation of a coating with a mirror effect.

How are aluminum and aluminum alloys processed?

Aluminum is one of the most popular metals from which many different parts are made. It is lightweight, durable, does not corrode, and is also easy to process.

Aluminum processing: types and features

Processing of aluminum blanks is possible in several ways, depending on the tasks and the desired result. Most often used:

- chemical polishing;

- electrochemical grinding;

- chemical oxidation.

Chemical polishing and its features

Chemical polishing can eliminate almost any visible surface defects without increasing its reflectivity. The essence of the procedure is that aluminum parts are immersed in a container with a special composition, under the influence of which the surface contour improves and irregularities become less noticeable. Before loading into an alkaline solution, all parts are thoroughly degreased.

Keep the parts in the solution for one to four minutes. The solution temperature is 100 degrees Celsius. After removal, all parts are thoroughly washed, first in hot and then in cold water.

Electrochemical grinding and its features

Most often, the BRYTAL method is used for electrochemical grinding of aluminum workpieces, the essence of which is that each part is first degreased, then carefully washed, and then immersed in an 80-degree solution containing sodium carbonate (15%) and trisodium phosphate (5%).

It is important to have a double impact here: first, by immersing the workpieces in the working solution for 20-30 seconds, the natural layer of aluminum oxide should be removed. After this, a 24-volt discharge is passed between the cathode and anode (which is the aluminum part), thus creating some kind of polarization.

The anode remains covered with an oxidized layer, which, in turn, is dissolved by the electrolyte over time. This takes him approximately the same amount of time as it takes to create, and the thickness of the layer does not increase.

Each part treated in this way is then dried. The result is a fairly thin oxidized layer. By itself, it is not a strong enough protection, and often requires subsequent anodization. As a result of this process, the surface of the workpieces acquires a reflective surface, which is valued, for example, in the manufacture of parabolic headlights. In addition, such products have a high level of wear protection.